Sample preparation system with functions of extraction and separation of inert gas, and use thereof

An inert gas, sample preparation system technology, applied in the preparation of test samples, analysis of materials, material analysis by electromagnetic means, etc., can solve the problems of reactive gas pollution, Ar gas pollution, low parameters of pretreatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

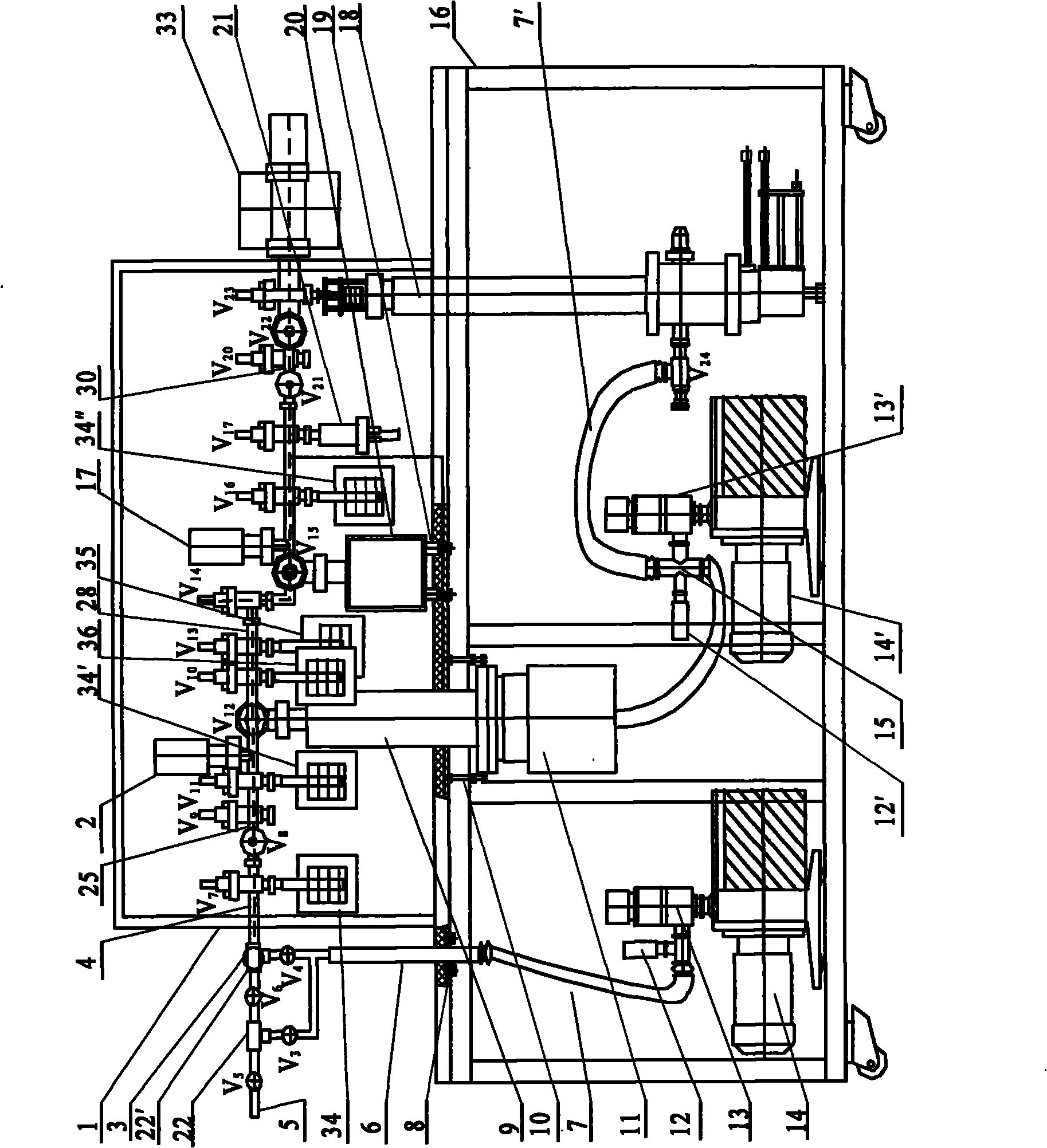

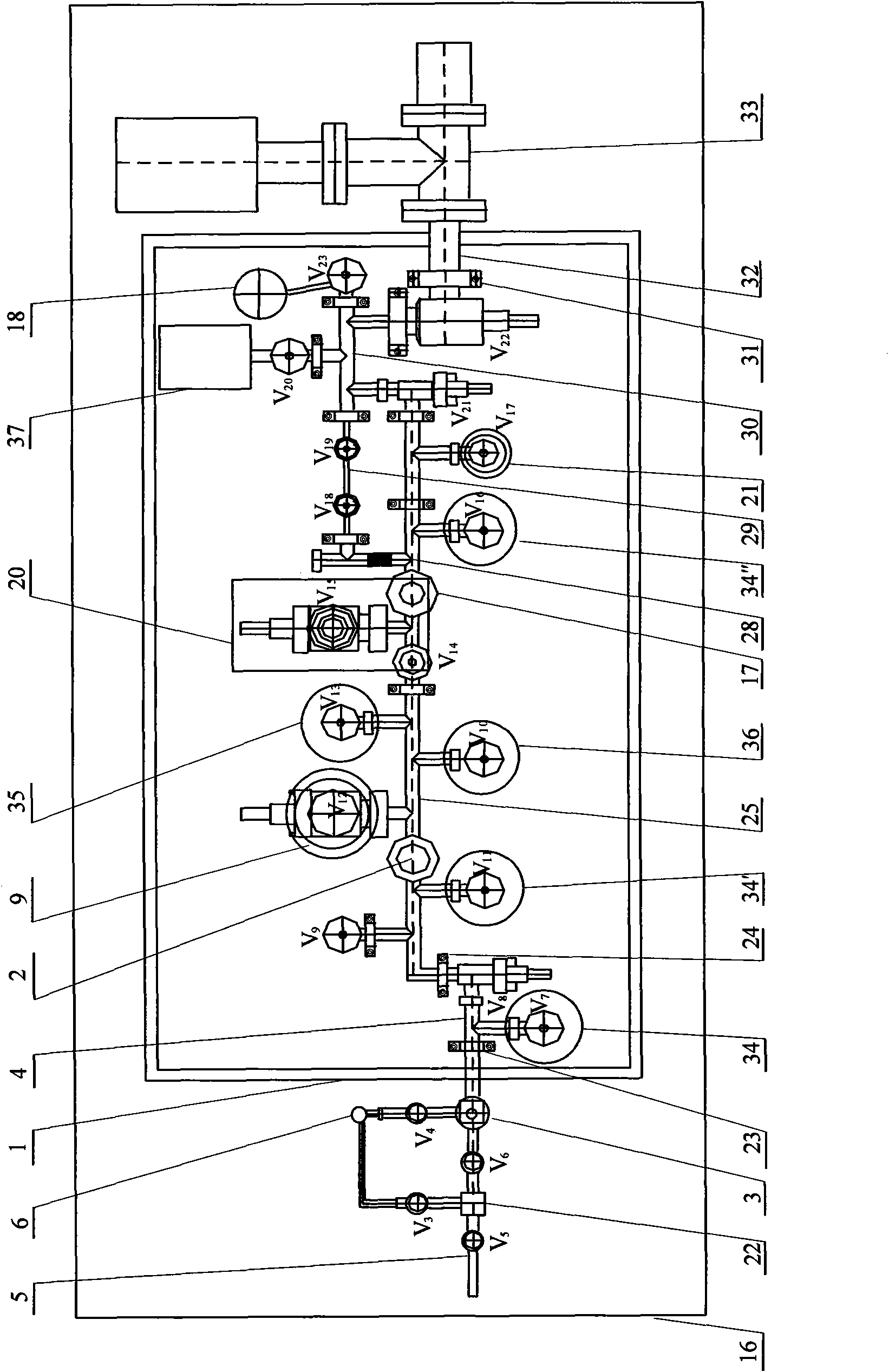

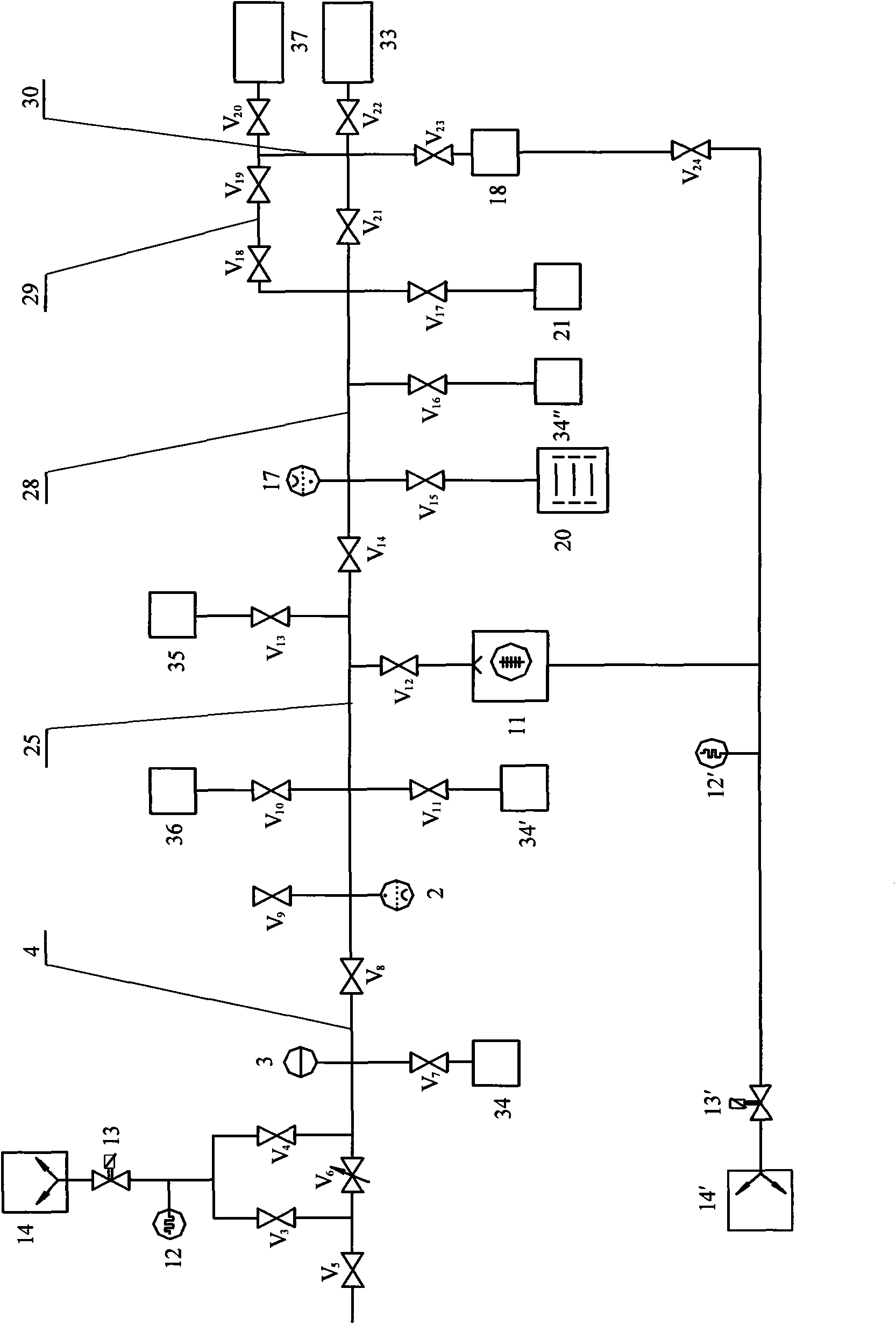

[0019] The sample preparation system for extraction and separation of inert gas in natural gas according to the present invention mainly includes corrosion-resistant metal pipelines, valves, connection components, oven 1 and system support 16;

[0020] The oven 1 is composed of front, rear, left, right and top panels, placed on the top panel of the system support 16;

[0021] The system bracket 16 is a box body, the left mechanical pump 14 and the right mechanical pump 14' are respectively placed in the system bracket box, and the left mechanical pump 14 passes through the left electromagnetic partition air release valve 13, the left low vacuum gauge 12, and the left stainless steel bellows 7 is connected with the stainless steel straight pipe 6, and the stainless steel straight pipe 6 passes through the top plate of the system bracket box and passes through the valve V respectively. 3 and valve V 4 It is connected with the lower ends of the first three-way 22 and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com