Cleaning mechanism for silicon wafers

A technology for cleaning silicon wafers and cleaning tanks, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of unrecoverable factory affairs, excessive acidity of waste lye, and reduction of the concentration of alkaline treatment liquid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

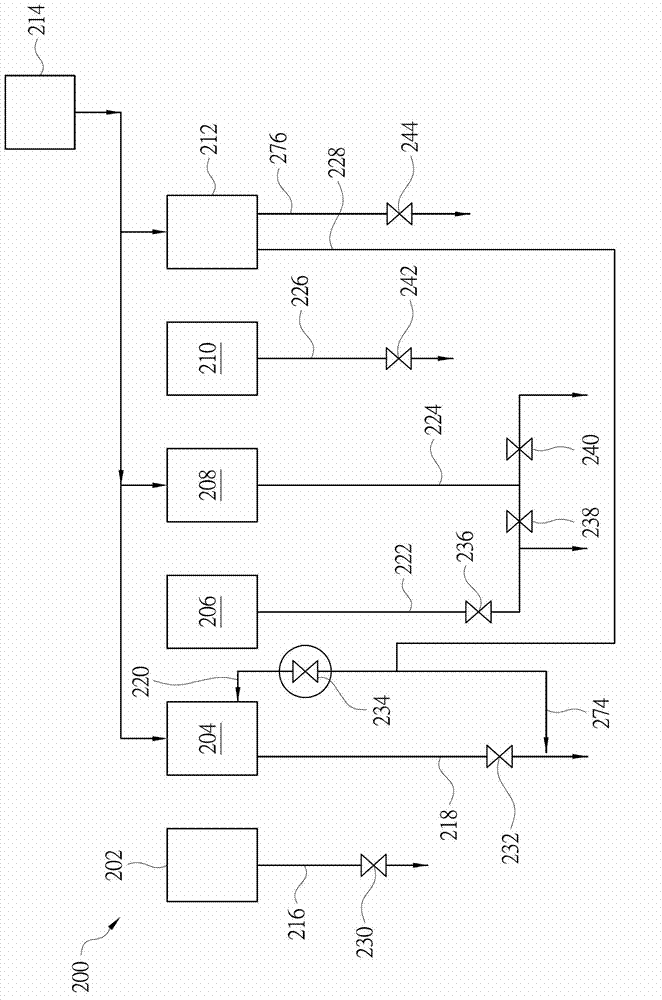

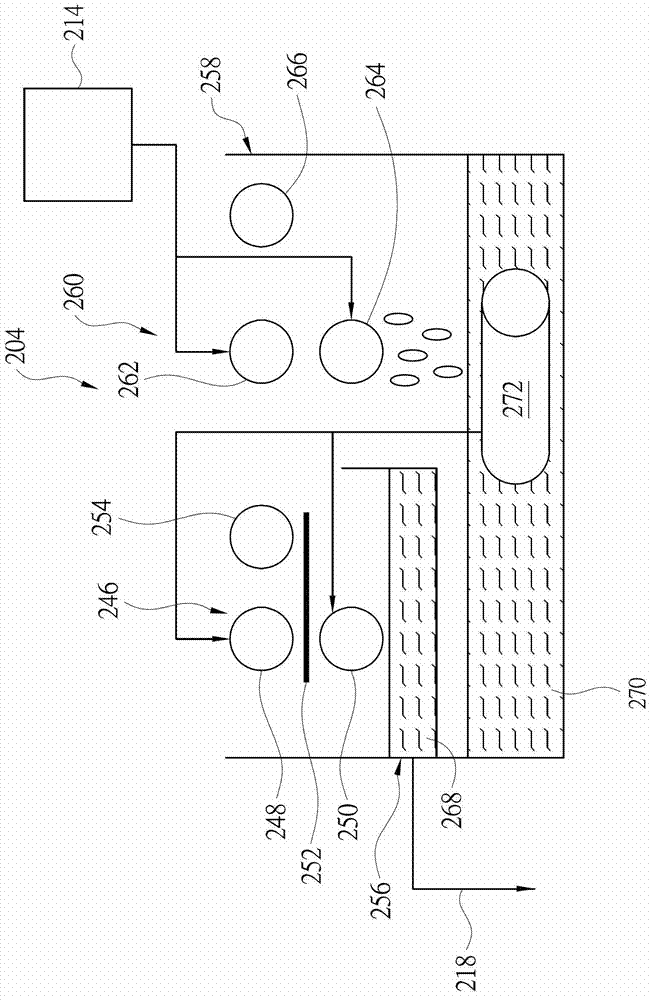

[0020] Please also refer to figure 2 and image 3 , figure 2 and image 3 It is a device schematic diagram of a silicon wafer cleaning mechanism according to an embodiment of the present invention, and a device schematic diagram of a cleaning station and two cleaning tanks of the silicon wafer cleaning mechanism. In this embodiment, the silicon wafer cleaning mechanism 200 mainly includes a first acid tank 202 , an alkali tank 206 , a cleaning station 204 , a drain valve 232 and a pump device 272 . In one embodiment, the first acid tank 202 may be filled with an acid solution such as hydrofluoric acid (HF) to perform wet processing such as etching on the silicon wafer 252 . In some examples, the silicon wafer cleaning mechanism 200 may be further provided with a pipeline 216 and a drain valve 230 according to process requirements, wherein the pipeline 216 communicates with the first acid tank 202 , and the drain valve 230 is disposed on the pipeline 216 . The discharge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com