Air-blowing-type roller washing machine and clothes-washing method thereof

A drum washing machine, gas-type technology, applied in the field of washing machines, can solve the problems of raising the water level of washing liquid and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

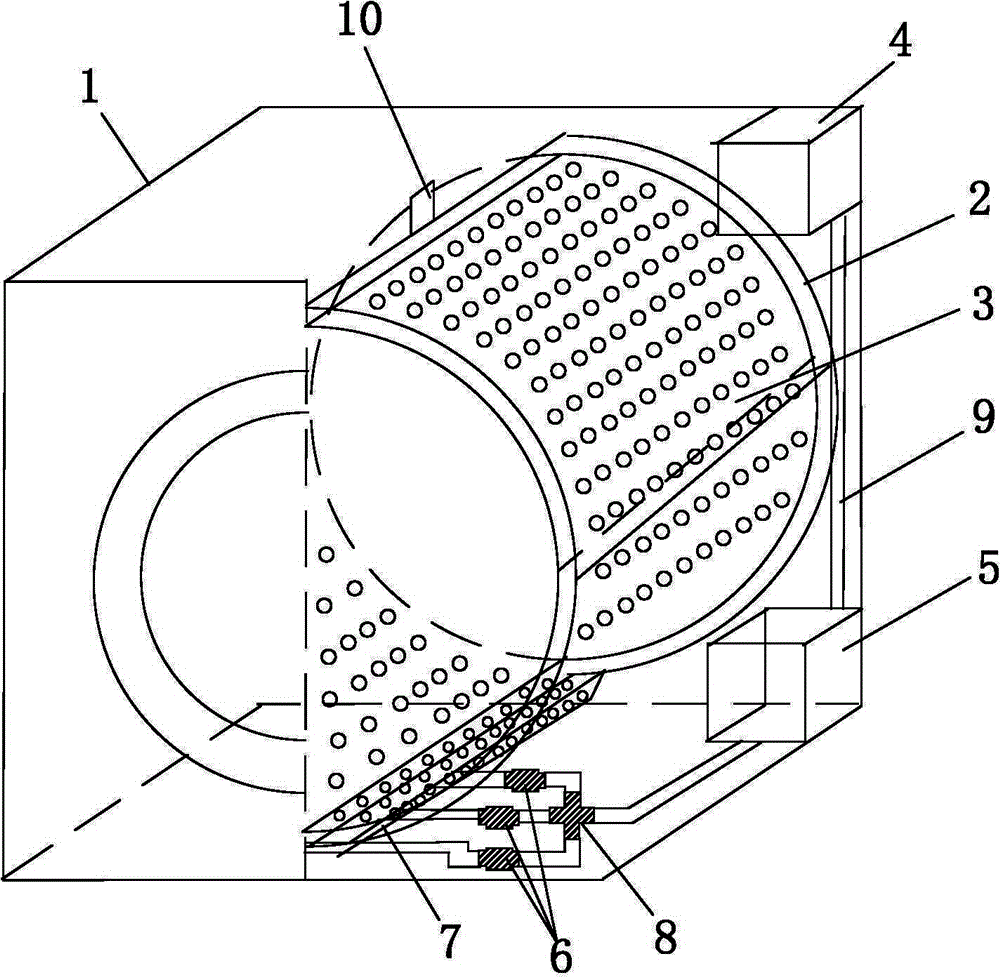

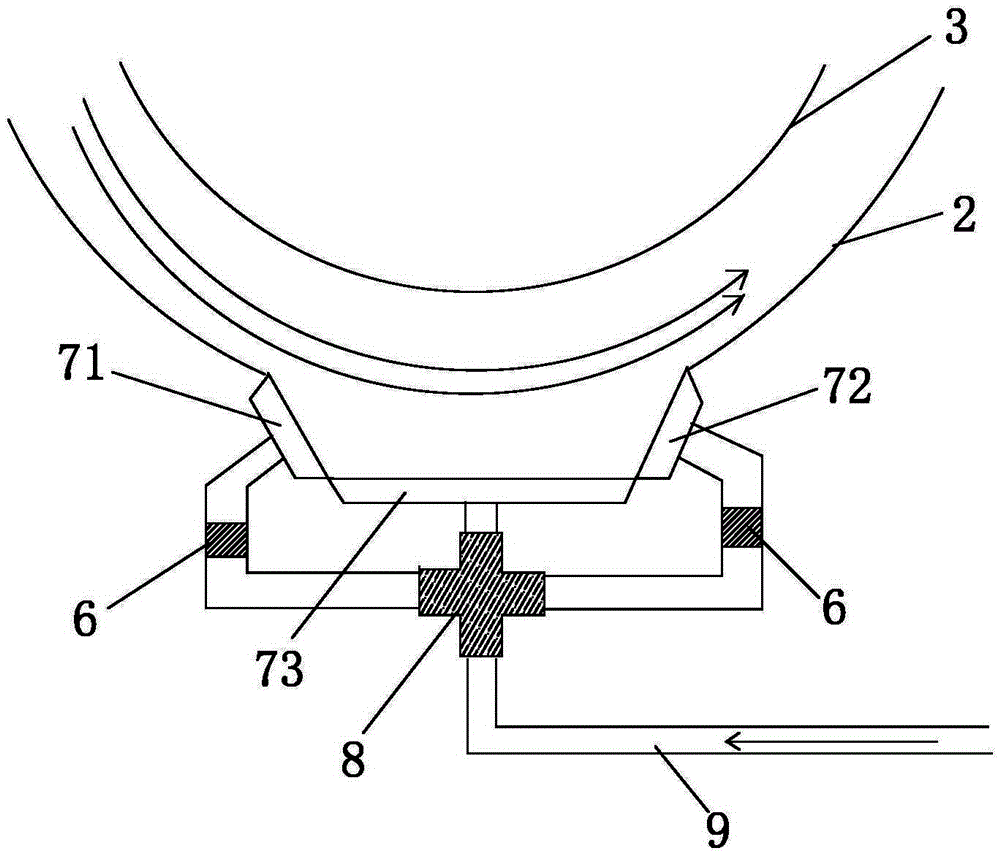

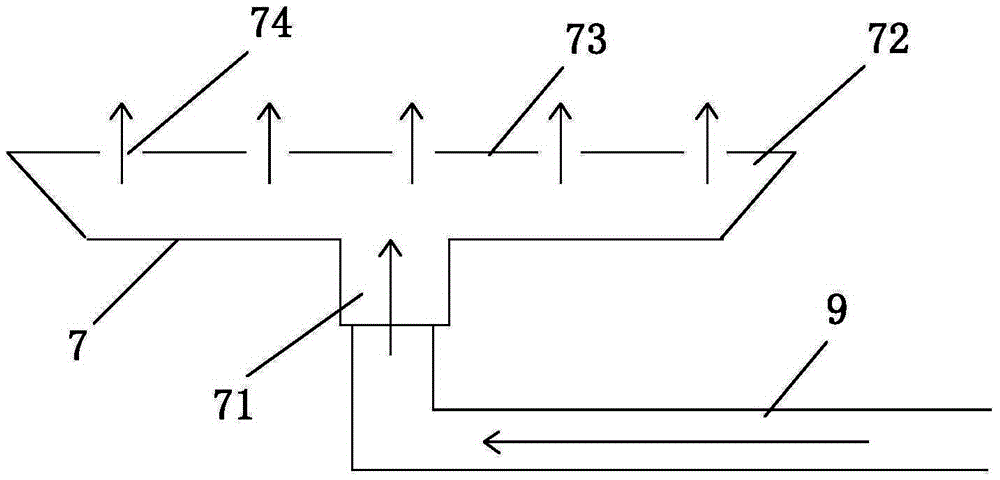

[0039] Such as figure 1 and Figure 5 As shown, the drum washing machine of the present invention has some structures of the traditional drum washing machine, such as the casing 1, the outer cylinder 2, the inner cylinder 3, the water inlet system, the drainage system, the driving system and the control system (not shown in the figure). Shown), also includes an air pump 4 and an air chamber 7, the air chambers 7 are at least two, independent of each other, at least one air chamber is blown in the same direction as the inner cylinder forward direction, and at least the other air chamber is blown in the same direction as the inner cylinder reverse direction Consistent, when washing, control the air chamber 7 whose air outlet direction is consistent with the rotation direction of the inner cylinder 3 to blow air into the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com