Constant force float auxiliary flushing time control valve

A float and constant force technology, used in flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of fragile valves and sanitary wares that cannot be used normally, and achieve the effect of improving the use function, saving space and optimizing the valve structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

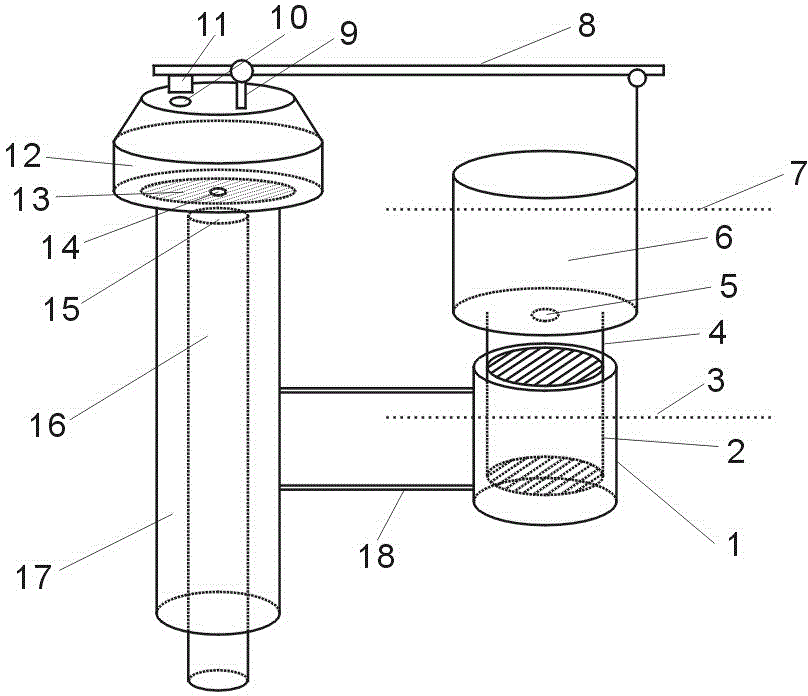

[0020] figure 1 The specific implementation manner of the constant force float assisted flushing time control valve of the present invention is shown. Regardless of whether the water tank is full of water at the high water level 7 or at the low water level 3 after flushing, there is always water in the water storage cup 1, and the constant pressure float 2 in the water storage cup 1 always has buoyancy through the lever arm 8 by blocking 11 Pressure relief hole 10 is sealed. Tap water goes to sealing port 15 through water inlet pipe 16, and the water that pressure guide hole 14 comes in makes the pressure of equal pressure chamber 12 and tap water network pressure equate, between inlet pipe 16 and outlet pipe 17 by spring pressure film 13 self intrinsic elastic seal. The top of the constant force float 2 is connected with the water storage chamber 6 by a connecting rod 4 . The lower part of the water storage chamber 6 is designed with an adjustment hole 5 . There is a fulcr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com