Patents

Literature

142 results about "First flush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

First flush is the initial surface runoff of a rainstorm. During this phase, water pollution entering storm drains in areas with high proportions of impervious surfaces is typically more concentrated compared to the remainder of the storm. Consequently, these high concentrations of urban runoff result in high levels of pollutants discharged from storm sewers to surface waters.

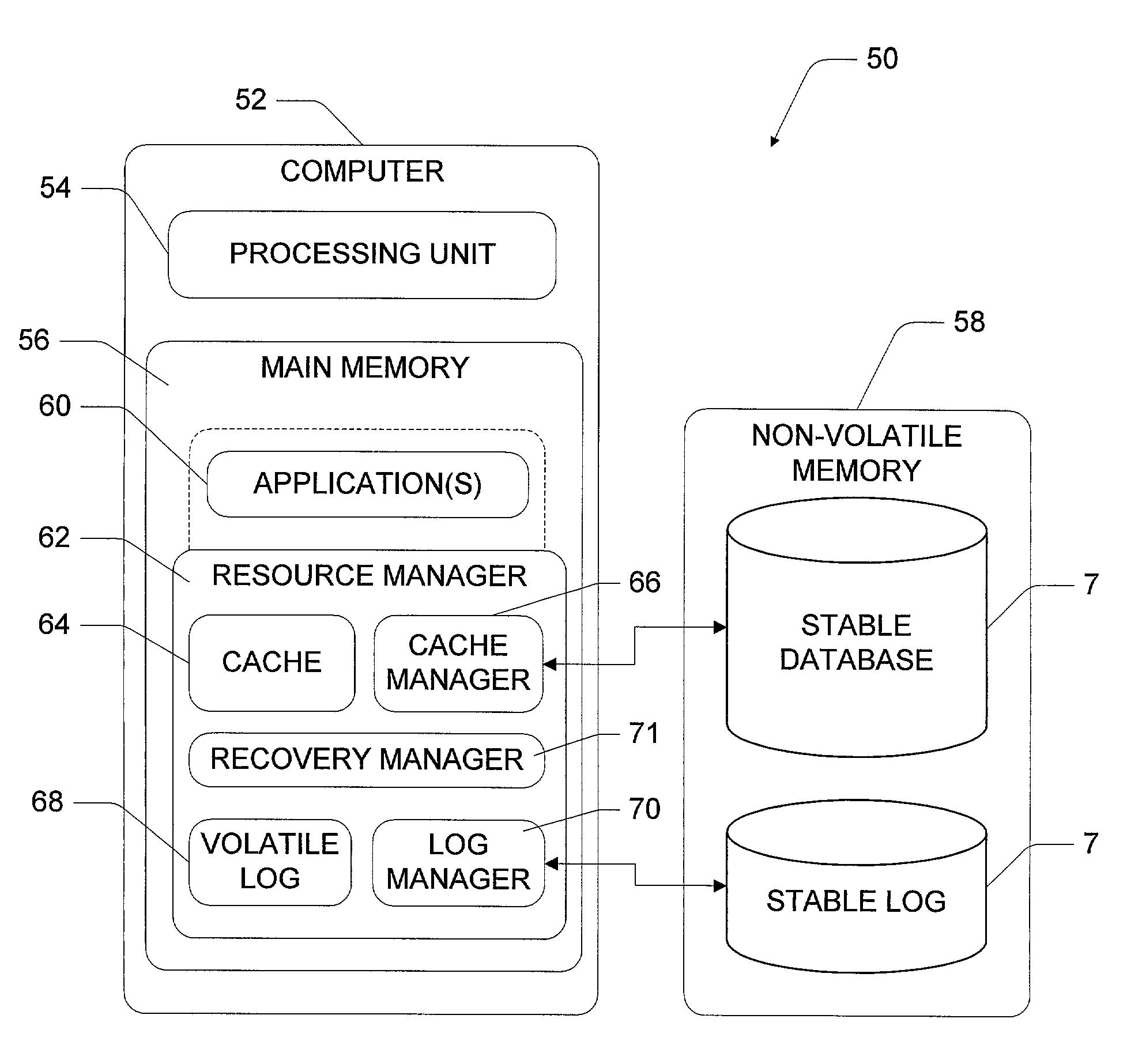

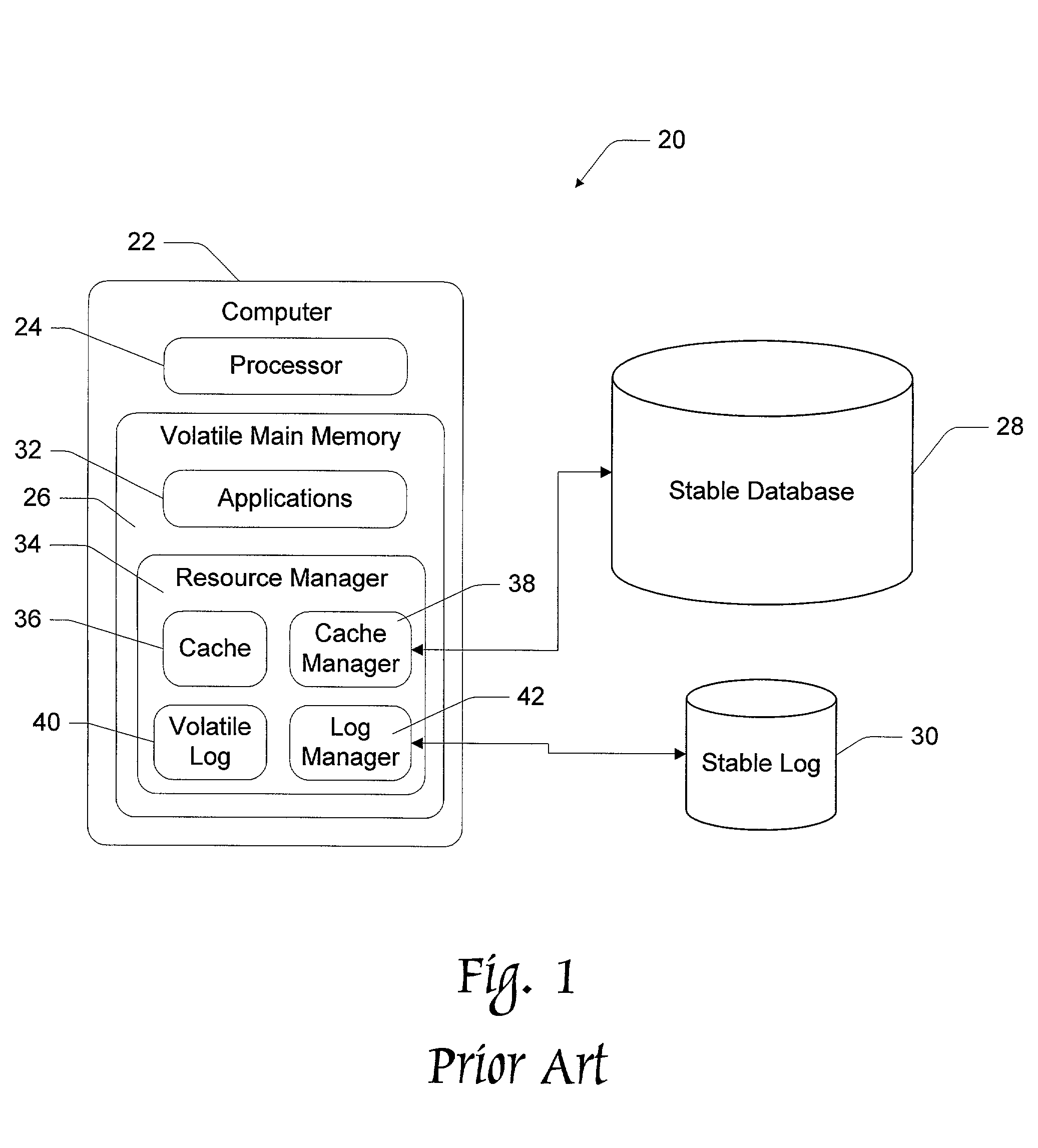

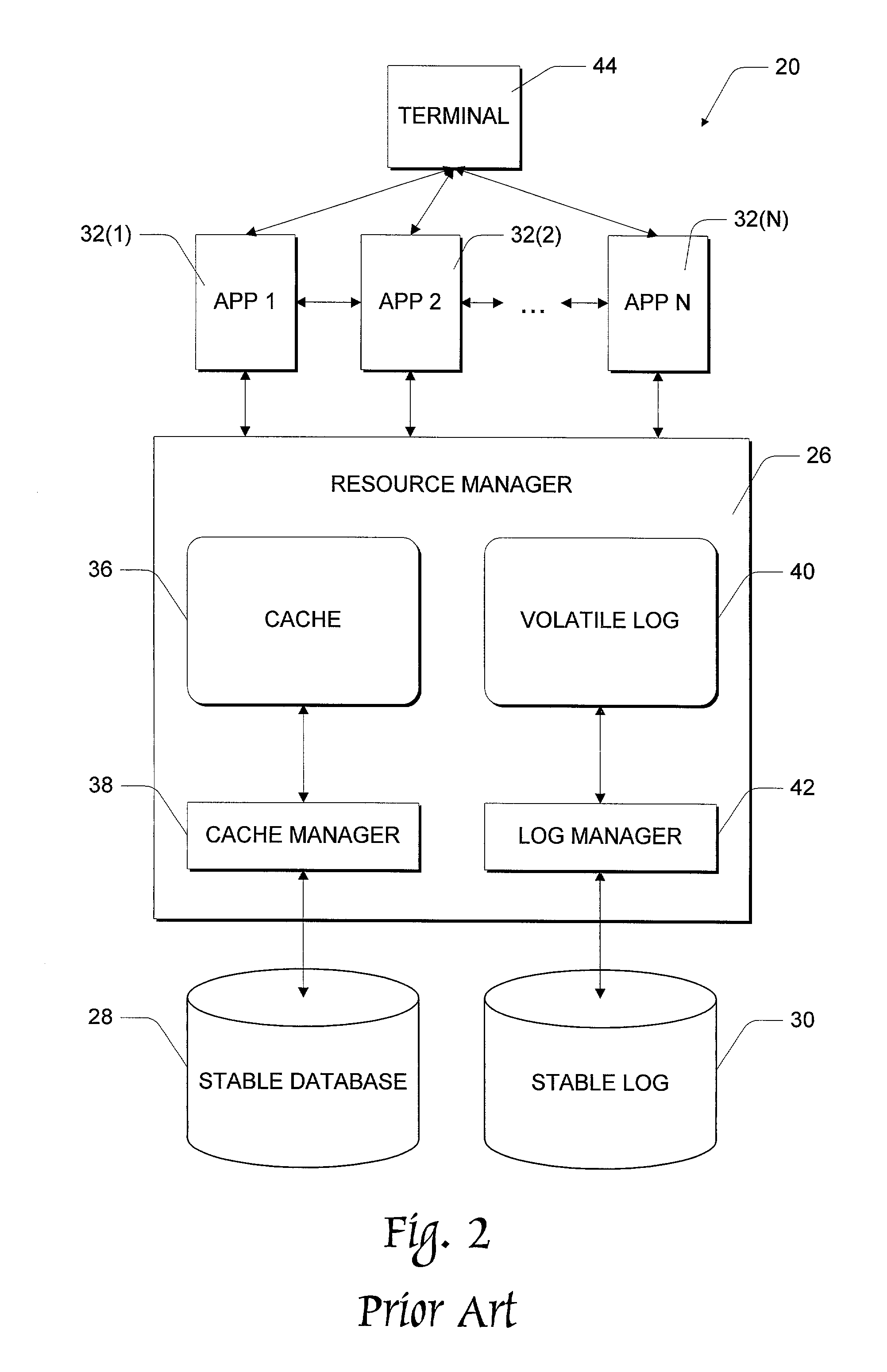

Database computer system using logical logging to extend recovery

InactiveUS6978279B1Reduce data volumeData processing applicationsError detection/correctionCheck pointDatabase machine

This invention concerns a database computer system and method for making applications recoverable from system crashes. The application state (i.e., address space) is treated as a single object which can be atomically flushed in a manner akin to flushing individual pages in database recovery techniques. To enable this monolithic treatment of the application, executions performed by the application are mapped to logical loggable operations that can be posted to the stable log. Any modifications to the application state are accumulated and the application state is periodically flushed to stable storage using an atomic procedure. The application recovery integrates with database recovery, and effectively eliminates or at least substantially reduces the need for check pointing applications. In addition, optimization techniques are described to make the read, write, and recovery phases more efficient. Atomic flush sets, whether generated from cyclic flush dependencies or otherwise, can be broken apart. This enables an ordered flushing sequence of first flushing a first object and then flushing a second object, rather than having to flush both the first and second objects simultaneously and atomically.

Owner:MICROSOFT TECH LICENSING LLC +1

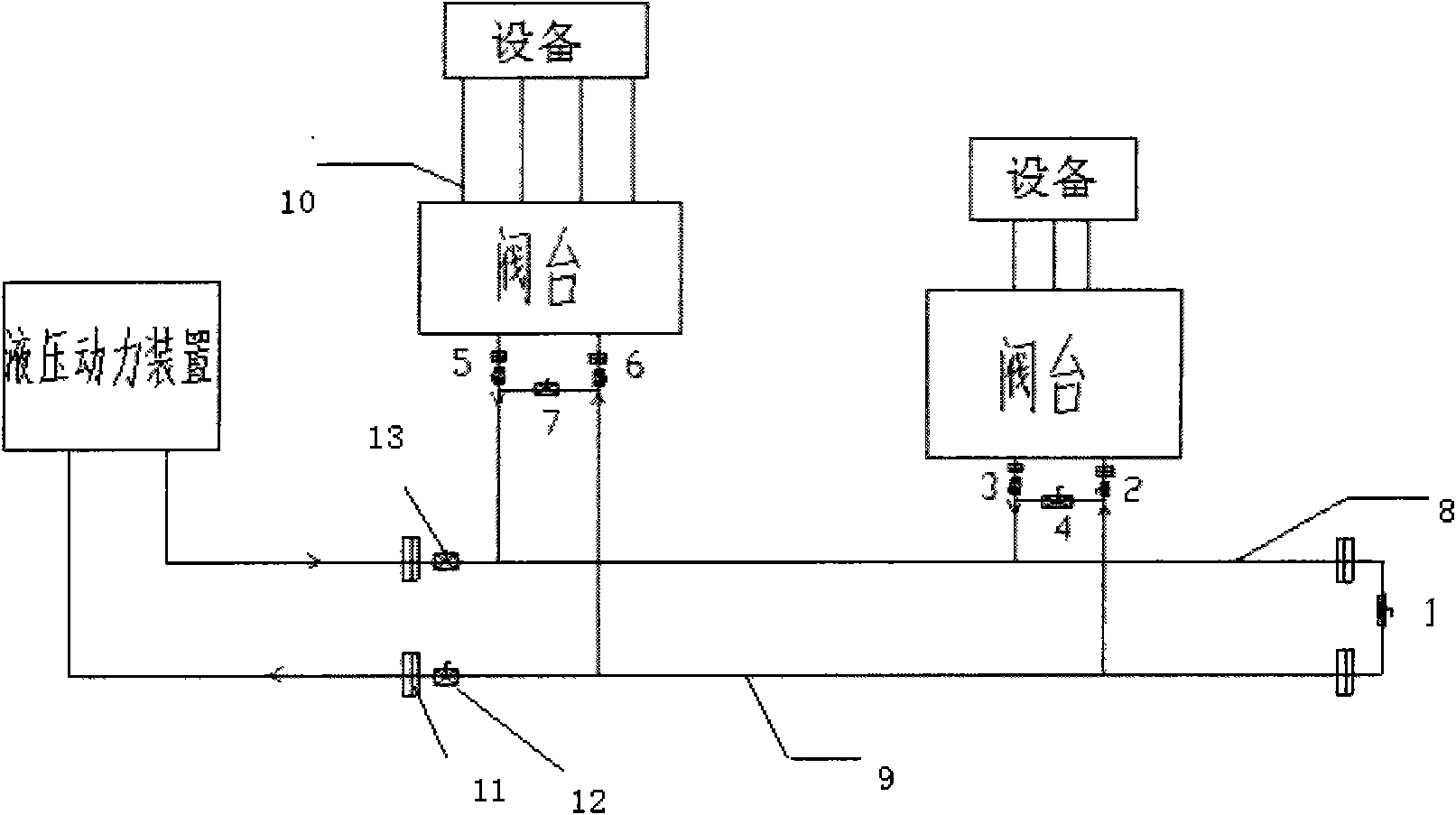

Pipeline cleaning method

ActiveCN101637768AWashed away wellCleaning time is shortHollow article cleaningIsolation valveEngineering

The invention relates to a pipeline cleaning method, which uses cleaning oil as medium and uses a pump to clean forcibly and circularly. The pipeline cleaning method comprises the following steps: 1)steps of processing and installing the pipeline: respectively installing a separating valve at a main pipeline, a branch pipeline and connecting part of bypass pipelines; 2) steps of installing a temporary cleaning device and disassembling the branch pipeline; 3) step of primary cleaning; 4) step of restoring the normal pipelines; and 5) step of secondary cleaning. Compared with the traditional construction process, the construction technique increases a control valve on the original basis, increases the step of reverse cleaning, uses the control of the bypass valve, has circular and thoroughcleaning, high cleanness, short time and low cost, avoids the defects that the dead angles are formed in cleaning and the like and has better technical effect and promotion value.

