Low-pressure oil-water well under-pressure well repairing device and under-pressure well repairing method

A low-pressure oil and workover technology, applied in wellbore/well components, drilling equipment, earth-moving drilling, etc., can solve the problems of short service life of annular blowout preventer rubber core, deterioration of construction environment, high procurement cost, etc. The effect of shortening the workover and well stop time, facilitating the operation of opening and closing the well, and shortening the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

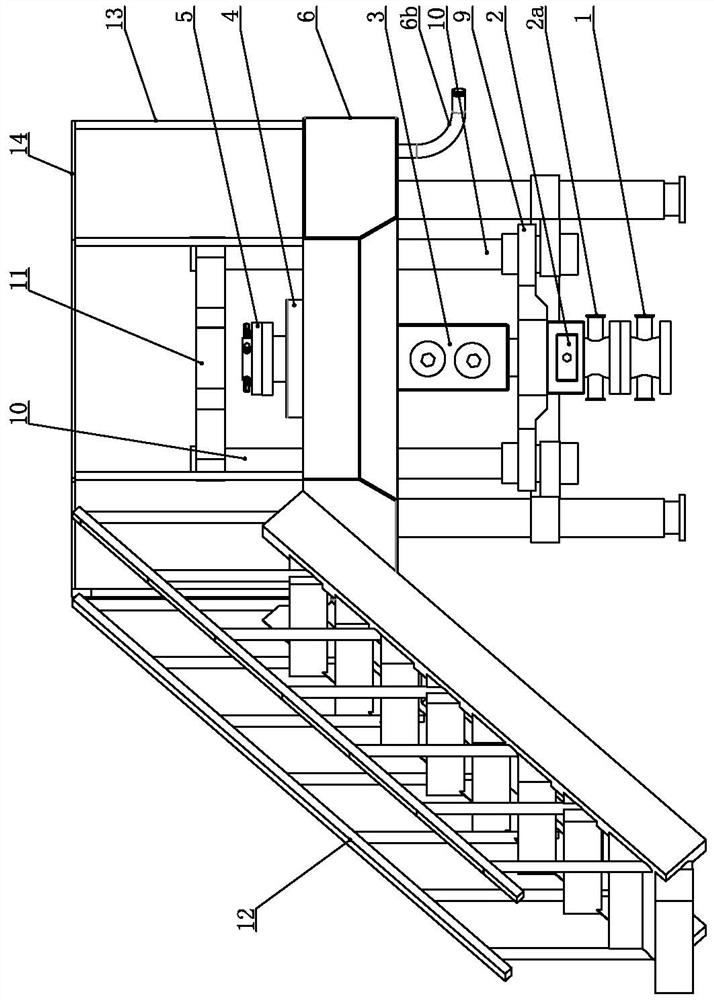

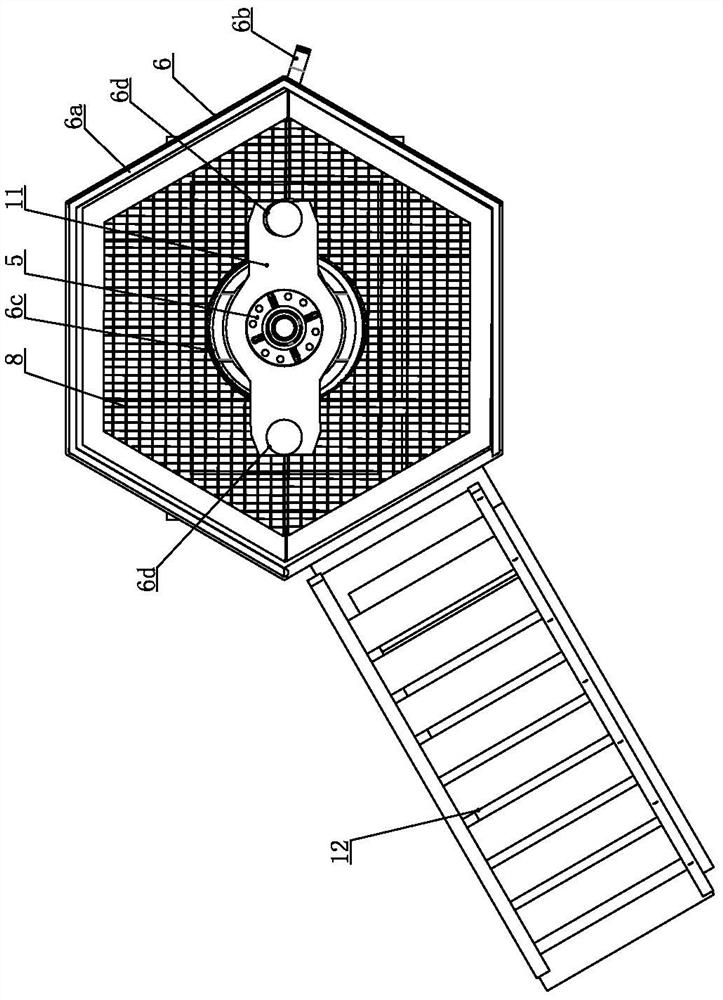

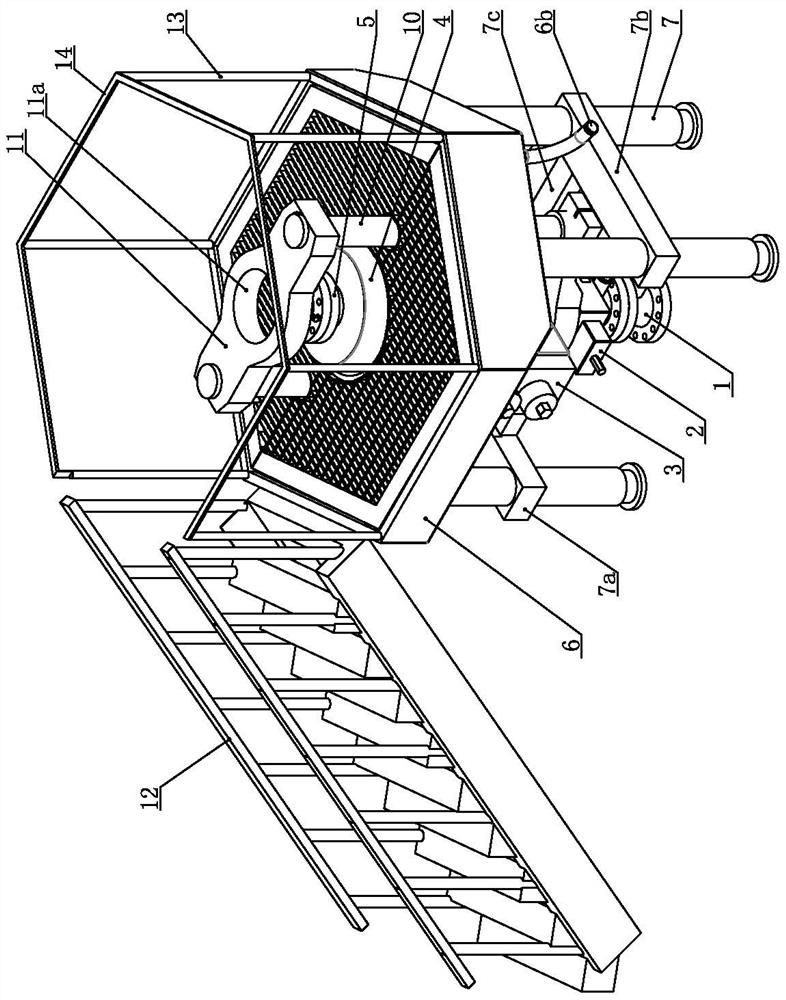

[0035] Such as Figure 1 to Figure 8 As shown, the pressurized workover device for low-pressure oil-water wells of the present invention includes a single ram blowout preventer 2 installed above the wellhead cross 1, the bottom of the single ram blowout preventer 2 has a cross, and the single ram preventer A double ram slip BOP 3 is installed above the injector 2, an annular BOP 4 is installed above the double ram slip BOP 3, and a hexagonal grid platform is installed on the outer periphery of the middle section of the annular BOP 4 8. A sunken collection box 6 is provided below the hexagonal grid platform 8. The bottom of the sunken collection box 6 is supported on the ground by four rectangularly distributed outriggers 7, and the bottom edge of the sunken collection box 6 A discharge elbow 6b is connected.

[0036] The hexagonal grid platform 8 can provide an operating platform for workers. The overflow during wellhead operation can flow into the sinking collection box 6. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com