Closed type recycle washing device for pipeline of hydraulic system

A closed cycle, hydraulic system technology, applied in the field of hydraulic system flushing, can solve the problems of large size of flushing station, on-site arrangement of flushing station, increase of flushing time, etc., to facilitate on-site layout and transportation, save oil flushing time, and quickly The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

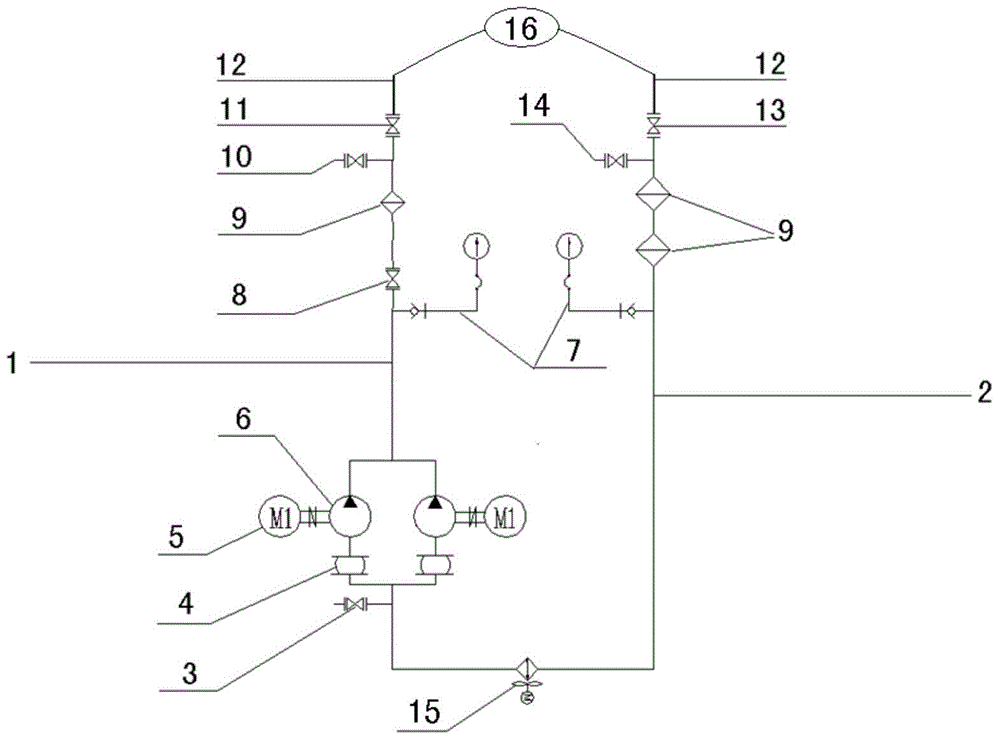

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 Shown: hydraulic system pipe closed cycle flushing device, including oil flushing pipe 1, oil return pipe 2, system to be flushed 16, motor 5, oil pump 6, oil flushing pipe 1 is provided with an oil pump 6 driven by motor 5, in this embodiment An oil pump 6 driven by two sets of motors 5 is installed. The motor 5 is a horizontal low-noise and large-flow helical gear pump with a power of 50KW. The rated working pressure of the oil pump 6 is 2.5MPA and the flow rate is 1000L / min.

[0022] The output end of oil pump 6 is connected with pressure gauge 7, ball valve 8, filter 9, ball valve 10 and ball valve 11 in sequence. The filter 9 on the oil pipe 1 is a PLF pressure line filter. This series of filters are available in the market, such as Guohai Filter Co., Ltd., and the specifications of the ball valve 10 and the ball valve 11 are DN25 and DN15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com