Owner:CHINA HUAYE GROUP

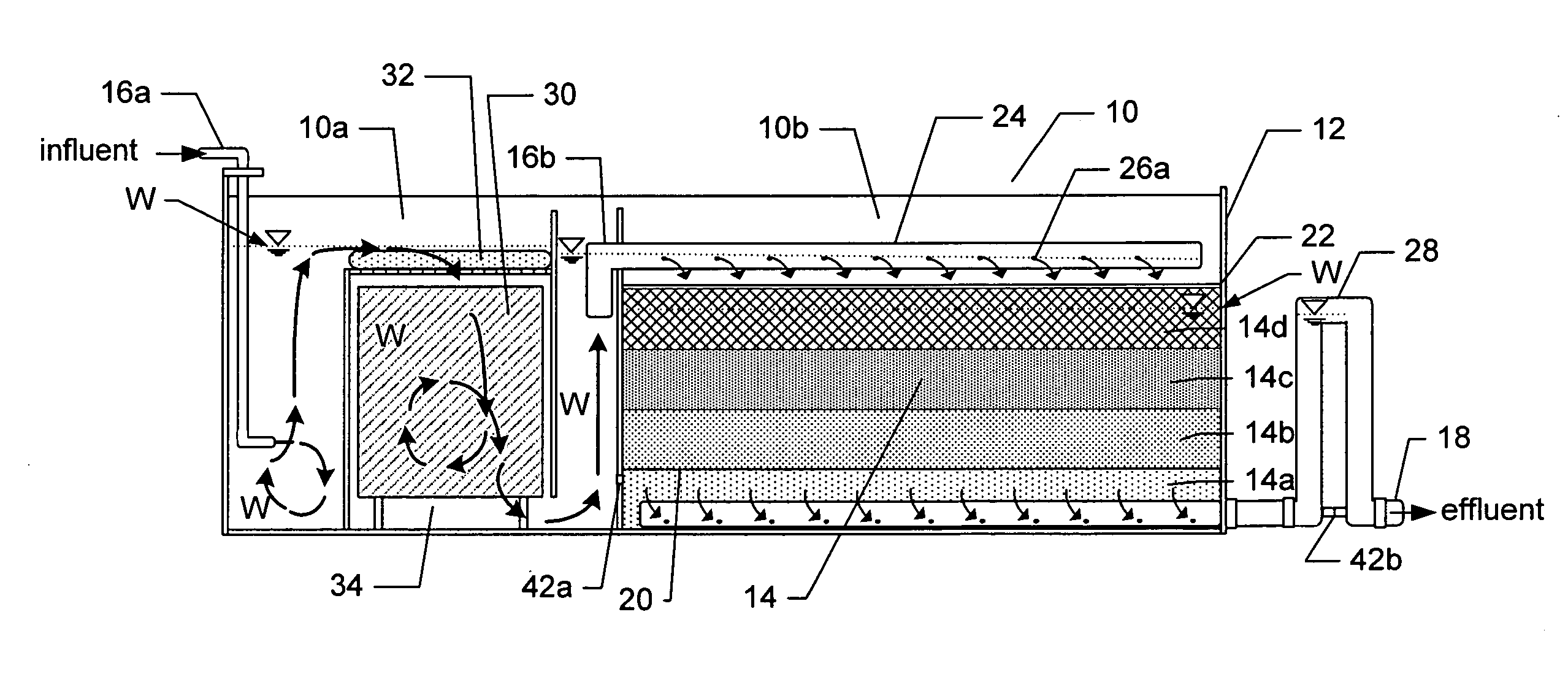

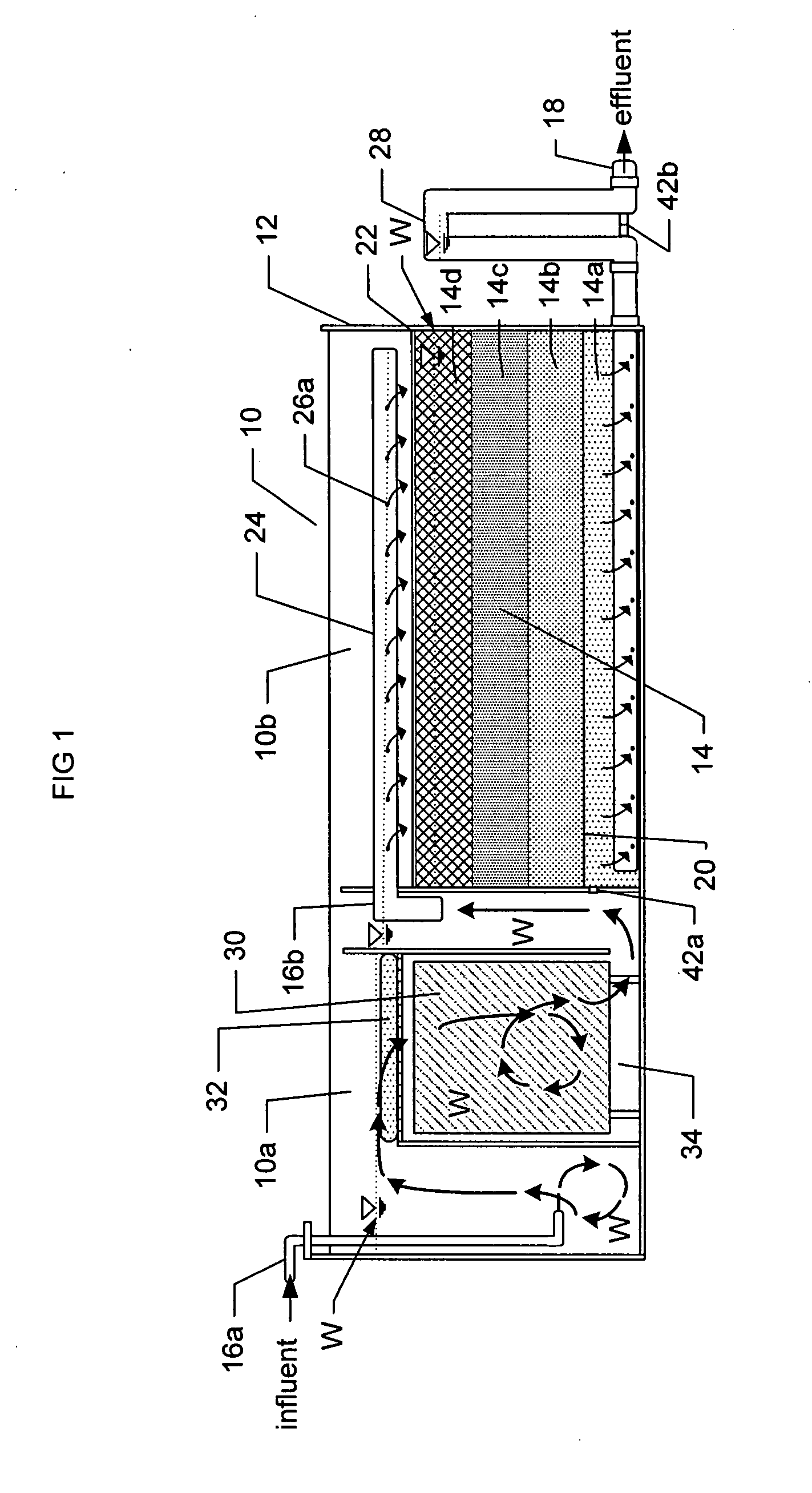

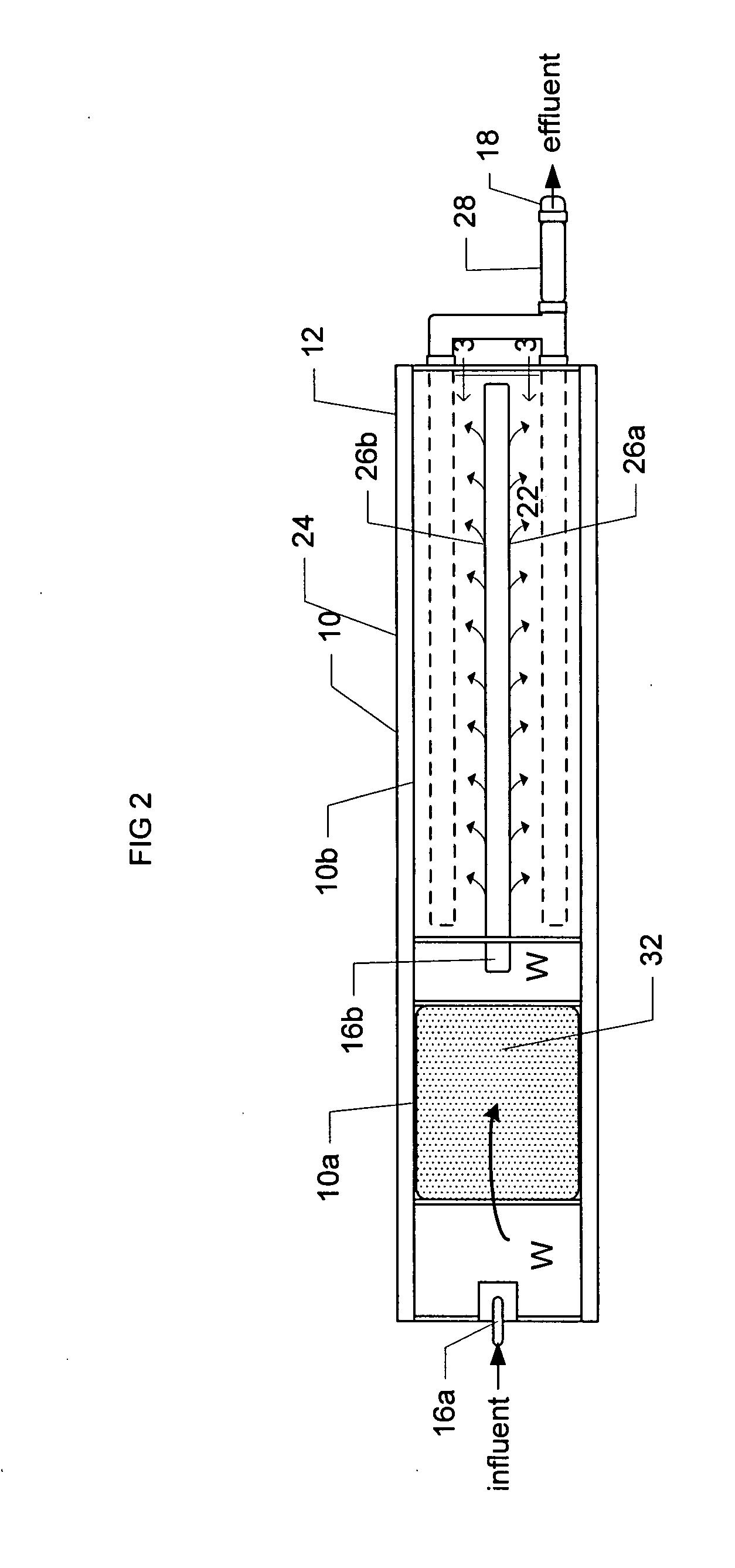

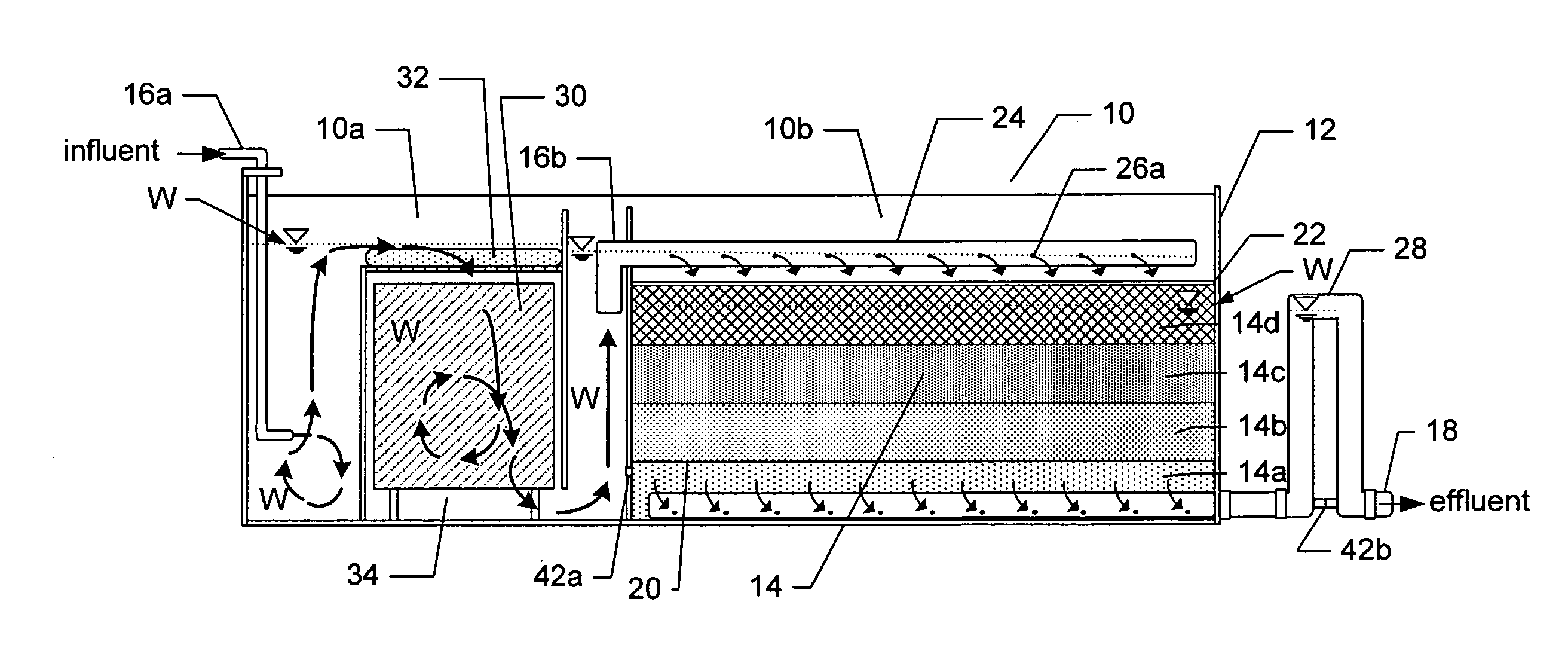

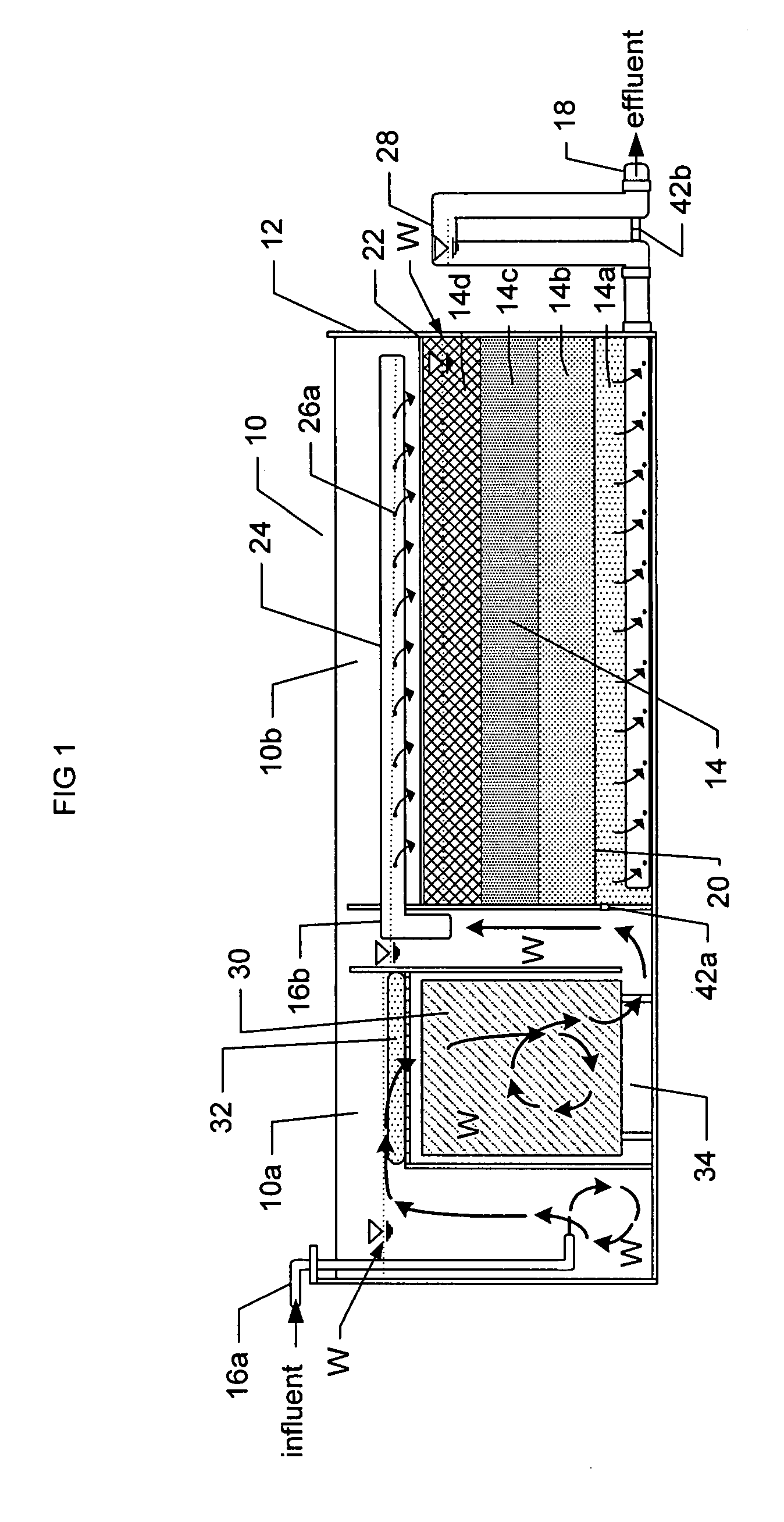

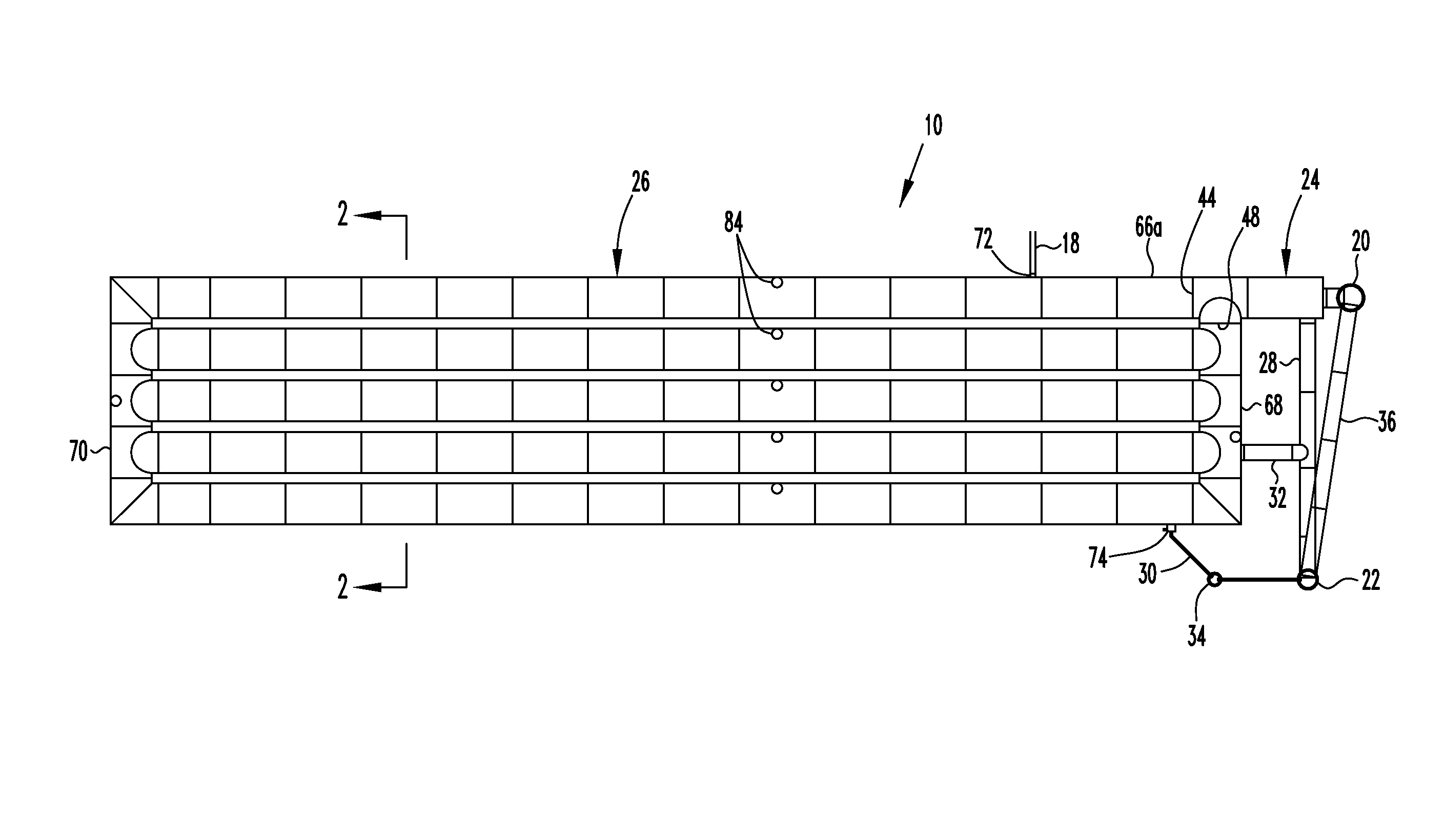

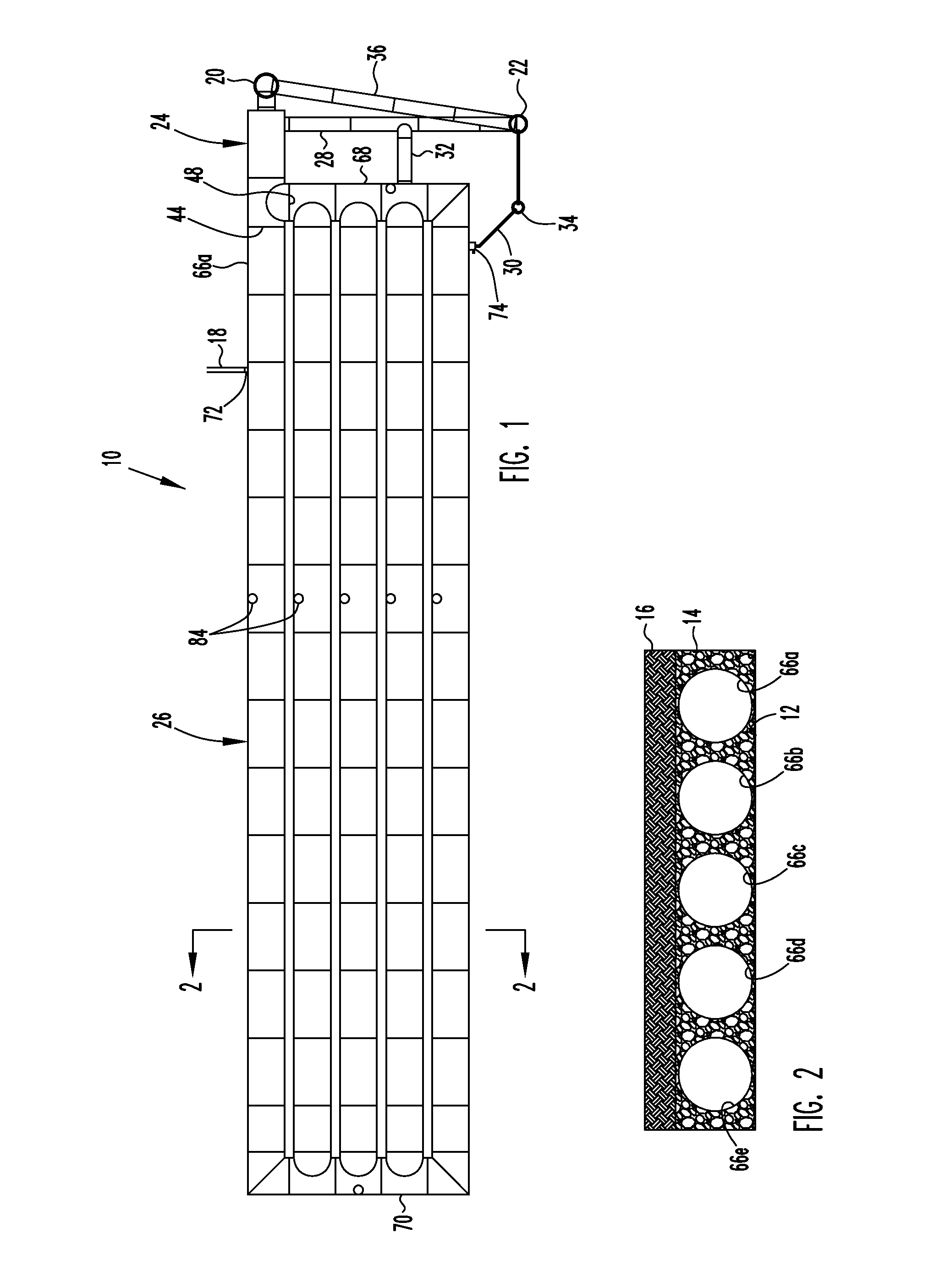

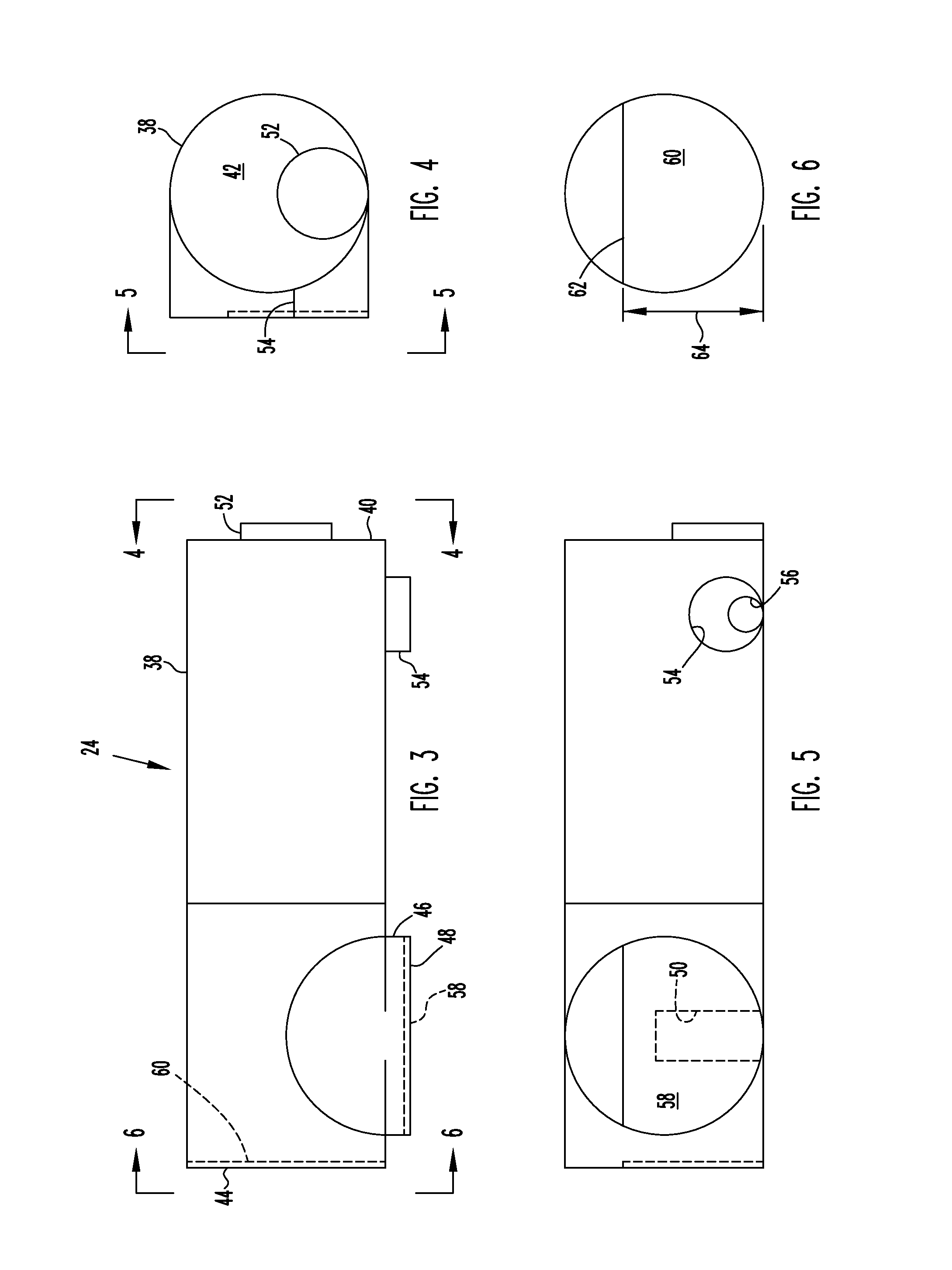

Passive stormwater management apparatus and system

ActiveUS20090101555A1Easy to cleanCost-effective and extremely effective in removingGeneral water supply conservationTreatment involving filtrationMean free pathParticulates

A stormwater inlet near an upper edge of a layered filter media vessel is equipped with a distribution header that ensures effective use of the surface area of the filter media by providing plural spaced streams of stormwater thereat, each at a point of impact having its energy dissipated by a layer of material that covers the upper layered filter media surface. The stormwater inflow is metered to control the stormwater pollutant removal process kinetics, thereby slowing the mean free path of the stormwater therethrough and optimizing pollutant capture. The water level within the vessel is height adjustable manually by a pivot arm in the form of a standing column of water coupled to the water within the container. Weep conduits are provided to slowly drain down the standing water in the system between storm events, simplifying maintenance and promoting best removal of pollutants from first-flush storm events. Stormwater pretreatment, e.g. by use of an oleophilic agent or a pH-buffering agent, is provided. Filter media are easily cleaned, as by scraping and / or adding filter media material when existing material's particulate capture capacity is exhausted.

Owner:NEWTERRA CORP INC

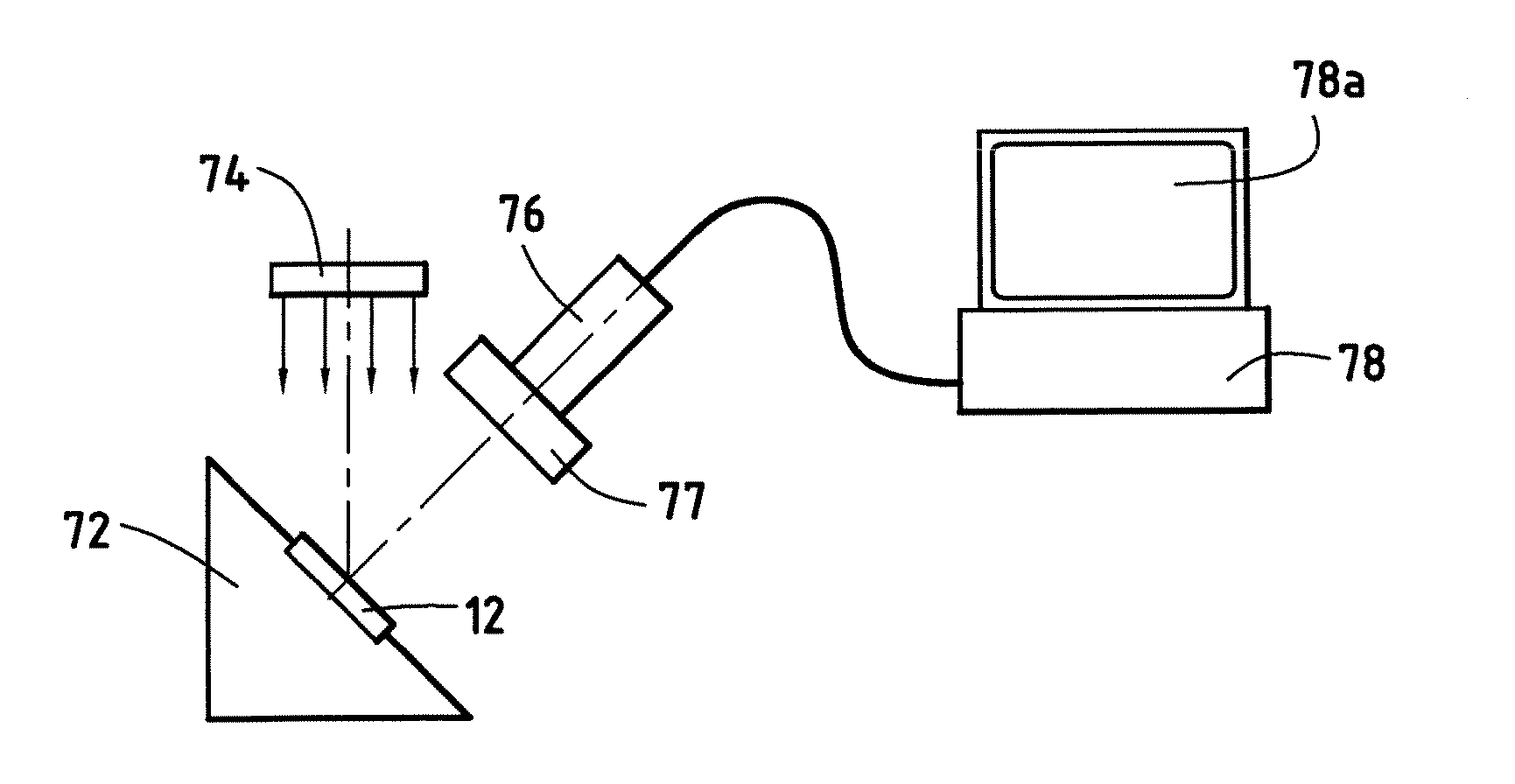

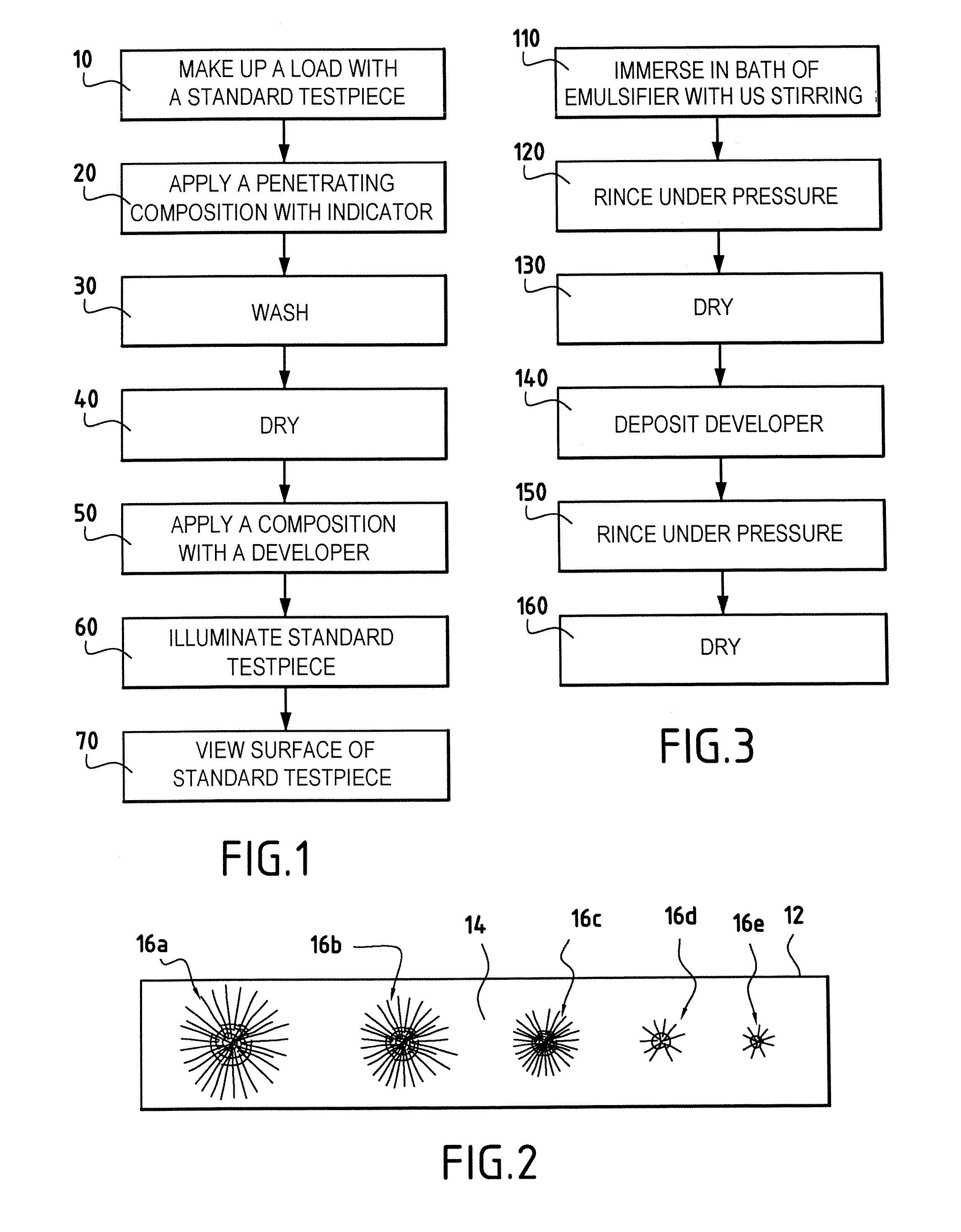

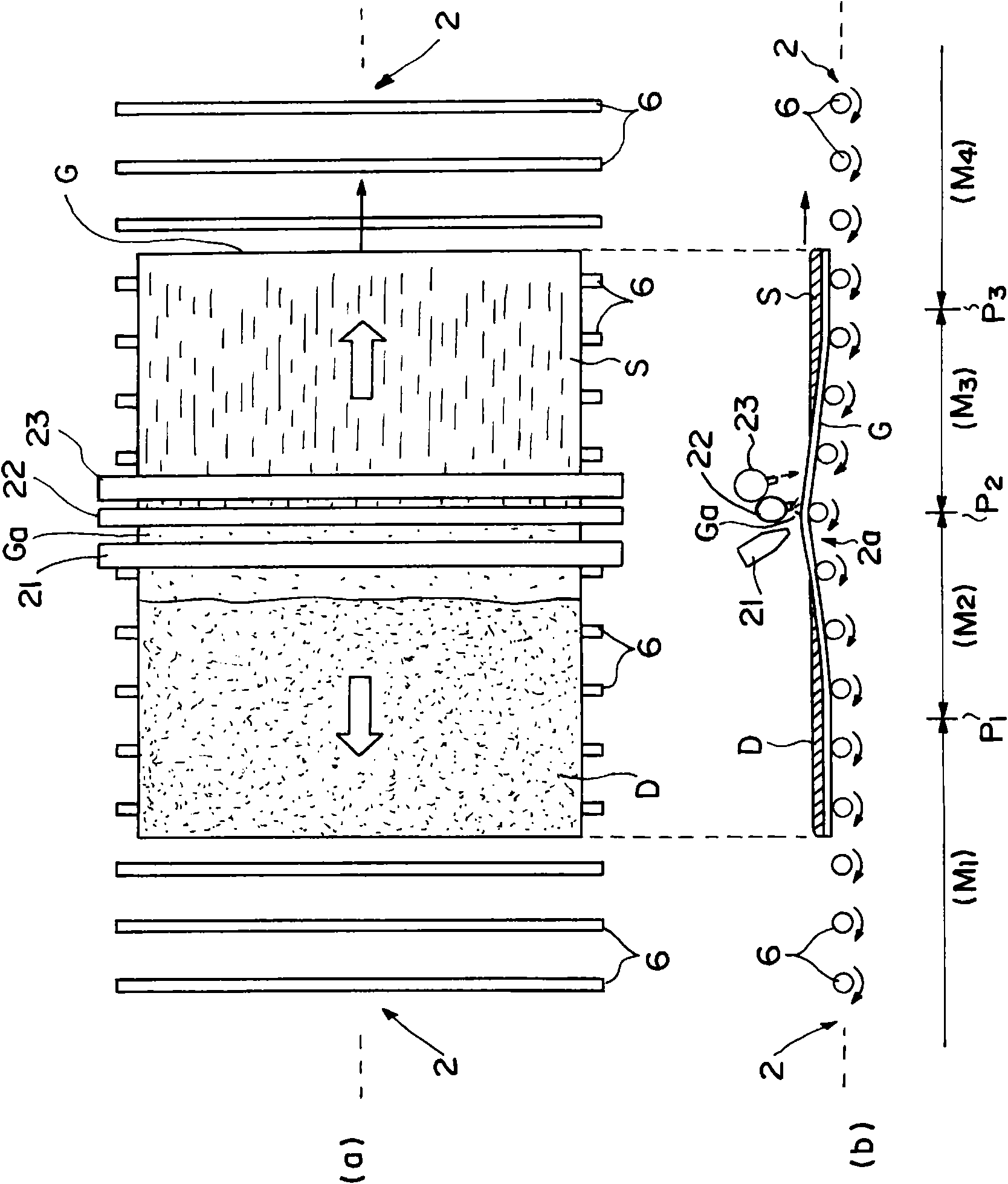

Diagnosing or determining parameters for an installation for detecting open defects in the surfaces of parts by sweating

InactiveUS20070097360A1Efficient use ofExclude influenceOptically investigating flaws/contaminationEngineeringStandard test

A method of diagnosing or determining parameters for an installation for detecting open defects in the surfaces of parts by sweating, the method comprising passing at least one standard testpiece through the installation, the testpiece having a surface possessing at least one pattern representative of the type of defect that is to be detected, applying to the surface of the testpiece a penetrating composition including an indicator substance, washing, drying, applying to the surface of the testpiece a composition including a developer, and illuminating the surface of the testpiece to illuminate any remaining indicator substance so as to form a developed image of the or each pattern and deduce therefrom an indication about the quality of the operation of the installation. Prior to passing through the installation, the standard testpiece is subjected to preparatory treatment comprising immersion in a bath containing an emulsifier, a first rinse under pressure, drying, applying a developer at the location(s) of the pattern(s), and a second rinse under pressure.

