Concentric-tube pulverized coal discharging system and method for coal-bed gas well

A coalbed methane well and concentric pipe technology, which is applied in the coalbed methane well concentric pipe pulverized coal discharge system and coalbed methane well concentric pipe pulverized coal discharge system, can solve the problem of low operating efficiency, inability to discharge all the coal powder at the bottom of the well, and a single workover method for coalbed methane wells and other problems, to achieve the effect of improving efficiency, shortening the time of washing coal powder, and shortening the time of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

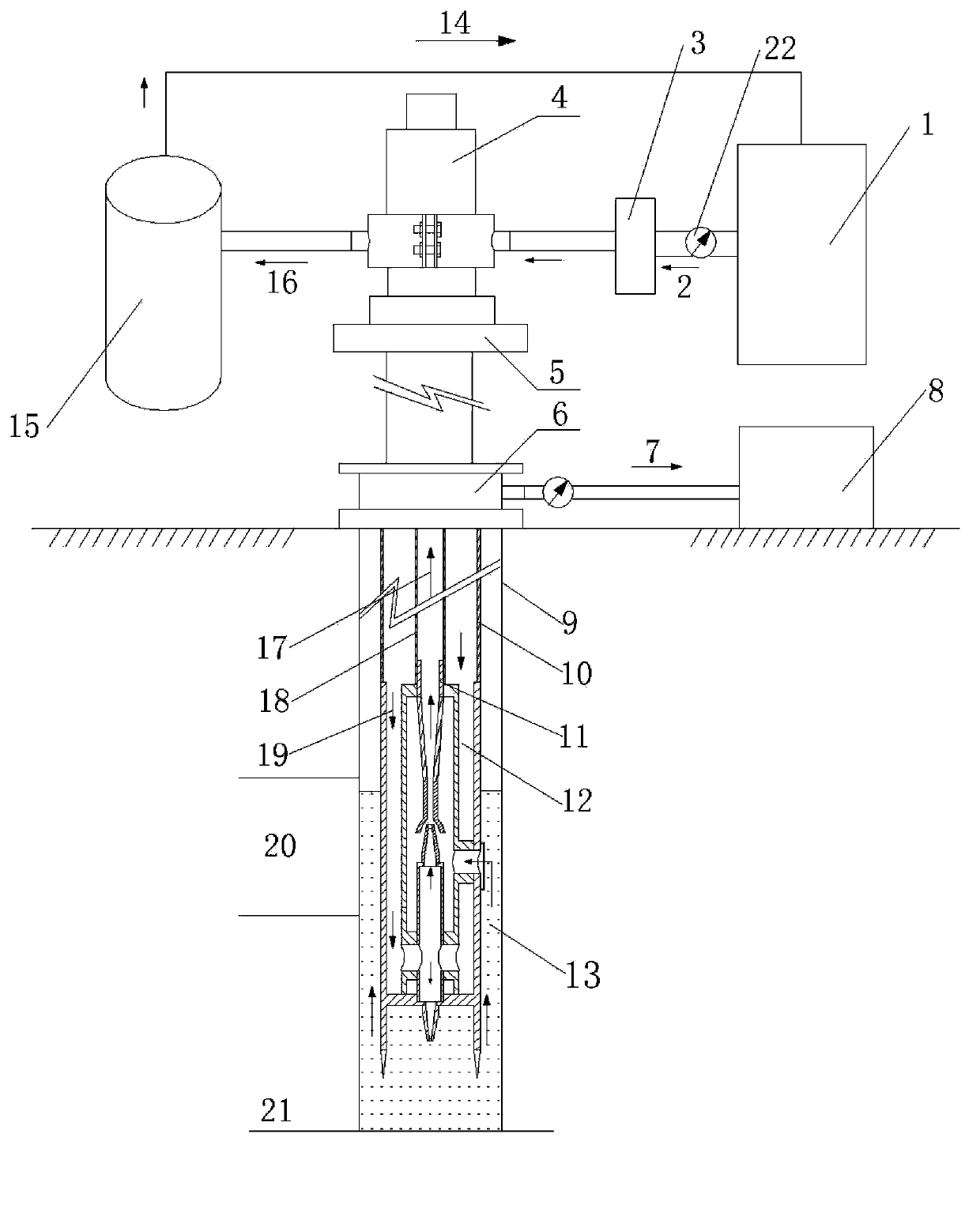

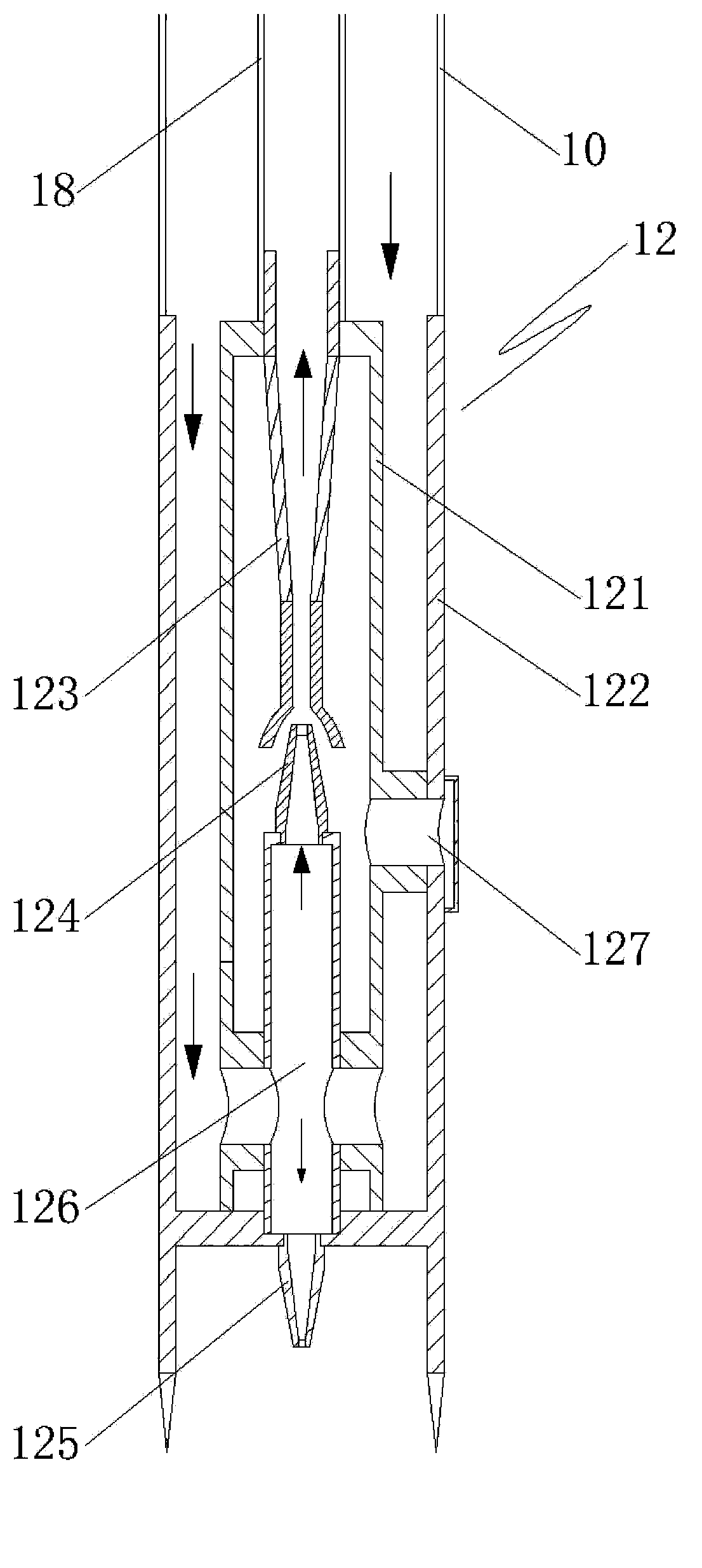

[0029] This embodiment provides a coalbed methane well concentric tube exhaust coal powder system, see figure 1 , figure 2 with image 3 , the system includes: a surface part installed on the surface of the wellhead of the operation well and an underground part installed under the operation well. Wherein, the surface part is the control mechanism of the concentric pipe coal discharge system of the coalbed methane well, and the underground part is the executive mechanism of the coalbed gas well concentric pipe pulverized coal discharge system.

[0030] Specifically, the ground part includes a three-plunger reciprocating pump 1 , a wellhead device 4 of a concentric tube pulverized coal discharge system, a wellhead casing cross 6 and a solid-liquid separation device 15 . Among them, the three-plunger reciprocating pump 1 is used as an increasing pump to change the normal-pressure liquid into a high-pressure liquid and transport it to the underground for coal powder flushing op...

