Rinse control method for washing machine

A control method and washing machine technology, applied in the control device of washing machine, other washing machines, washing machine appliances, etc., can solve the problems of reducing rinsing performance, increasing water and drainage time, etc., and achieve the goal of improving rinsing efficiency, reducing waste, and shortening rinsing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described below with reference to the accompanying drawings.

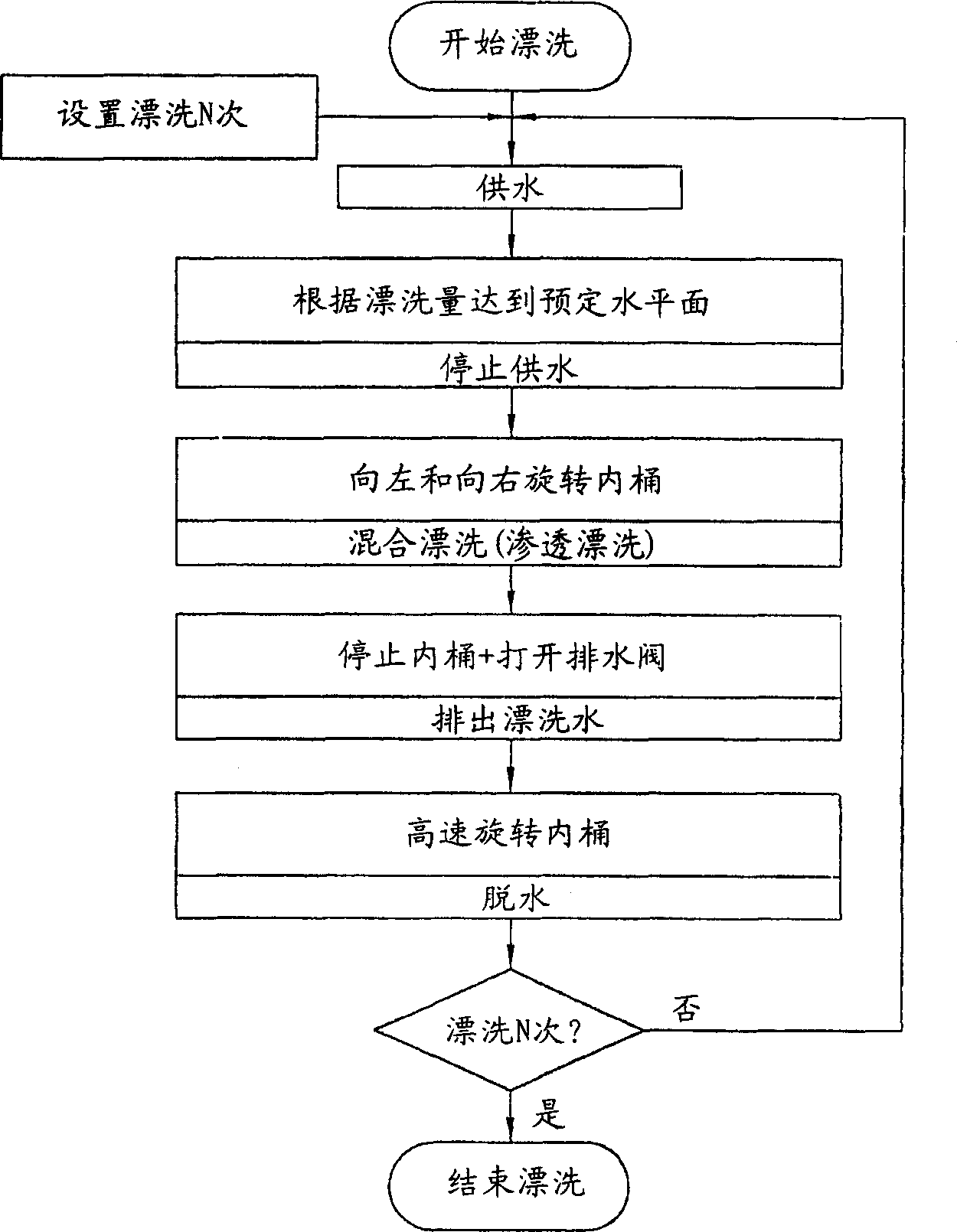

[0070] Figure 4 is a flowchart illustrating a washing machine rinse control method according to a first embodiment of the present invention.