Owner:TURBOMECA SA

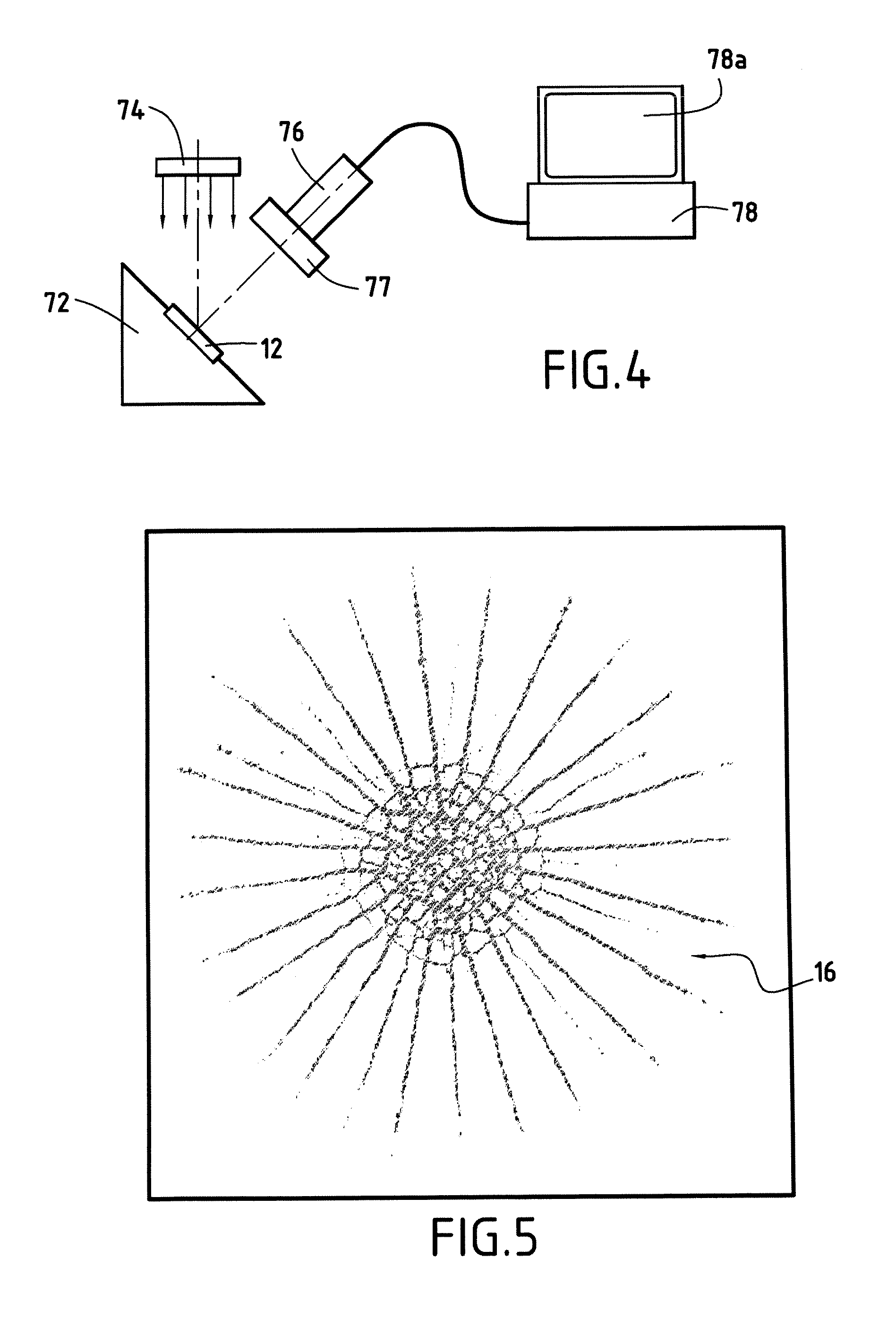

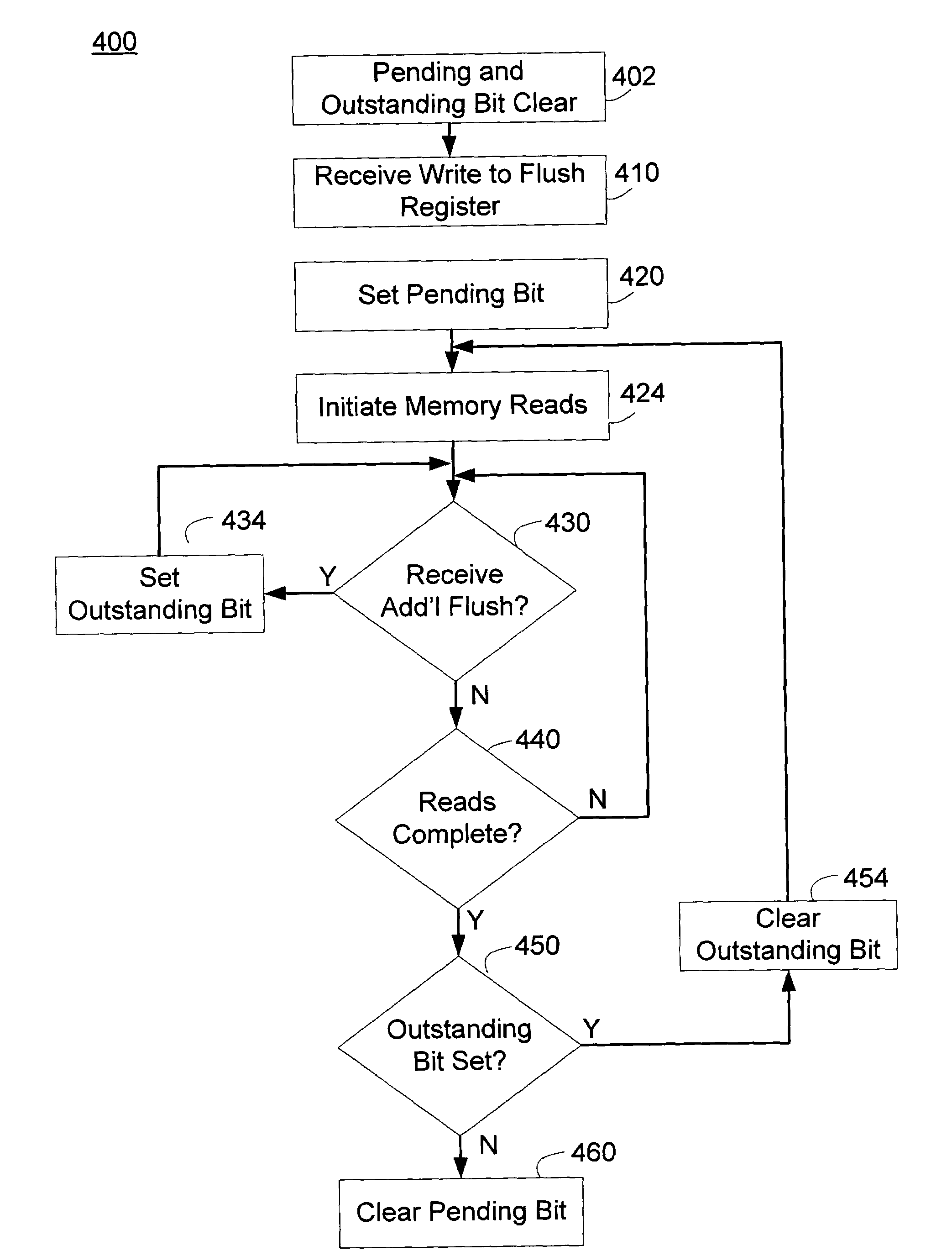

Data synchronization with multiple producers

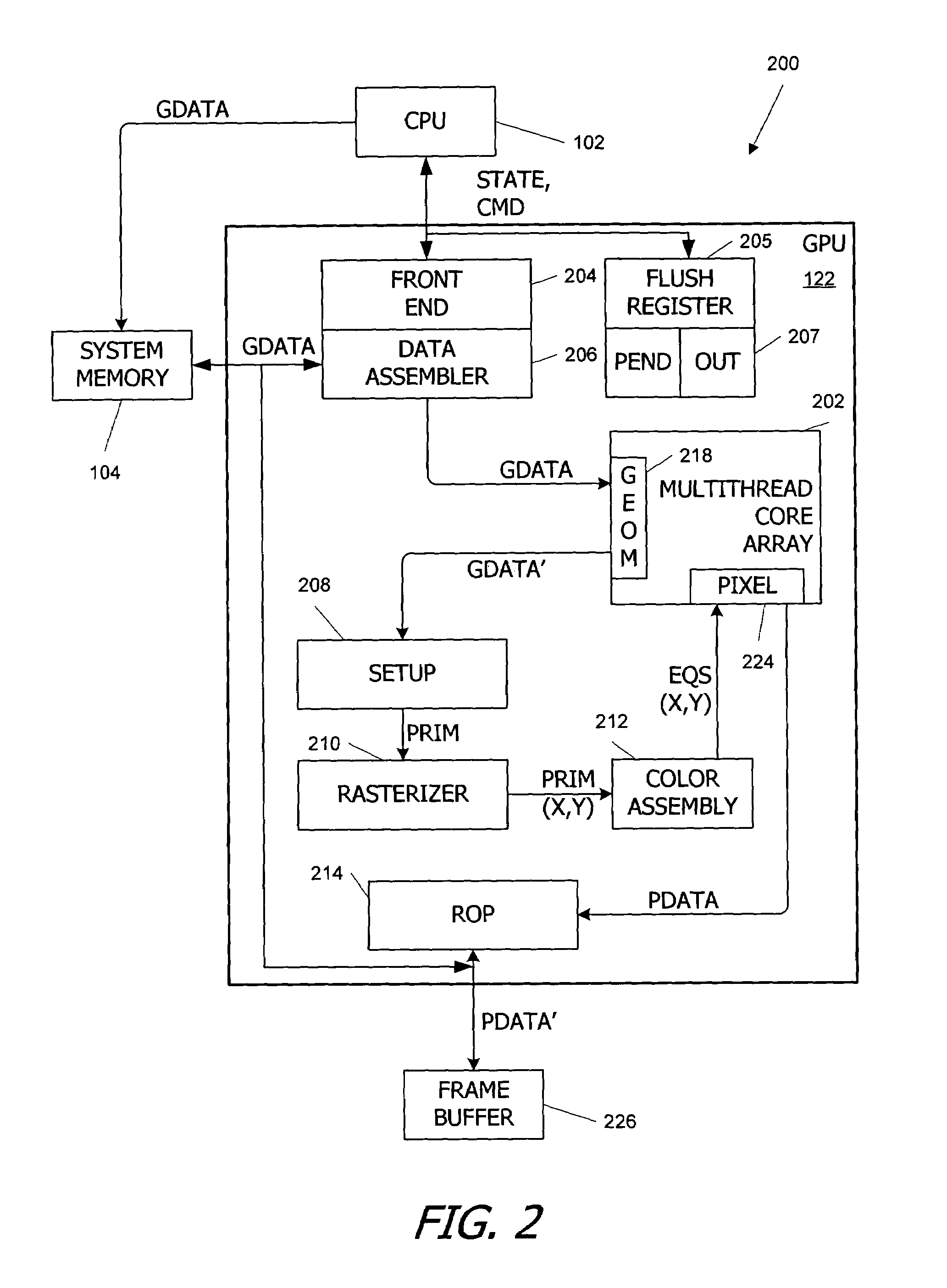

ActiveUS7685370B1Program synchronisationGeneral purpose stored program computerData processing systemData synchronization

A data processing system can establish or maintain data coherency by issuing a data flush operation. An agent can initialize a first flush operation by writing to a flush register. The agent can determine that the flush operation is complete by reading a status indicator from a status register. Additional agents can independently issue flush operations during the pendency of the first flush operation. A second flush instruction and any additional flush instructions that issue during the pendency of the first flush operation set a flush pending indicator in a status register. Once the first flush operation completes, the host performs all pending flush operations in a single second flush operation. The status indicator does not indicate a completed flush operation for the first flush operation until all flush operations are complete. Multiple co-pending flush operations are collapsed into at most two flush operations.

