Preparation process of honeycomb catalyst for coal-fired flue gas denitration in thermal power plant as well as product and application of preparation process

A technology of honeycomb catalyst and denitrification catalyst, which is applied in the field of nitrogen oxide catalytic reduction materials, which can solve the problems of high mechanical strength, low content of active ingredients, and low catalytic activity, and achieve high compressive strength, not easy to crack, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

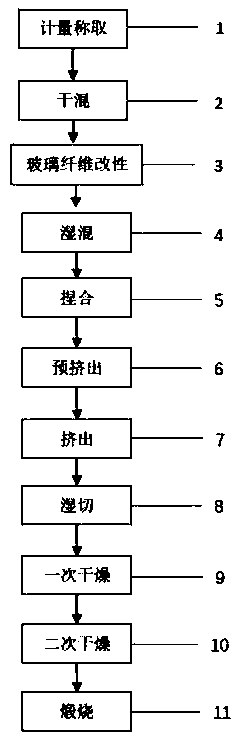

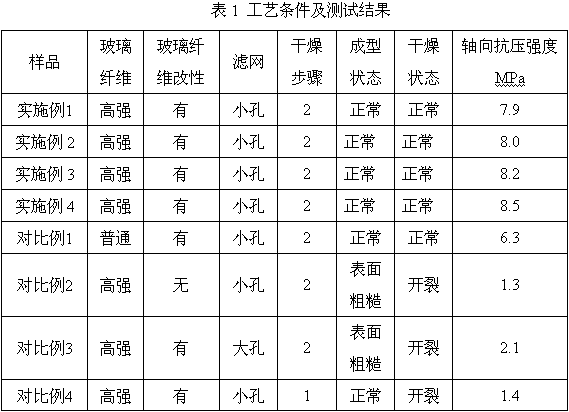

[0055] figure 1 The schematic diagram of the process flow for the preparation of the denitration catalyst, the preparation method according to the process flow is as follows:

[0056] Weigh 4.84kg of titanium dioxide, 0.6kg of tungsten trioxide, 0.11kg of molybdenum trioxide, and 0.21kg of vanadium pentoxide, and mix them evenly.

[0057] Weigh 0.44kg of 1cm high-strength glass fiber chopped strands (strength 8.5GPa, modulus 90GPa), add 0.57kg polyvinyl alcohol to modify it.

[0058] The above materials were mixed, and 0.44kg of clay, 0.07kg of carbon black, 0.24kg of 25% industrial grade ammonia water, 0.41kg of ethanol and 2.07kg of water were added, and fully stirred in a mixer.

[0059] Put the fully stirred mud into a kneader for kneading; then filter and pre-extrude in a pre-extruder equipped with a filter screen with a mesh size of 2mm; put the pre-extruded material into a vacuum extruder , extruded through the mold as a whole, and cut into segments according to the s...

Embodiment 2

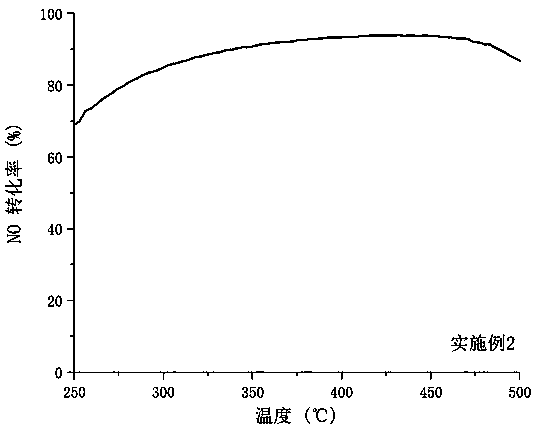

[0064] Weigh 5.50kg titanium dioxide, 0.11kg tungsten trioxide, 0.10kg molybdenum trioxide, 0.15kg vanadium pentoxide,

[0065] 0.54kg of 1.5cm high-strength glass fiber chopped strands (strength 8.5GPa, modulus 90GPa), add 0.48kg polyvinyl alcohol to modify it.

[0066] The above materials were mixed, and 0.65kg of clay, 0.36kg of carbon black, 0.24kg of 25% industrial grade ammonia water, 0.47kg of ethanol and 2.03kg of water were added, and fully stirred in a mixer.

[0067] Put the fully stirred mud into a kneader for kneading; then filter and pre-extrude in a pre-extruder equipped with a filter screen with a mesh size of 1.5mm; put the pre-extruded material into a vacuum extruder In the process, it is extruded as a whole through a mold and cut into segments according to the specified length.

[0068] After cutting, the wet billet is dried once. The primary drying conditions are: drying temperature 45°C, drying humidity 50%, drying time 72 hours.

[0069] The wet billet...

Embodiment 3

[0074] Weigh 5.9kg of titanium dioxide, 0.21kg of molybdenum trioxide, and 0.05kg of vanadium pentoxide, and mix them evenly.

[0075] Weigh 0.54kg of 1.5cm high-strength glass fiber chopped strands (strength 8.5GPa, modulus 90GPa), and add 0.27kg of polyvinyl alcohol to modify it.

[0076] Mix the above materials, add 0.35kg clay, 0.1kg cornstarch, 0.24kg 25% industrial grade ammonia water, 0.37kg acetone and 1.97kg water and mix them well in a mixer.

[0077] Put the fully stirred mud into a kneader for kneading; then filter and pre-extrude in a pre-extruder equipped with a filter screen with a mesh size of 0.5mm; put the pre-extruded material into a vacuum extruder In the process, it is extruded as a whole through a mold and cut into segments according to the specified length.

[0078] After cutting, the wet billet is dried once. The primary drying conditions are: drying temperature 40°C, drying humidity 50%, and drying time 48 hours.

[0079] The wet billet after primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com