Fischer-Tropsch wax and catalyst filtering and back-flushing method for Fischer-Tropsch synthetic slurry bed reactor

A Fischer-Tropsch synthesis, slurry bed technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems such as how to realize unknown, unbackwashed filter implementation method description, etc., to achieve backwash frequency The effect of less, smooth and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

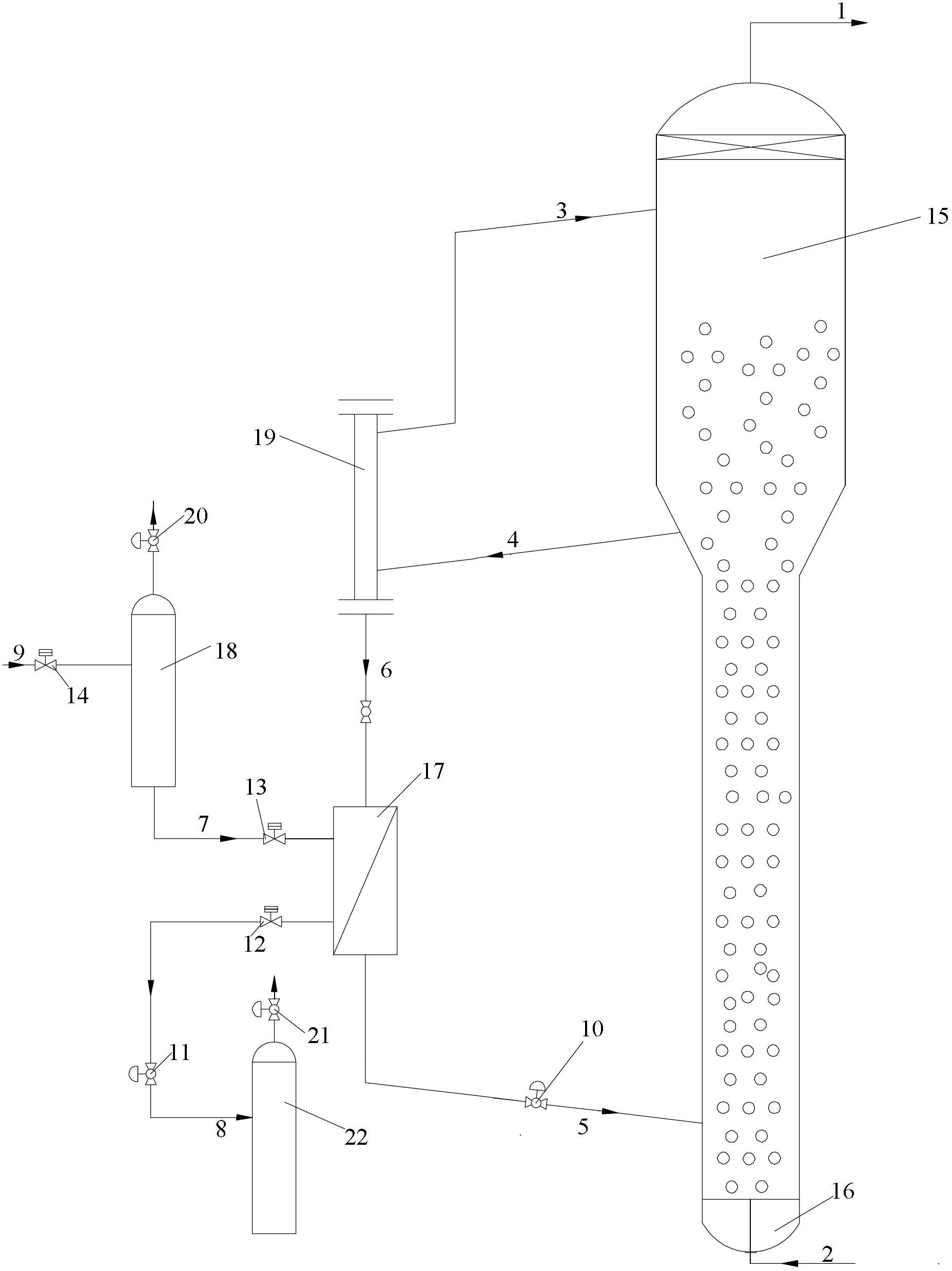

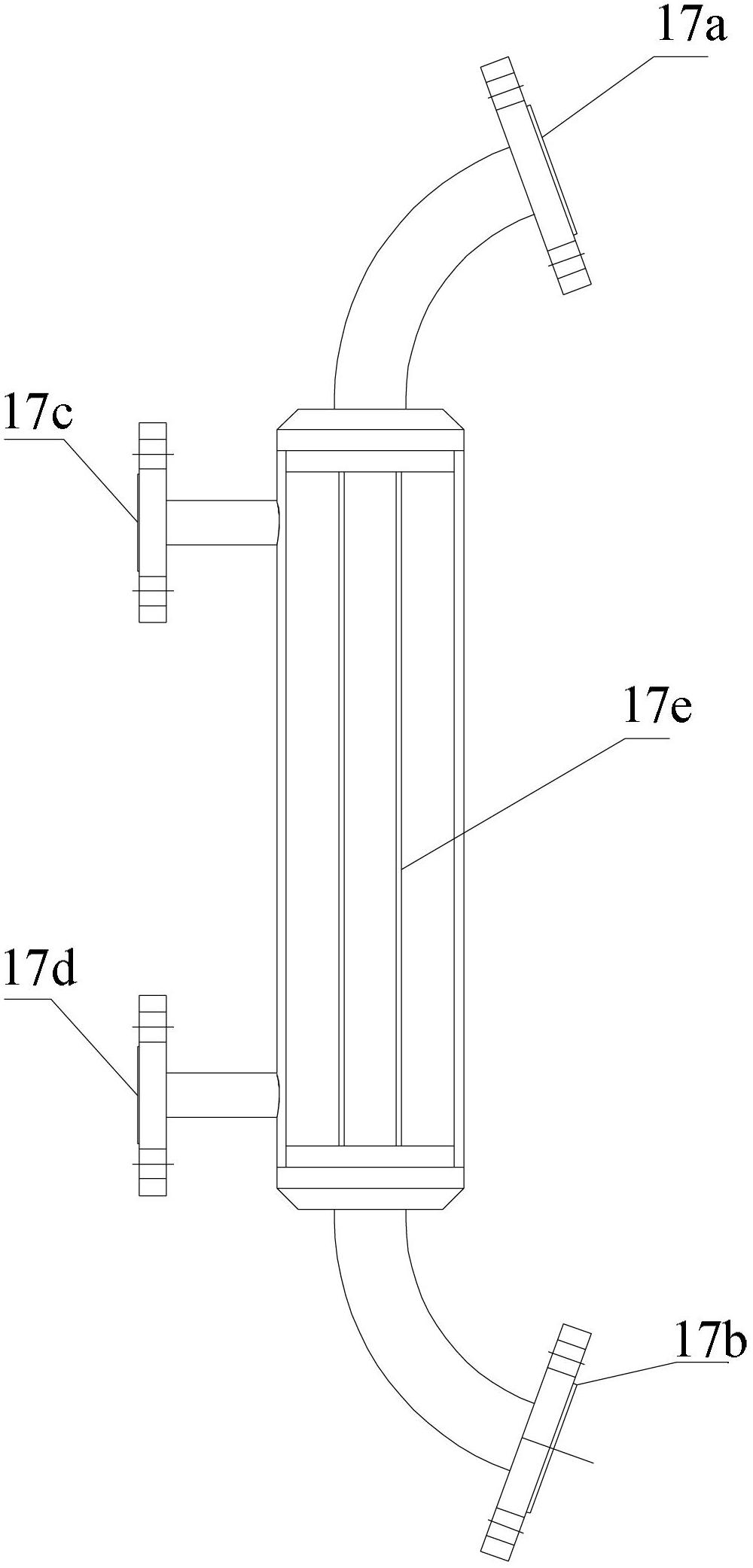