Owner:NVIDIA CORP

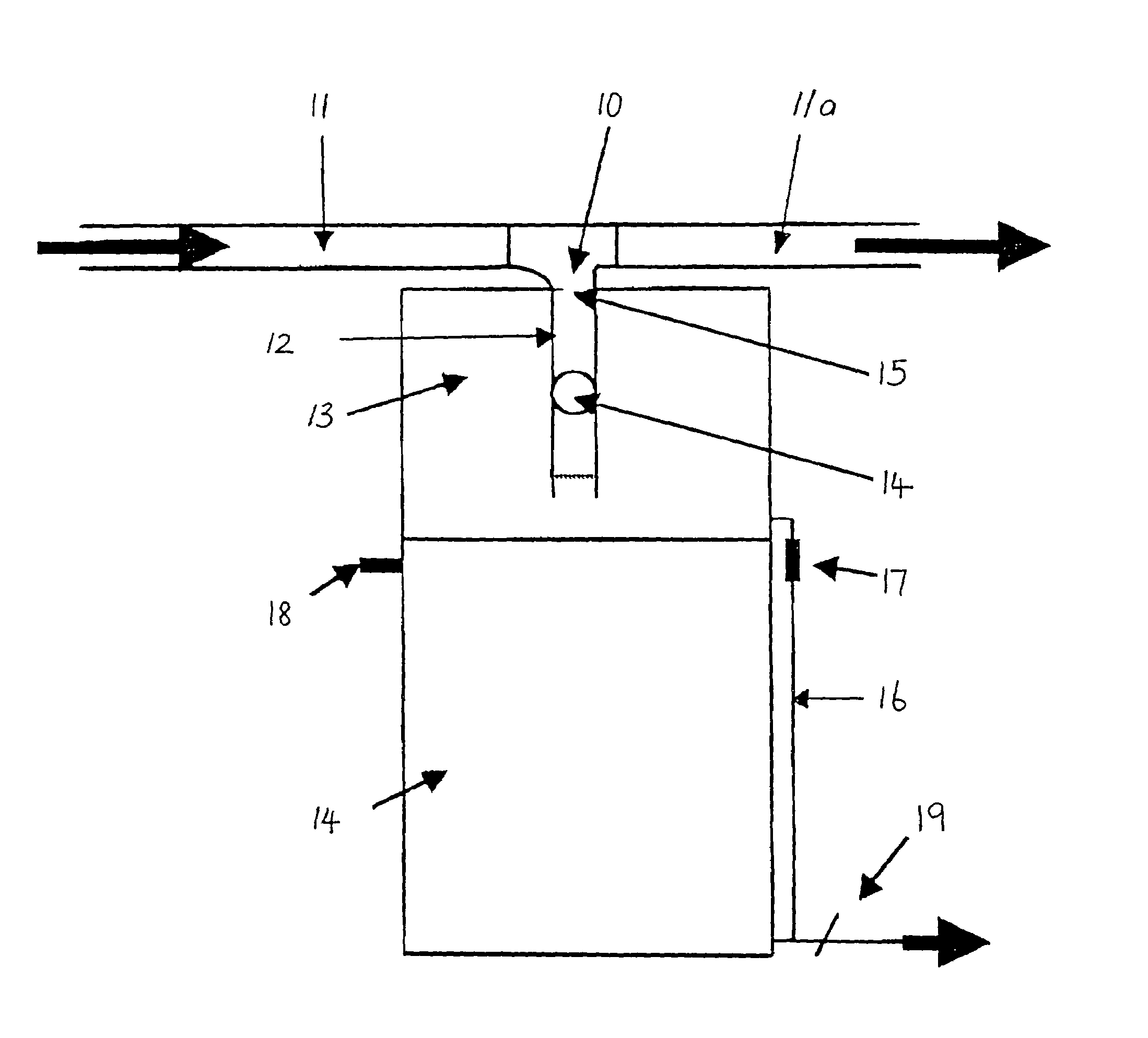

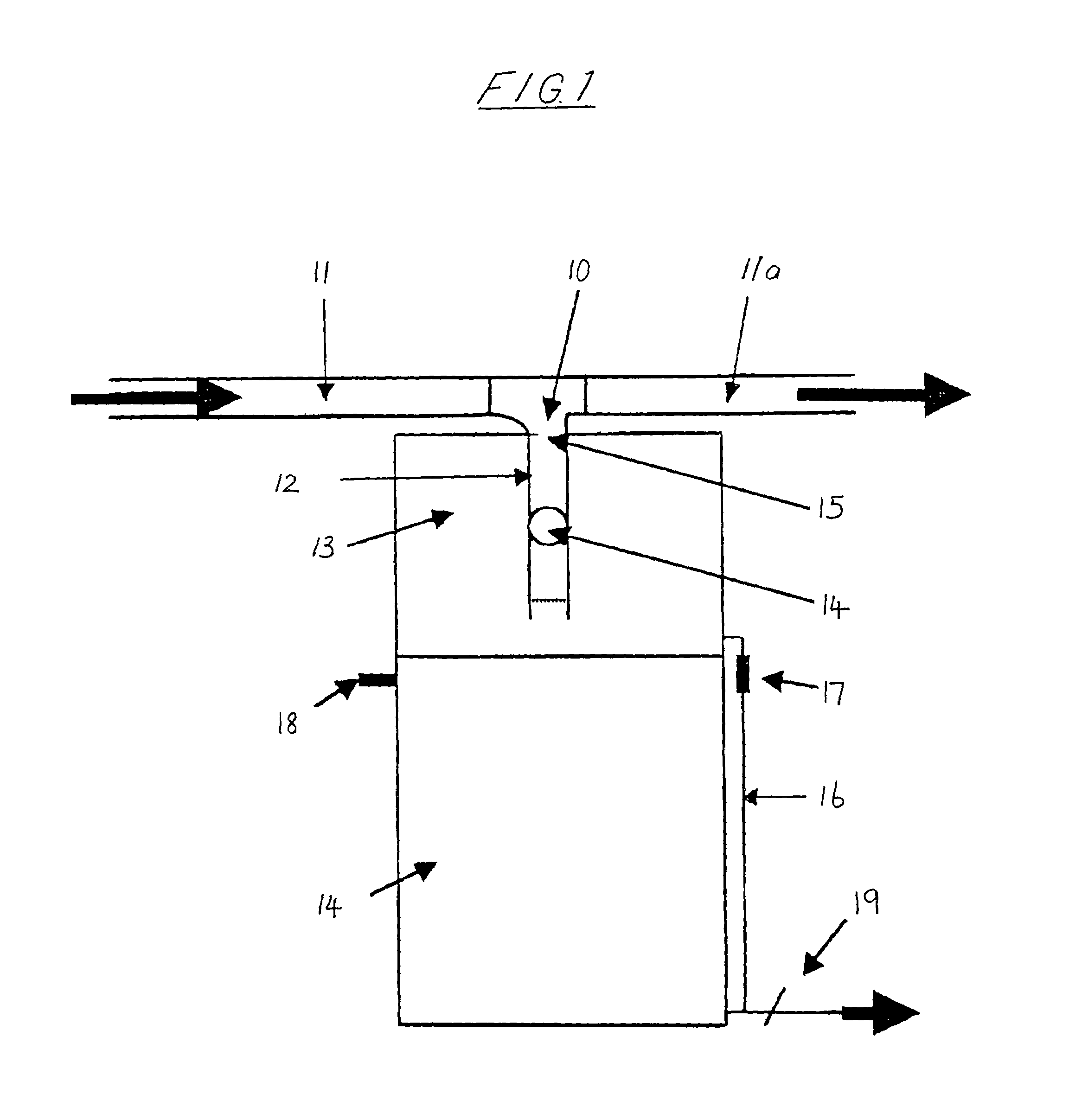

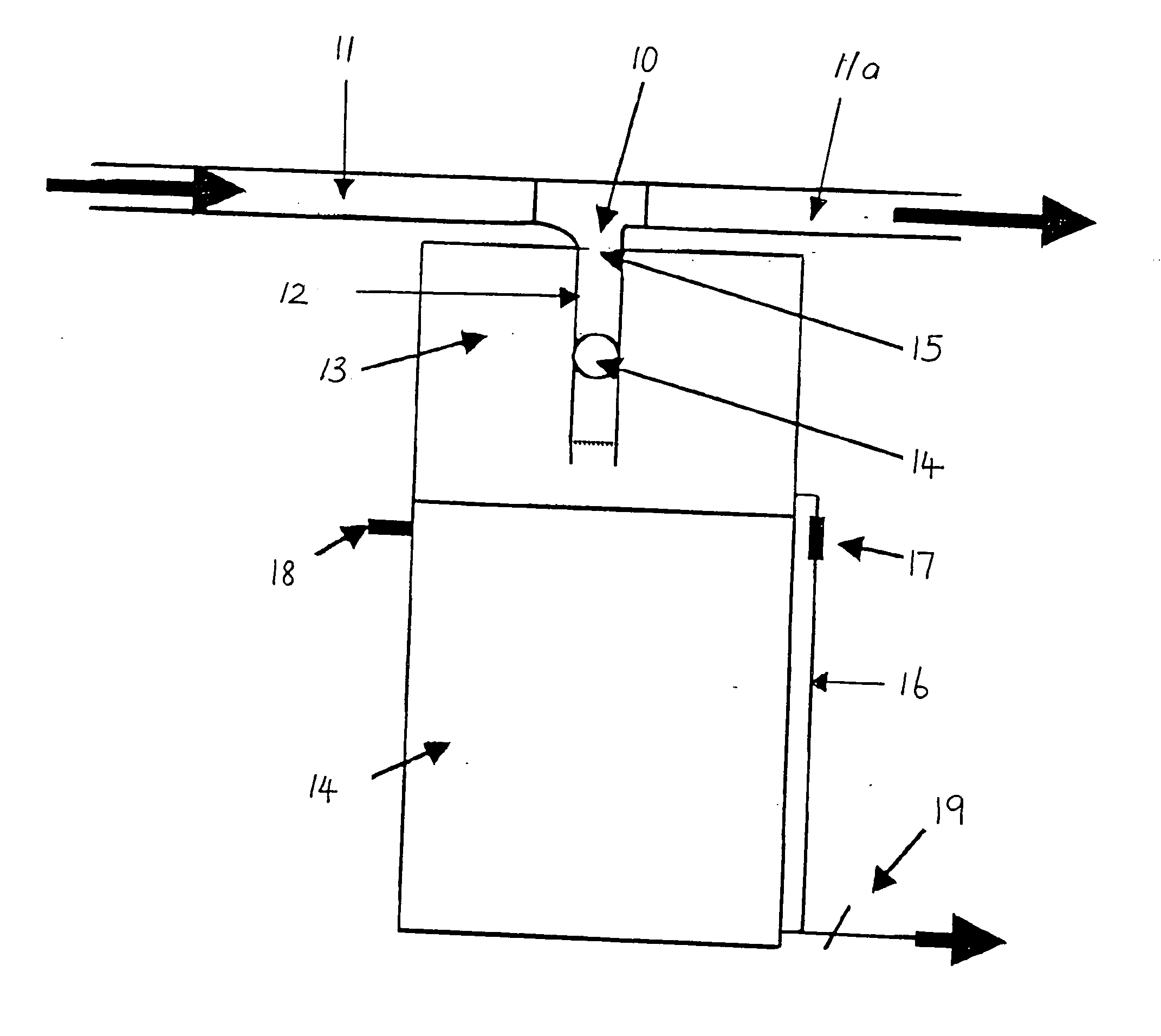

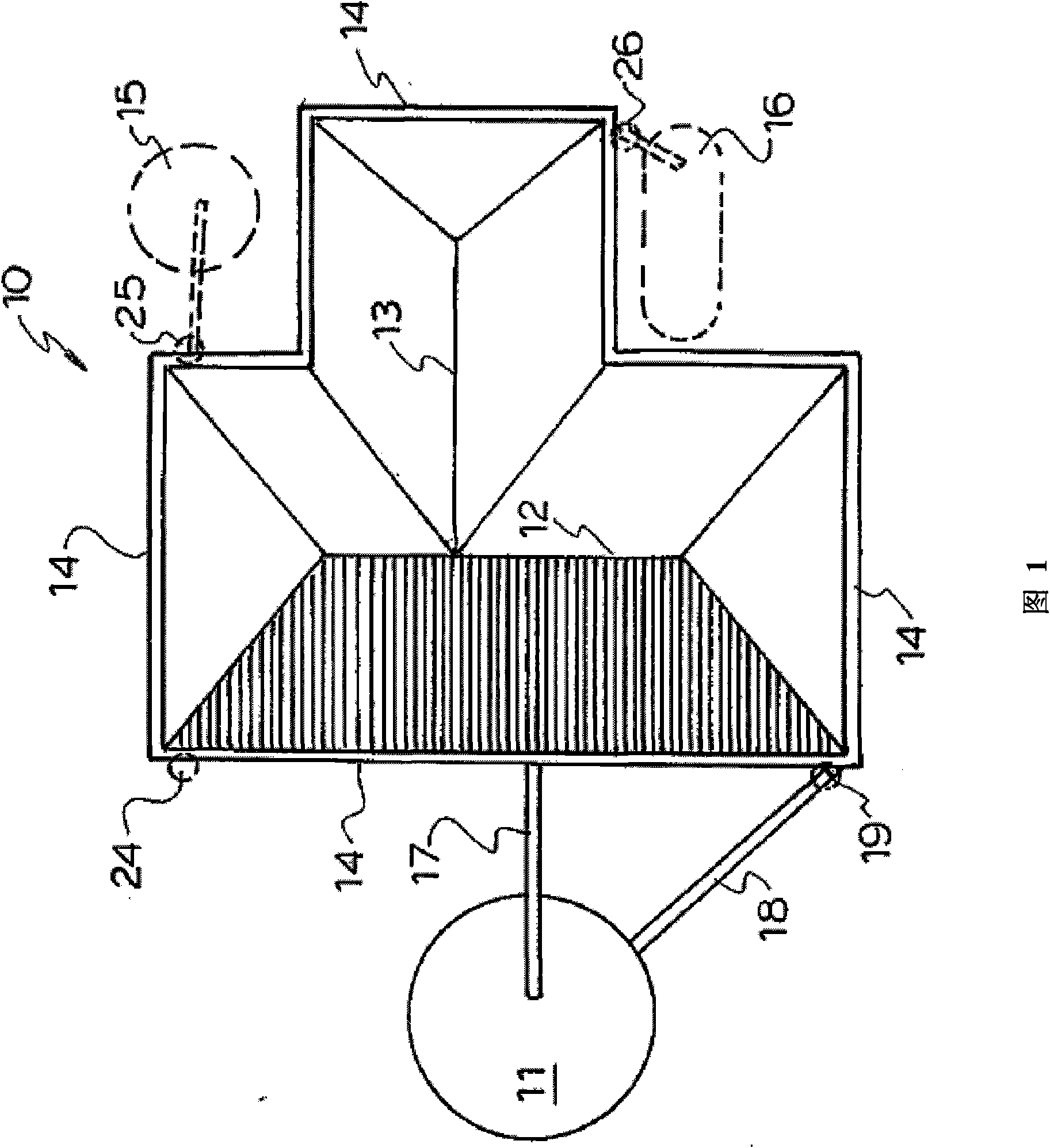

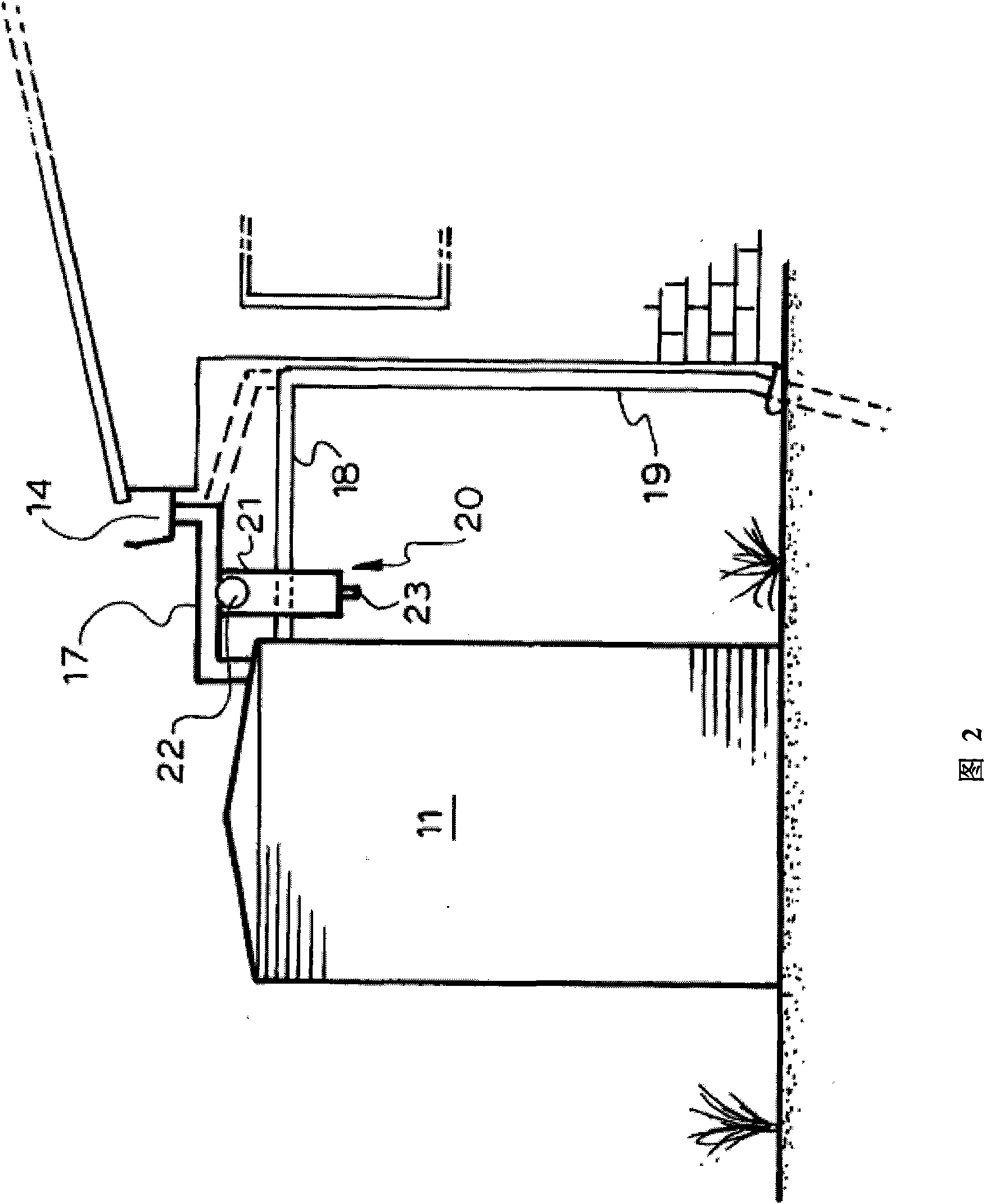

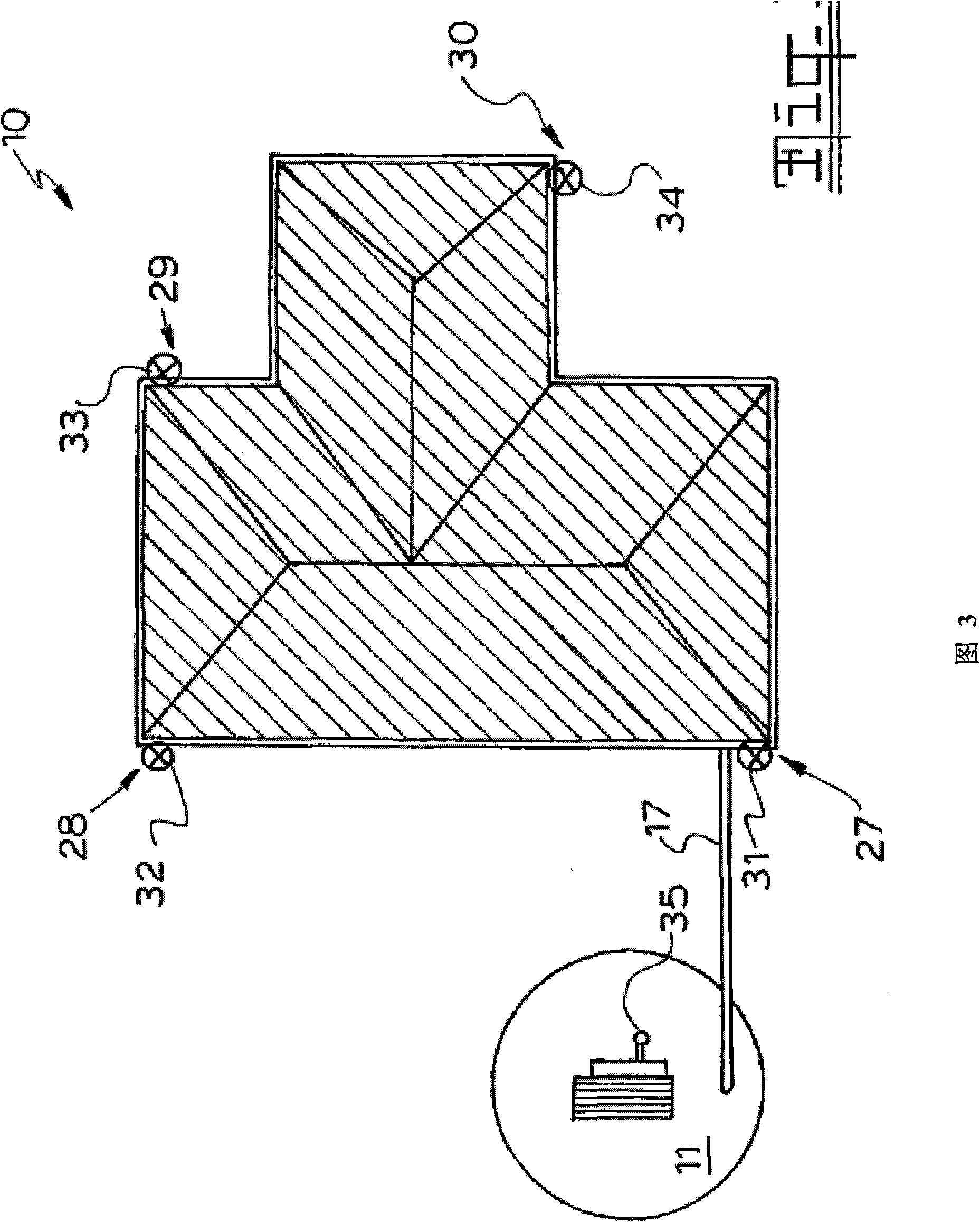

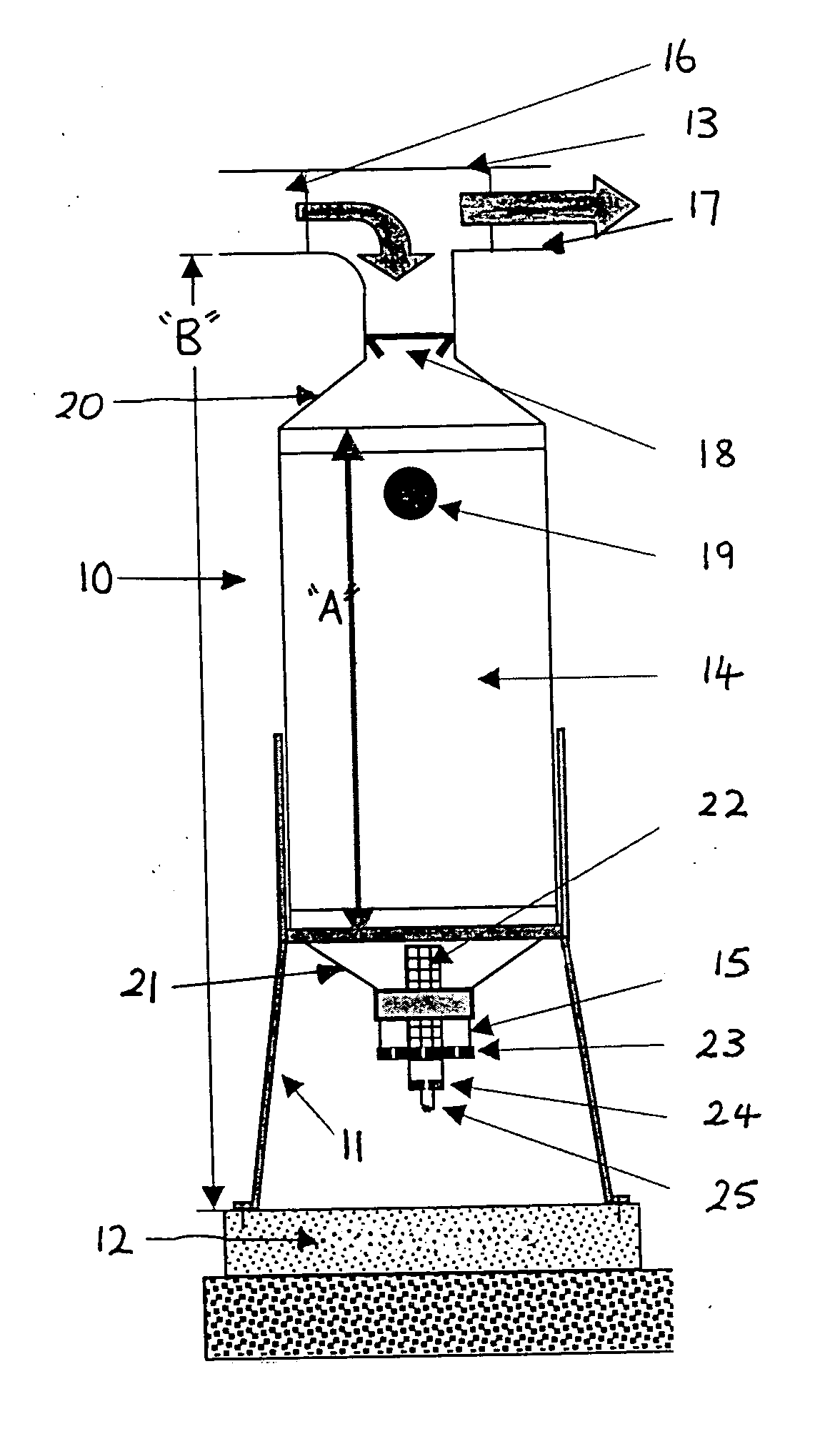

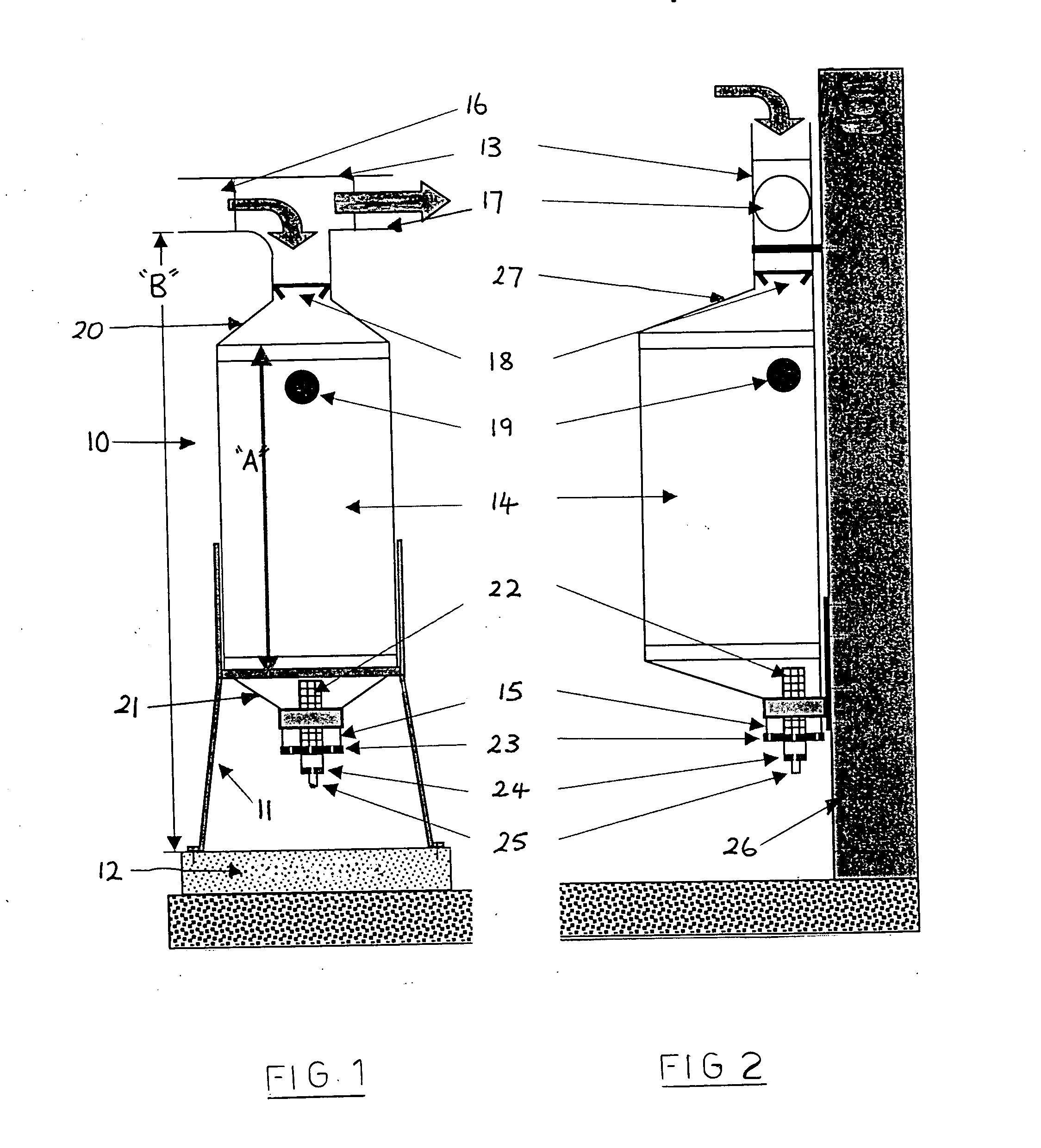

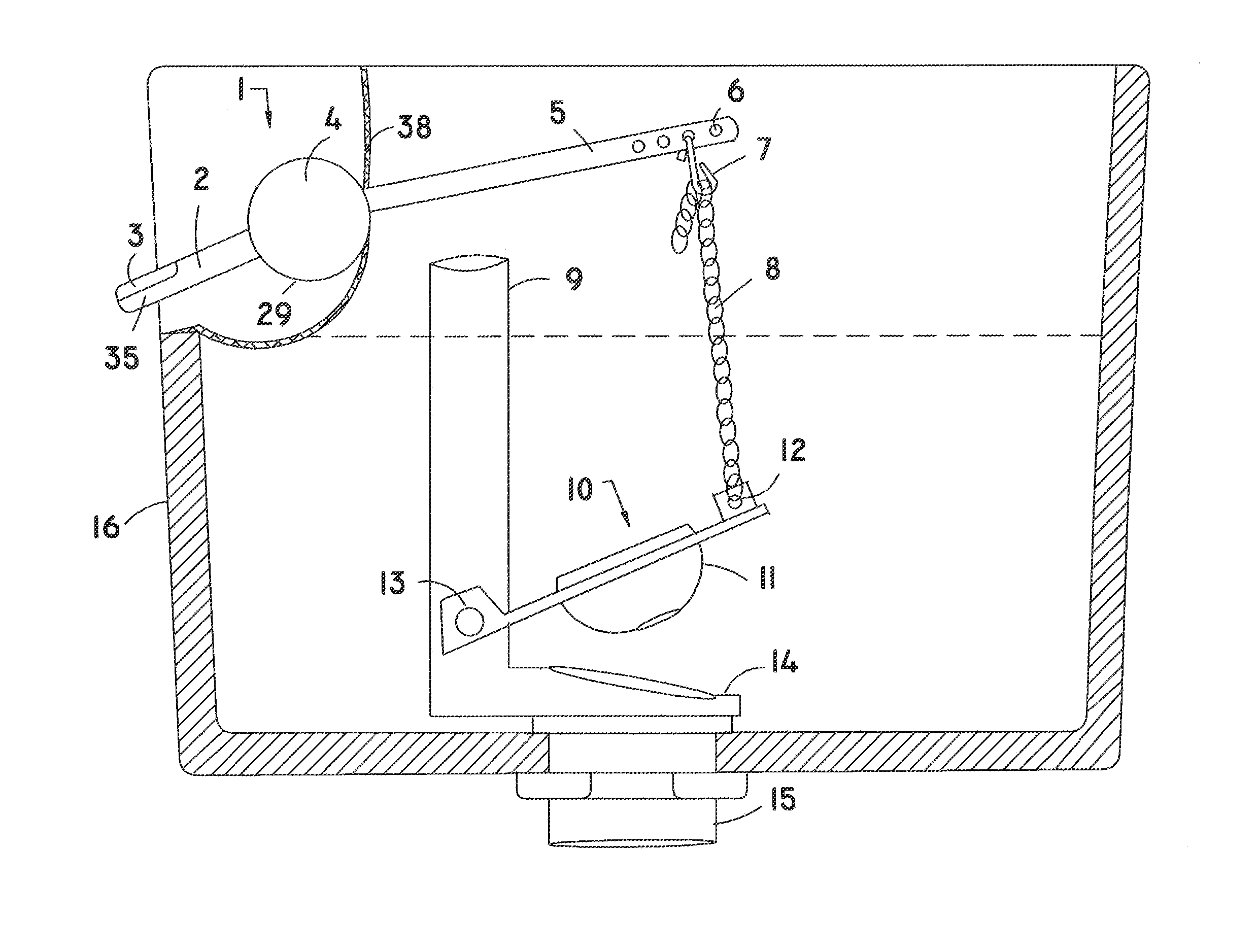

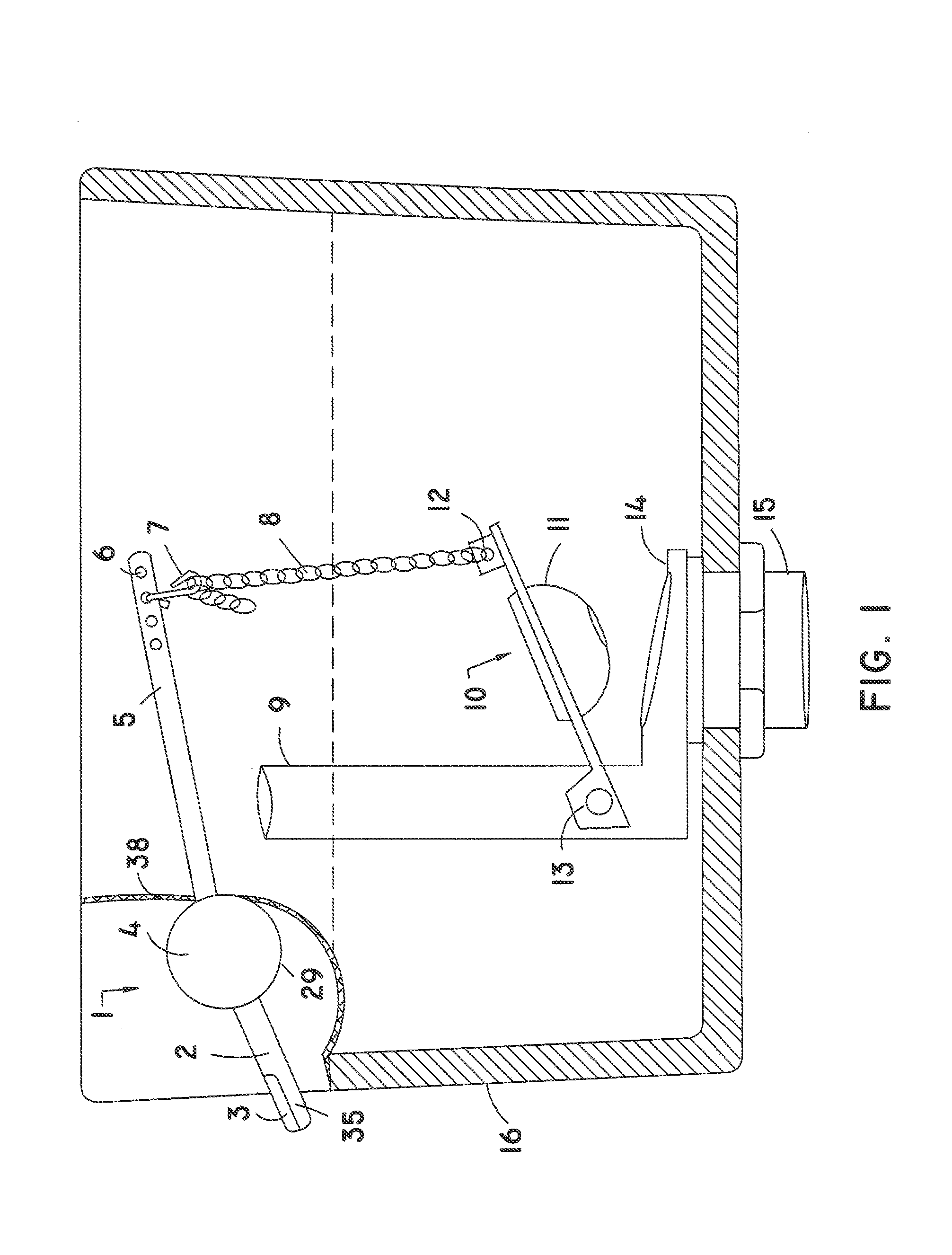

First flush rainwater diverter and collection system

ActiveUS7048849B2LevelLower the volumeLarge containersLiquid displacementCollection systemEngineering

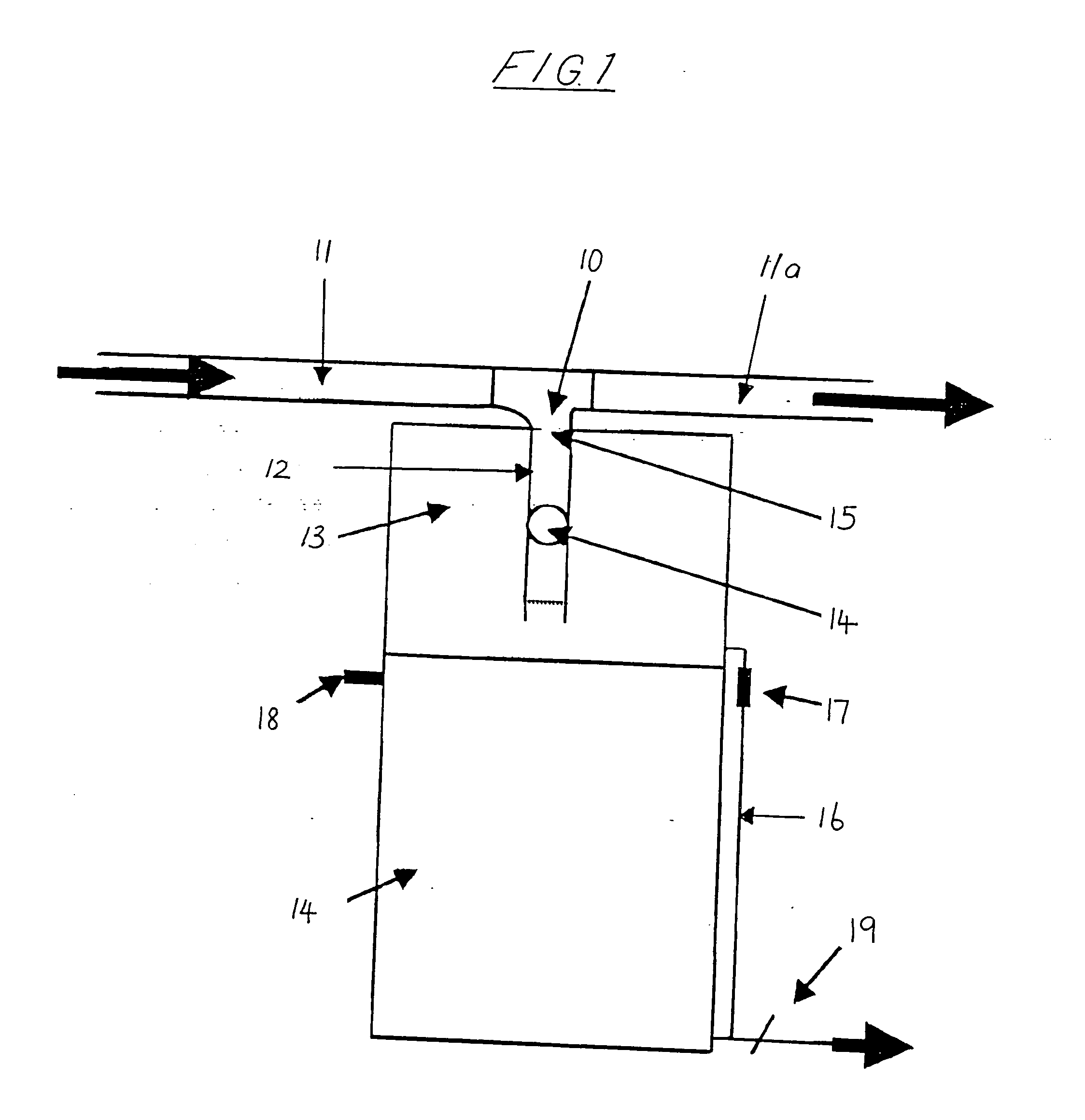

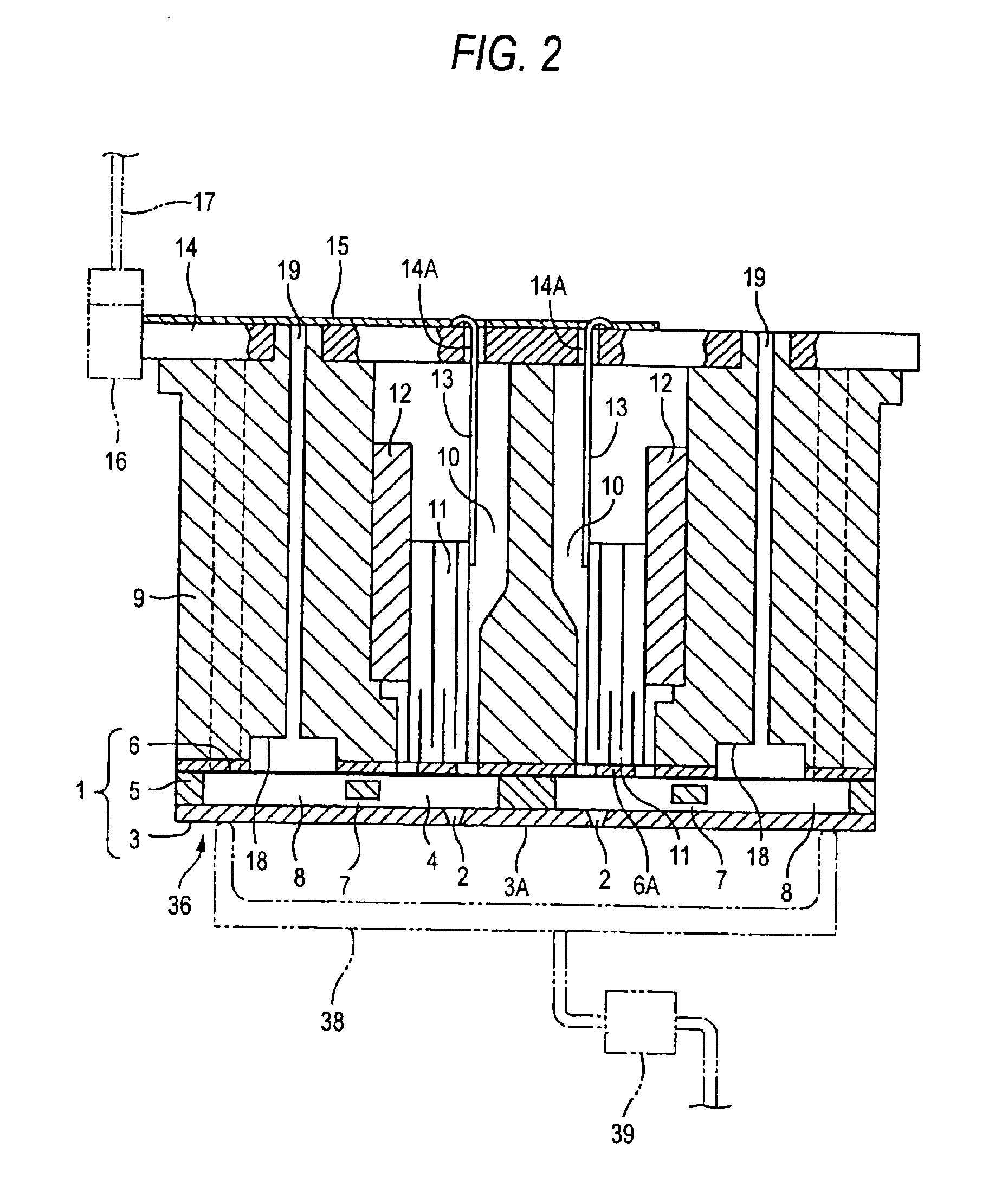

A first flush rainwater diverter and collection system for use with rainwater storage tanks primarily in domestic situations. The system comprises primary (13) and secondary (14) storage chambers, a T-piece (10) for connection in a rainwater flow path, a fall pipe (12) connected to the T-piece and extending into the primary storage chamber, a float within the fall pipe which seals on a seat when the level of rainwater reaches a preset level, a rainwater flow regulator (17) which regulates the flow of rainwater from the primary storage chamber to the secondary storage chamber, an overflow (18) and an outlet (19) in the secondary storage chamber.

Owner:WADE RODNEY GEORGE

First flush rainwater diverter and collection system

A first flush rainwater diverter and collection system for use with rainwater storage tanks primarily in domestic situations. The system comprises primary (13) and secondary (14) storage chambers, a T-piece (10) for connection in a rainwater flow path, a fall pipe (12) connected to the T-piece and extending into the primary storage chamber, a float within the fall pipe which seals on a seat when the level of rainwater reaches a preset level, a rainwater flow regulator (17) which regulates the flow of rainwater from the primary storage chamber to the secondary storage chamber, an overflow (18) and an outlet (19) in the secondary storage chamber.

Owner:WADE RODNEY GEORGE

Tilt diverter to control storm-water

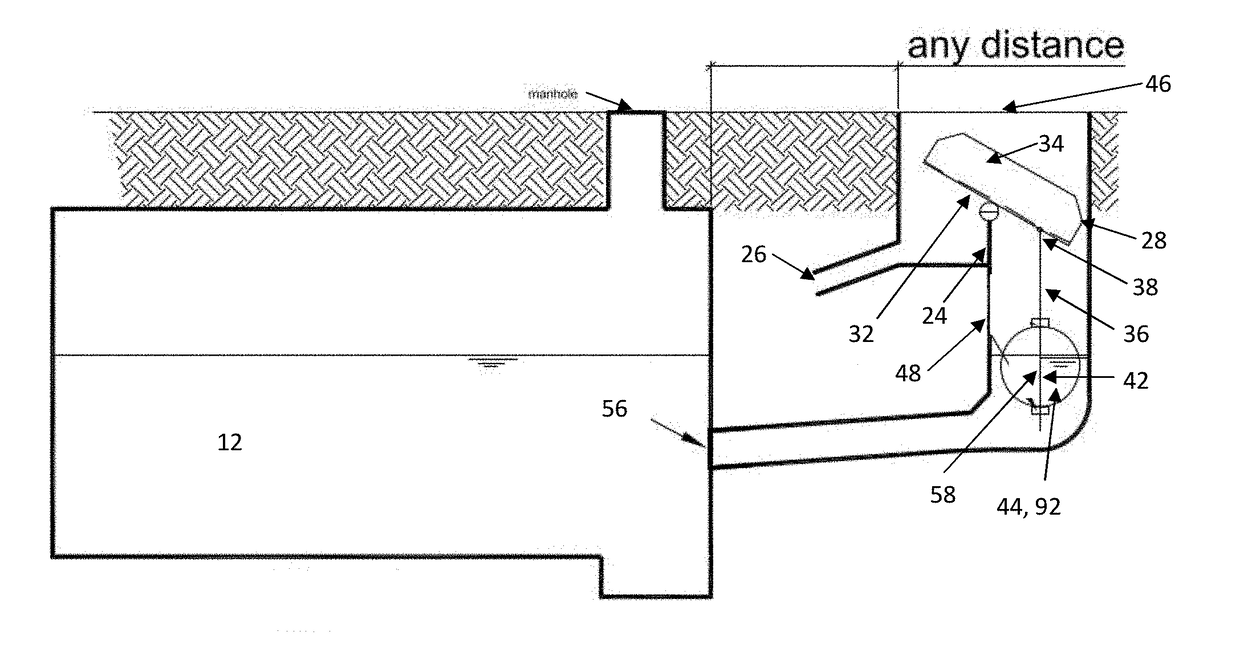

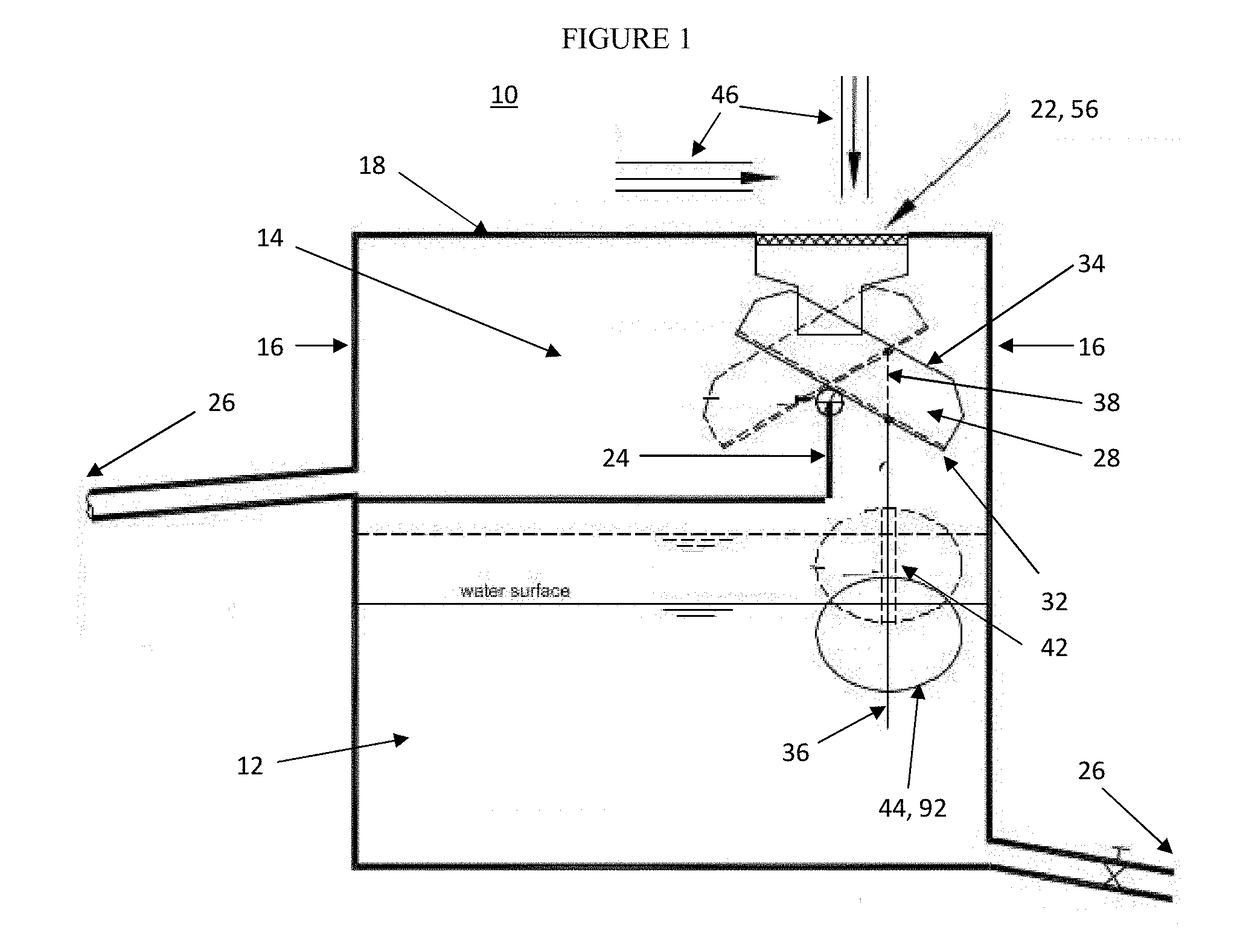

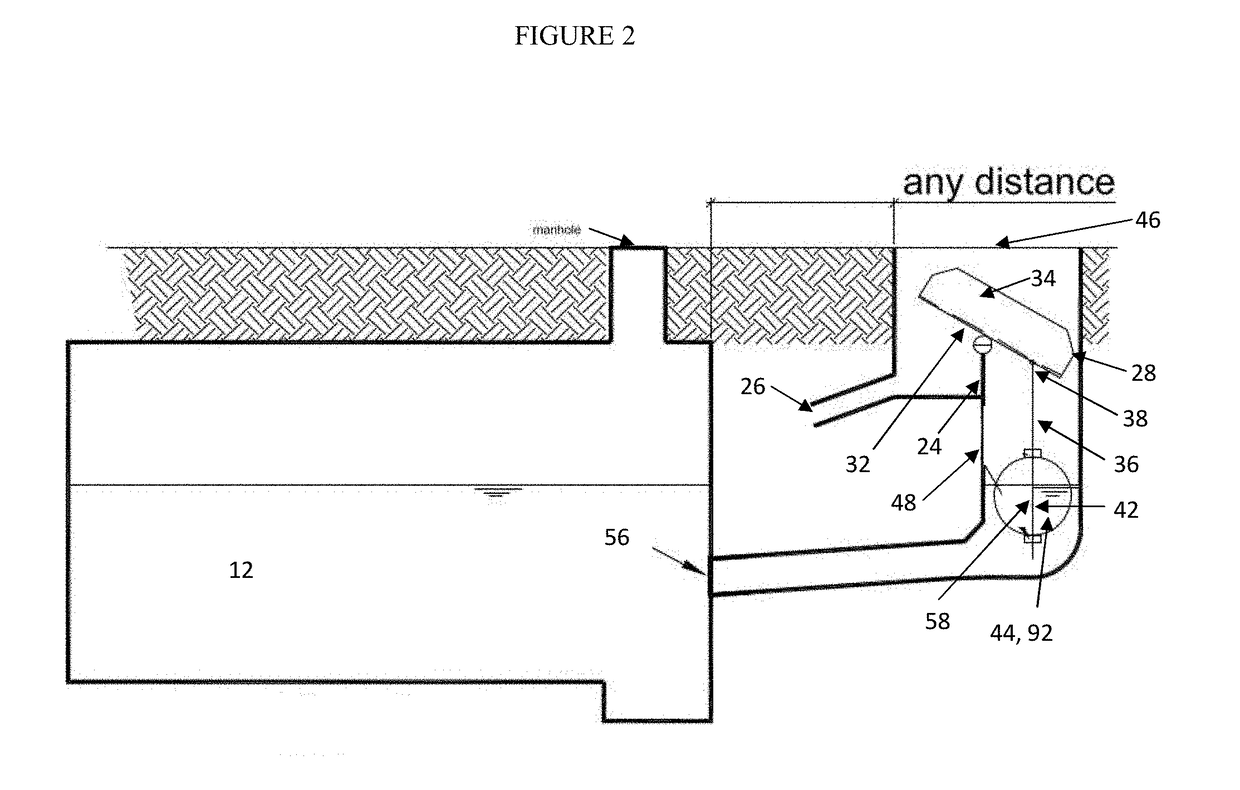

InactiveUS10106971B2Water resource protectionSewerage structuresHigh concentrationWater storage tank

The device herein disclosed and described provides a water collection system that separates the initial flush of rainwater, which contains higher concentrations of undesirable contaminants from later received rainwater having lower concentrations of contaminants to be stored for later use or to be discharged directly to receiving bodies of water. The device contains a cistern for treating first flush rainwater, a basin for receiving water in fluid connection with the cistern and a water storage tank, a water diversion channel that diverts first flush rain water to the cistern and additional rainwater to a water storage tank, a floatation device on a connecting rod affixed to the diversion channel that acts to operate the diversion channel when the water in the cistern achieves a desired height by diverting the additional water received to the water storage tank.