Embodiment 2

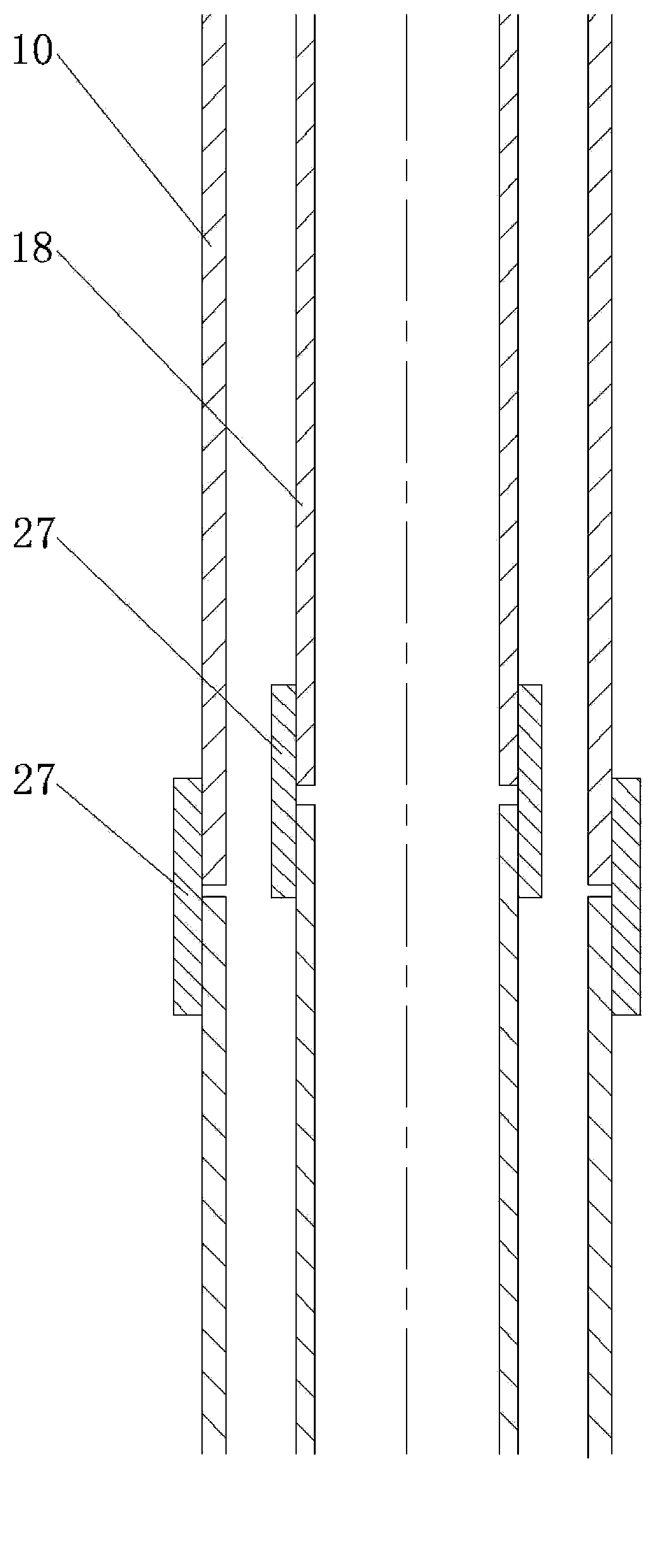

[0042] This embodiment provides an installation method of the concentric pipe exhaust coal powder system for coalbed methane wells, see Figure 1 to Figure 4 , the composition and principle of the coalbed methane well concentric pipe exhaust coal discharge system provided in this embodiment are consistent with those described in Embodiment 1. This installation method is aimed at operating wells with different depths, or as the scour depth increases, it is necessary to extend the inner and outer oil pipes , describe the way to extend the inner and outer oil pipes.

[0043] First install the first quick-change joint 23 on the wellhead device 4 of the concentric tube pulverized coal system, install the second quick-change joint 25 on the upper end of the wellhead casing cross 6, and use the high-pressure pipeline to connect the reversing valve 3, the second The quick coupling 25 communicates with the solid-liquid separation device 15 . In this way, during the pulverized coal flu...

Embodiment 3

[0045] This embodiment provides a coalbed methane well concentric tube pulverized coal discharge method, using the coalbed methane well concentric tube pulverized coal discharge system described in Embodiment 1. The specific steps of the method are:

[0046] S1, determine the operating well, install the upper wellhead casing cross 6 at the wellhead of the operating well, and lower the outer oil pipe 10 carrying the concentric tube hydraulic negative pressure jet coal powder flushing device 12 to the expected position of the operating well.

[0047] S2, run the inner oil pipe 18 into the outer oil pipe 10 with the downhole connecting tool 11, and communicate the inner oil pipe 18 with the inner cylinder 121 through the downhole connecting tool 11 under the action of the centralizer.

[0048] S3, install the ground part, that is, install the wellhead device 4 of the concentric pipe pulverized coal discharge system above the wellhead casing cross 6, install the three-plunger recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com