Nuclear power plant start secondary circuit flushing method

A secondary circuit, nuclear power plant technology, used in nuclear power plants, flushing, nuclear power generation, etc., can solve the problems of large flushing water consumption, uncontrolled flushing time, incomplete flushing, etc., to reduce wastewater discharge pressure and reduce flushing. Water consumption, effect of shortening flushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

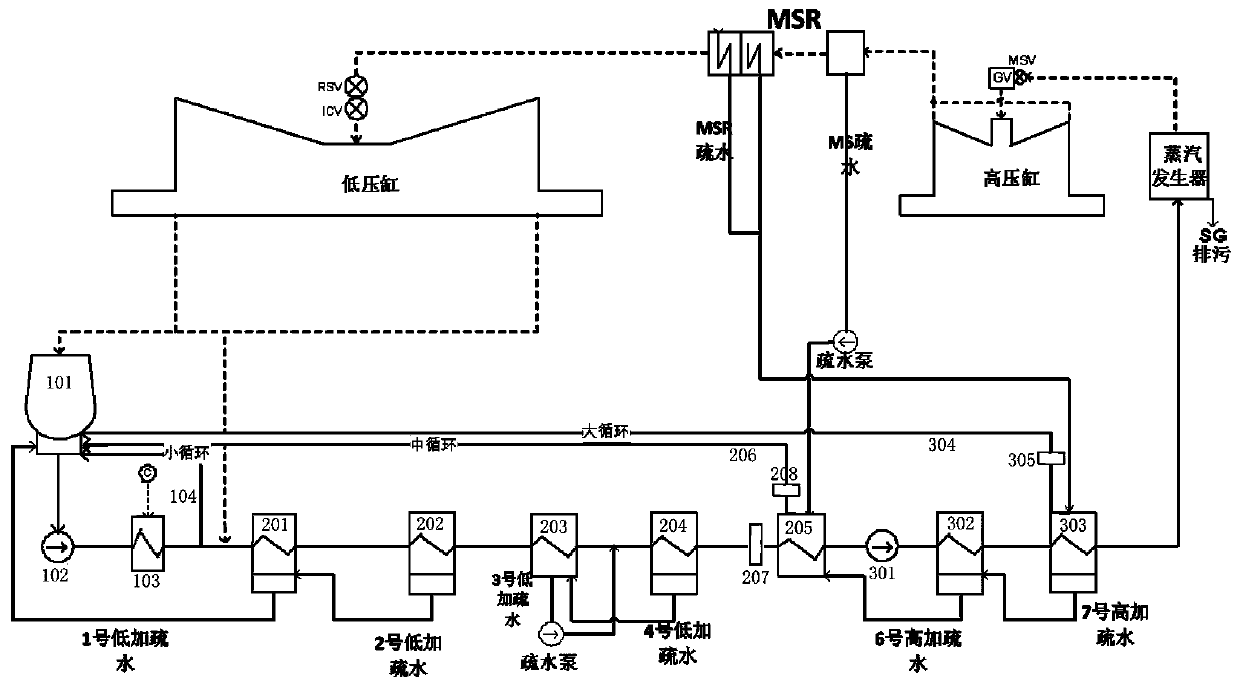

[0040] The secondary loop device used in this embodiment is as attached figure 1 As shown, it includes: a condensate water system, a low-pressure water supply system and a high-pressure water supply system, wherein the condensate water system includes a condenser 101, a condensate water pump 102, and a shaft seal condenser 103 connected in sequence, and the desalted water in the shaft seal condenser 3 can pass through The first loop pipe 104 flows back into the condenser 101, and the shaft-sealed condenser 103 is additionally connected with a pipeline to connect the fine treatment bed body (not shown in the figure); the low-pressure water supply system includes No. 1 low-pressure heater group 201, No. 2 Low-pressure heater group 202, No. 3 low-pressure heater group 203, No. 4 low-pressure heater group 204, first valve 207, and deaerator 205. The low-pressure heaters in each group are connected in parallel to form a low-pressure heater group. The deaerator The desalinated water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com