Owner:VILLANUEVA ARTURO J +2

Water collection system

InactiveCN101517174ADiversion to avoidGeneral water supply conservationRoof drainageWater storage tankWater diversion

The present invention relates to a water collection system, which blocks down-pipes to collect water from a roof. A down-pipe (27) is located adjacent a rain water diversion unit (31). The unit comprises a box (36) with the down-pipe (27) fitted to an opening (37) in bottom (38) of the box (36). The gutter (14) has two side-by-side openings (39 and 40), the opening (40) has an overflow in the form of upstanding wall (41) while the opening (39) has a valve plate (42) hinged to the front edge at (43). A pneumatic actuator (44) is used to move the valve plate (42) to the closed position. When the valve is closed, the opening (40) and the upstanding wall (41) serve as an overflow back to the stormwater via the box (36). The tank pipe (17) also has an opening (45) with an upstanding wall (46) which has its upper edge (47) set lower than the upper edge (48) of the wall (41) of the overflow. All down-pipes are fitted with diversion units. A controller includes a rain sensor to detect a rain event whereupon a time delay is imposed for first flush to flush the roof before the valves close the down-pipes. When the tank is full a float is used to operate the controller to open the valves if they are closed or prevent them closing in the case of a new rain event and the tank being already full.

Owner:RAINMAX

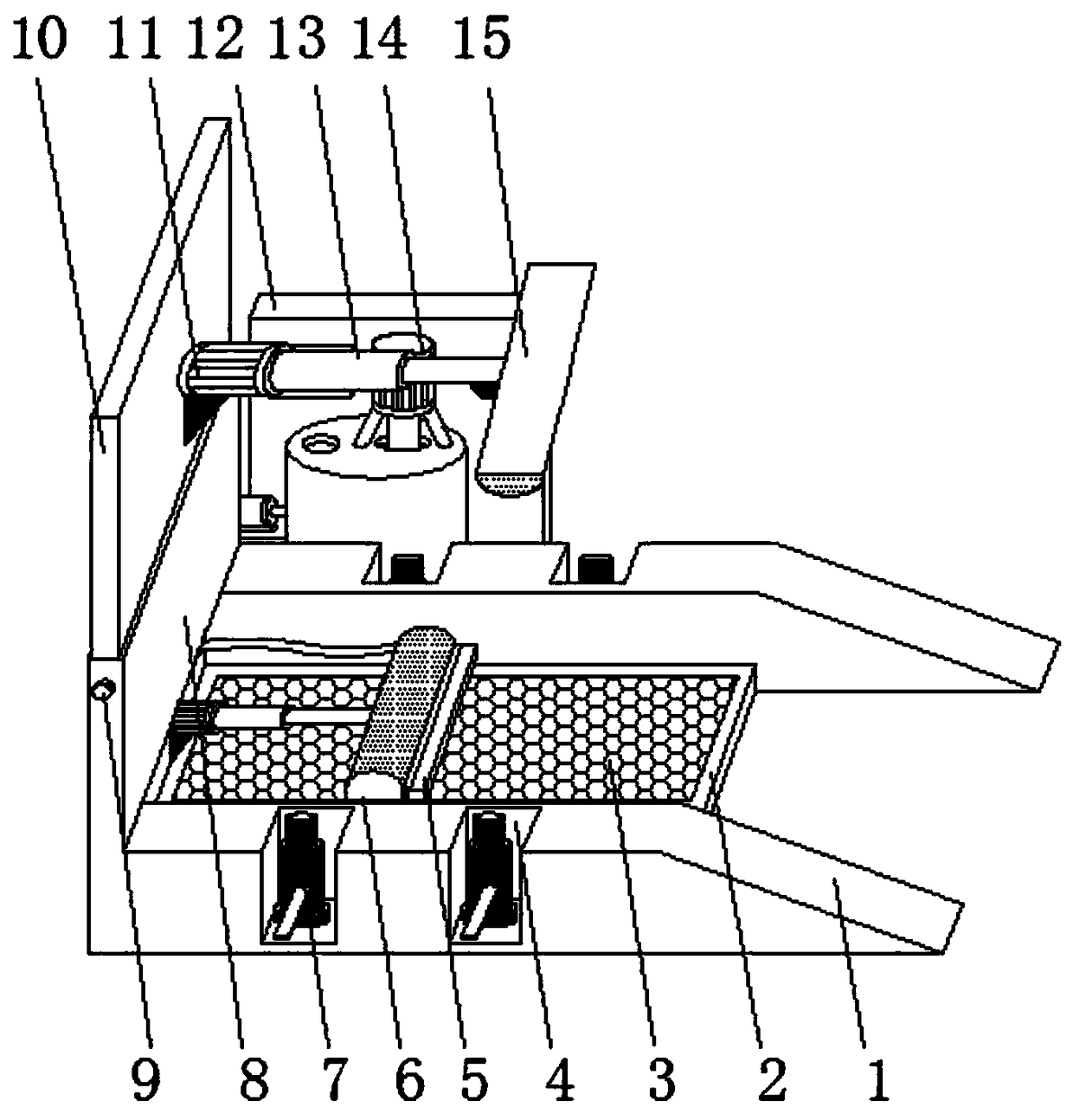

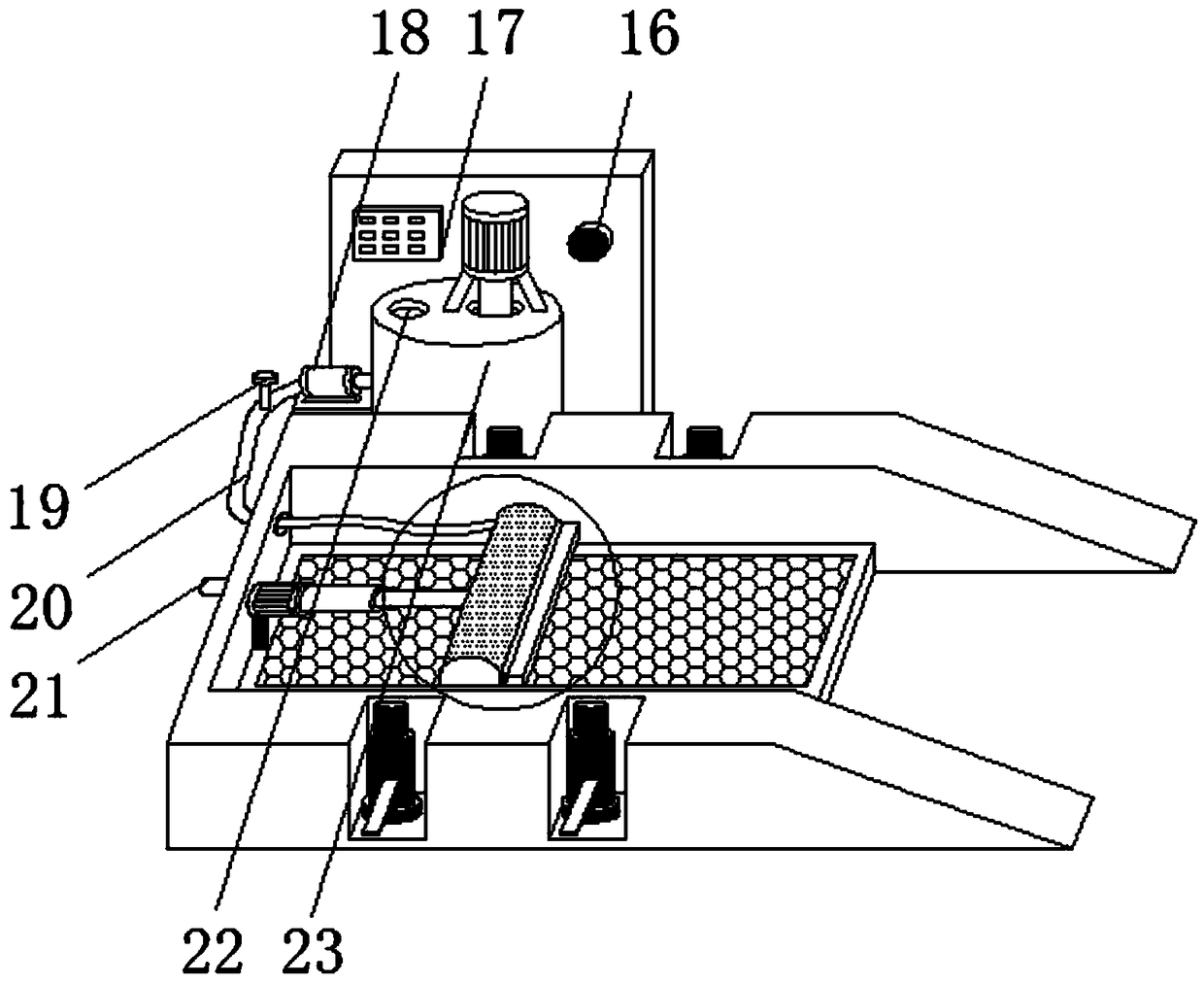

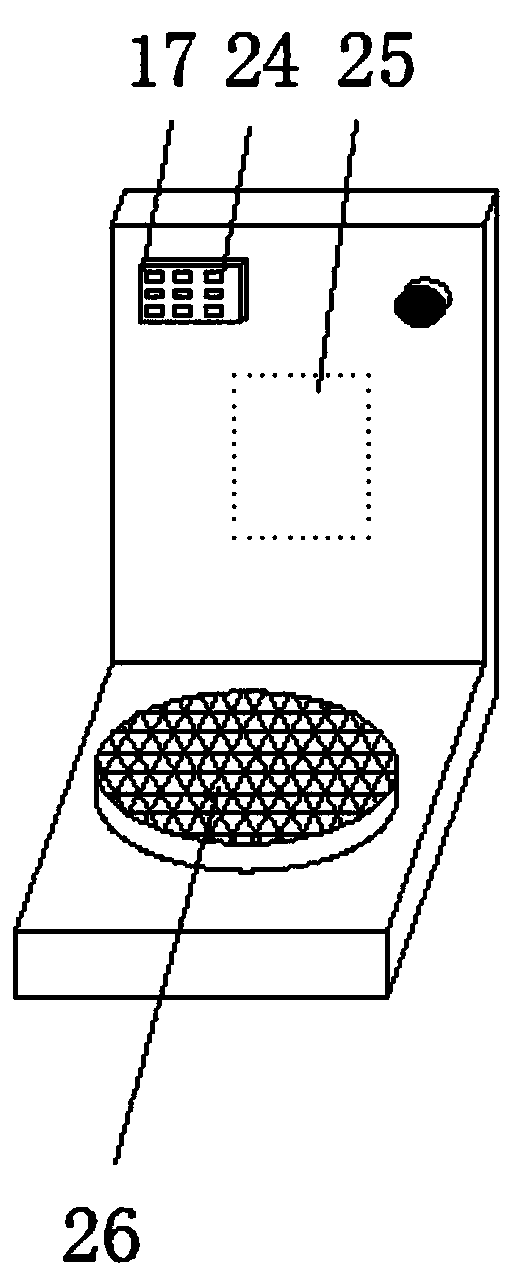

Cleaning device for new energy vehicle

ActiveCN108705992ANovel shapeFunctionalCleaning apparatus for vehicle exteriorsSolenoid valveNew energy

The invention discloses a cleaning device for a new energy vehicle. The cleaning device comprises a supporting seat, a header tank, a filter screen, a groove, a movable plate, first flushing spray heads, a jack, a bracing plate, a rotary knob, a lifting plate, push rod motors, an L-shaped bracket, a push rod, a mixer, second flushing spray heads, a switch button, a control panel, a water pump, a solenoid valve, a water guide pipe, a drain pipe, an opening, a water supply barrel, function keys, a single chip microcomputer, a heater, a rotating shaft, a connecting rod, a rotor shaft and stirringblades. The cleaning device has innovative design and practical function, the vehicle can be propped up through installing the jack on the supporting seat, and the push rod motors with the first flushing spray heads and the second flushing spray heads are installed on the bracing plate and the lifting plate, a vehicle chassis and the upper portion of a vehicle body are fully flushed and cleaned in a repeated mode, the entire cleaning process is almost completely realized by manual operating the function keys on the control panel, so that the cleaning efficiency is high, time and labor are saved, and the promotion and use are recommended.

Owner:山东神麒农业科技有限公司

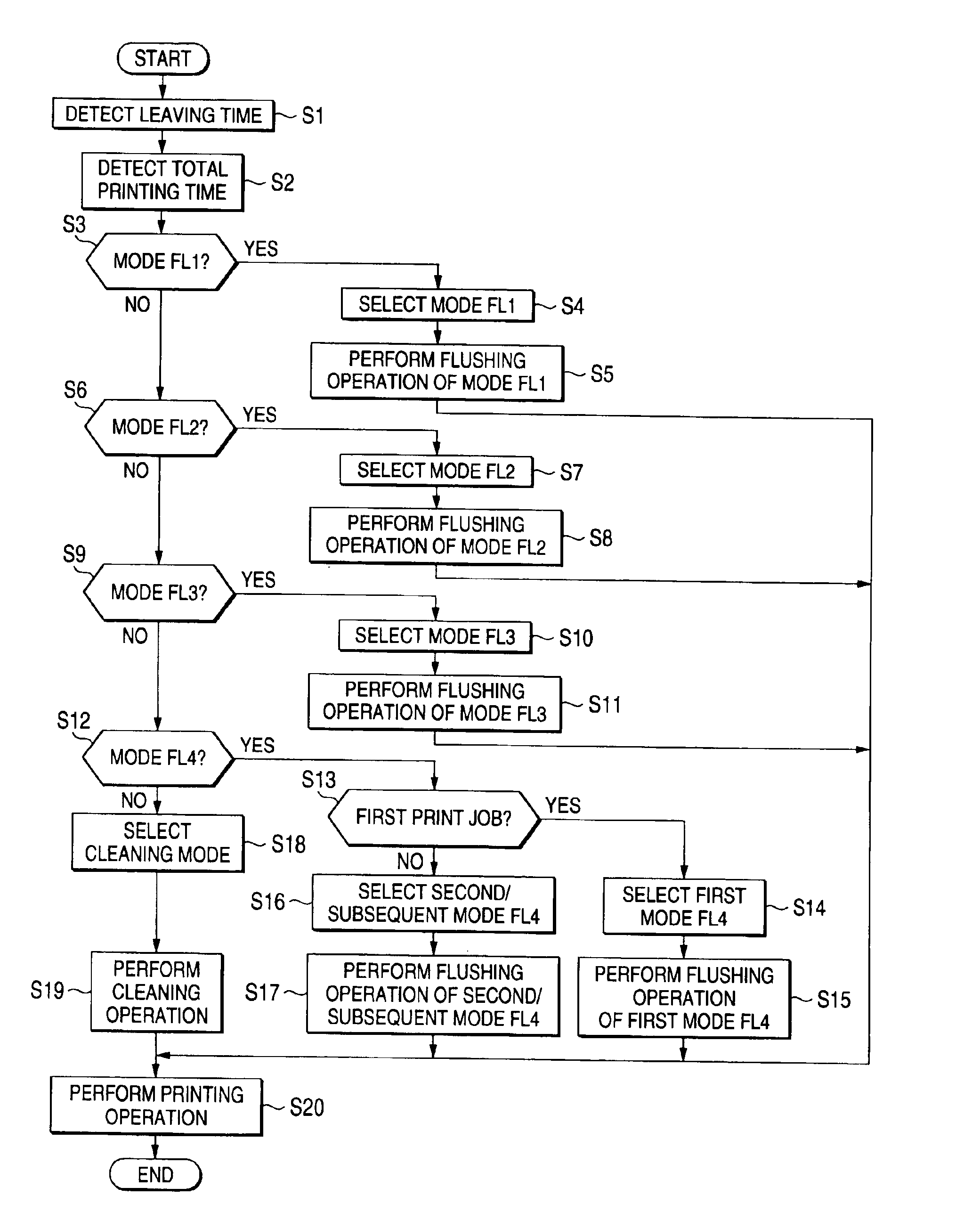

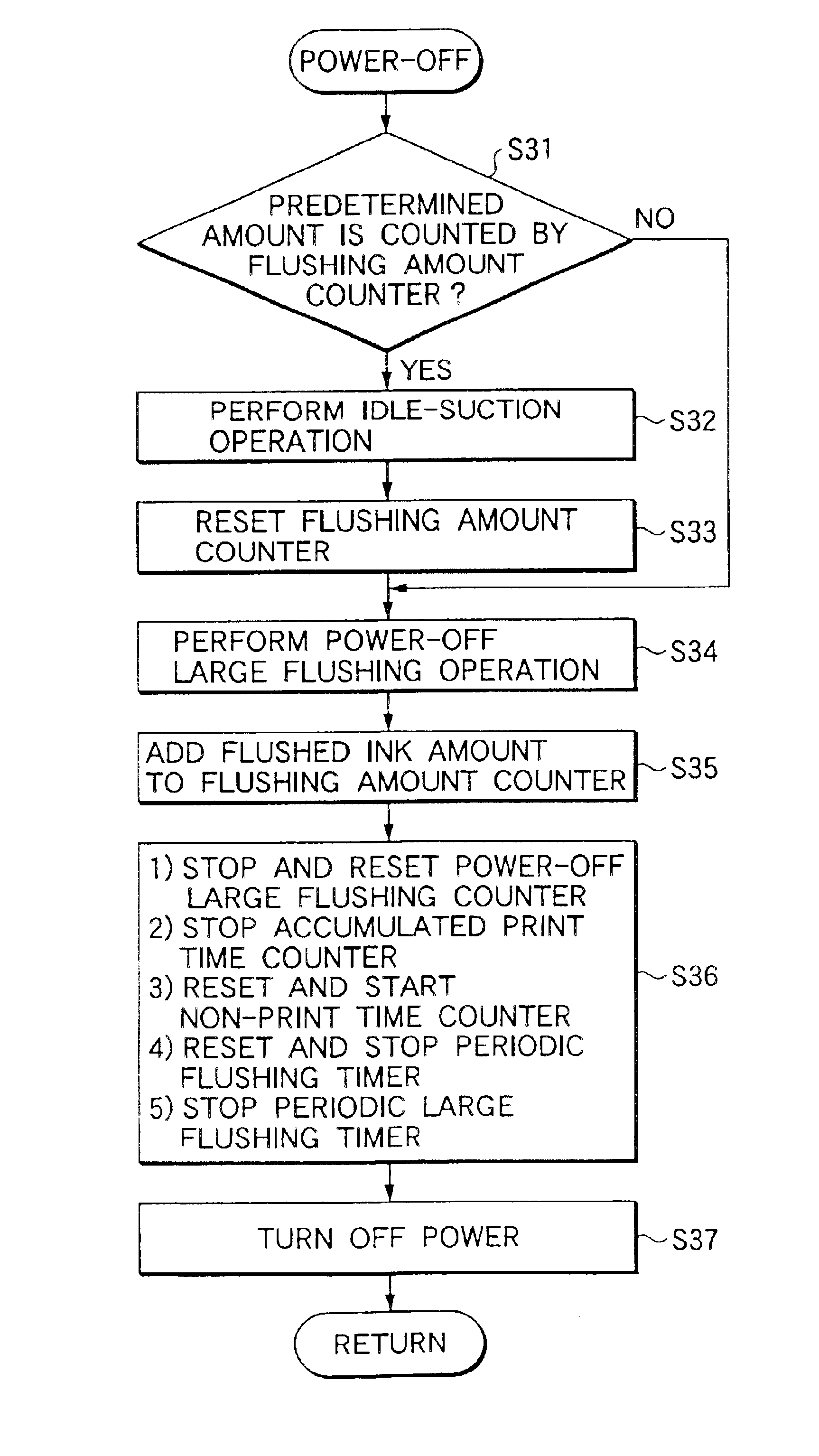

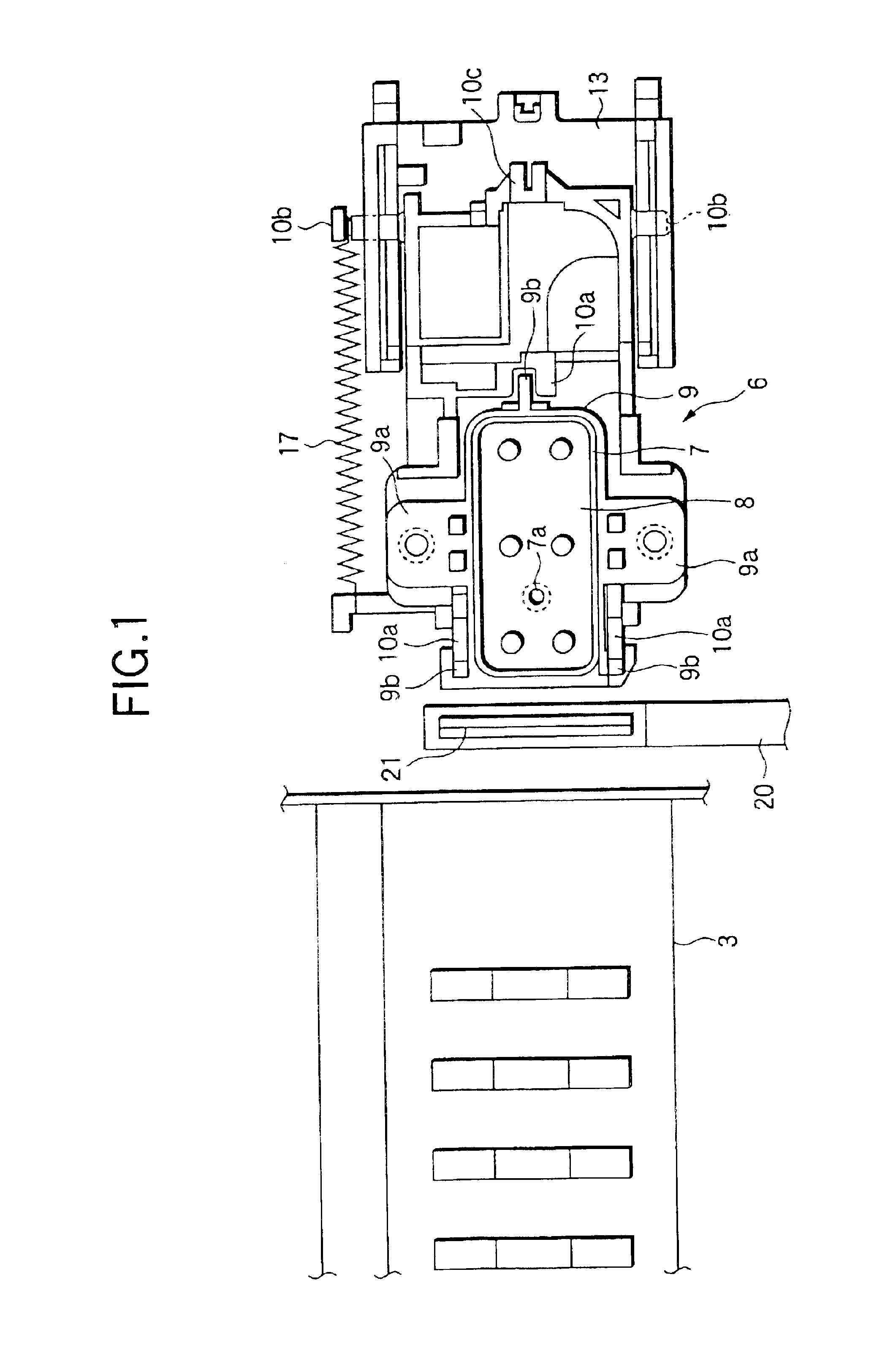

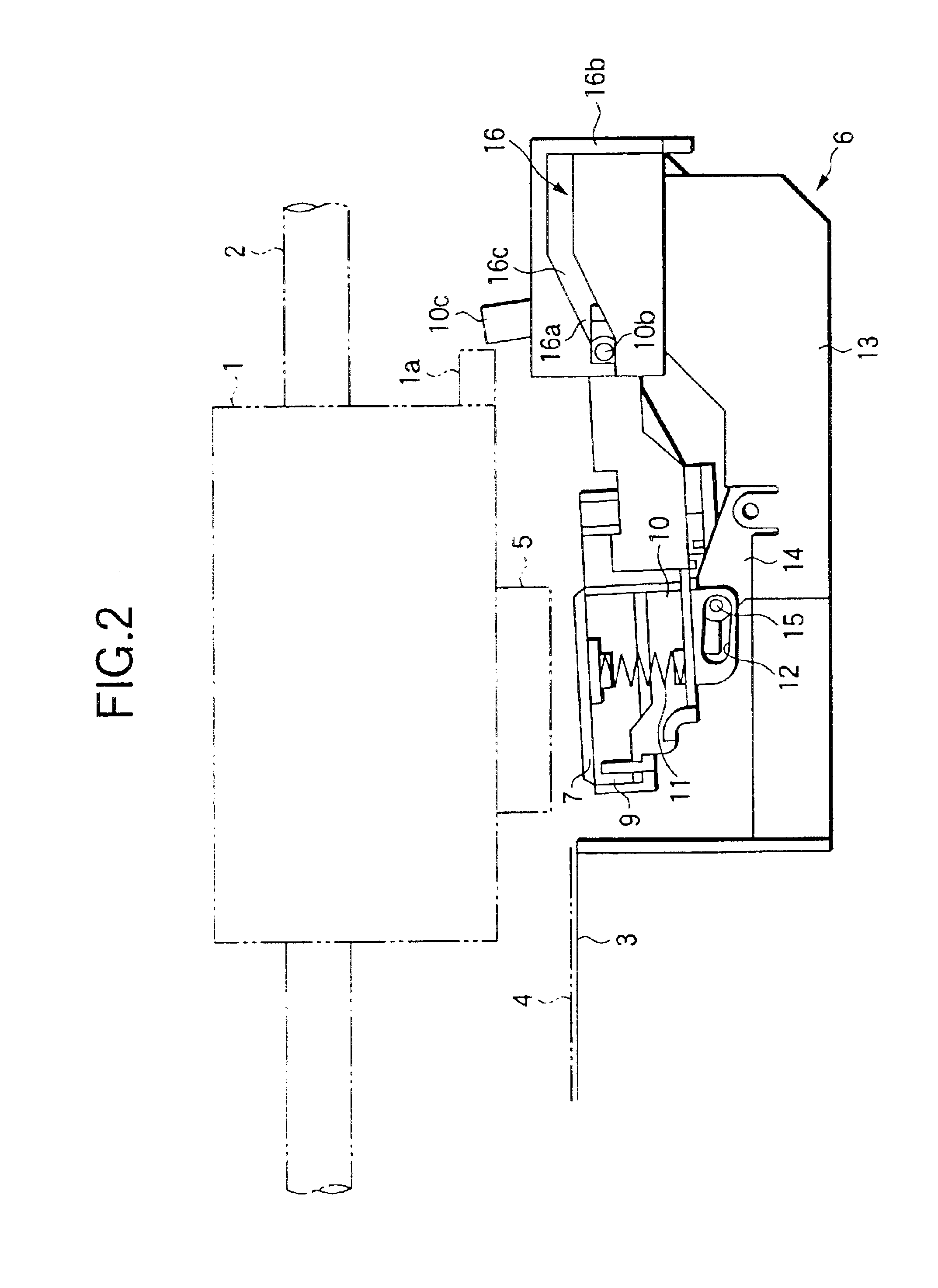

Liquid ejecting device

A liquid ejecting device includes a liquid ejecting head which has a nozzle formation face on which nozzle orifices for ejecting liquid drops are formed and a controller which performs a recovery operation for removing a liquid having a changed liquid property. The recovery operation is performed by using at least a flushing mode in which liquid drops are ejected in a state that the nozzle formation face is sealed. The controller selectively performs a plurality of flushing modes which are set in accordance with degrees in change of a liquid property of the liquid drops being at and near the nozzle orifices. The degrees in change of the liquid property of the liquid drops are determined by a relation between an accumulative time that the nozzle orifices are left in a sealing state and an accumulative time that a liquid ejection is executed. A high flushing mode of the flushing modes for removing the liquid having a high degree in change of the liquid property has a first flushing mode which is performed at a first time and second and subsequent flushing modes which is performed at a second and subsequent time. The number of liquid drops ejected in the first flushing mode is greater than the number of liquid drops ejected in the second and sequent flushing modes.

Owner:SEIKO EPSON CORP

Tilt Diverter to Control Storm-Water

InactiveUS20180230687A1Water resource protectionSewerage structuresHigh concentrationWater storage tank

Owner:VILLANUEVA ARTURO J +2

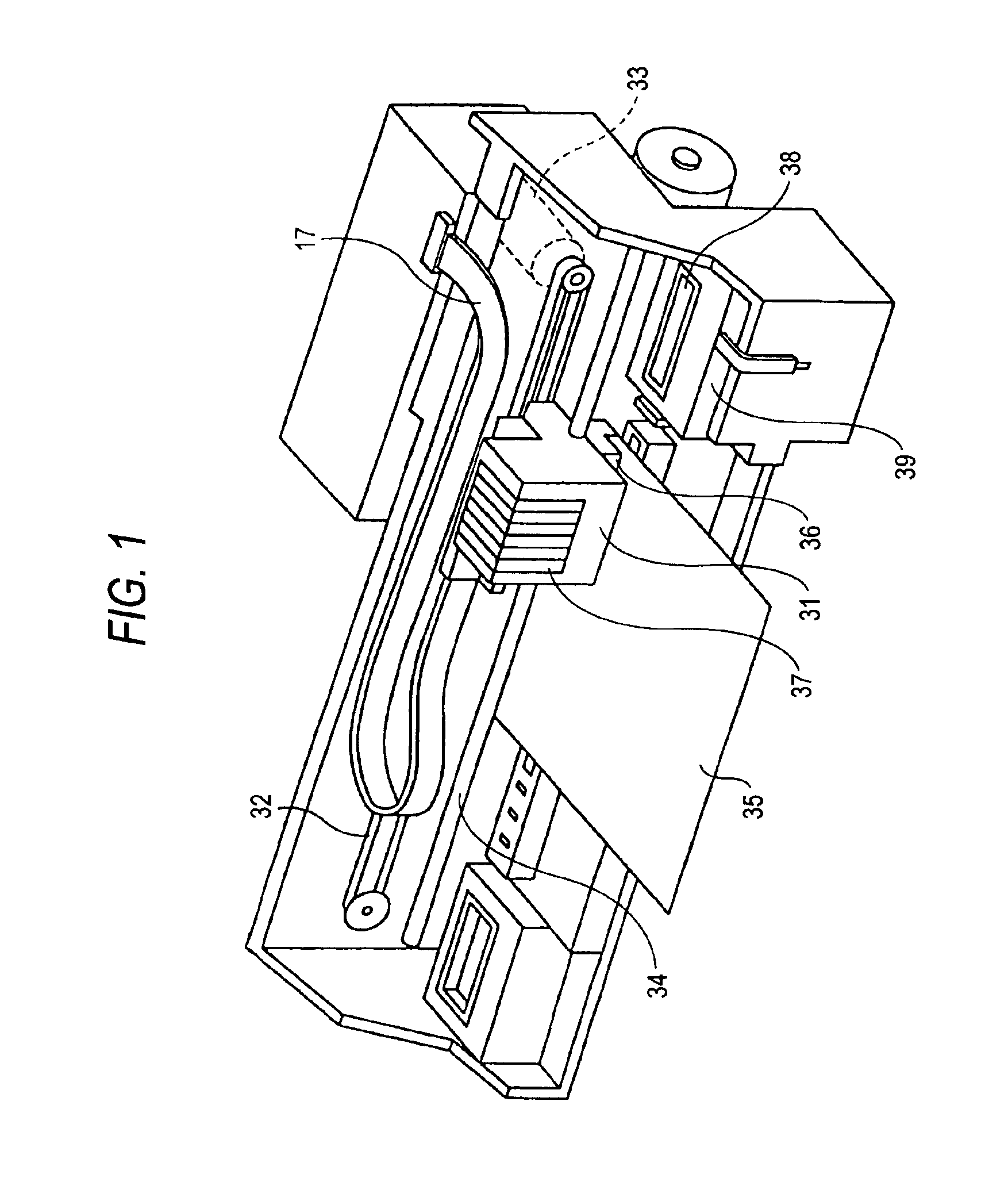

Ink jet recording apparatus and flushing control method used in the same

An ink jet recording head is provided with a nozzle formation face on which nozzles for ejecting ink drops in accordance with print data are formed. A capping member for sealing the nozzle formation face has an inner space formed with a bottom. An ink absorbing member is provided on the bottom of the inner space. In a first flushing mode, ink drops are ejected into the capping member in a state that the nozzle formation face is sealed by the capping member. In a second flushing mode, ink drops are ejected into the capping member in a state that the capping member is separated from the nozzle formation face. Either the first flushing mode or the second flushing mode is selectively performed.

