Pre-filling type catheter flusher and pre-filling type catheter flusher assembling and outputting method

An output method and technology of a flusher, applied in the field of medical devices, can solve the problems of long time consumption and large waste, and achieve the effect of reducing the flushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

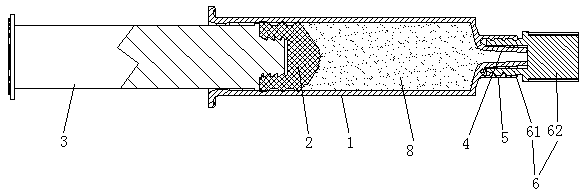

[0020] Example 1, see figure 1 , a pre-filled catheter flusher, comprising an outer casing 1, a piston 2 sealed and movably connected in the outer casing, and a core rod 3 that is connected to the piston and protrudes from one end of the piston. The other end of the outer casing is provided with a liquid outlet 4 and an inner thread sleeve 5 sleeved on the outside of the liquid outlet. A cap 6 for closing the liquid outlet is detachably connected to the liquid outlet. A normal saline storage cavity 8 is formed between the jacket, the piston and the liquid outlet. The physiological saline is stored in the physiological saline storage cavity. The cap includes a threaded pipe segment 61 and a gripping means 62 arranged in sequence. The threaded pipe section 61 is sleeved on the liquid outlet. The outer threaded pipe section is threadedly connected in the inner threaded sleeve to close the liquid outlet.

[0021] When rinsing, remove the cap, connect the outlet nozzle to the ...

Embodiment 2

[0023] Embodiment two, the difference with embodiment one is:

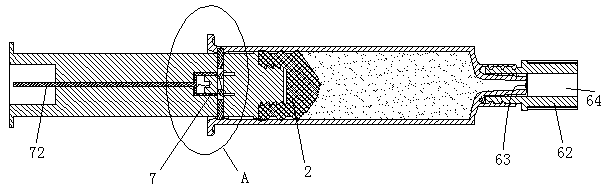

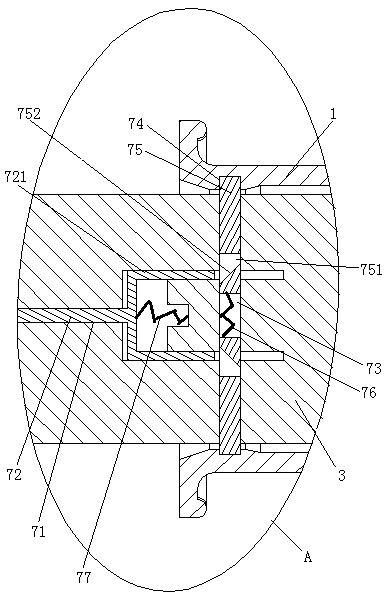

[0024] see figure 2 and image 3 , the cap is also provided with a sealing film 63 . The cap seals off the spout by sealing against the port of the spout with a sealing membrane. The grasping means are also tubular structures. The inner space of the grasping means constitutes an air hole 64 on the outer surface of the cap which communicates with the surface of the side of the sealing membrane away from the liquid outlet, so that the membrane is exposed in opening. Under the action of the pressure difference between the inside and outside of the physiological saline storage cavity, the sealing film is recessed toward the inside of the liquid outlet to close the port of the liquid outlet. The core rod and the outer casing are fixed together by the positioning structure 7 .

[0025] The positioning structure 7 includes a drive rod mounting hole 71 extending along the axial direction of the core rod and passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com