Method for directly treating air cooling drum boiler unit water supply

A direct technology for feed water treatment, applied in the components of steam boilers, reduced water/sewage treatment, steam boilers, etc., can solve the problem of short operation cycle of condensate polishing treatment, high hydrogen conductivity of boiler feed water, and iron scale deposition on the heating surface. problems such as high rate, achieve significant economic and social benefits, reduce the amount of flushing water, and reduce the flushing time of start-up water

Active Publication Date: 2007-04-11

ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The present invention aims to solve the problems caused by the reductive treatment method used in the existing direct air-cooled drum boiler unit, the serious excess of dissolved oxygen in the condensed water during operation, the high hydrogen conductivity of the boiler feed water, the high iron content, the short operation period of the condensed water polishing treatment and the In order to solve the problems of high deposition rate of iron scale on the heating surface of the thermal system, a new and practical method for water treatment of direct air-cooled drum boiler units is provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0045] Example: An industrial experiment in which the feed water of a 300MW subcritical direct air-cooled drum boiler unit is converted from a reductive treatment method to an oxidative treatment method described in the present invention is illustrated as an example.

[0046] 1. Purpose of the experiment:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to boiler feed water treating technology, and is especially water treating method for directly air cooled steam drum boiler. Under the reductive condition, the condensed water from the condensing water tank is added with ammonia before entering the boiler directly under the condition of closing the oxygen discharging door of deaerator and the water hydrogen conductivity is controlled below 0.2microS / cm. In case of poor water quality, the oxygen discharging door is opened to convert into reductive mode. The present invention alters the traditional concept that dissolved oxygen will result in corrosion, and has double compact oxide film formed on surface of metal to inhibit the flow corrosion in thermal system, fine treatment of condensed water for long running time, no use of carcinogenic hydrazine and lowered ammonia adding amount for environment protection and health, and raised equipment utilization.

