High-pressure water online flushing device for condenser

A flushing device and condenser technology, which is applied in the direction of flushing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve problems affecting the heat exchange capacity of the condenser, low recovery rate of rubber balls, and corrosion of the condenser. To achieve the effect of ensuring sustainable operation, long service life of equipment and reducing flushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

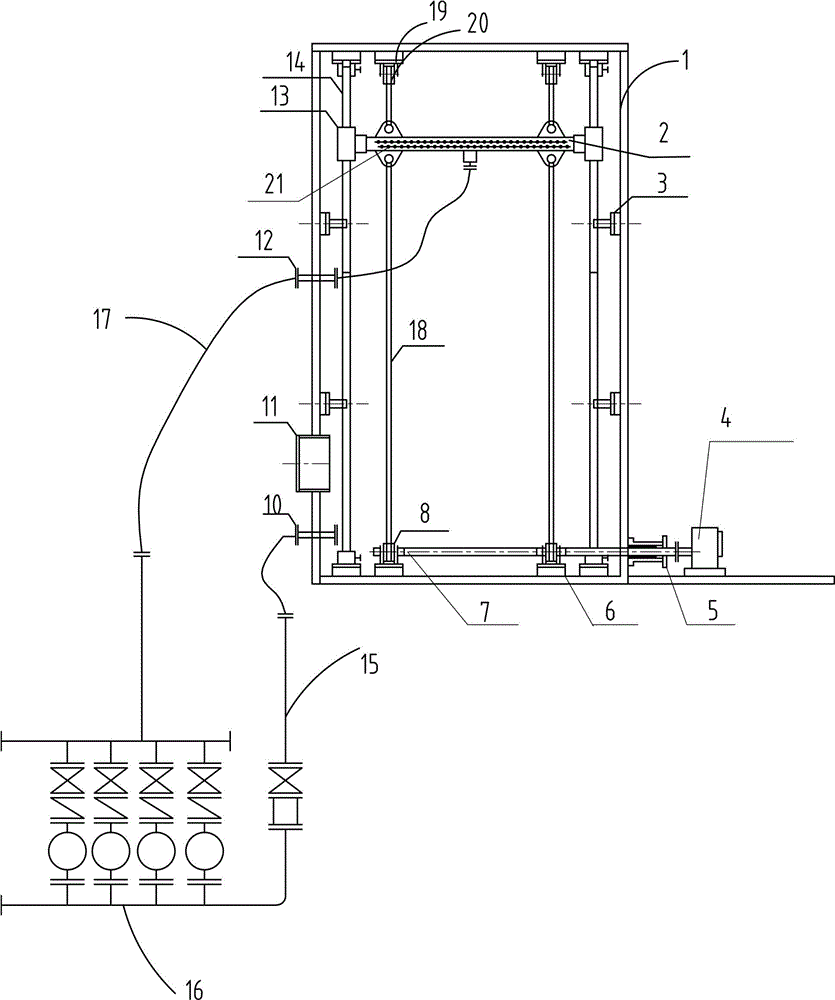

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] See attached figure 1 , the present embodiment includes a transmission system and a high-pressure water flushing device; the high-pressure water flushing device includes at least one set of high-pressure water pumps 16, a water intake pipe 15 arranged between the high-pressure water pumps 16 and the condenser 1, and a water inlet pipe 17 The water spray pipe 2 communicated with the high-pressure water pump group 16 and the side-by-side high-precision nozzles 21 arranged on the water spray pipe 2 . The water intake pipe 15 and the water inlet pipe 17 all adopt high-pressure water pipes.

[0020] The transmission system includes two vertical guide rails 14 arranged in parallel at a certain distance and positioned on the condenser 1, and a bushing 13 slidably arranged on each vertical guide rail 14. The water spray pipe 2. Both ends are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com