Backwash type front water filter

A water filter and backwashing technology, applied in the field of household appliances, can solve the problems of incomplete filter washing and low filter washing efficiency, and achieve the effects of shortening washing time, increasing washing sales, and saving washing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

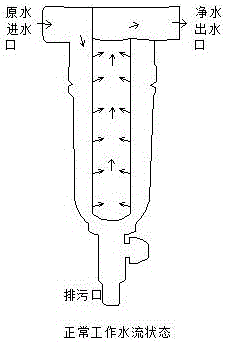

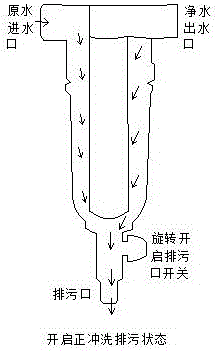

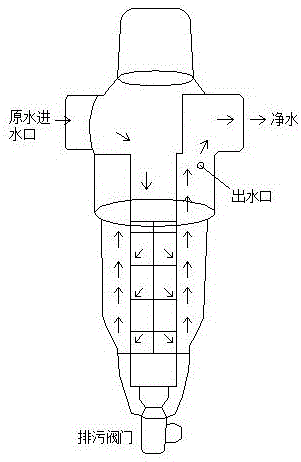

[0022] to combine Figure 5 and Figure 6 Shown: a backwash type pre-water filter, including a cover 1 with a water inlet 1-1 and a water outlet 1-2, and a cylinder 2 detachably connected to the cover 1 (in this embodiment, the cover and The cylinder body is threaded, and other connection methods can also be used, such as buckle connection), the cylinder body 2 defines a filter cavity, and the filter screen 3 is arranged in the cylinder body 2 and divides the filter cavity into inner Filter chamber 4 and outer filter chamber 5, the water inlet 1-1 communicates with the inner filter chamber 4, the water outlet 1-2 communicates with the outer filter chamber 5; the bottom of the cylinder 2 A drain port 7 is provided, on which a drain valve 8 is arranged; the drain port 7 communicates with the inner filter cavity 4 . In order to improve the stability of the filter screen 3 placement, the bottom of the filter cavity is provided with a filter screen mounting seat 6, and the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com