Vacuum belt press filter

A vacuum belt type, filter press technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problem of no obvious reduction in moisture content, reduce the vacuum degree of vacuum pressure rollers, etc. The effect of reducing comprehensive cost and high comprehensive treatment benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

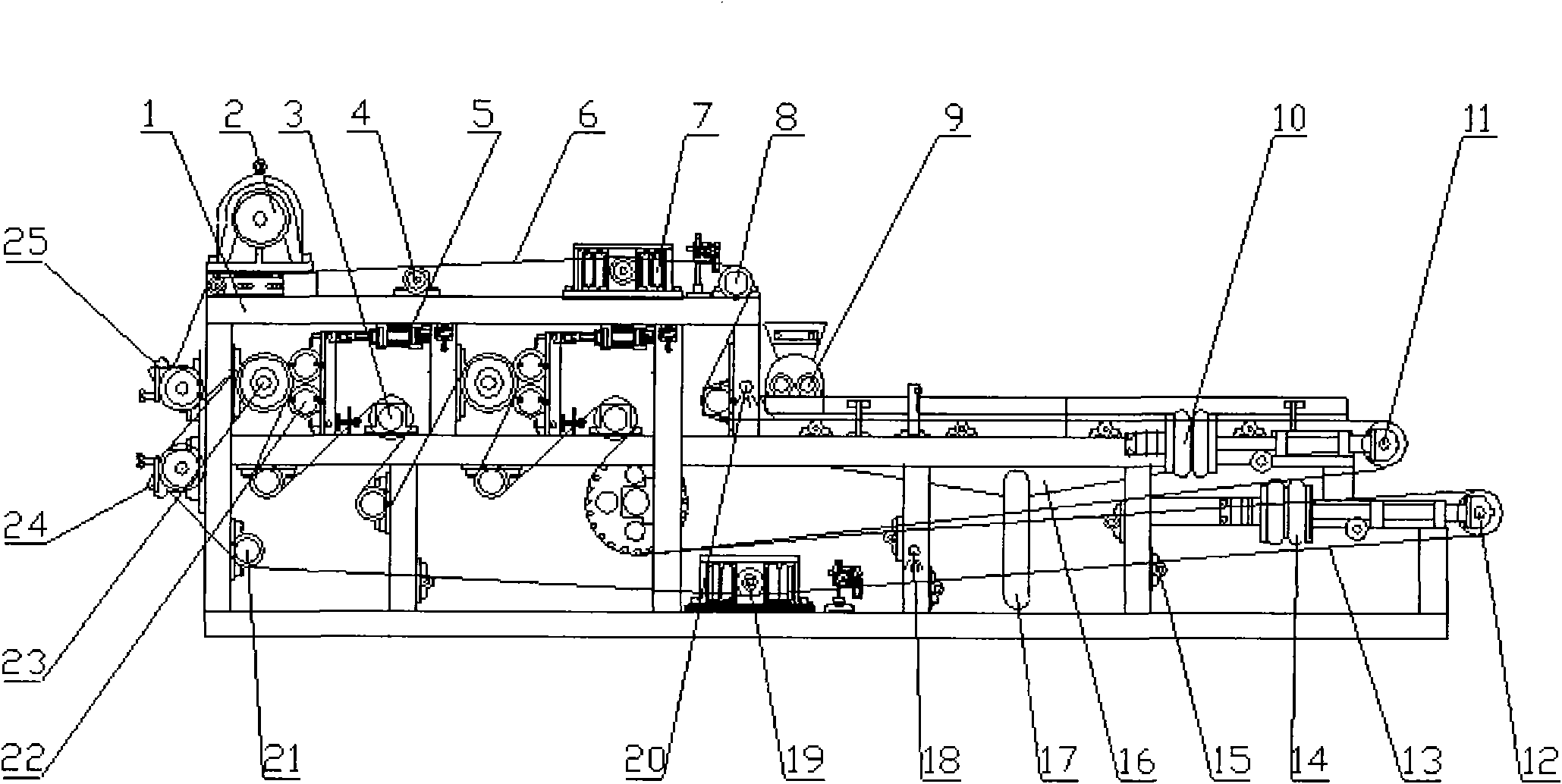

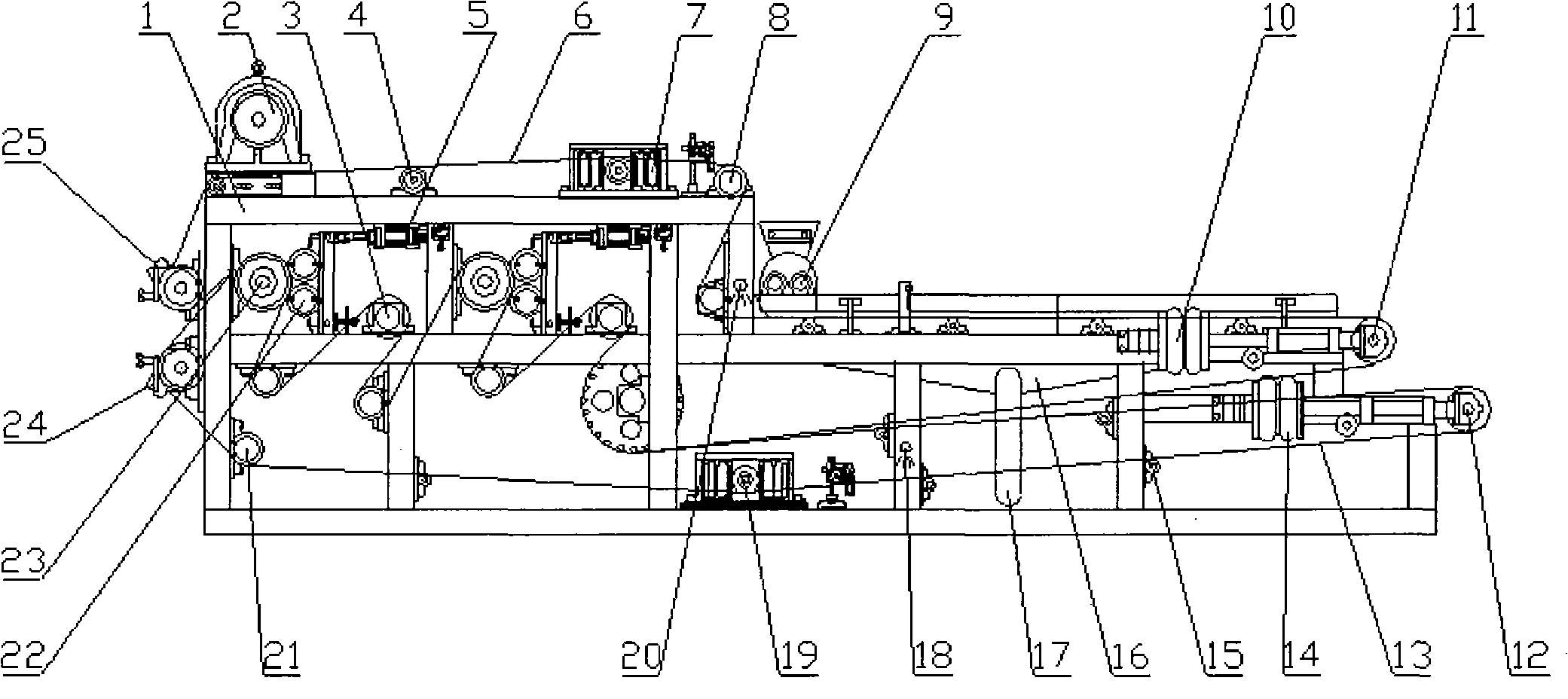

[0030] Such as figure 1 as shown,

[0031] The frame 1 of the vacuum belt filter press of the present invention is equipped with a driving device 2, and the driving device 2 can be a frequency modulation motor, an electromagnetic speed regulating motor, or a diesel (steam) oil machine; it can also be an ordinary motor and various A combination of transmissions or a combination of various speed regulating motors and various transmissions. The filter belt of the filter press is divided into an upper filter belt 6 and a lower filter belt 13. A constant pressure pressure roller 3, an upper filter belt support roller 4, an upper correction device 7, and an upper filter belt guide roller are installed above and below the upper filter belt 6. 8. Upper filter belt tension pneumatic adjustment device 10, upper filter belt tension roller 11, upper filter belt 6 is installed with a feeder 9, and two spiral shafts with opposite feeding directions are installed at the outlet of the feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com