Integrated device for separating, concentrating, dehydrating and drying liquid impurities

A technology for liquid impurities and impurities, applied in filtration separation, separation methods, drying gas layout, etc., can solve the problems of efficient separation, concentration, dehydration and drying difficulties, and achieves a small footprint, a wide range of applications, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

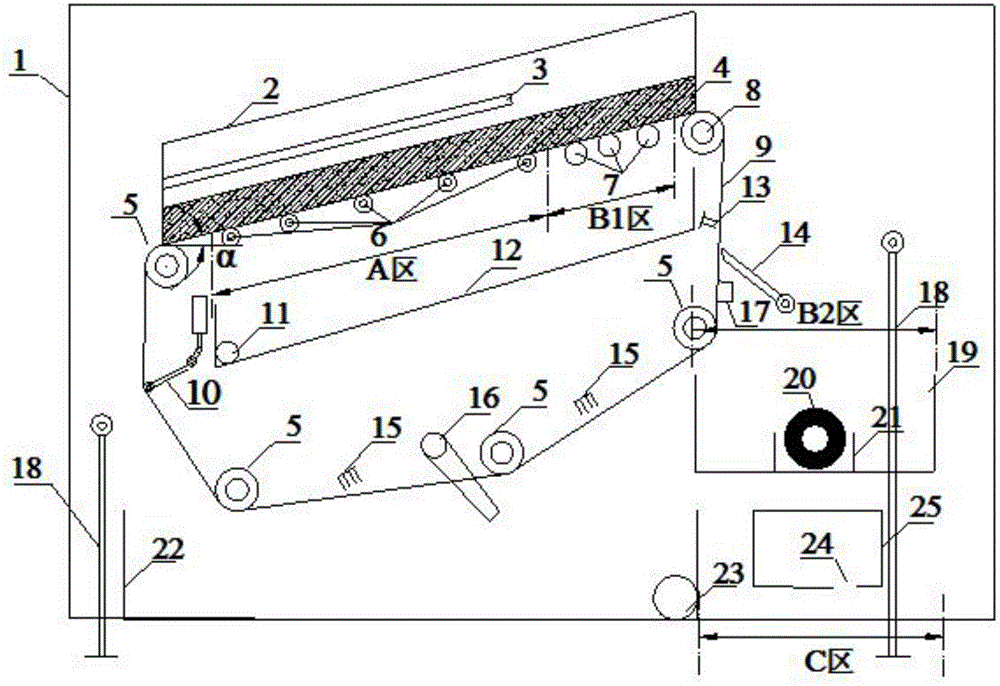

[0036] This embodiment provides an integrated device for separating, concentrating, dehydrating and drying liquid impurities, such as figure 1 As shown, it includes a liquid impurity separation mechanism, a liquid impurity concentration mechanism, a liquid impurity dehydration mechanism and a liquid impurity drying mechanism;

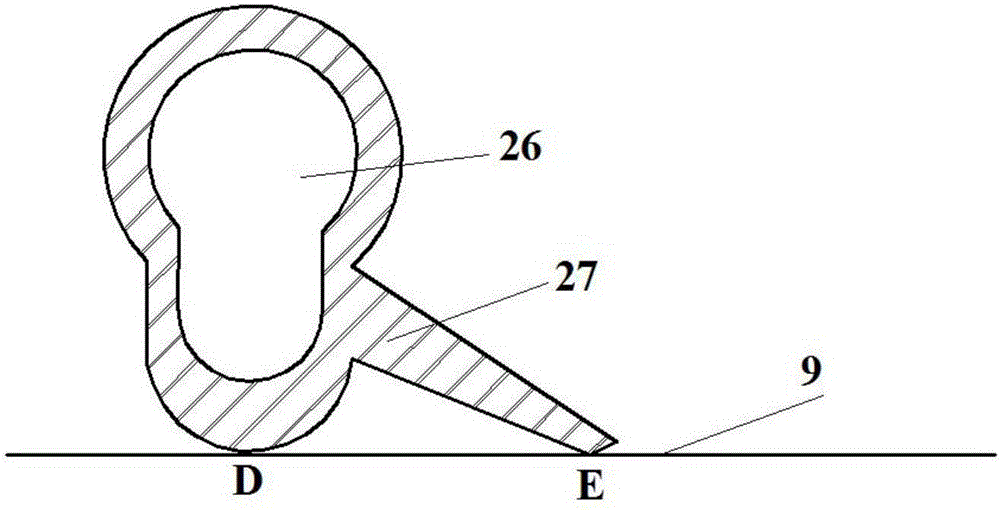

[0037] The liquid impurity separation mechanism comprises a liquid inlet channel 2, a first filter belt 9 and a first transmission wheel, such as Figure 6 As shown, the liquid inlet channel 2 includes a front baffle 21 and side baffles 202 arranged on both sides of the front baffle 201 and connected to both sides of the front baffle 201, and the front baffle 201 of the liquid inlet channel 2 is provided with a water distribution pipe 3. The rear end of the bottom of the liquid inlet channel 2 is higher than the front end, that is, the liquid outlet end of the liquid inlet channel is higher than the liquid inlet end, and the horizontal inclination angle...

Embodiment 2

[0042] This embodiment is a further improved embodiment of Embodiment 1, which includes all the content of Embodiment 1, that is, the liquid impurity separation, concentration, dehydration and drying integrated device provided in this embodiment includes Embodiment 1 Liquid impurity separation, All the structural features of the concentration, dehydration and drying integrated device, the improvements are as follows:

[0043] The water distribution pipe 3 is evenly distributed with a plurality of water outlet holes, which can evenly distribute the mixed solution on the first filter belt 9 to improve the filtration efficiency and filtration effect, such as figure 1 As shown, the first transmission wheel includes a first driving wheel 8 and a plurality of first driven wheels 5, and the tangential speed range of the first driving wheel 8 is 0.01m / s-2m / s. The first driving wheel 8 is arranged at the liquid outlet end of the liquid inlet channel 2, and the angle between the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com