Owner:SEIKO EPSON CORP

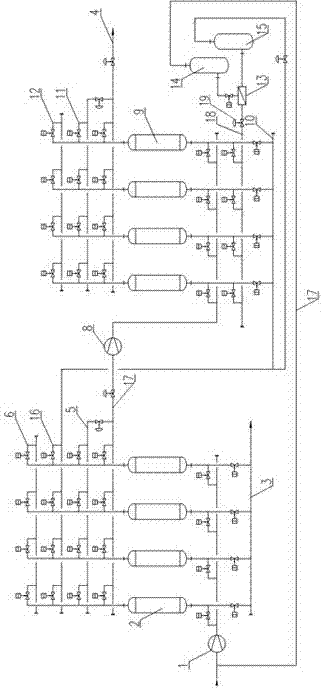

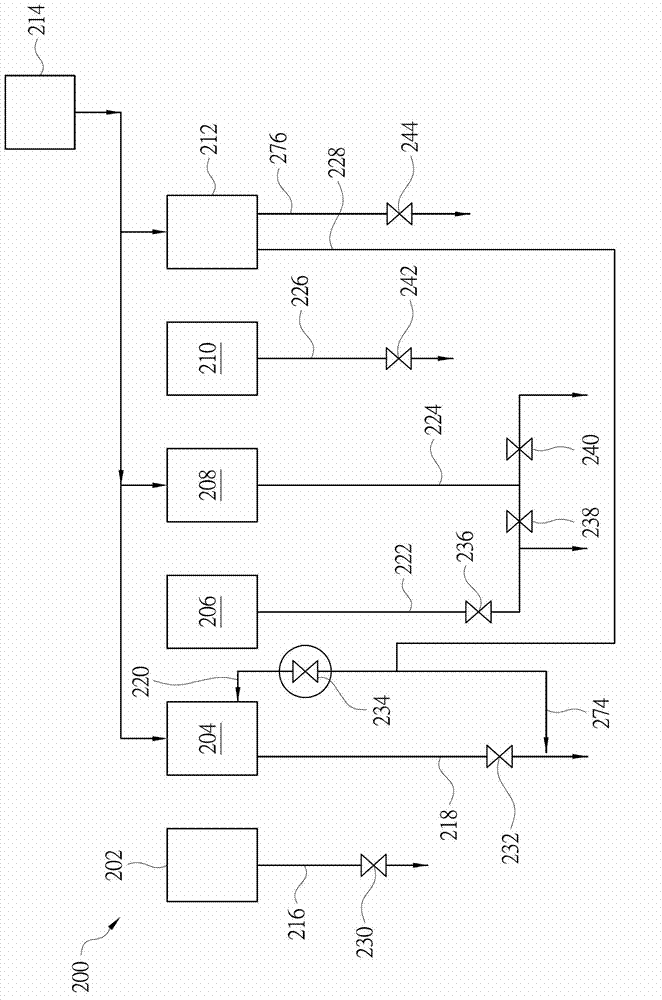

Method and device for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation

InactiveCN103112823AHigh yieldHigh purityHydrogen separation using solid contactHydrogen purityPressure rise

The invention discloses a method for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation. The method comprises a one-stage pressure swing adsorption, a two-stage pressure swing adsorption and a regeneration step, wherein the regeneration step specifically comprises the following steps that: reverse release is carried out after uniform pressure drop of a one-stage pressure swing adsorption tower, the reverse release is carried out after the uniform pressure drop of a two-stage pressure swing adsorption tower, the one-stage pressure swing adsorption tower is subjected to the first washing by the reverse gas release of the two-stage pressure swing adsorption tower, uniform pressure rise of the two-stage pressure swing adsorption tower is carried out, then the two-stage pressure swing adsorption tower is subjected to high-pressure washing by using hydrogen, and at the same time, the high-pressure washing gas is introduced in a membrane separation device, permeate gas with high hydrogen content is recycled, un-permeate gas is used for carrying out the second washing on the one-stage pressure swing adsorption tower, and the one-stage pressure swing adsorption tower is subjected to the uniform pressure rise after the washing is accomplished. The invention further discloses a device for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation. The method and device have the advantages of high yield, high hydrogen purity, low cost investment and low energy consumption.

Owner:SICHUAN TECHAIRS

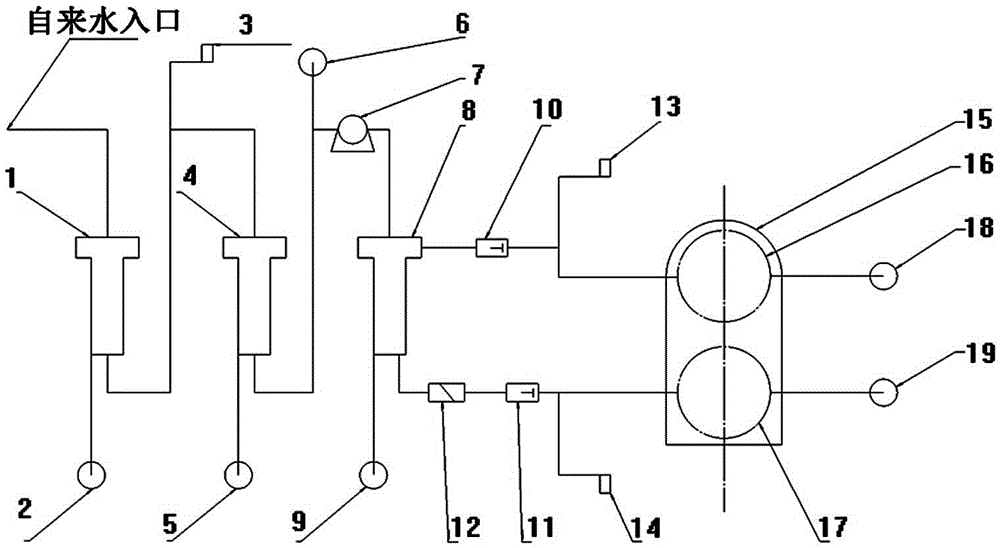

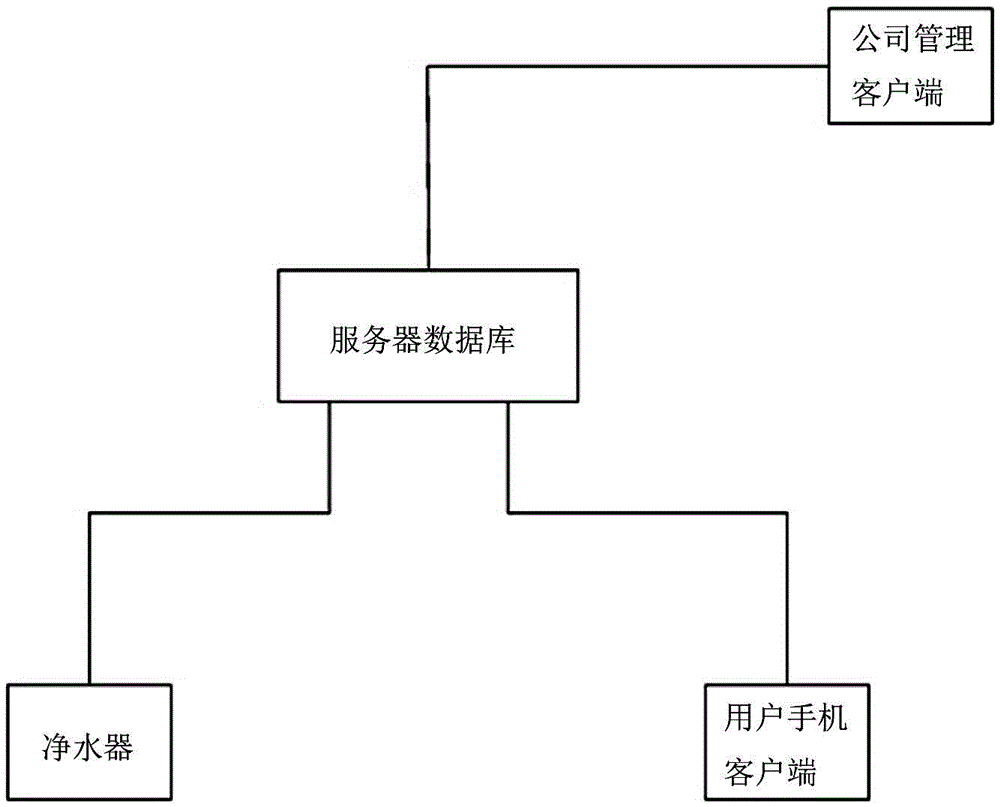

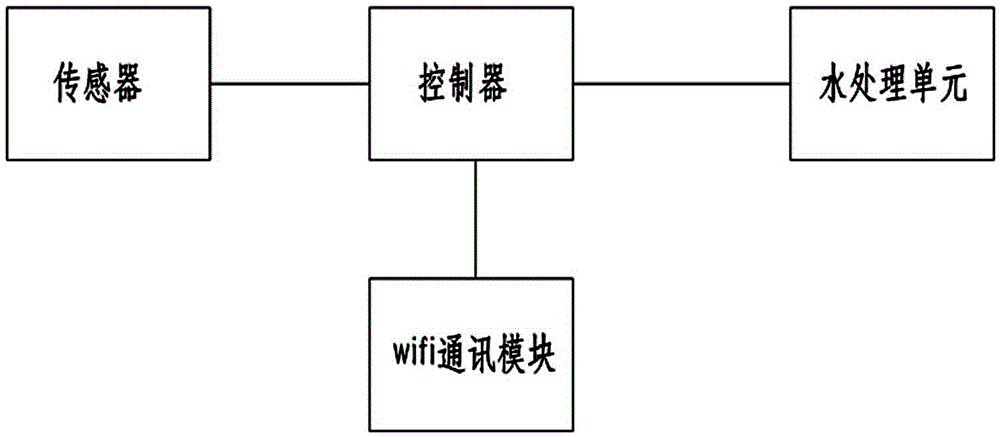

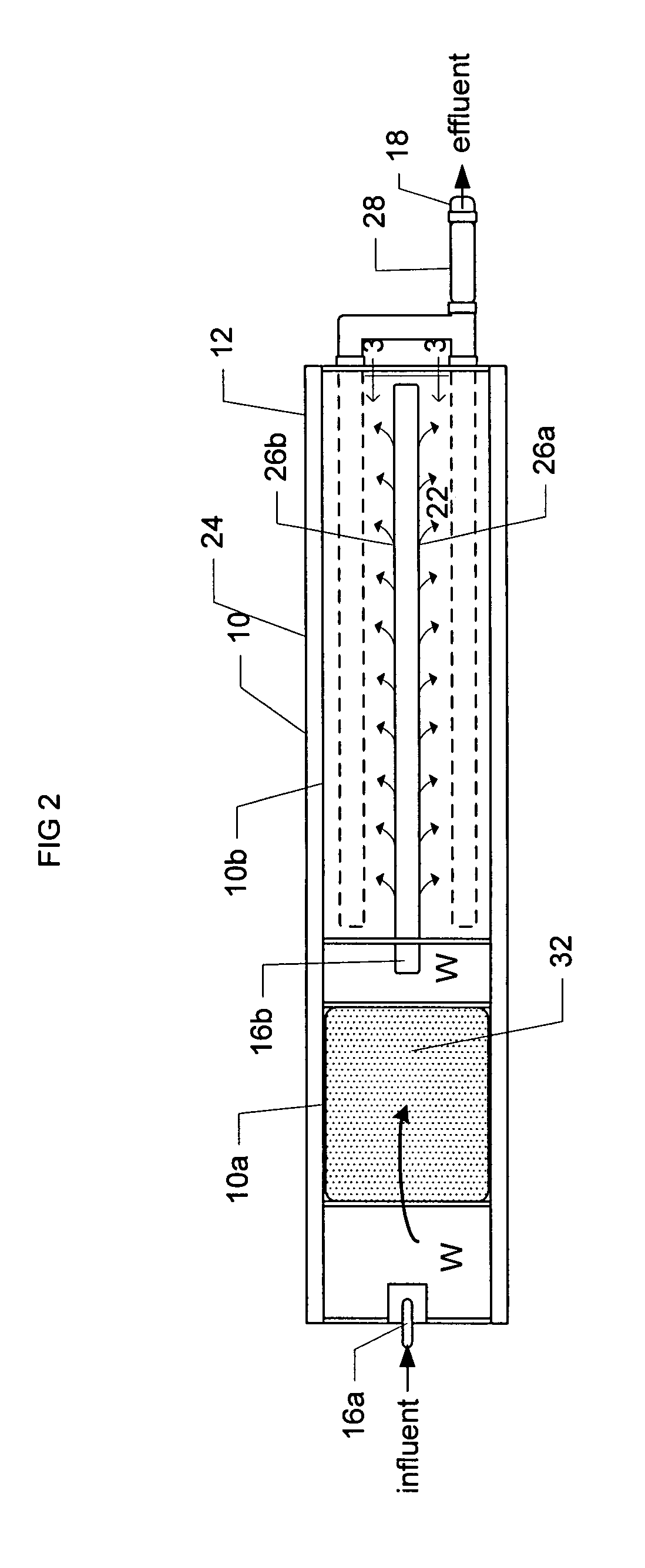

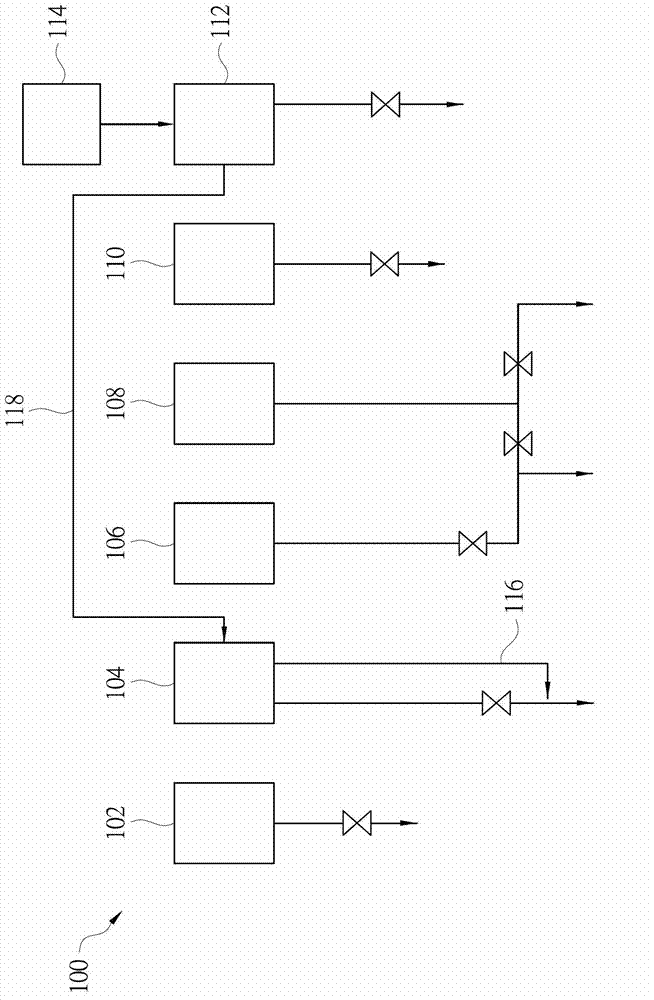

Water purifier

ActiveCN105417751AAbility to analyze habitsImprove experienceWater/sewage treatmentMultistage water/sewage treatmentFiberCarbon fibers

The invention discloses a water purifier, which comprises a water treatment unit, a Wifi communication module, a sensor and a controller, wherein the water treatment unit comprises a pure water fabrication device and a tail water / pure water storage device; the pure water fabrication device comprises a UF purification film filter core 1, a first flush valve 2, a low-voltage switch 3, a carbon fiber filter core 4, a first flush valve 5, an ultrafiltration water valve 6, a booster pump 7, an RO film filter core 8 and a third flush valve 9; the tail water / pure water storage device comprises a storage tank 15, a first check valve 10, a second check valve 11, a tail water proportional valve 12, a second high-voltage valve 14 and a first high-voltage valve 13; and the storage tank 15 comprises a pure water storage part 16 and a tail water storage part 17. By the technology, an intelligent, simple, compact, safe and convenient water purifier which is capable of saving water resources and achieving high-intelligence and long-term purification and is high in water preparation amount and free of tail water loss is provided.

Owner:BEIJING GUOTIEKELIN TECH

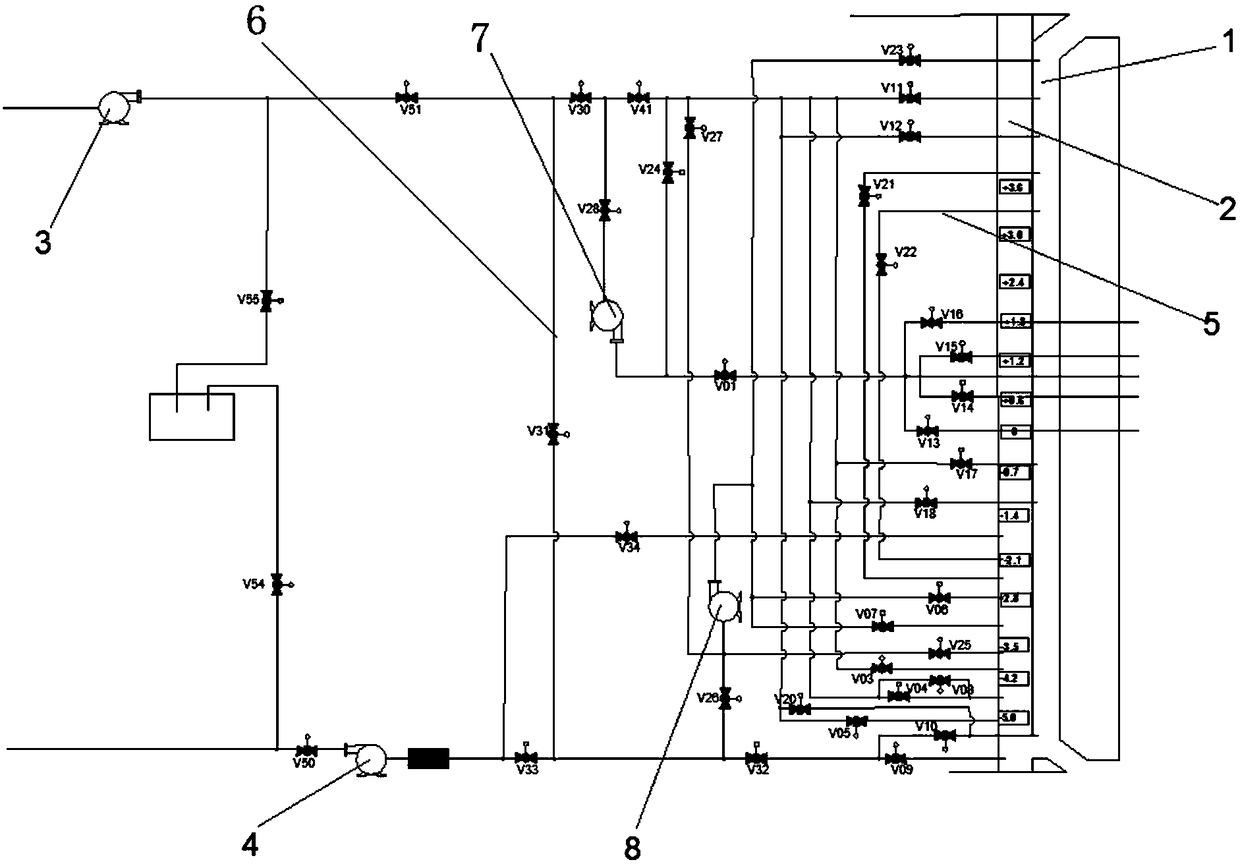

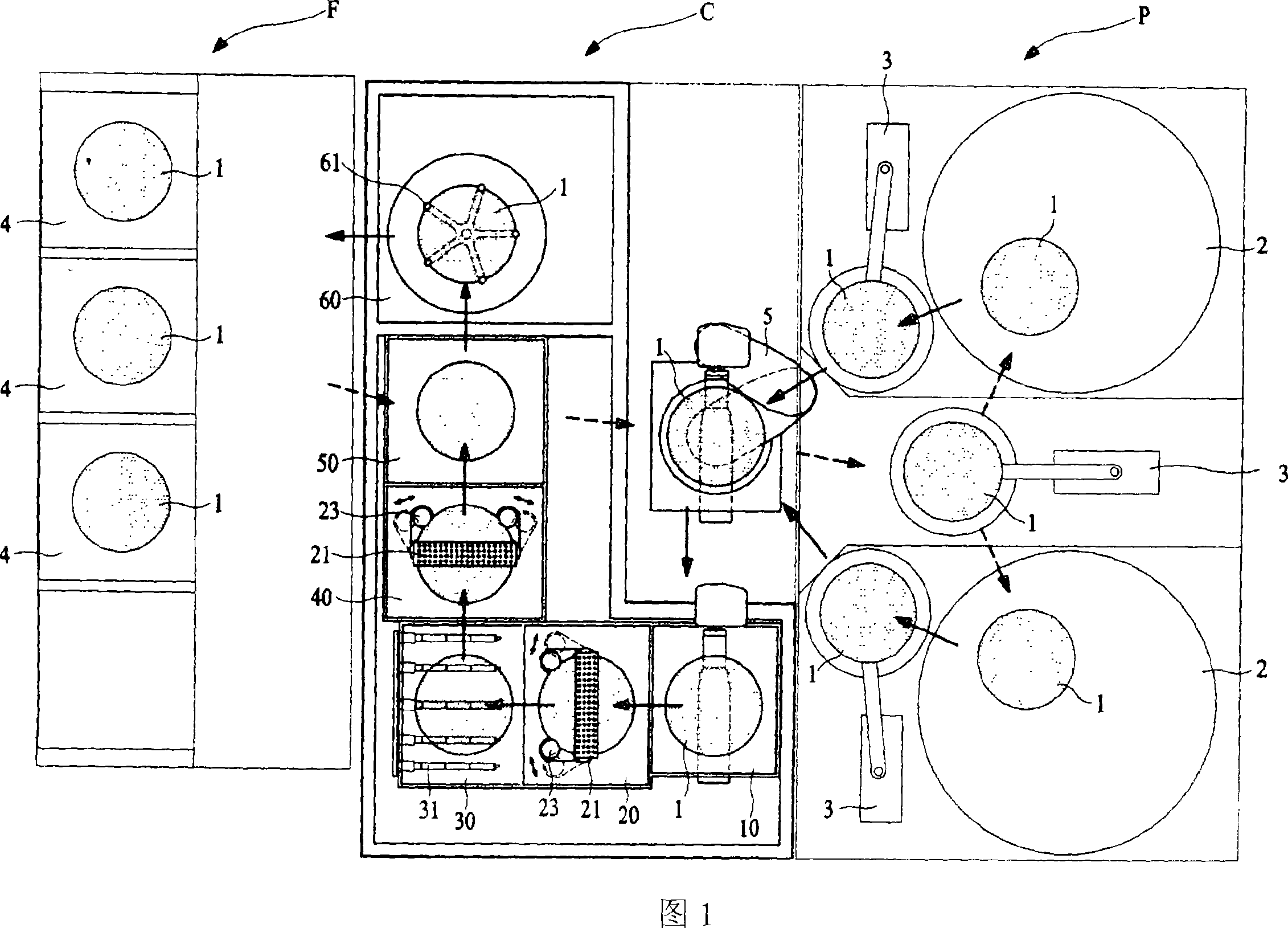

Slurry loop circulation system for slurry shield

InactiveCN108194089AImprove processing efficiencyReduce the probability of cloggingTunnelsControl systemSlurry

The invention discloses a slurry loop circulation system for slurry shield. The slurry loop circulation system comprises an excavation bin and an air cushion bin, a slurry inlet pump is connected witha main slurry inlet pipeline, the main slurry inlet pipeline communicates with the excavation bin through a plurality of first shunt slurry inlet pipelines, and the lower side of the air cushion bincommunicates with the main slurry inlet pipeline through a plurality of second shunt slurry inlet pipelines; the lower side of the excavation bin communicates with a main slurry discharging pipeline through first shunt slurry discharging pipelines, and the lower side of the air cushion bin communicates with the main slurry discharging pipeline through second shunt slurry discharging pipelines; a first flushing system is connected to the position between a cutterhead panel and the main slurry inlet pipeline, the tops of a stirrer, a slurry door and the excavation bin are connected with a secondflushing system, and the main slurry inlet pipeline communicates with the main slurry discharging pipeline through a by-pass pipeline; and an output end opening of the slurry inlet pump and an inputend opening of a slurry discharging pump are provided with sensors correspondingly, a ball valve and the sensors are connected with a control system, by optimizing the slurry circulation mode, standbypipelines are additionally arranged to improve the treatment efficiency of slurry, and the plugging probability of a slurry outlet is reduced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

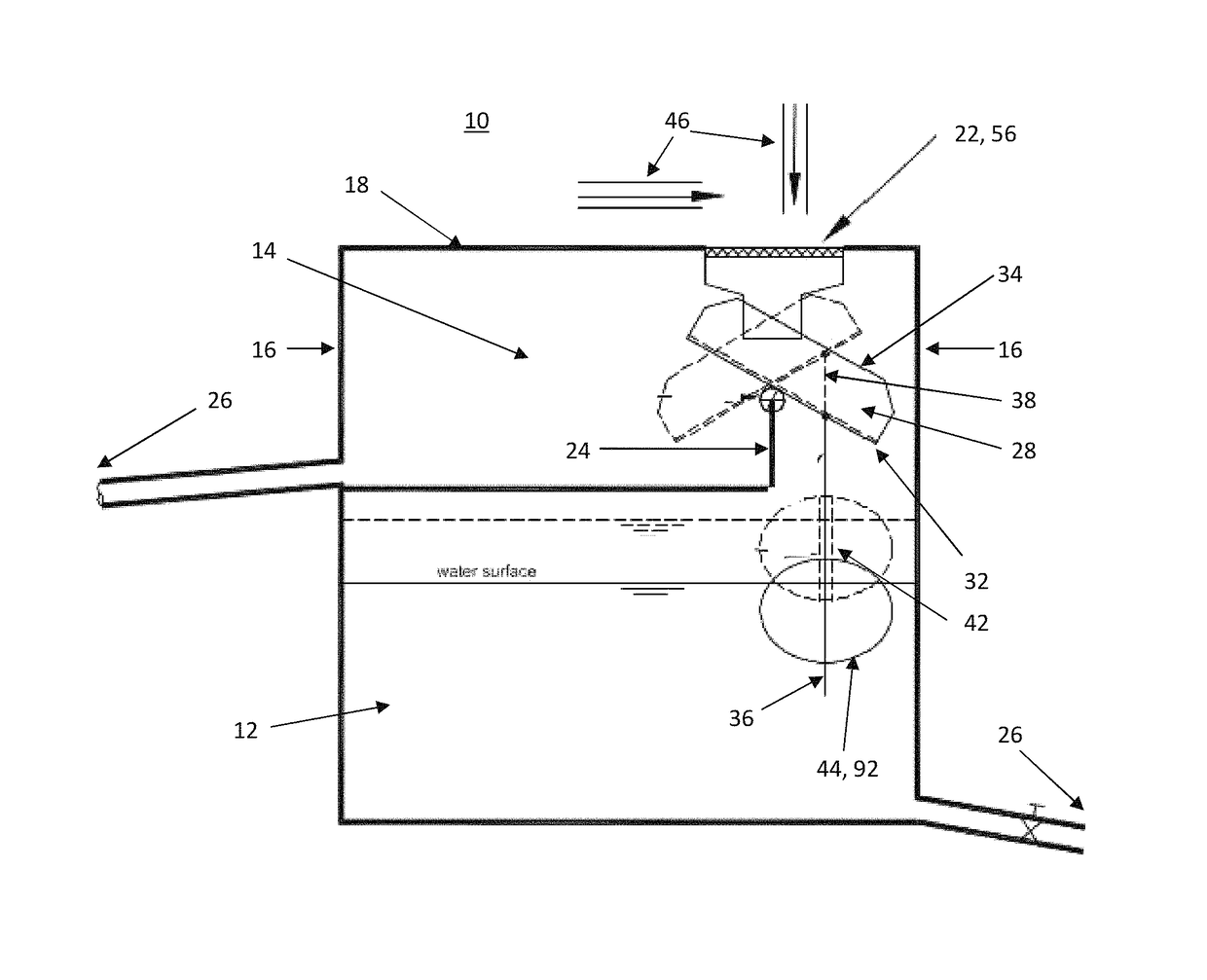

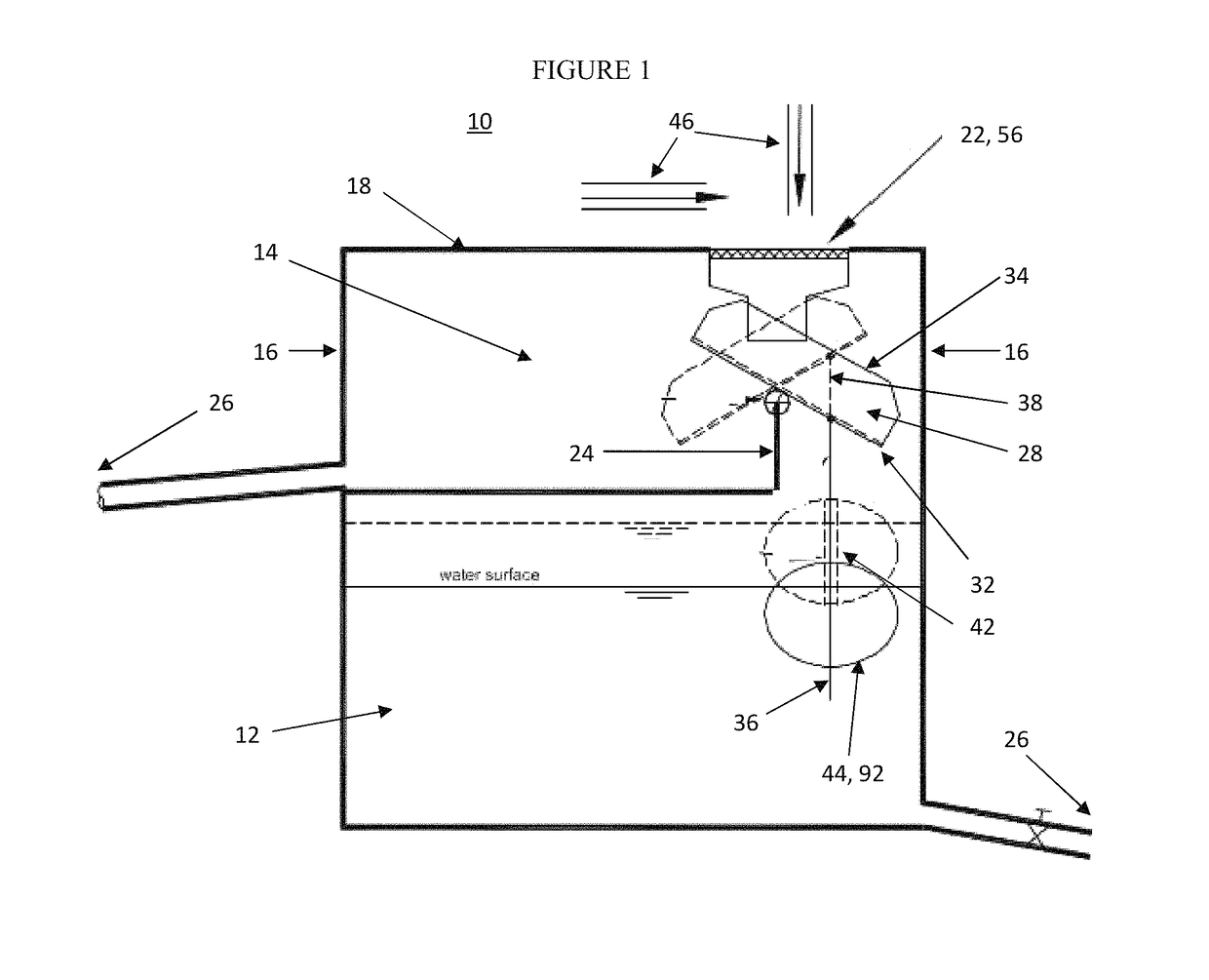

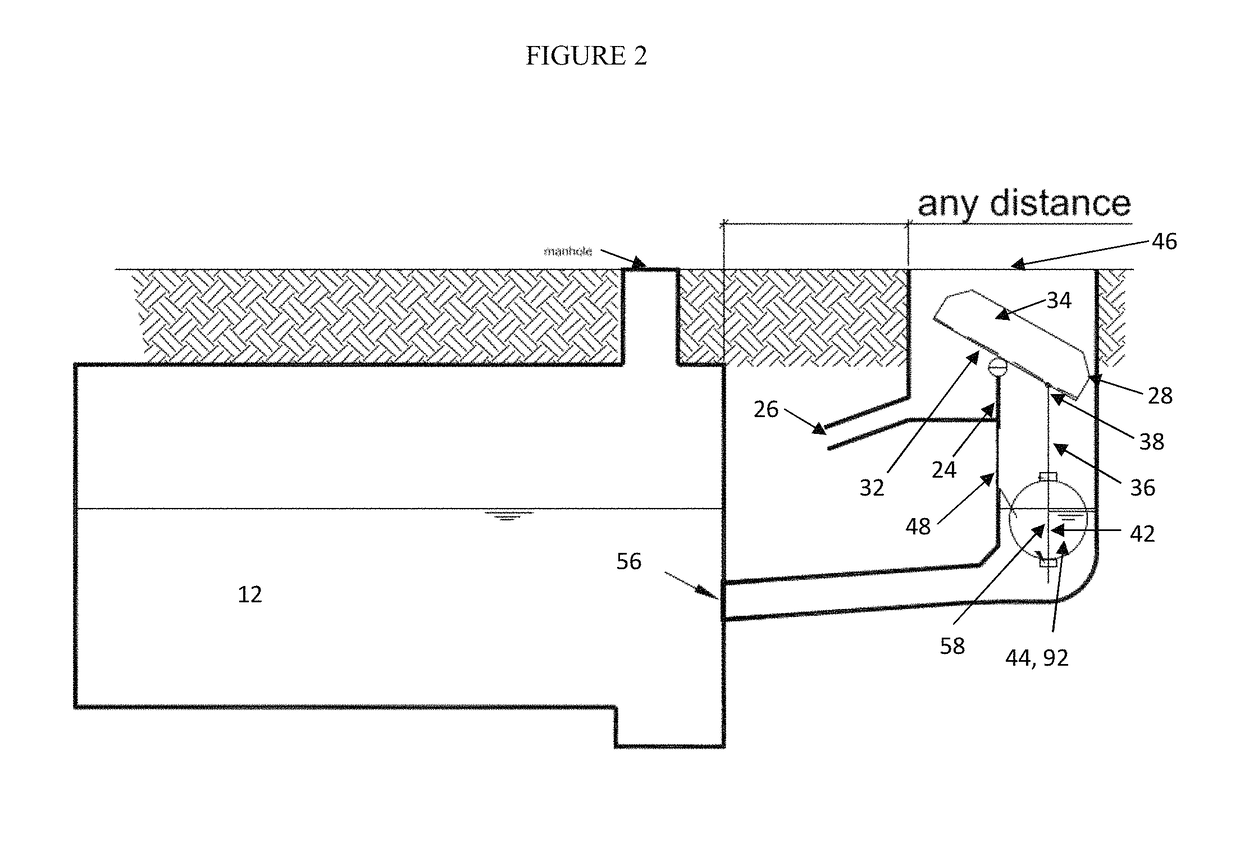

Passive stormwater management system

ActiveUS8002974B2Easy to cleanCost-effective and extremely effective in removingGeneral water supply conservationTreatment involving filtrationMean free pathParticulates