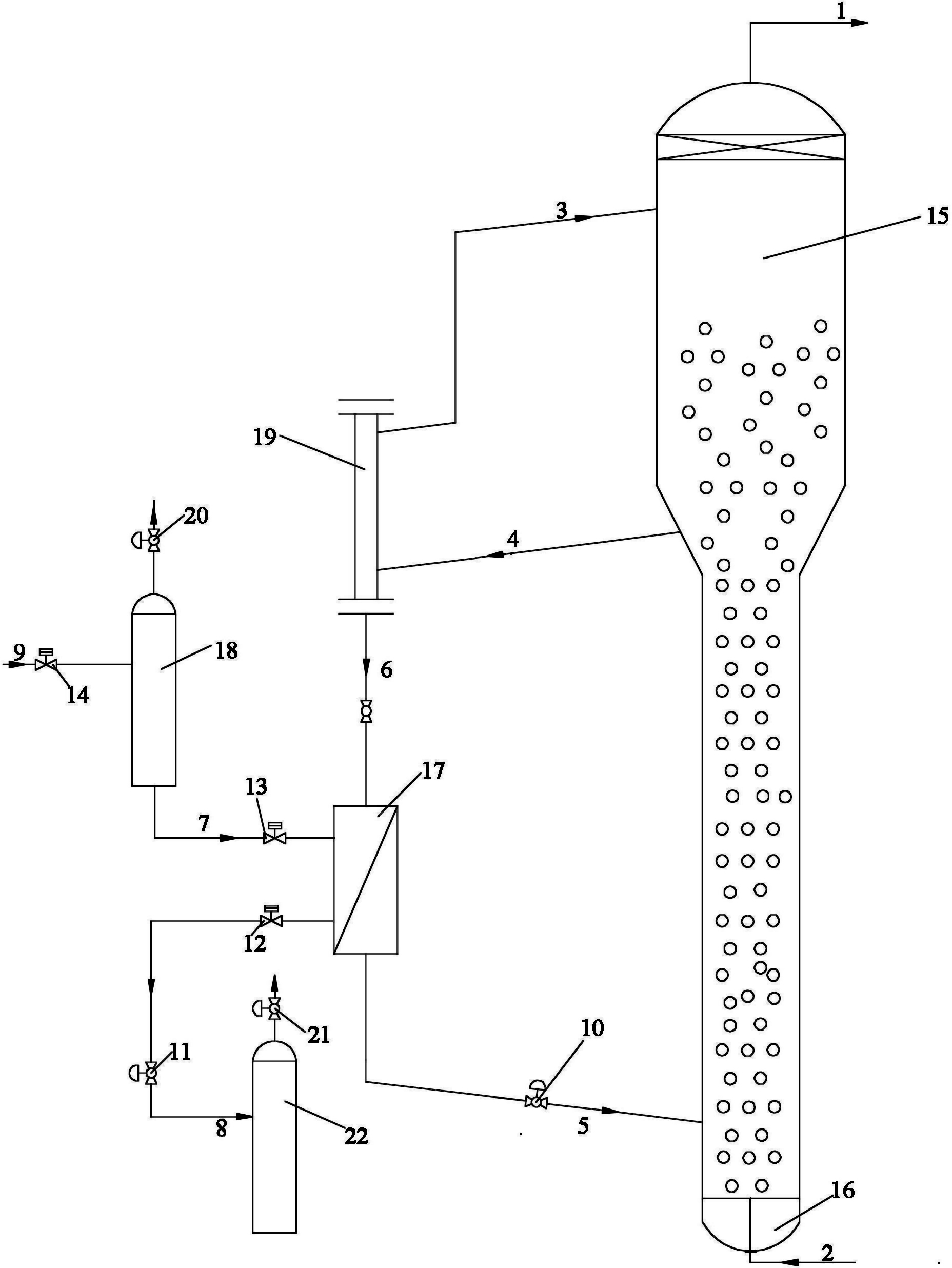

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] In the Fischer-Tropsch synthesis slurry bed reactor filtration system, the slurry buffer tank with gas-liquid separation function and the external and internal cross-flow filter of the wax vessel and the slurry bed reactor are arranged according to the external loop flow reactor, between them The slurry stream forms an external circulation, or it is arranged in the internal cross-flow circulation pipe inside the slurry bed reactor. The slurry inside the internal cross-flow circulation pipe and the slurry in the reactor form an internal circulation. According to the working principle of the circulation reactor, The flow density difference between the flow in the reactor and the flow outside the reactor or in the loop pipe in the reactor and the upward drag force of the synthesis gas in the reactor are used as the driving force to form an outer circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com