Apparatus used for determining sediments in crude oil and fuel oil

A measuring device and fuel oil technology, applied in the direction of measuring device, material weighing, analyzing materials, etc., can solve the problems such as the oil organic components are not easy to clean, the detection efficiency of the staff is low, and the accuracy of the detection results is affected, so as to achieve saving Effects of heating electricity and cooling water, shortening flushing time, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

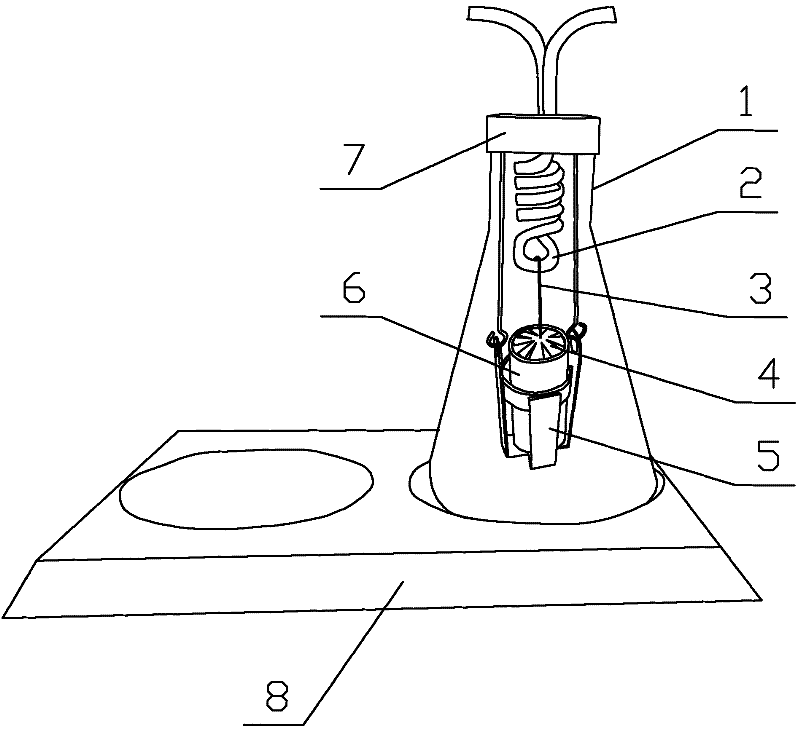

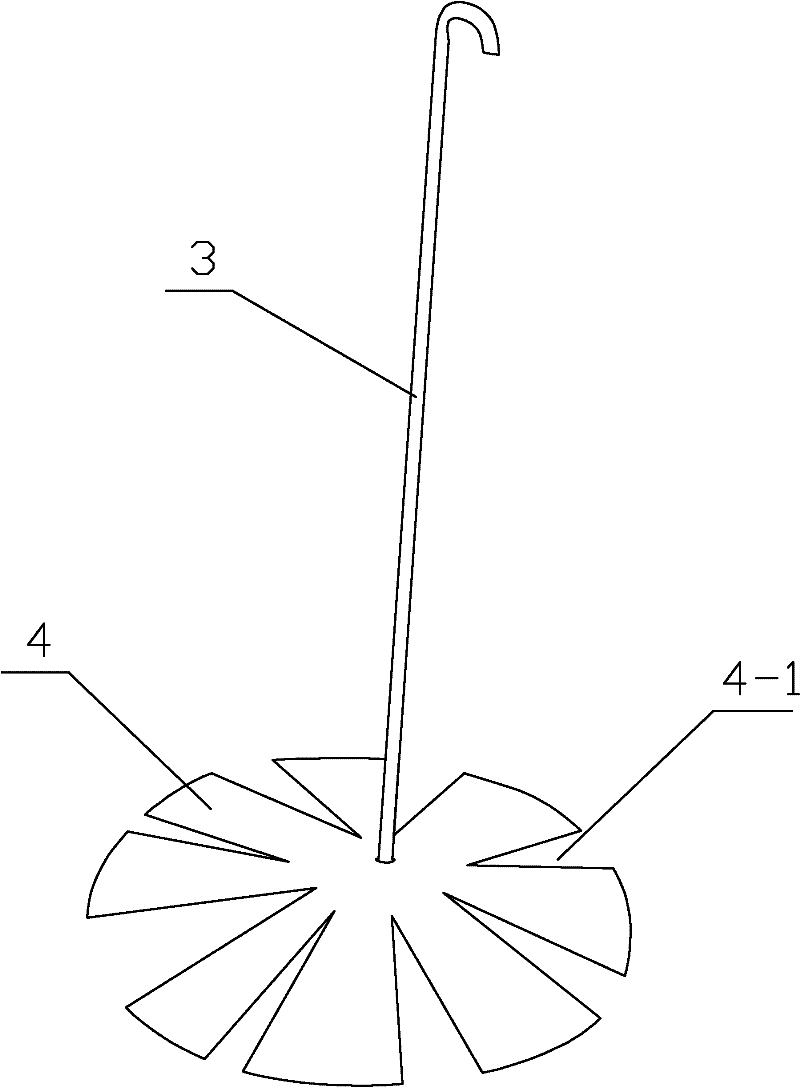

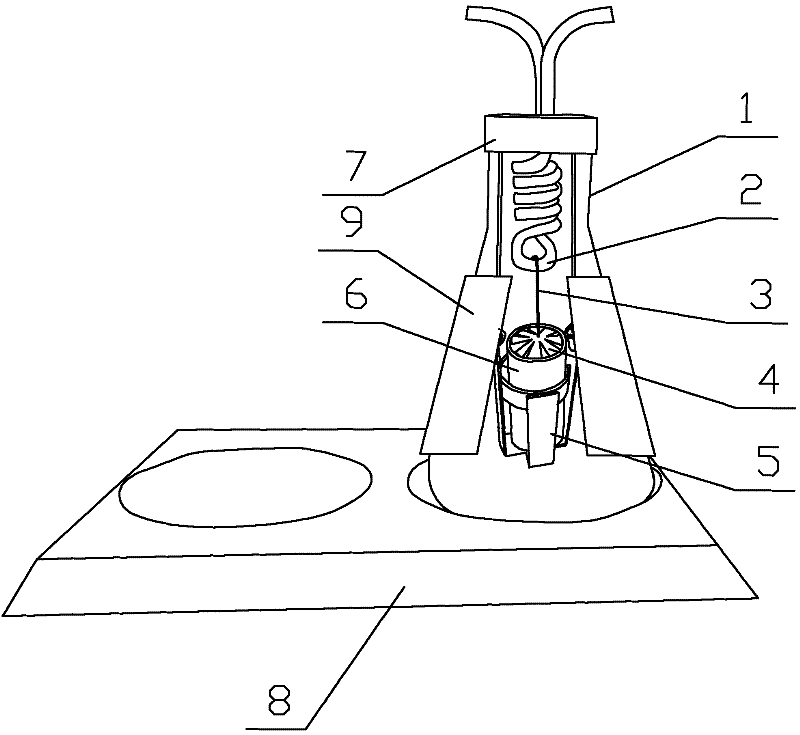

[0023] exist figure 1 In the illustrated embodiment, the sediment determination device in crude oil and fuel oil of the present invention is composed of an electric heater and an extraction device, and the extraction device includes an extraction flask 1, a condensation coil 2, and an extraction sleeve 6 , sleeve support 5 and a flow guiding device, the condensation coil 2 is fixed on the bottle cap 7 of the extraction flask 1, and its two ends pass through the bottle cap 7 to externally connect the cooling water, and the rest is located in the extraction flask 1 , the sleeve support 5 is fixed on the bottle cap 7 by a metal wire and is suspended between the condensation coil 2 in the extraction flask 1 and the solvent liquid level contained in the extraction flask 1, the extraction sleeve 6 is placed in the sleeve bracket 5; the deflector includes a circular deflector 4 with a diameter slightly smaller than the inner diameter of the extraction sleeve 6 and a metal deflector 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com