Concentric double pipe column reverse circulation continuous coal dust washing system well head device

A technology of sealing device and outer pipe, which is applied in the direction of flushing wellbore, drill pipe, casing, etc., can solve the problems of low operation efficiency, suspension of drainage and production, insufficient drainage, etc., and achieve the effect of improving efficiency, reliable operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is provided by the following examples, and the present invention will be further described below in conjunction with the accompanying drawings.

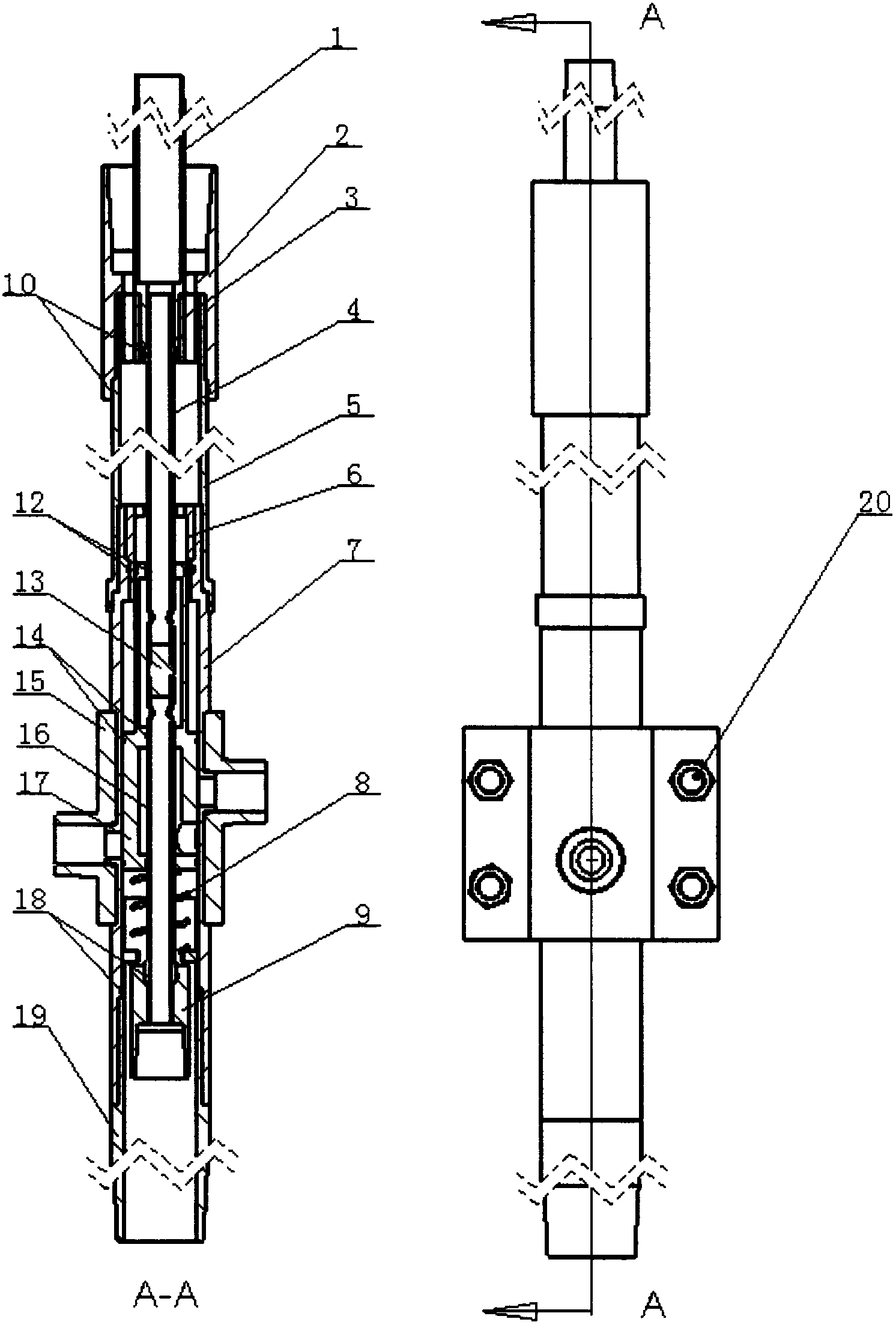

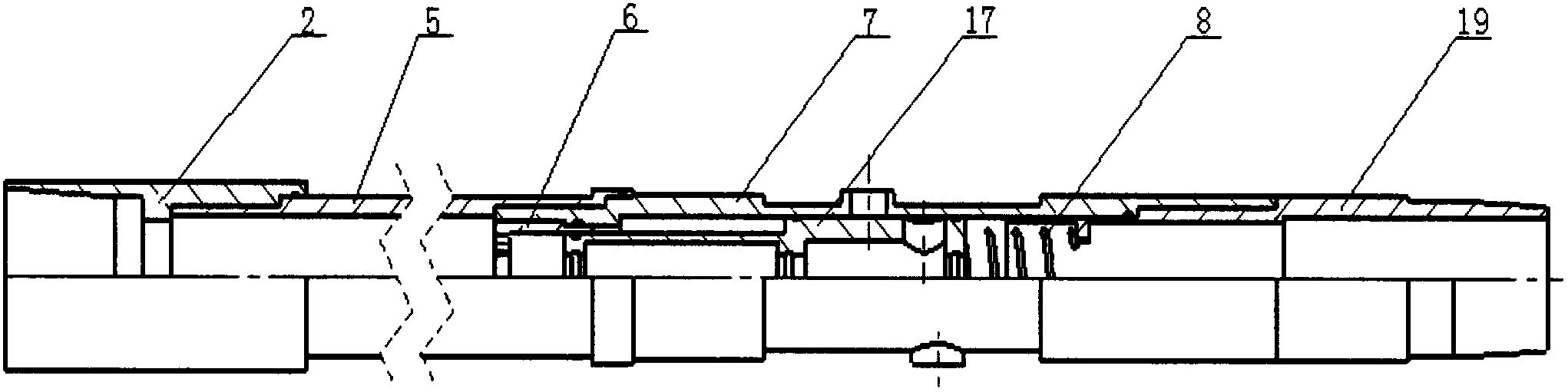

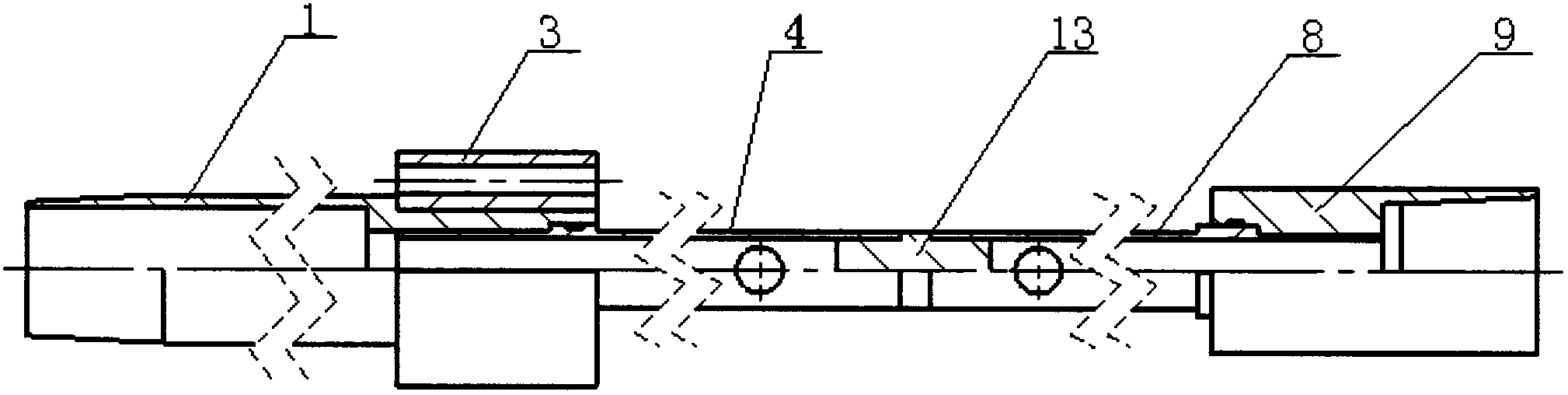

[0016] 1. If figure 1 The present invention shown is by inner pipe joint I1, outer pipe joint I2, moving joint 3, inner pipe I4, outer pipe I5, top seat 6, outer pipe 7, spring 8, inner pipe joint 9, O-shaped seal ring 10,12 , 14, 18, connecting plug 13, quick change joint 15, inner pipe 16, moving sealing pipe 17, outer pipe joint 19, and bolt 20. Wherein the inner pipe joint I1, the movable joint 3, the inner pipe I4, the connecting plug 13, the inner pipe 16 and the inner pipe joint 9 constitute a mobile inner pipe device; the outer pipe joint I1, the outer pipe I5, the top seat 6, and the movable sealing pipe 17 , Outer pipe 7, outer pipe connector 19 and spring 8 constitute outer pipe sealing device. Its assembly relationship is as follows: the upper end of the inner pipe 16 is connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com