A stormwater inlet near an upper edge of a layered filter media vessel is equipped with a distribution header that ensures effective use of the surface area of the filter media by providing plural spaced streams of stormwater thereat, each at a point of impact having its energy dissipated by a layer of material that covers the upper layered filter media surface. The stormwater inflow is metered to control the stormwater pollutant removal process kinetics, thereby slowing the mean free path of the stormwater therethrough and optimizing pollutant capture. The water level within the vessel is height adjustable manually by a pivot arm in the form of a standing column of water coupled to the water within the container. Weep conduits are provided to slowly drain down the standing water in the system between storm events, simplifying maintenance and promoting best removal of pollutants from first-flush storm events. Stormwater pretreatment, e.g. by use of an oleophilic agent or a pH-buffering agent, is provided. Filter media are easily cleaned, as by scraping and / or adding filter media material when existing material's particulate capture capacity is exhausted.

Owner:NEWTERRA CORP INC

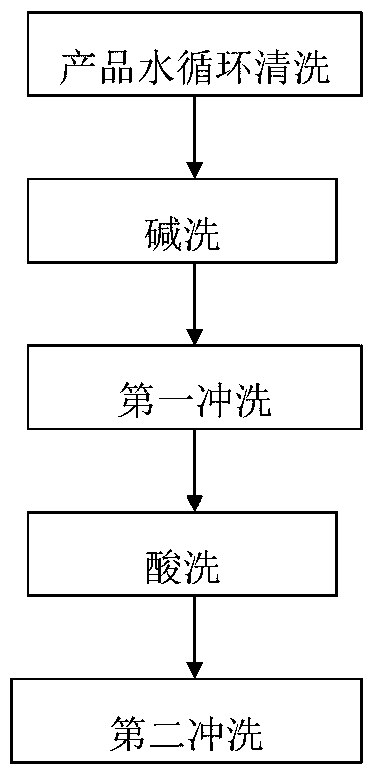

Method for cleaning floor heating pipes

The invention provides a method for cleaning floor heating pipes. The method is characterized by comprising the following steps of: firstly flushing, removing loams in the pipes, then soaking the pipes by cleaning fluid, dissolving rust and scale in the pipe, and finally Secondarily flushing the pipe. Through the method, the cleaning is safe and convenient, the cleaning time is short, the cleaning effect is excellent, the cleaning cost is low, the excellent radiation function of the pipe after cleaning can be kept, the service life of the floor heating pipe can be prolonged, no harm to human body is generated in the cleaning process, the equipment is not corroded, and the environment is not affected.

Owner:山西省第二建筑工程公司

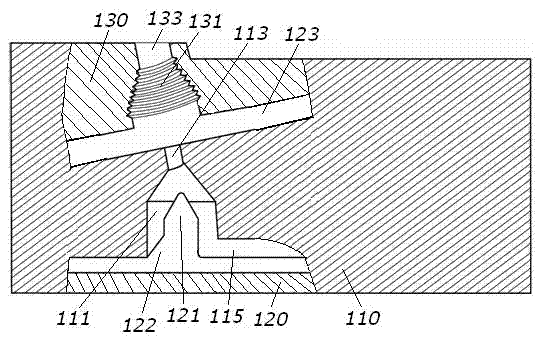

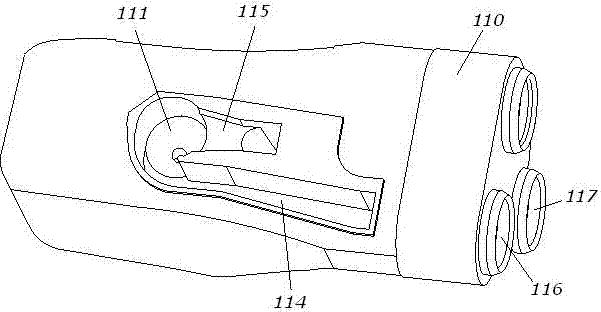

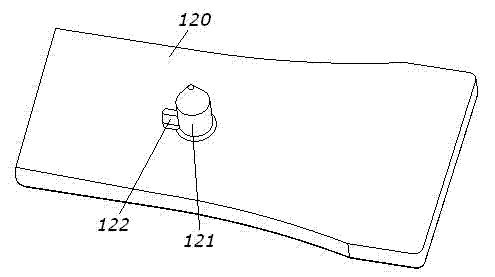

Intelligent closestool and nozzle device capable of spraying swirling water current of intelligent closestool

ActiveCN102359168AAchieve laxative effectImprove comfortSpray nozzlesLavatory sanitorySmall dropletWater flow

The invention discloses an intelligent closestool and a nozzle device capable of spraying swirling water current of the intelligent closestool. The nozzle device comprises a base and a bottom cover, wherein an inner spray nozzle is arranged on the base and is communicated with an inlet at the tail of the base through a channel at the bottom of the base; a swirling chamber with a conical surface at the top is arranged between the inner spray nozzle and the channel; a conical lug pillar is arranged on the bottom cover corresponding to the center of the bottom of the swirling chamber; the channel comprises a first channel and a second channel; the first channel is tangentially communicated with the swirling chamber along the side wall of the swirling chamber; and the second channel is radially communicated with the swirling chamber along the conical lug pillar. Due to the adoption of the swirling chamber with the lug pillar and two channels, two strands of water current form a swirling water jet with an axial speed, a radial speed and a tangential speed during confluence; the stripped cleaning for stubborn dirt can be finished by using a normal impact force and a tangential stripping force of the swirling jet and the first-time flushing effect after defecation is improved; low water-pressure spin also brings excellent comfort to people; and no small droplet in the swirling water jet splashes so as to prevent other parts of a human body from being wetted.

Owner:NINGBO SOOJEE SANITARY WARE

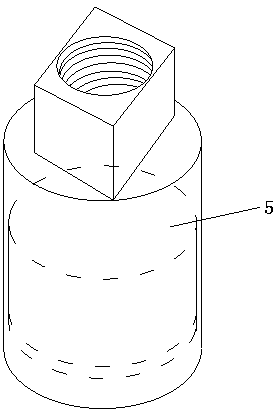

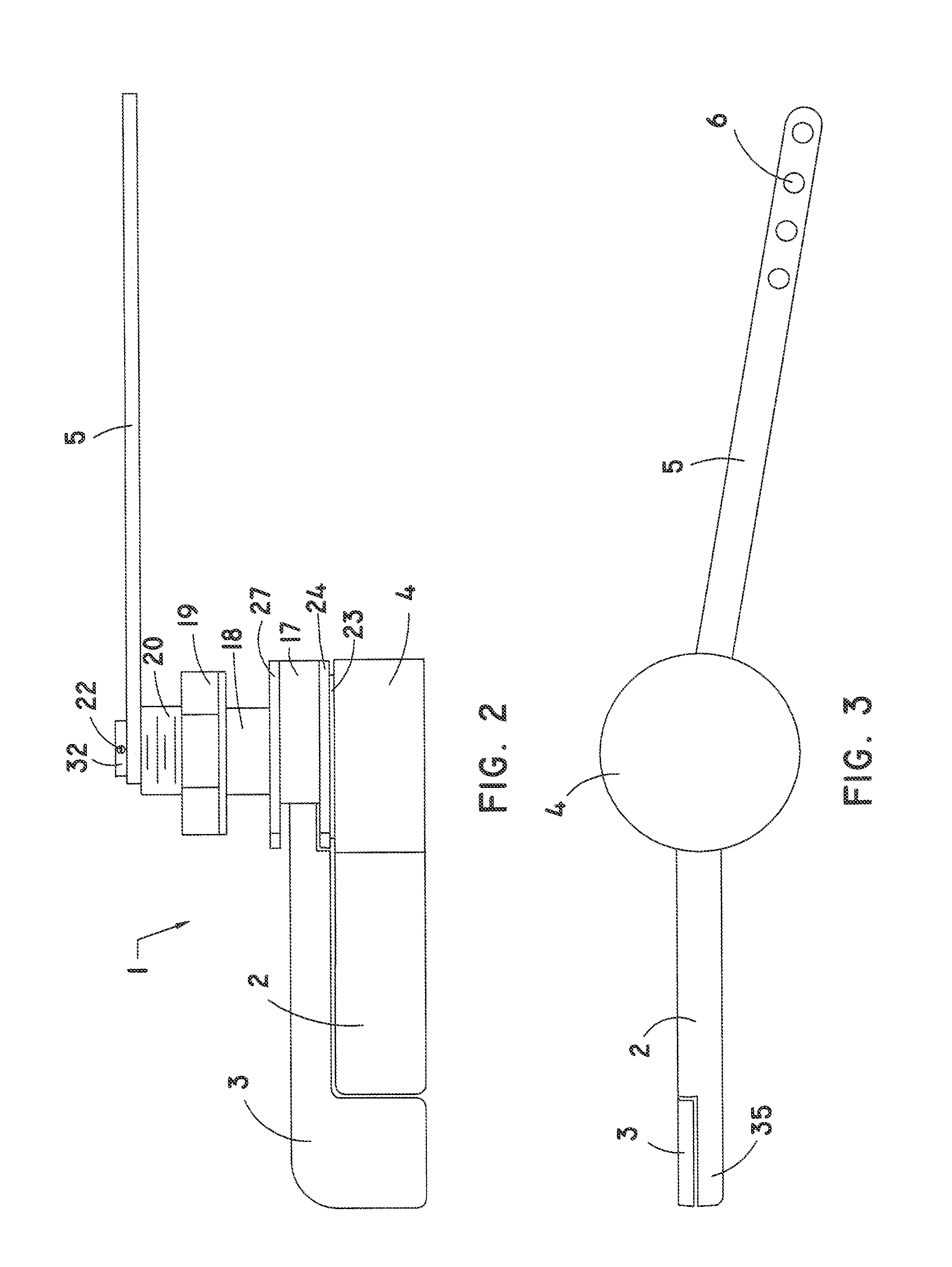

First flush water diverter

InactiveUS20050081926A1Lower the volumeGeneral water supply conservationPipeline systemsCarrying capacityCollection system

A first flush water diverter for use with domestic rainwater collection systems. The diverter comprises a T-piece (13) and a collection chamber (14), with an outlet (15) connectable to a hose by way of a flow control valve (24) and hose connector (25). The collection chamber (14) is variable in length to suit the environment and size of the roof from which the rainwater flows. The carrying capacity of the collection chamber (14), and have its length, is determined from the formula: DF=RA×PF×1000 where DF is the rainwater carrying capacity, or diversion factor, measured in litres, RA is the associated roof area measured in square metres, PF is the Pollution Factor for the roof location which is determined on site and varies between 0.0005 for light pollution locations and 0.002 for heavy pollution locations, and wherein said collection chamber includes an outlet and associated flow control valve to regulate the flow of diverted rainwater from the collection chamber.

Owner:WADE RODNEY GEORGE

Method for washing NF membranes and RO membranes

InactiveCN109224869ARestore performanceExtended service lifeSemi-permeable membranesAdditive ingredientAcid washing

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Diverter valve

ActiveUS8490643B2Easily and reliably and controlledEasy to operatePlug valvesConfectioneryVALVE PORTPiston

