Flushing method for drum washing machine

A drum washing machine and detergent technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of wasting energy, skin diseases, insensitivity, etc., to prevent energy waste, improve washing effect, The effect of preventing skin diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

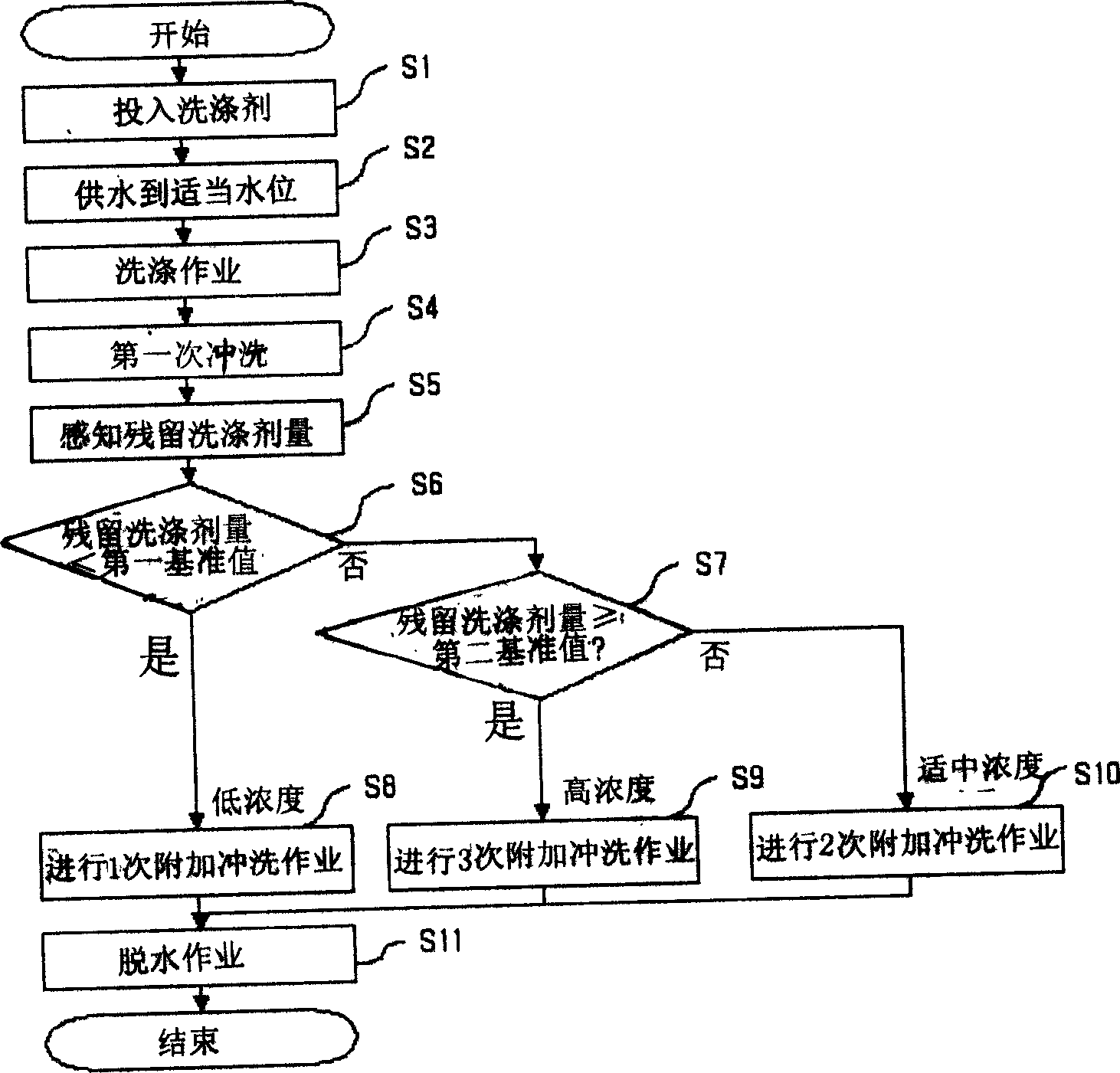

[0016] In order to achieve the above-mentioned purpose of the present invention, the present invention provides a washing method for a drum washing machine, which is carried out in the following four stages: that is,

[0017] The first stage: the first stage of supplying washing water and detergent to the washing tank;

[0018] The second stage: after the washing operation is completed, the second stage of the first washing operation is carried out;

[0019] The third stage: after the above-mentioned second stage is completed, compare the perceived amount of residual detergent in the washing water with the reference value, and determine the third stage of additional rinse times;

[0020] Fourth stage: The fourth stage of the flushing operation based on the results of the perceptual comparison of the third stage above.

[0021] The reference values include: a first reference value for distinguishing low concentration and moderate concentration of residual detergent, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com