Automatic washing system for coal conveying viaduct

An automatic flushing and trestle technology, which is applied to conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of complex construction, high cost, limited flushing effect, etc., to prevent dead corners, reduce water consumption, and avoid repeated flushing. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

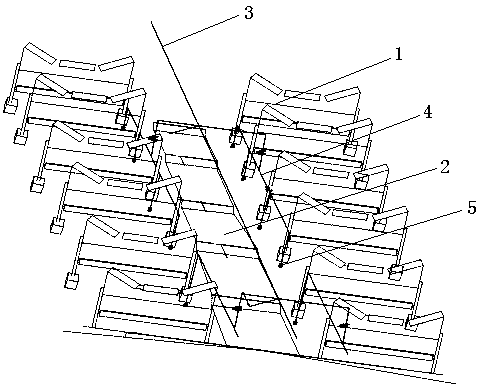

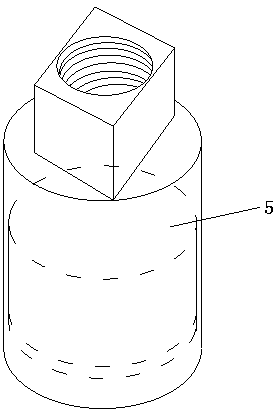

[0025] see figure 1 and 3 , an automatic flushing system for a coal trestle, comprising a double-belt unit 1, a belt conveyor corridor 2 is arranged in the middle of the double-belt unit 1, a double-belt conveyor main pipe 3 is installed above the belt conveyor corridor 2, and a double-belt conveyor main pipe 3 is installed on the top of the belt conveyor corridor 2. Both sides of the pipe 3 are connected with two groups of branch pipes 4, and the ends of the branch pipes 4 are equipped with a water nozzle 5 through a quick connector female head. The opening angle direction of the water nozzle 5 corresponds to the leg of the double belt unit 1 perpendicular to the ground.

[0026] Find through the research of the present invention, if main pipe 3, branch pipe 4 inner diameters are too large then easily cause the waste of water source, main pipe 3, branch pipe 4 inner diameters are too small then flushing efficiency is low, therefore, the inner diameter of double belt conveyor ...

Embodiment 2

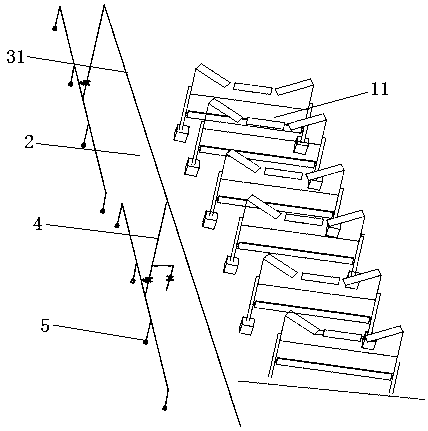

[0032] see figure 2 and 3 , an automatic flushing system for a coal trestle, comprising a single-belt unit 11, one side of the single-belt unit 11 is provided with a belt conveyor gallery 2, and a single-belt conveyor main pipe 31 is installed above the side wall of the belt conveyor gallery 2; The upper connection branch pipe 4 of belt conveyor main pipe 31, the end of branch pipe 4 is equipped with water nozzle 5 by quick connector female head, and the opening angle direction of water nozzle 5 is corresponding to the support leg perpendicular to the ground of single belt unit 1. Also be provided with electromagnetic valve on branch pipe 4, electromagnetic valve is interlocked with belt motor, is convenient to automatic control, saves water. A shut-off valve is also arranged on the main pipe 31, and the shut-off valve is used to control the size of the water flow. Further preferably, the branch pipe 4 is vertically connected to the main pipe 31, such a design increases the...

Embodiment 2

[0033] In embodiment 2, parameters such as the inner diameter of the main pipe and the branch pipe, the height of the main pipe from the ground, the distance between it and the double-belt unit, the width and opening angle of the nozzle of the water nozzle adopt the same preferred settings as in embodiment 1.

[0034] The coal conveying trestle automatic flushing system, from the head of the single-belt unit 11 to the first flushing through the water nozzle 5, can clean the aisle in the middle of the belt conveyor according to the order from the head to the tail, and can clean the belt conveyor. Sweep all the dead corners at the root of the outrigger to prevent dead corners from remaining, avoid repeated washing, and waste resources.

[0035] To sum up: the automatic flushing system of the coal conveying trestle sweeps all the dead corners of the legs of the belt conveyor through the water nozzle 5, reduces the work intensity of the workers on site, and avoids the safety hazard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com