High purity ammonia low temperature reciprocating pump

A high-purity ammonia, reciprocating pump technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of inability to meet electronic-grade high-purity ammonia delivery, pressurization requirements, waste of flushing time, waste of media, etc. Achieve the effect of ensuring reliability, ensuring cleanliness, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

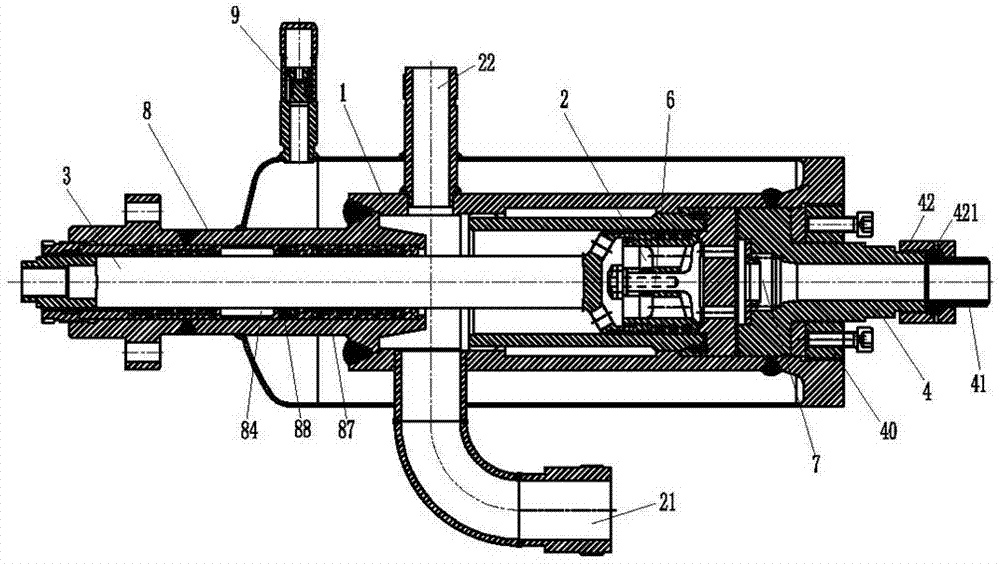

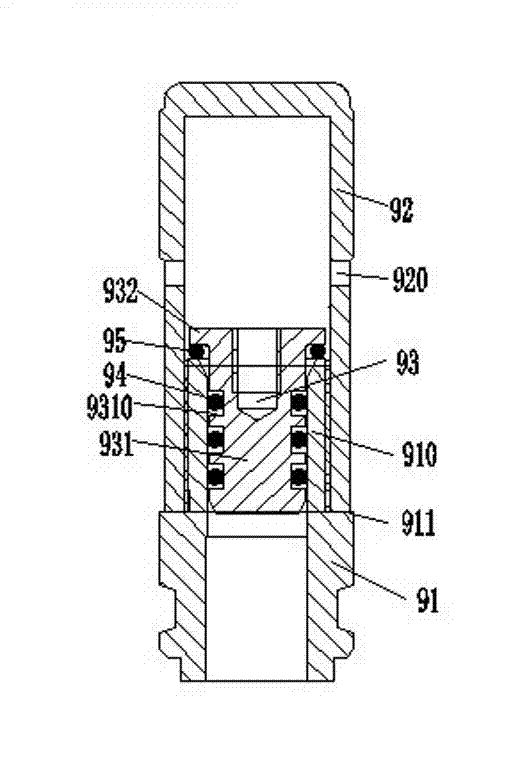

[0017] Example 1, such as figure 1 , 2 As shown, a high-purity ammonia low-temperature reciprocating pump includes a pump body 1, an inner cylinder 2 is provided in the pump body 1, an inlet 21 and an air return port 22 are communicated with the inner cylinder 2, and a liquid inlet valve 6 is provided at one end of the inner cylinder 2. One end is provided with a liquid outlet valve 7 opposite to the liquid inlet valve 6, and a piston rod 3 is provided on the side of the pump body 1 close to the liquid inlet valve 6, and the pump body 1 is provided with a sealing assembly 8 around the inner wall of the piston rod 3, The pump body 1 is located on the side of the liquid outlet valve 7 and is equipped with a liquid outlet flange 4. The liquid outlet flange 4 is connected with a liquid outlet pipe 41, and the connection position between the liquid outlet flange 4 and the liquid outlet pipe 41 is fixed externally by a casing nut 42. Connected, the pump body 1 is also provided ...

Embodiment 2

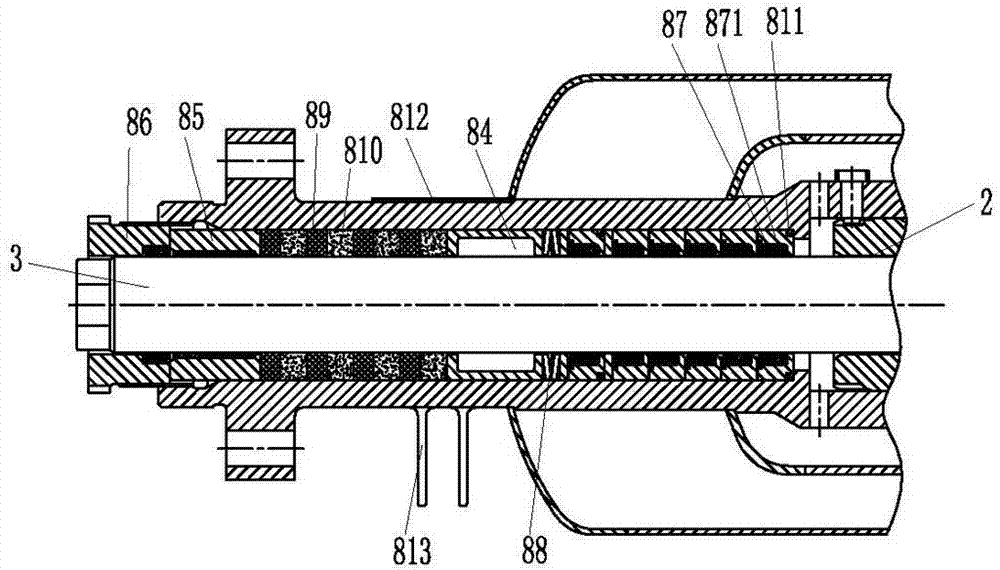

[0018] Example 2, such as image 3 As shown, the difference between it and Embodiment 1 lies in the difference of the sealing assembly 8. The sealing assembly 8 includes a front liquid medium sealing part, an air storage chamber 84, and a rear section arranged in sequence from the side of the cylinder 2 inside the pump body 1 to the outside. The gas phase medium sealing part, the guide sleeve 85 and the compression nut 86, the shell of the pump body 1 is provided with an explosion-proof electric heating belt 812 near the gas storage chamber 84, and the liquid medium sealing part in the front section includes a row of lip seals 87 And a disc spring 88, the gas-phase medium sealing portion of the rear stage includes graphite gaskets 89 arranged at intervals and tetrafluoroethylene tetrafluoroethylene gaskets located between the adjacent two graphite gaskets 89 and between the gas storage chamber 84 and the adjacent graphite gaskets 89. Fill the sealing part 810, the lip seal 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com