Description

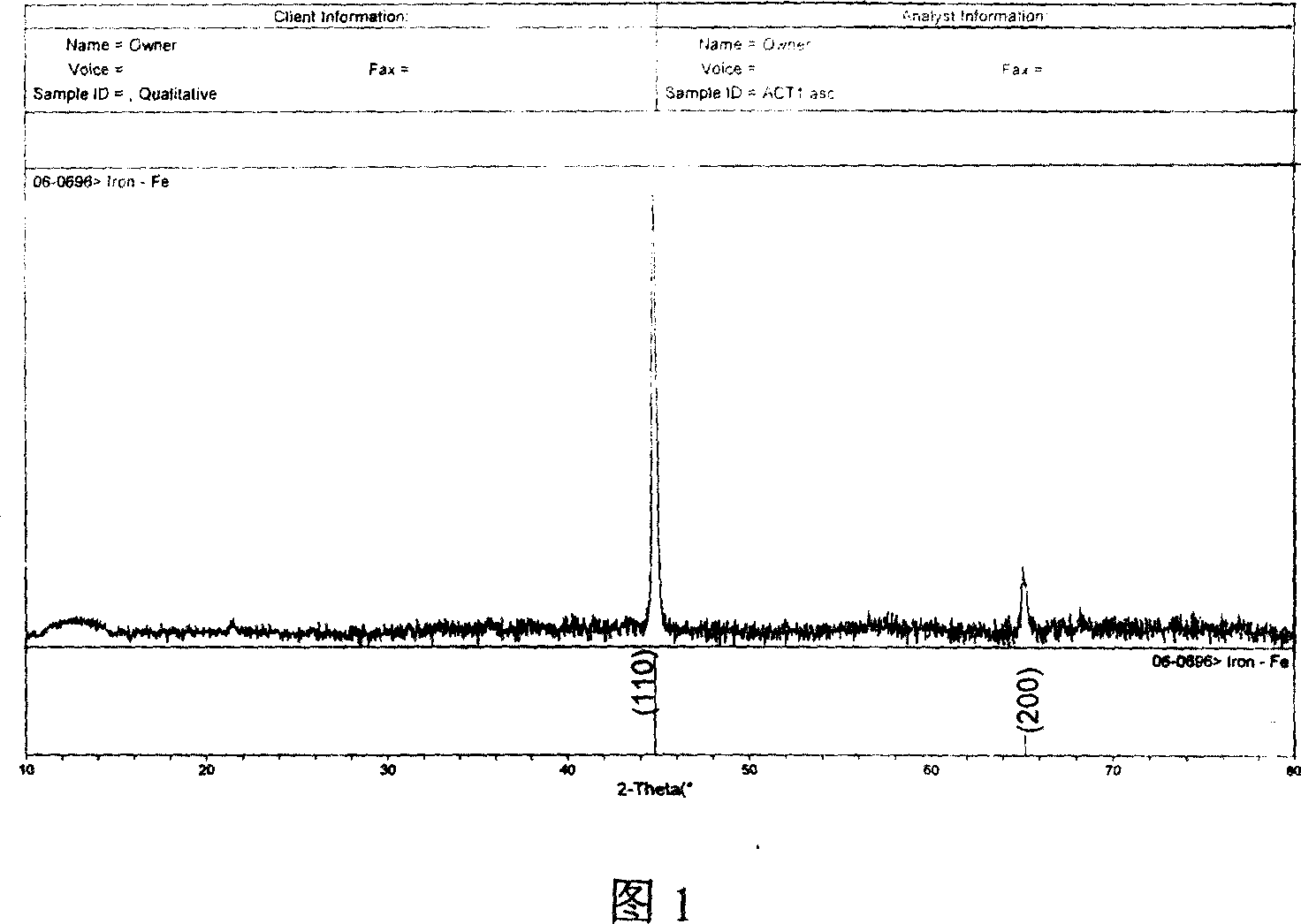

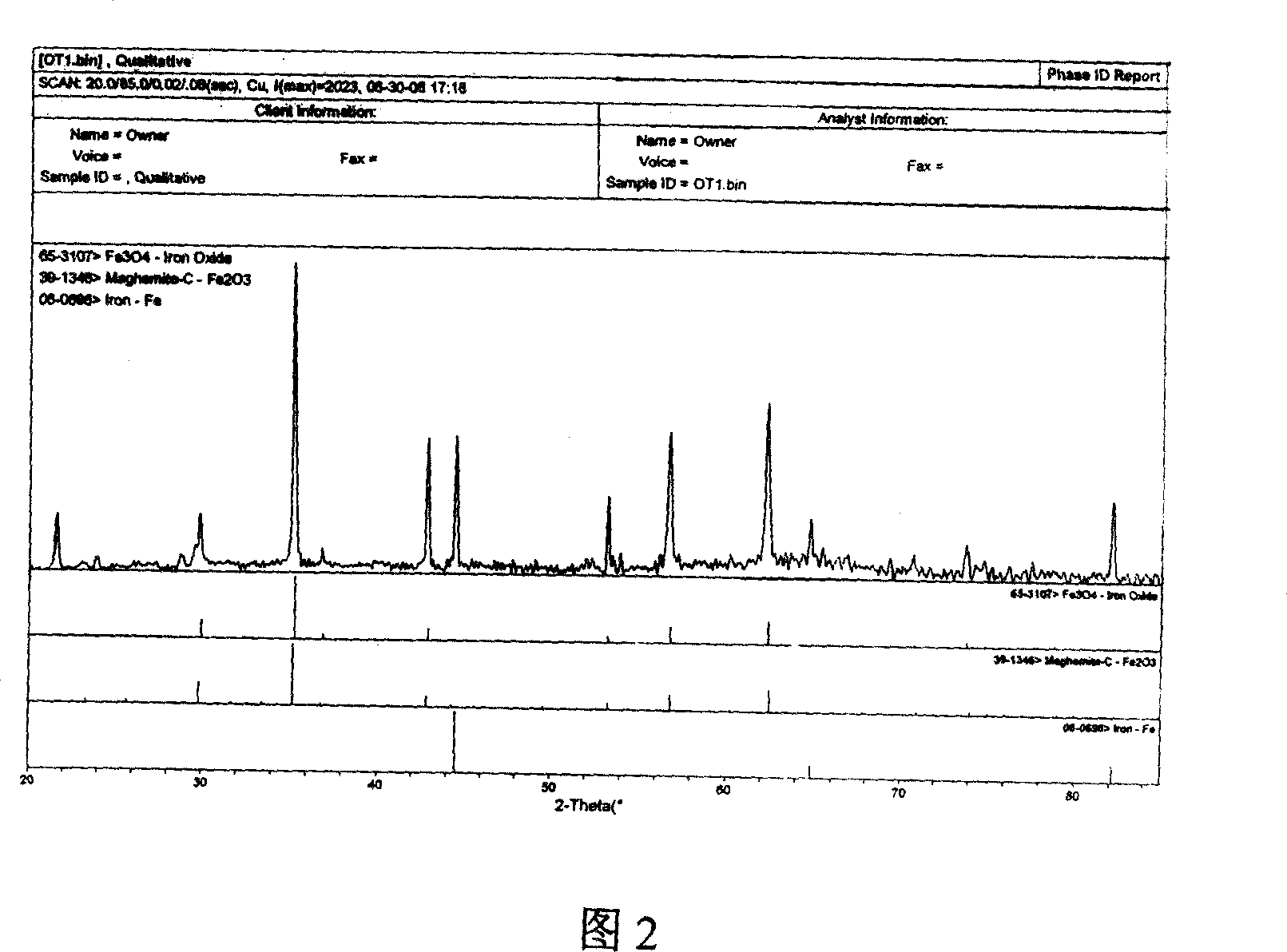

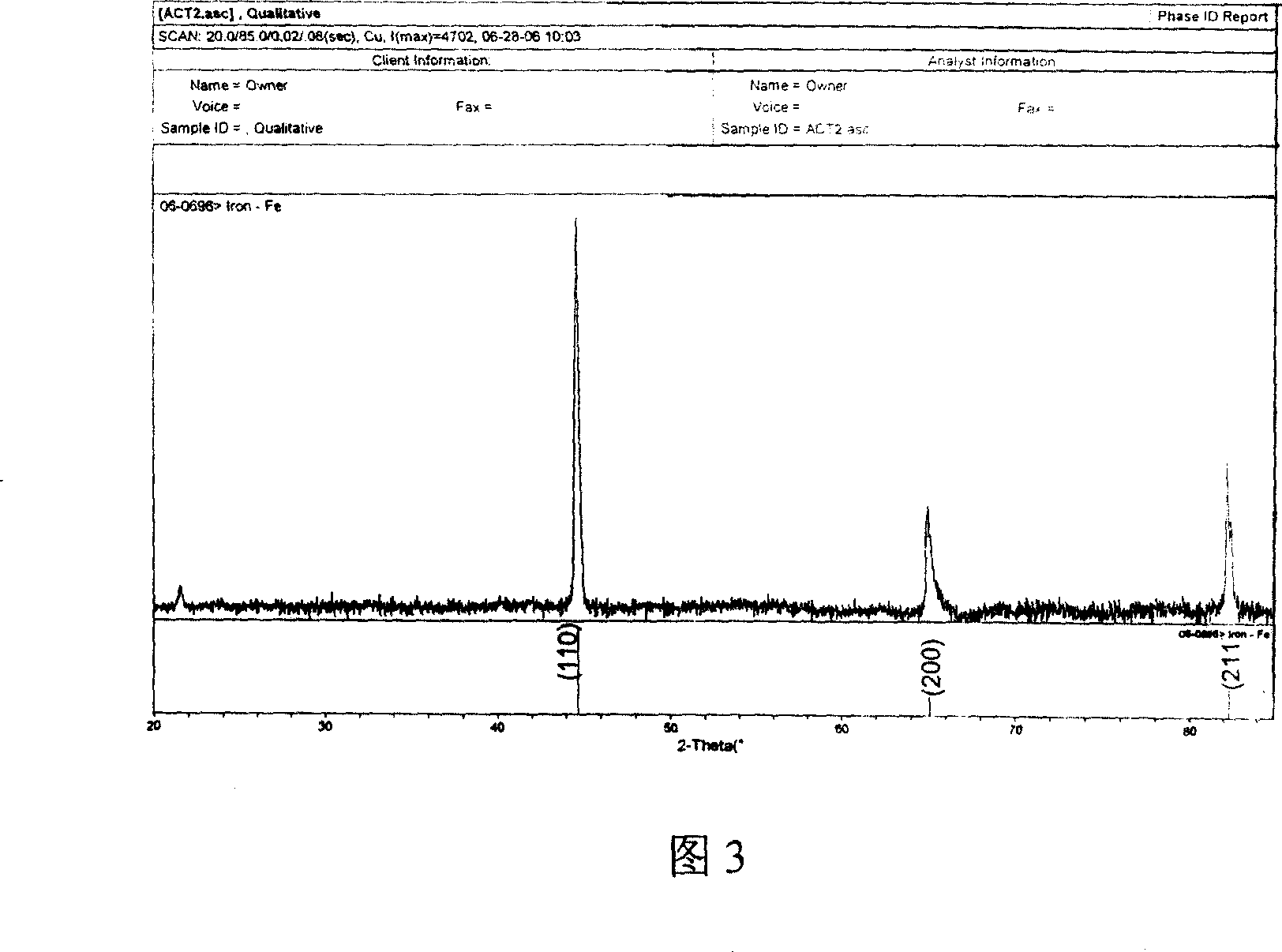

technical field [0001] The invention relates to the technical field of boiler feedwater treatment, in particular to a method for treating feedwater of a direct air-cooled drum boiler unit. Background technique [0002] At present, the commonly used cooling methods for large thermal power generating units are divided into circulating water cooling and direct air cooling units. Since direct air-cooled units can greatly save water, and the site selection is not restricted by water sources, they are suitable for promotion in water-scarce areas. In addition to saving water, they are superior to circulating water-cooled units in terms of investment, operation, and maintenance. As we all know, the direct air-cooled drum boiler unit has its obvious chemical characteristics in practical application: 1. The condensed water has low and stable salt content: air cooling is adopted, and there is no leakage of the condenser of the conventional water-cooled unit, which pollutes the condense...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F22B37/00C02F1/70

Inventor 郝晋堂杨杰尚玉珍张雷张邯平

Owner ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com