Anti-blocking blocking-relieving method and apparatus for coke oven flue gas SCR (selective catalytic reduction) denitration catalyst

A denitration catalyst and coke oven flue gas technology, which is applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problems such as the inability of the acoustic sootblower to meet the cleaning requirements, the blockage of the airflow channel, and the decrease of the denitration efficiency. , to achieve the effect of eliminating disassembly and replacement work, preventing blockage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

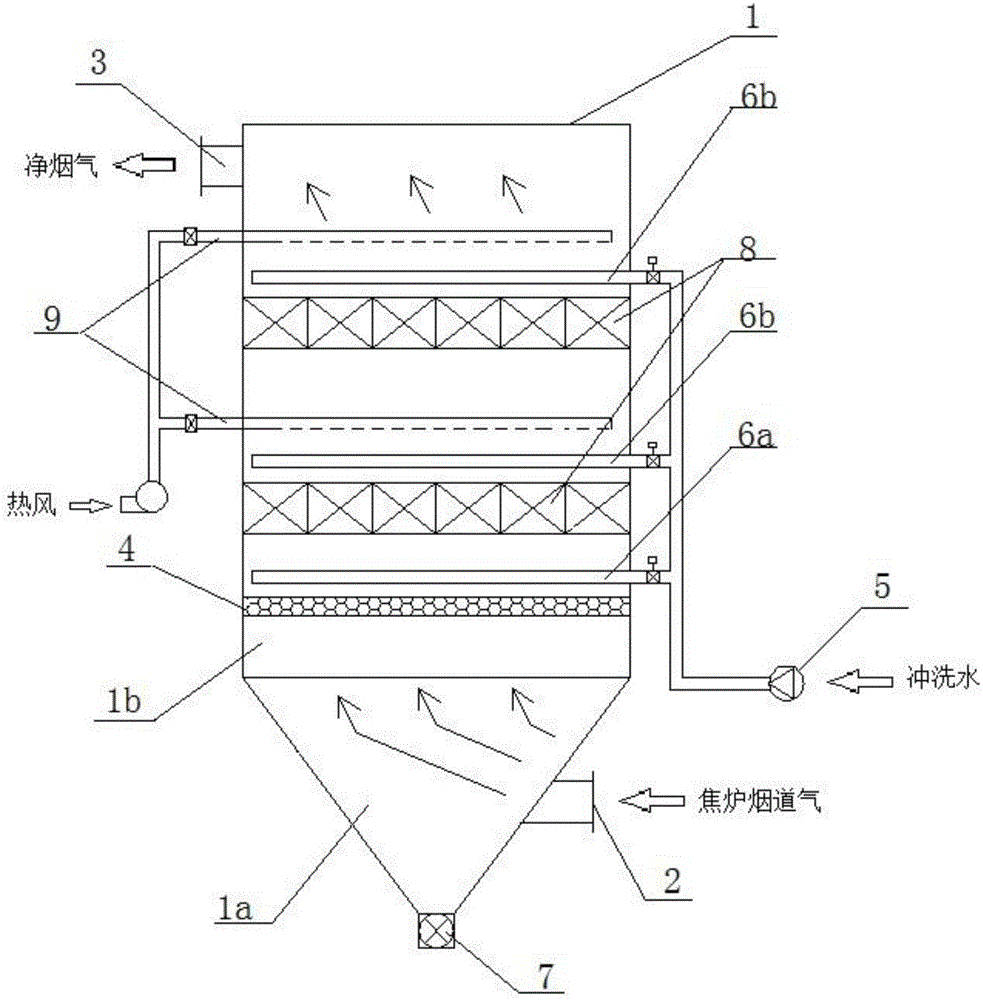

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] The coke oven flue gas SCR denitrification catalyst anti-clogging and cleaning methods include:

[0027] 1) The coke oven flue gas enters from the flue gas inlet 2 at the bottom of the denitration reactor 1, and is first filtered through the metal filter 4, and then denitrated and purified by the multi-layer denitration catalyst 8, and the purified coke oven flue gas is denitrated from the denitration reaction The net flue gas outlet 3 at the top of the device 1 flows out;

[0028] 2) The metal filter screen 4 is arranged in the upper straight cylinder 1b of the denitrification reactor, below the denitrification catalyst 8, and is used to intercept ammonia salt and sticky particles in the coke oven flue gas to prevent the denitrification catalyst 8 from clogging; above the metal filter screen 4 A flushing pipe 6a is provided for flushing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com