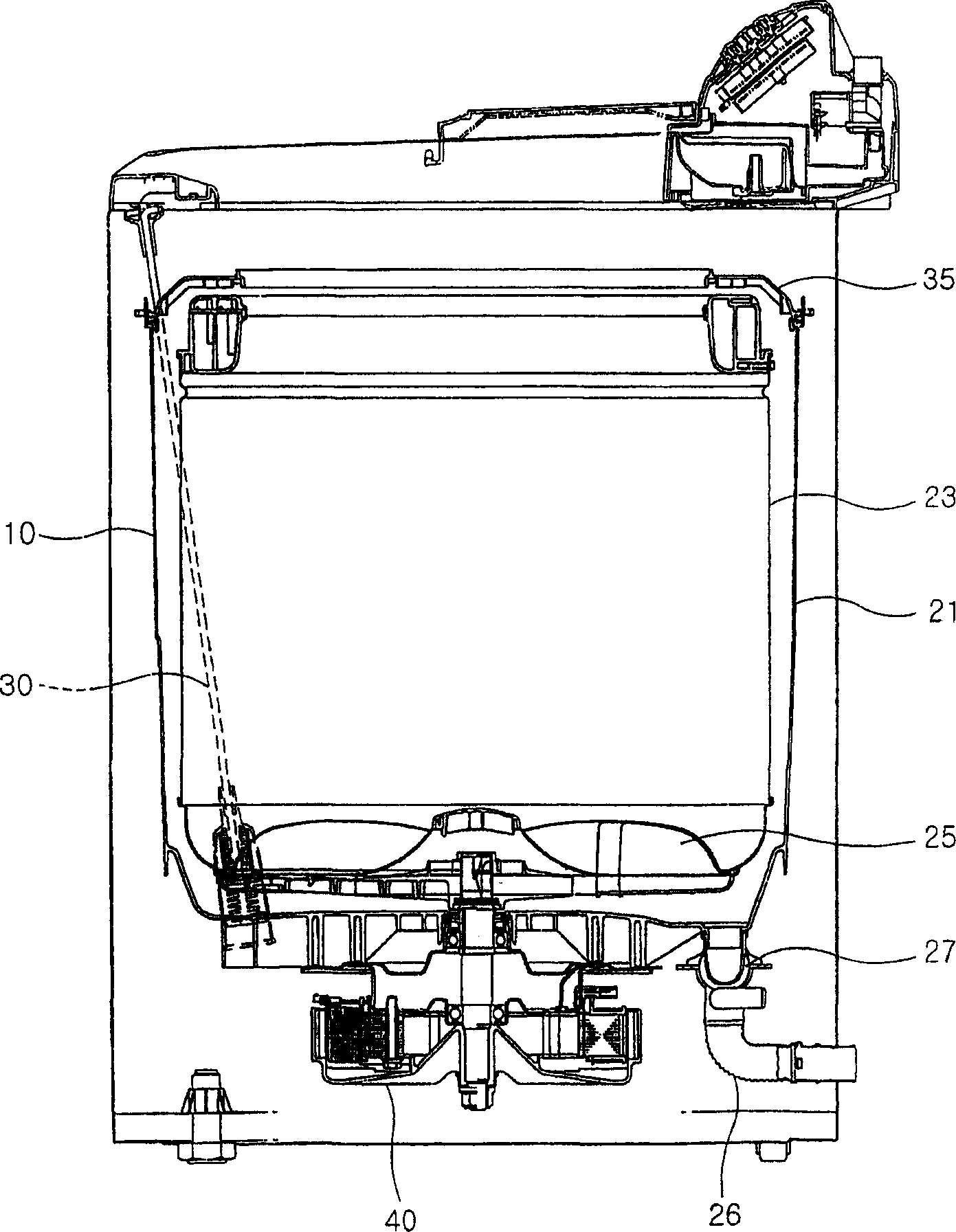

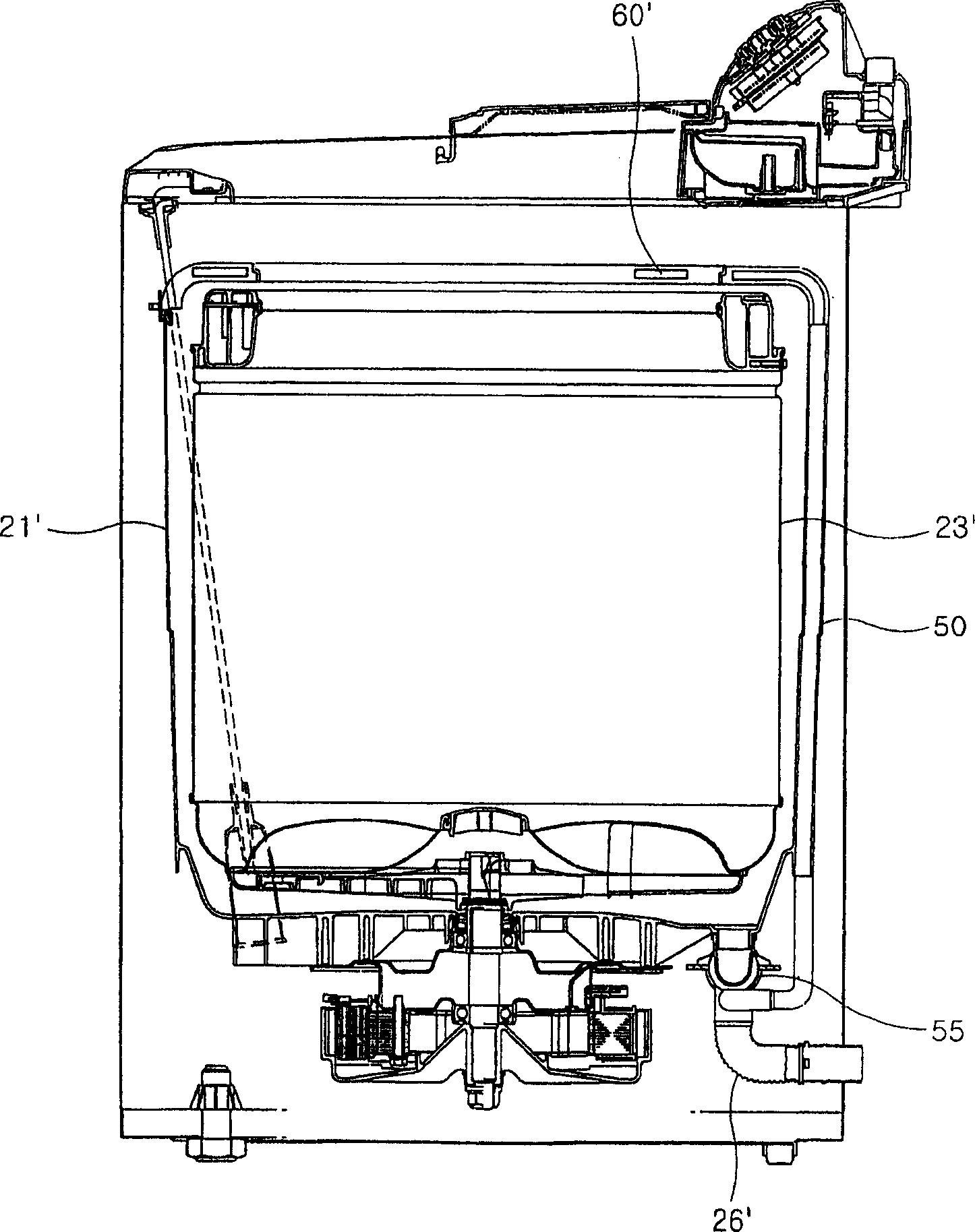

[0071] will refer to figure 1 and 4 A rinse control method for a washing machine according to the present invention is described.

[0072] First, by supplying rinsing water, controlling a driving motor to operate at a speed at which rinsing water is permeated into laundry to rotate the inner tub at a low speed, a rinsing water supply and permeation operation is performed (S1).

[0073] Here, the reason for rotating the inner tub at a low speed is as follows: because if rinsing water is supplied when the inner tub 23 is rotated at a high speed, the laundry rotates with the inner tub 23 at a high speed, and the rinsing water hits the laundry and splashes, so that the rinsing water cannot penetration.

[0074] Therefore, the inner tub ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com