Owner:PROCESSING TECH

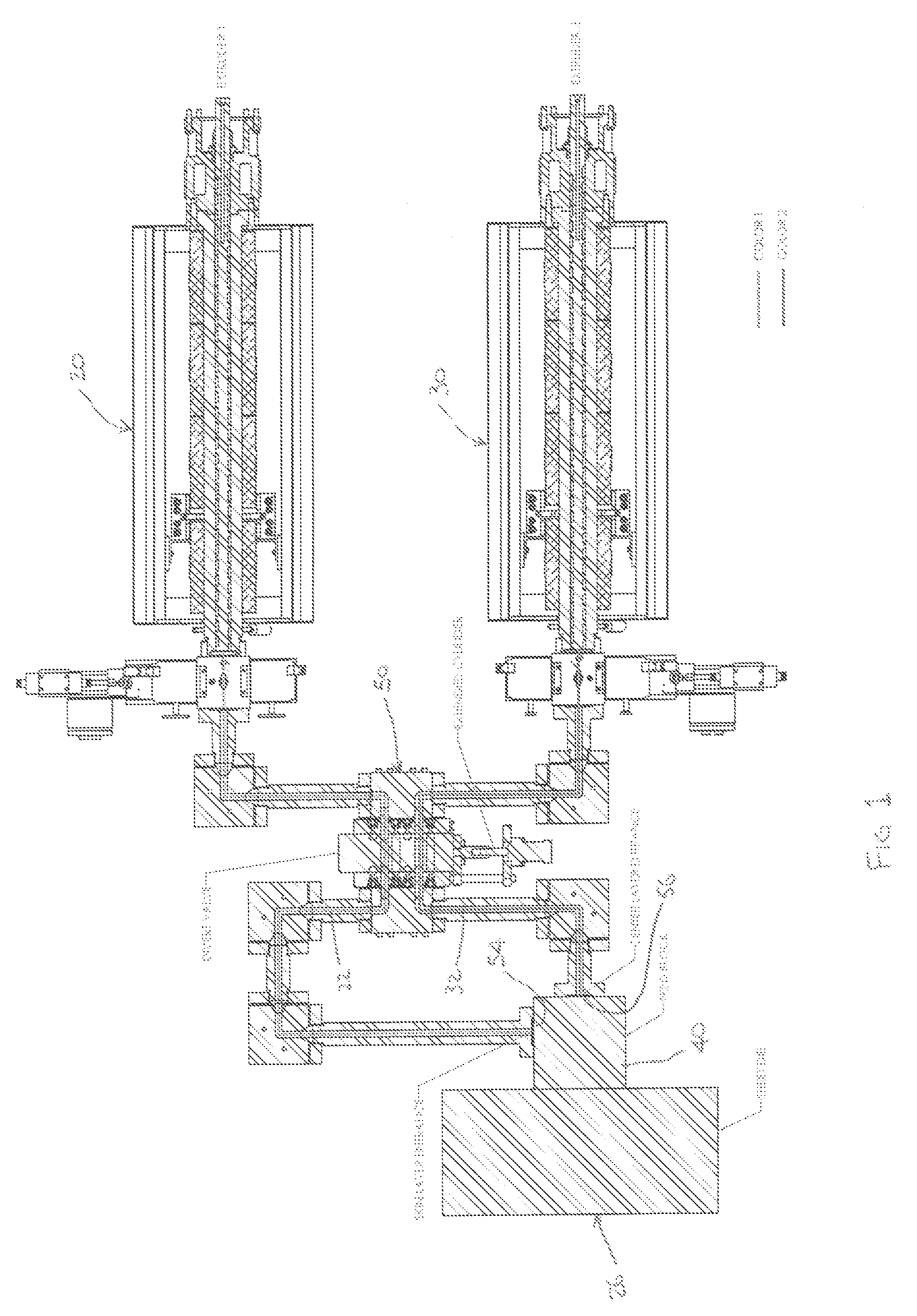

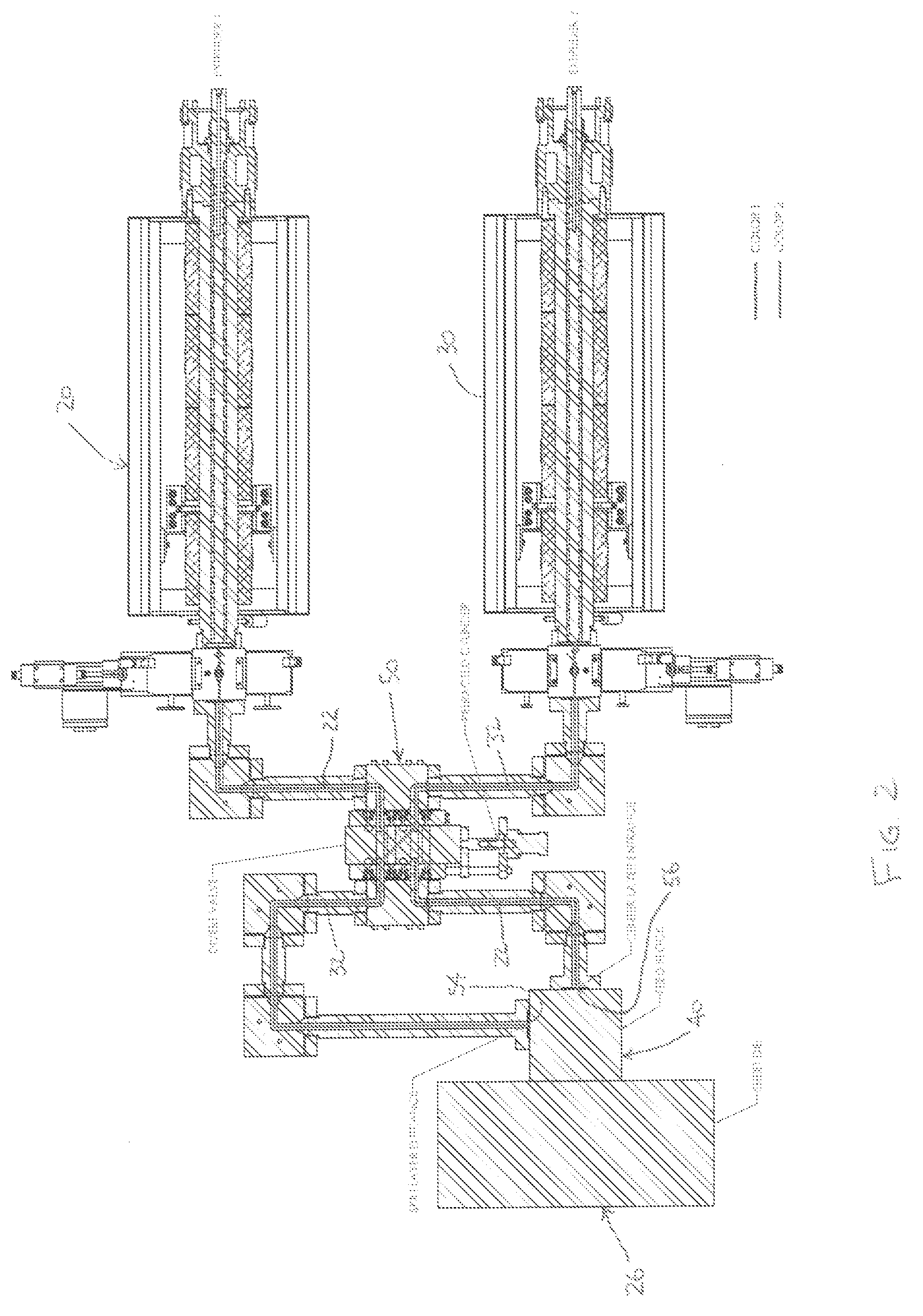

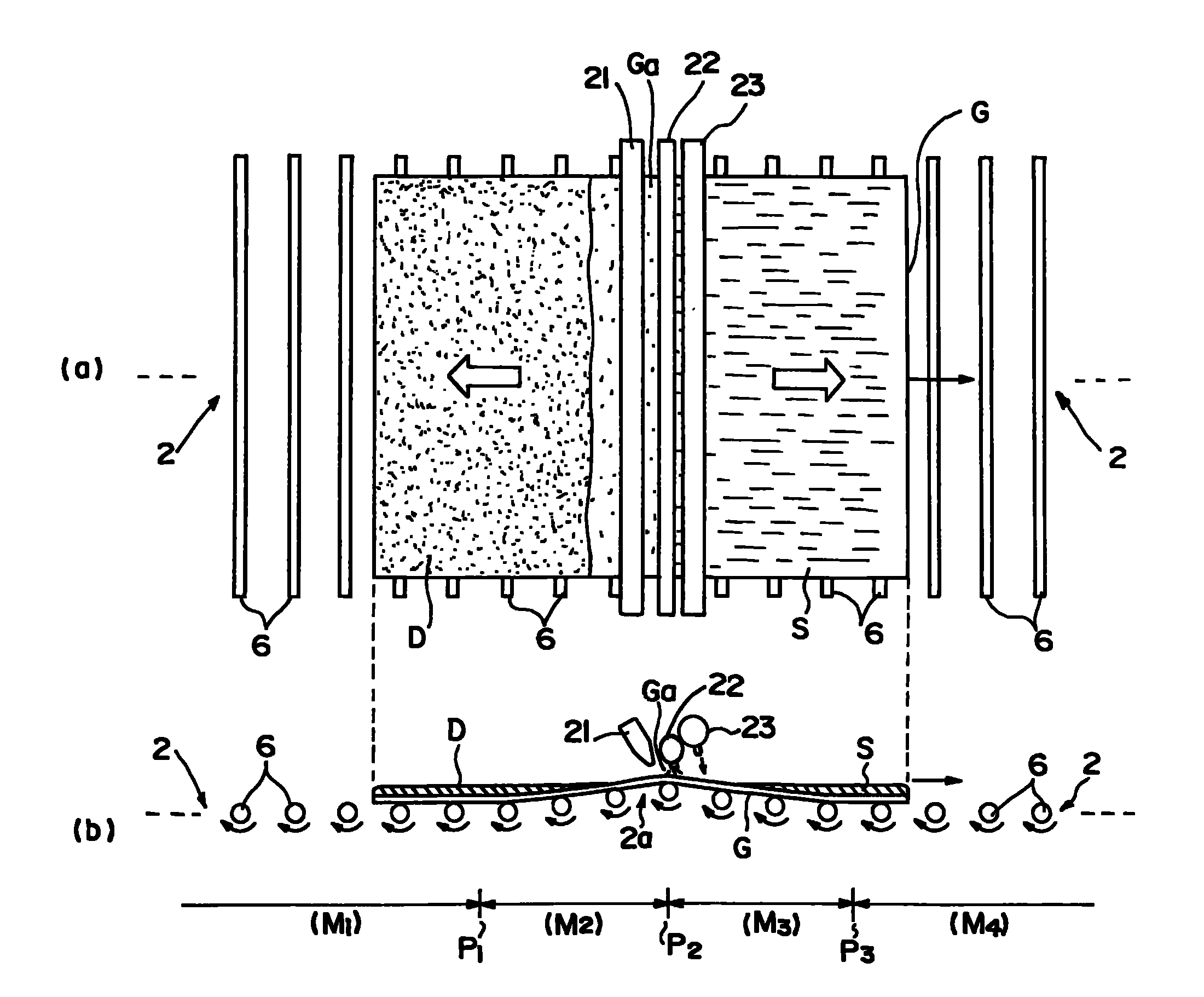

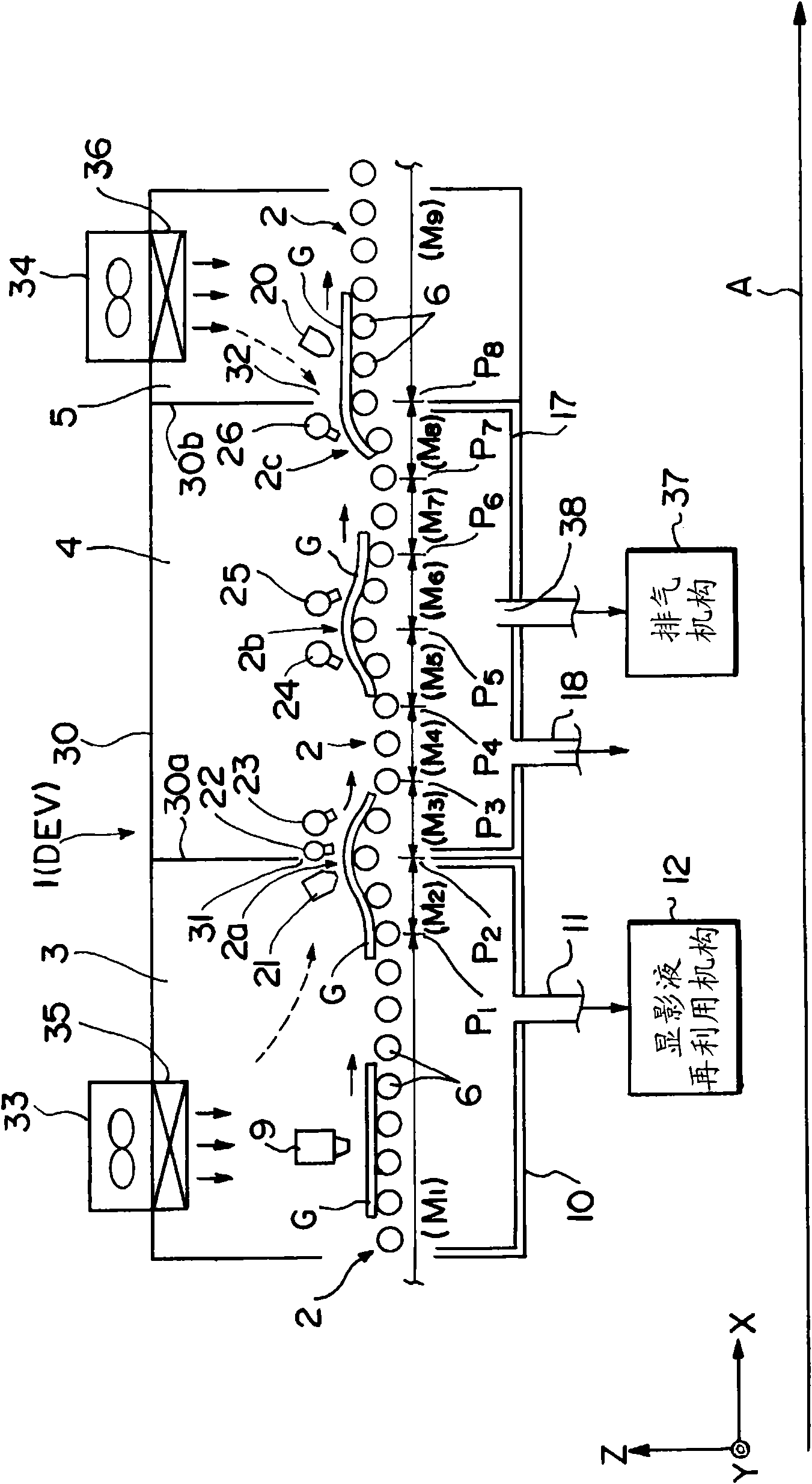

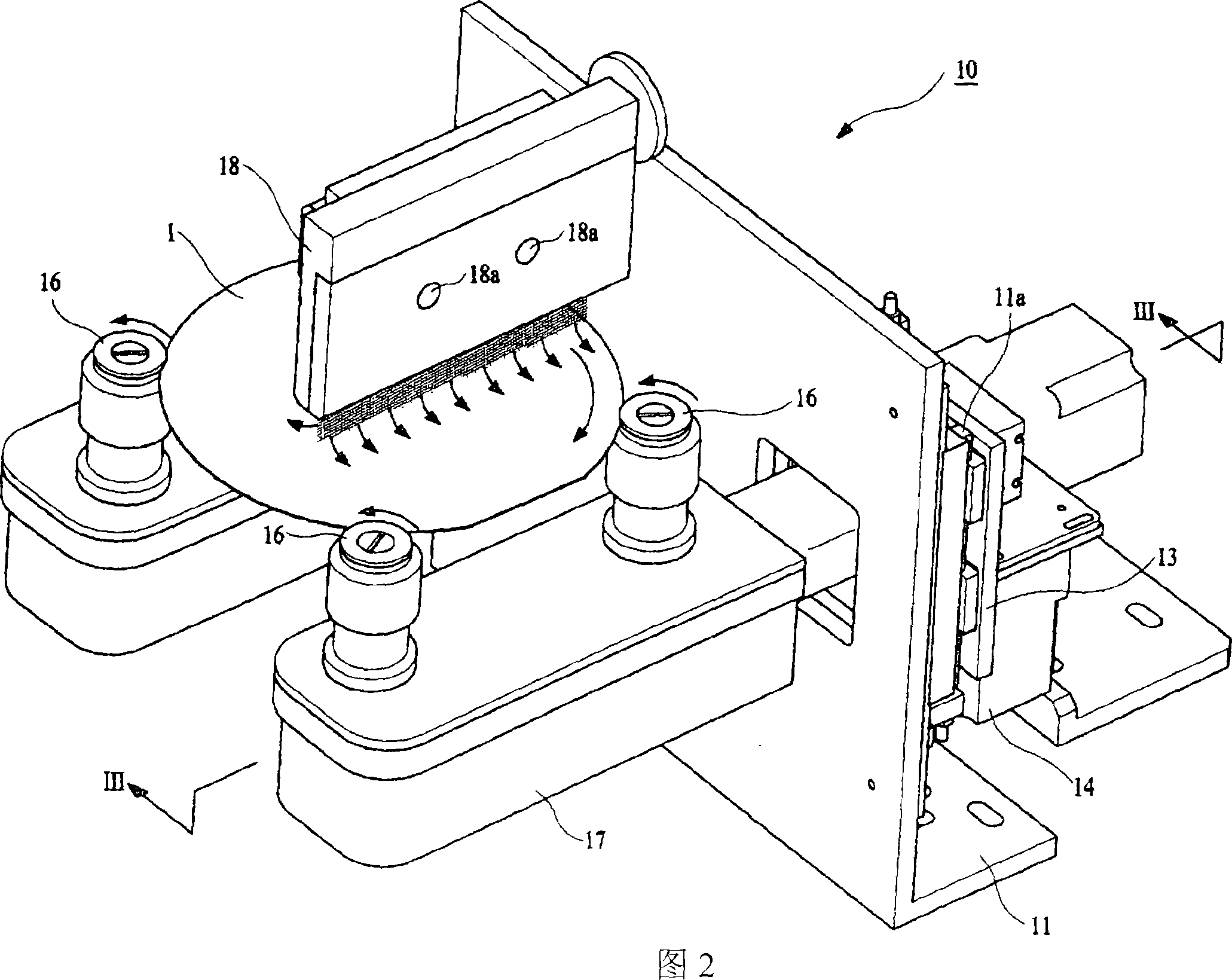

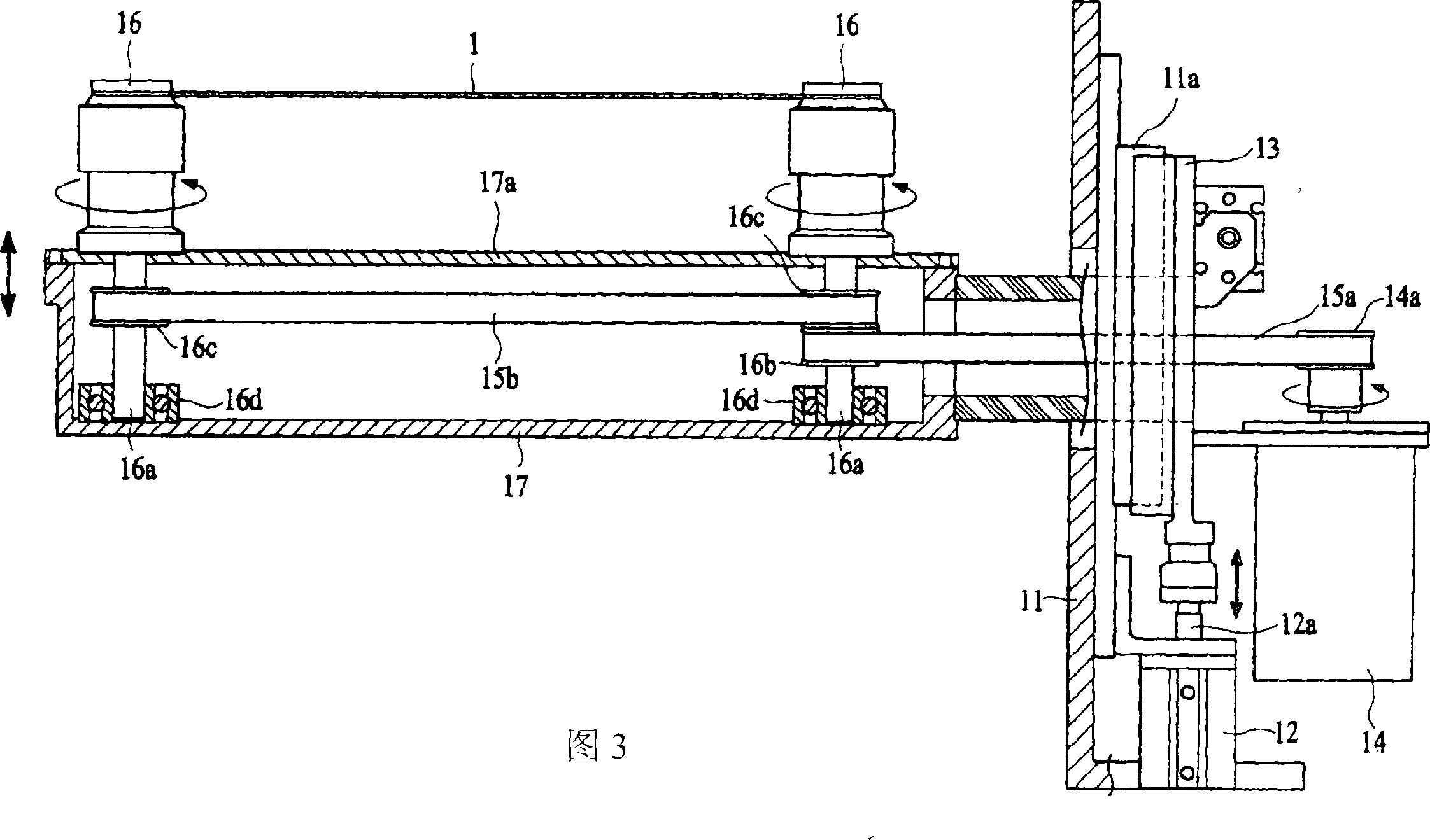

Substrate disposing device and method thereof

ActiveCN101814424AEfficient and smooth supplyLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringGas supply

This invention provides a substrate disposing device and method thereof , including: a substrate transport path that transmits disposed substrate with a smooth gas flow; a first disposing liquid feed part which feeds disposing liquid to disposed substrate being delivered to the substrate transport path; gas supply part which blows certain gas flow to the disposed substrate supplied with first disposing liquid and delivered in the substrate transport path from the vertical direction to any directions of the delivery downstream; a first flush fluid supplying part which feeds a second disposing fluid at a certain speed to the surface of the disposed substrate being blown with gas flow from a gas flow supplying part and delivered in the substrate transport path; a second flush fluid supplying part which feeds a second disposing fluid at a higher speed than that of the first flush fluid to the surface of the disposed substrate being supplied with second disposing fluid and delivered in the substrate transport path.

Owner:TOKYO ELECTRON LTD

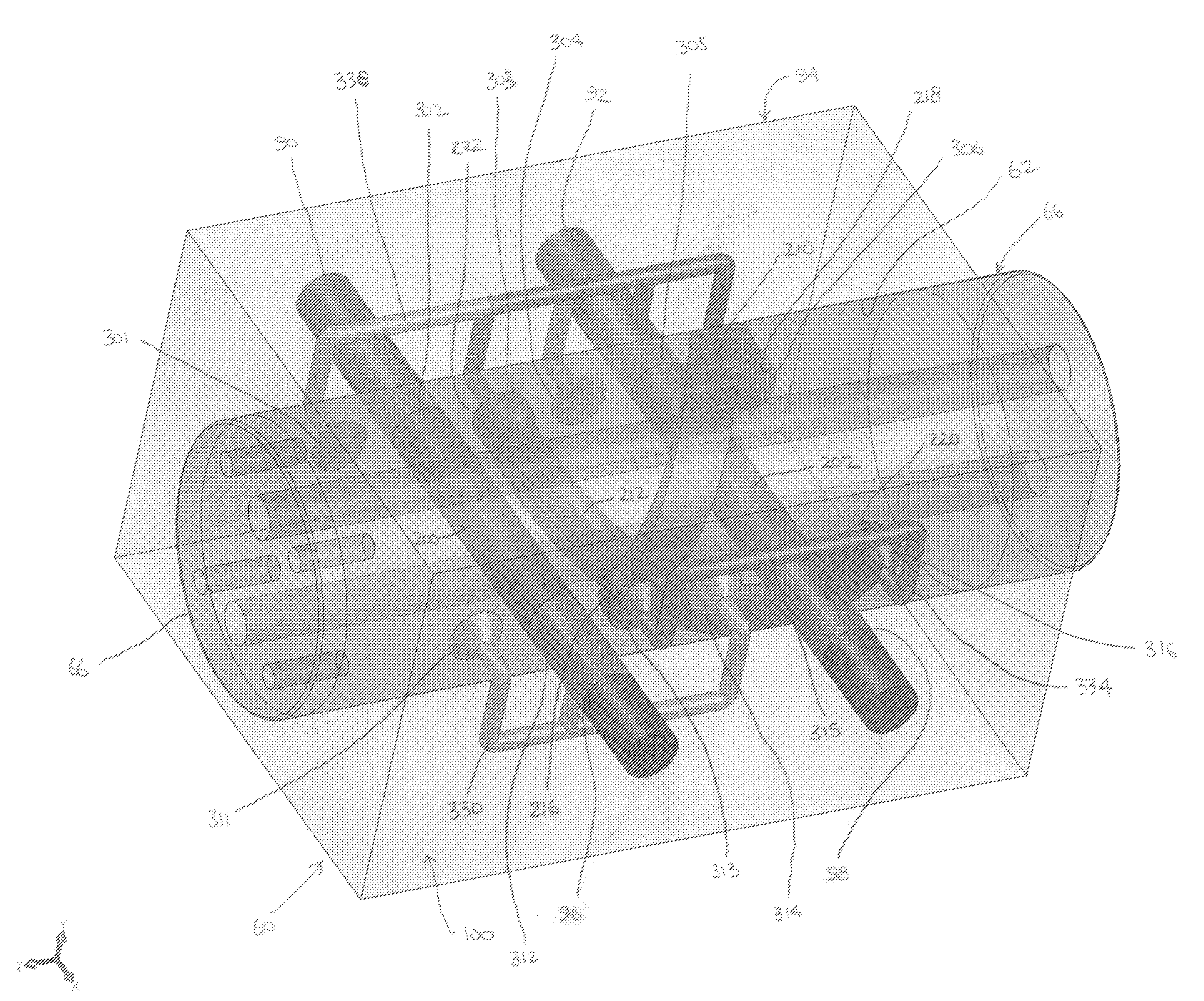

Underground stormwater management system and method

InactiveUS8062531B1Increase effective storage capacityEasy to useLiquid displacementLoose filtering material filtersWater management systemEngineering

An underground stormwater management system includes a receiving tank connected to a source of non-first flush runoff and a storage chamber that accumulates stormwater runoff for discharge to a storm drain. The storage chamber includes a first inlet connected to a source of first flush runoff, a second inlet connected to receive overflow from the receiving tank, a first discharge and a second discharge above the first discharge. First flush is discharged from the first discharge and is filtered before reaching the storm drain. The receiving tank assists in delaying the receipt of non-first flush runoff into the storage chamber during a major rain event. During major rain events runoff is also discharged from the storage chamber directly to the surrounding media.

Owner:LANE ENTERPRISES

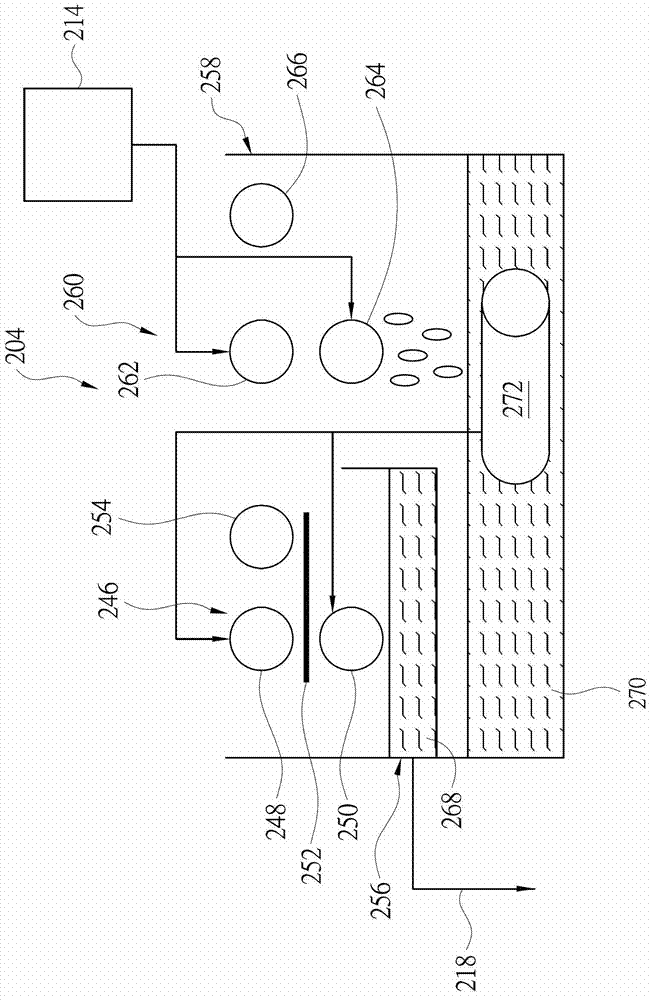

Semiconductor chip cleaning system

InactiveCN101180711AImprove productivityReduce waiting timeSemiconductor/solid-state device manufacturingProduction rateSemiconductor chip

The present invention related to a semiconductor wafer cleaning system comprising a preliminary cleaning station for removing particles on a wafer in advance by spraying deionized water thereon; a first cleaning station for cleaning remaining particles firstly by rotating frictionally a pair of brushes disposed to be contacted with a front surface and a back surface of the wafer and by spraying chemicals thereon through a chemical sprayer being provided independently; a first rinsing station for rinsing by spraying a cleaning liquid onto the firstly cleaned wafer at the first cleaning station; a second cleaning station for cleaning particles secondly remained on the front surface and the back surface of the wafer by spraying the chemicals onto the firstly rinsed cleaned wafer at the first rinsing station through a chemical sprayer being provided independently using the same structure and manner as those of the first cleaning station; a second rinsing station for rinsing by spraying the cleaning liquid onto the secondly cleaned wafer at the second cleaning station; and a dry station for drying the remained cleaning liquid using centrifugal force generated by rotating the rinsed wafer at the second rinsing station at a high speed. According to the present invention, a waiting time of entry into each cleaning station is minimized by processing a cleaning operation and a rinsing operation of a surface-polished wafer in a cleaning station and a rinsing station which are provided separately and independently thereby improves wafer productivity significantly by solving a delayed phenomenon in a whole process of wafer manufacturing.

Owner:K C TECH

Cleaning mechanism for silicon wafers

InactiveCN104226626AReduce surface residual acidAvoid breakingCleaning using liquidsWater dischargeBiochemical engineering

The invention provides a cleaning mechanism for silicon wafers. The cleaning mechanism for the silicon wafers comprises the components of: a first acid trough, an alkali trough, a first cleaning trough, a first flushing device, a water discharging valve, a second cleaning trough, a second flushing device and a pump device. The first flushing device is arranged between the first acid trough and the alkali trough. The first flushing device is arranged in the first cleaning trough. The first cleaning trough is suitable for receiving first cleaning liquid after cleaning by the first flushing device. The water discharging valve is communicated with the first cleaning trough. The first cleaning liquid is discharged through the water discharging valve. The second cleaning trough is arranged between the first cleaning trough and the alkali trough. The second flushing device is arranged in the second cleaning trough. The second cleaning trough is suitable for receiving second cleaning liquid after cleaning by the second flushing device. The pump device is suitable for circulating the second cleaning liquid to the first cleaning trough for use by the first flushing device.

Owner:MOTECH INDUSTRIES

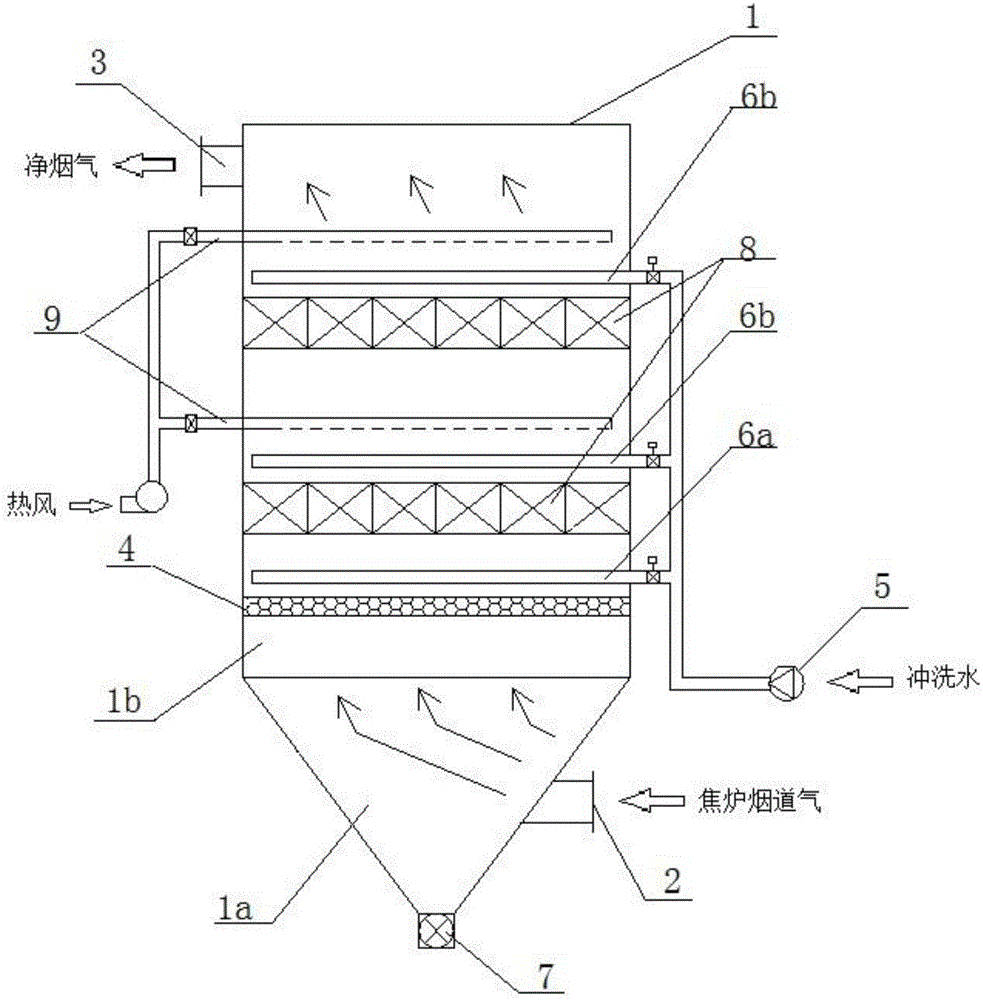

Anti-blocking blocking-relieving method and apparatus for coke oven flue gas SCR (selective catalytic reduction) denitration catalyst

InactiveCN106215696AAvoid cloggingAvoid inactivationDispersed particle filtrationTransportation and packagingFlue gasCoke oven

The invention relates to an anti-blocking blocking-relieving method and apparatus for coke oven flue gas SCR (selective catalytic reduction) denitration catalyst. One side of a lower ash bucket of a denitration reactor is provided with a flue gas inlet, the other side of the top end of an upper straight barrel is provided with a purified flue gas outlet, a metal strainer and multiple layers of denitration catalyst are arranged in the upper straight barrel sequentially from bottom to top, a first flushing pipe is arranged above the metal strainer, a second flushing pipe and a heating air pipe are arranged above each layer of denitration catalyst, the first flushing pipe and the second flushing pipes are connected with an external flushing water supply device through a pressure pump after being communicated, the heating air pipes are connected with an external heating device after being communicated, and the bottom of the lower ash bucket is provided with a drain valve. The metal strainer is disposed at the front of the denitration catalyst to intercept ammonia salts and sticky particles in the coke oven flue gas and prevent blocking of the denitration catalyst; the flushing pipes are arranged above the denitration catalyst to flush blockage; therefore, efficient denitration of the denitration catalyst is guaranteed, and the life of the denitration catalyst is extended.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

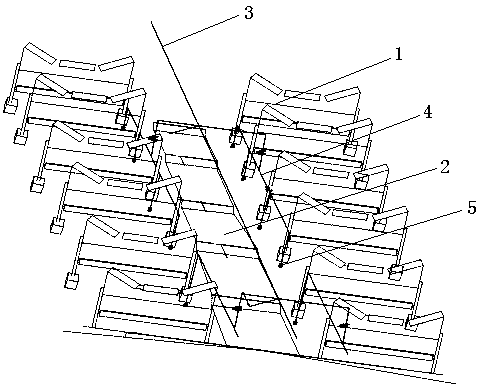

Automatic washing system for coal conveying viaduct

PendingCN109051641APrevent dead endsReduce water consumptionCleaningCleaning using liquidsEngineeringWater spray

The invention discloses an automatic washing system for a coal conveying viaduct. The automatic washing system for the coal conveying viaduct comprises two belt conveyors. A belt conveyor gallery is arranged between the two belt conveyors. A double-belt conveyor main pipe is mounted above the belt conveyor gallery. Branched pipes are connected to the double-belt conveyor main pipe. Water spray heads are mounted at the tail ends of the branched pipes. The opening angles and directions of the water spray heads correspond to the roots of supporting legs, perpendicular to the ground, of the two belt conveyors. According to the automatic washing system for the coal conveying viaduct, the two belt conveyors are washed downwards from the heads for the first time through the water spray heads, then the two sides of the first belt conveyor and the two sides of the second belt conveyor are sequentially washed, and in this way, the galley between the two belt conveyors can be completely washed; and dead corners of the roots of the supporting legs of the belt conveyors can be washed without being left, and resource waste caused by repeated washing is avoided.

Owner:恒力石化(大连)炼化有限公司

Dual flush toilet devices

InactiveUS20130232678A1Shorten the lengthWater resource protectionOperating means/releasing devices for valvesWater savingEngineering

A dual flush device is disclosed to provide a full flush for removing solid waste and a water-saving partial flush for removing liquid or light solid waste in a toilet. It includes a first flush handle attached to a shaft to raise a lever to open a flapper valve, and a second flush handle that overlaps the first handle and opens the flapper valve through the first handle. A float assembly is disclosed to be used either with the dual flush device or with the original single flush lever assembly to prematurely close an opened flapper valve and reduce water consumption. Using the original flapper valve in a conventional toilet tank, a dual flush function is achieved by any of the three implementation choices: (1) the dual flush device alone; (2) the dual flush device and a float assembly; and (3) a float assembly alone.

Owner:HAN JAMES T

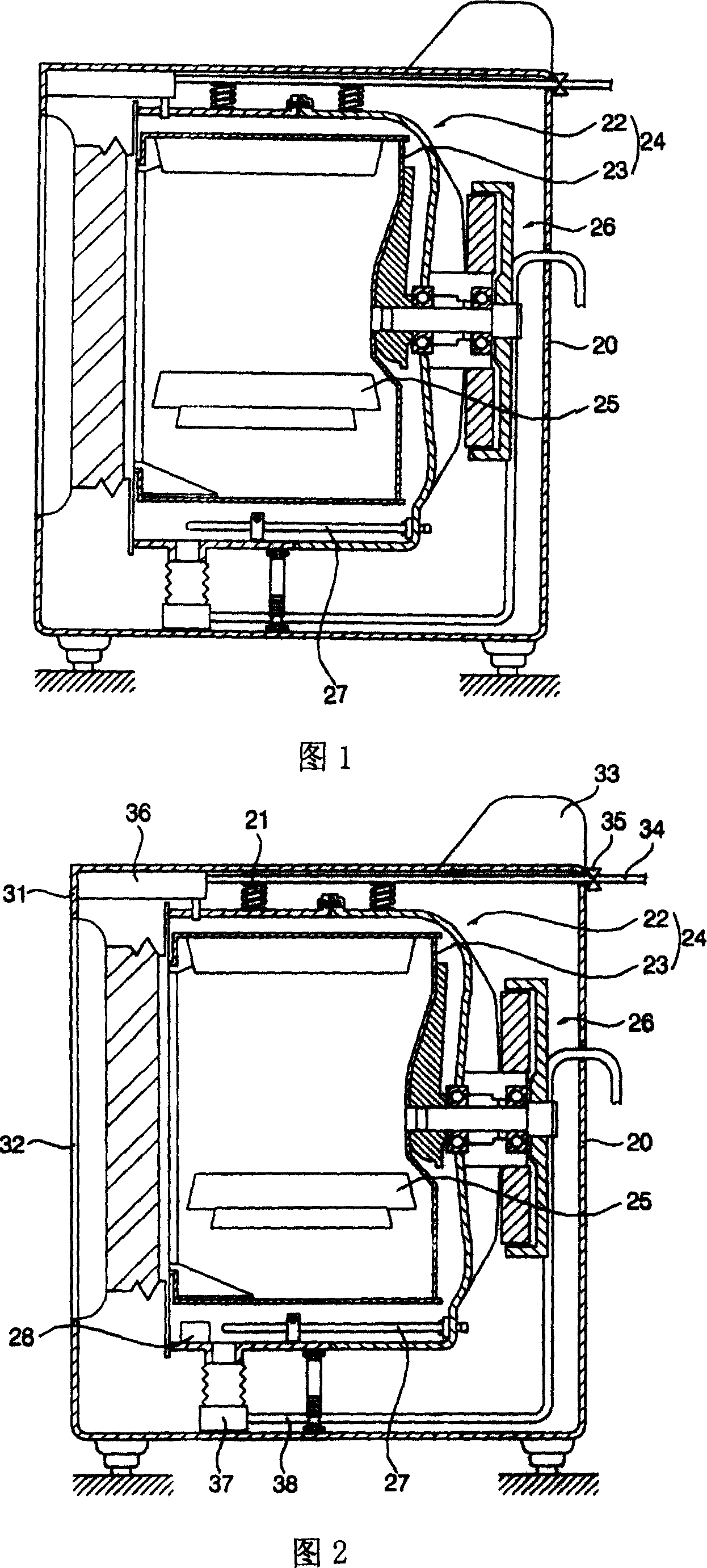

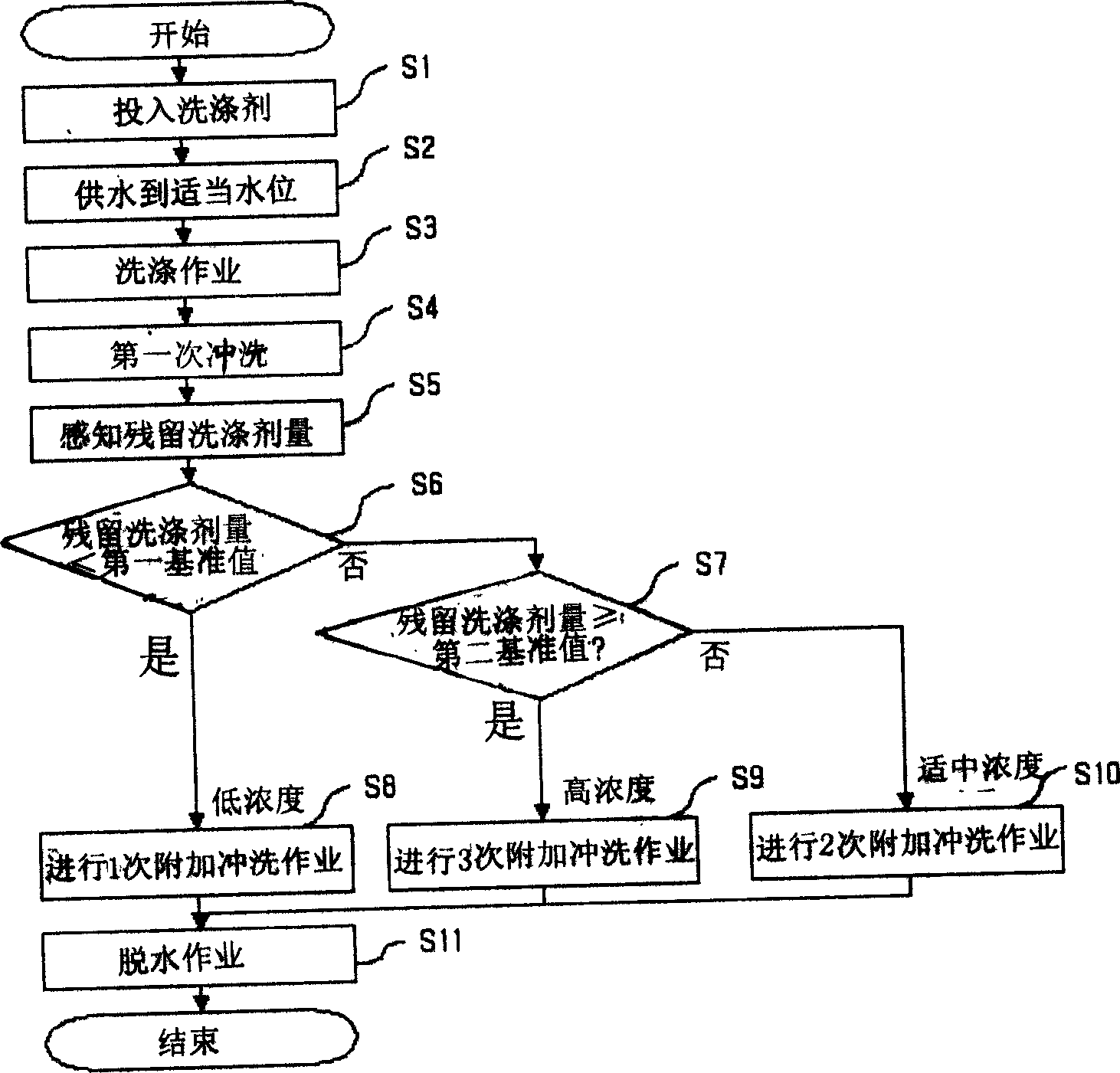

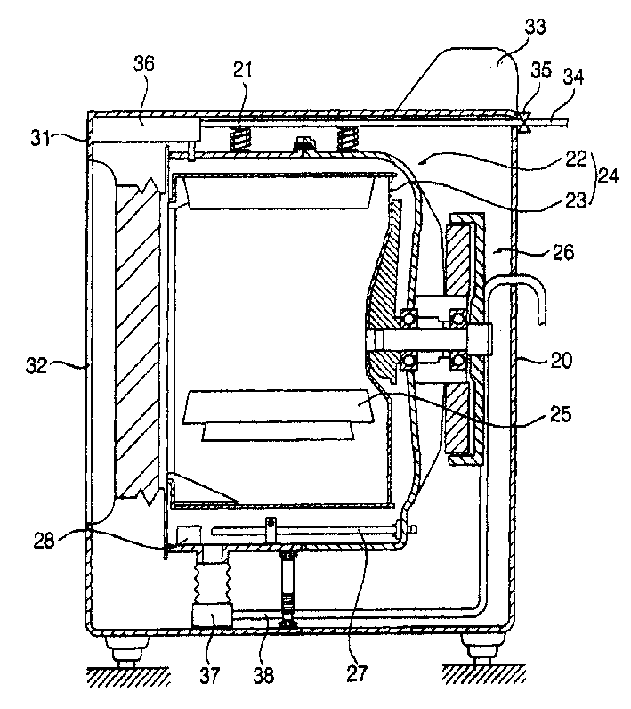

Flushing method for drum washing machine

InactiveCN1566437AAvoid wastingImprove comfortControl devices for washing apparatusTextiles and paperFlushing timeEngineering

The invention provides a flushing method for a cylinder washing machine, which includes the following four steps: 1. supplying water and detergent to the washing groove; 2. flushing for the first time after washing is complete; 3. comparing the sensed detergent residual amount in the washing water to the reference value, then determining additional flushing times; 4. flushing according to the comparative results in step 3. The invention can effectively prevent energy waste, improve flushing effect and comfort feelings of washings, and also can prevent skin diseases caused by residual detergent.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com