High-pressure-head low-flow non-isolated online cleaning device for rotary air preheater

An air preheater and cleaning device technology, applied in the direction of cleaning heat transfer device, flushing, removing solid residue, etc. Simple structure and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The high-pressure water flushing device of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] In the present invention, the loosening agent can be any loosening machine of the prior art, and the organic lye can be any organic lye of the prior art, as long as it can promote the descaling of the surface of the heat exchange element, the purpose of the present invention can be achieved.

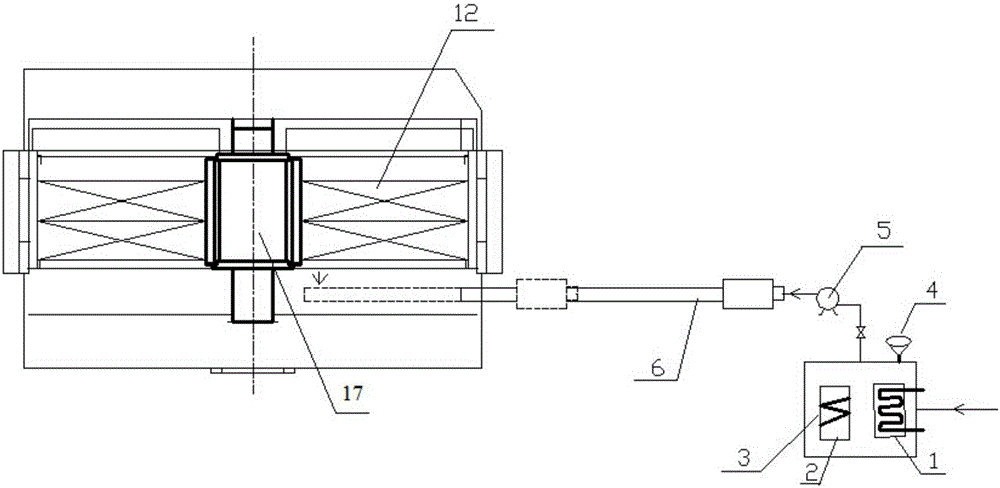

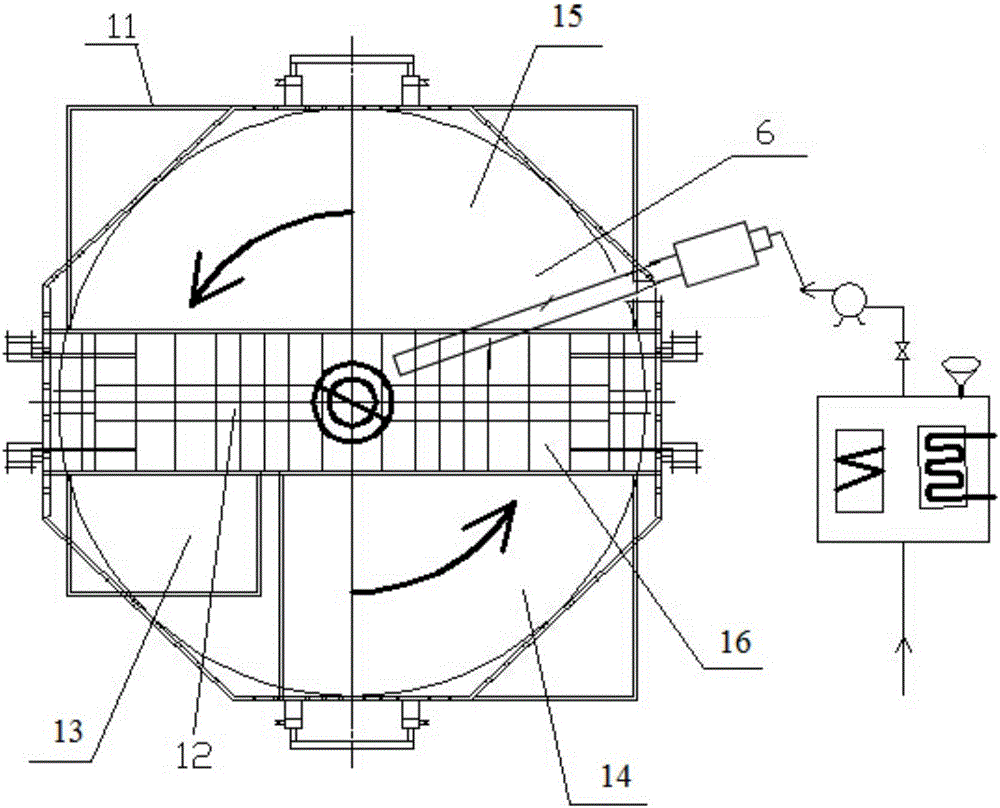

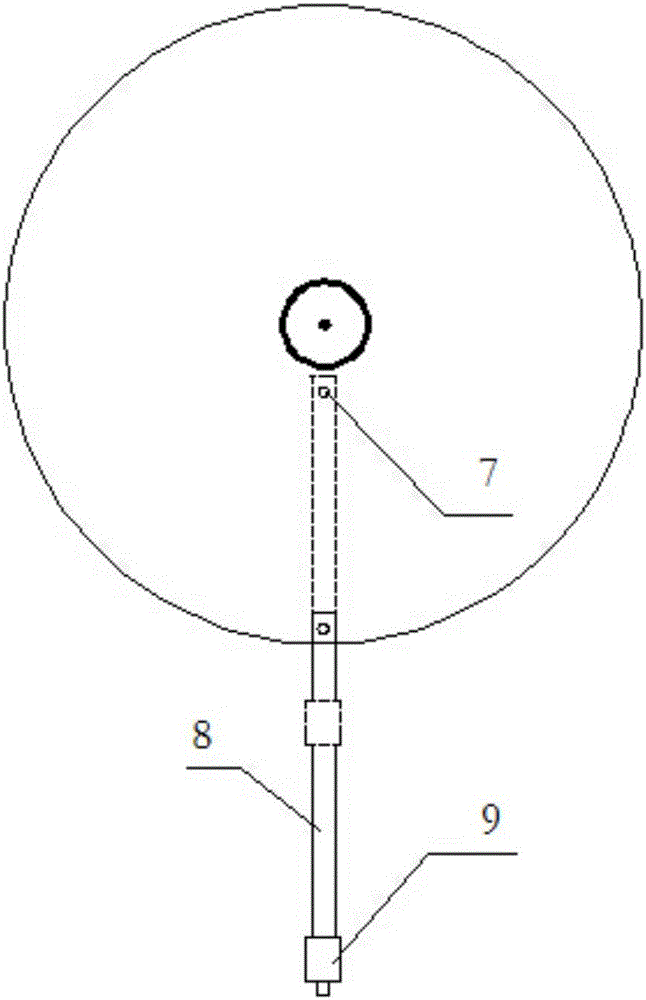

[0038] Rotary air preheaters, see figure 1 with 2 , including online cleaning device, air preheater body 11, air preheater rotor 12, primary air duct 13, secondary air duct 14, flue 15; air preheater rotor 12 is fixed to air preheater body 11 through rotor support 16 Inside, the primary air passage 13, the secondary air passage 14, and the flue 15 are respectively arranged near the air preheater rotor 12 in the air preheater body 11; the online cleaning device includes a steam heating device 1, an electric heating device 2 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com