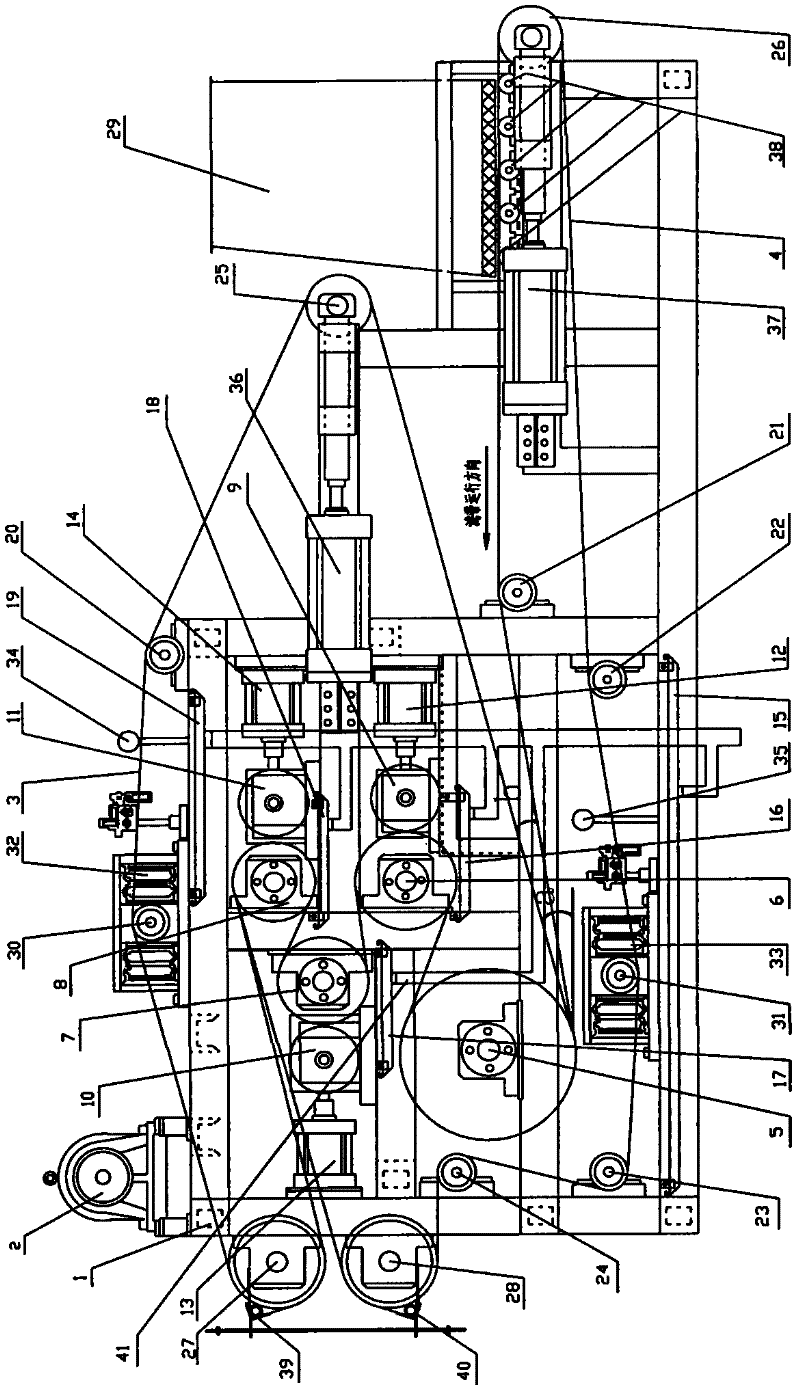

Novel high-performance belt pressure filter

A belt-type filter press, high-efficiency technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of insufficient material dehydration, low water outlet efficiency, uneven feeding, etc., to achieve improved dehydration Efficiency, favorable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0110] Aiming at the defects and deficiencies existing in the drive system of the existing belt filter press, such as easy tooth skipping and low operational reliability, the present invention adopts a new drive technical solution, that is, the upper filter belt drive roller 27 and the lower filter belt drive roller 27. The belt drive rollers 28 are respectively equipped with transmission devices that cooperate with each other for transmission. The transmission device is a meshing gear or a mating friction wheel, a belt and a pulley, a chain and a sprocket; the driving device 2 is independently driven by a chain drive or a gear drive, a friction drive, a belt drive, or a coupling The upper filter belt drive roller 27 or the lower filter belt drive roller 28. This technical solution has several implementation modes, enumerates two examples below:

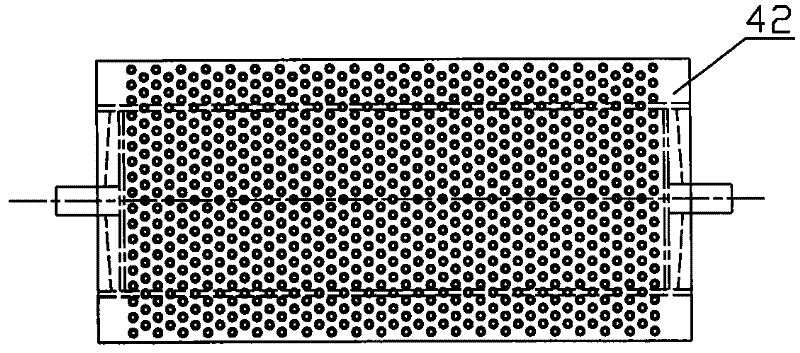

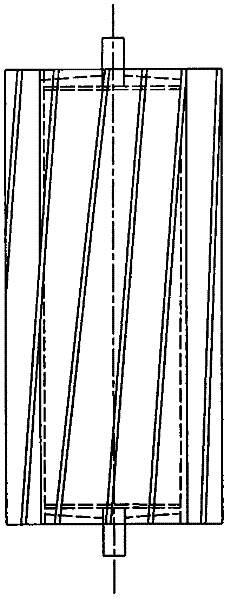

[0111] Example 1: If Figure 7a , Figure 7b , Figure 7c As shown, the driving device 2 installed on the belt filter press fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com