Patents

Literature

41results about How to "Avoid possession" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

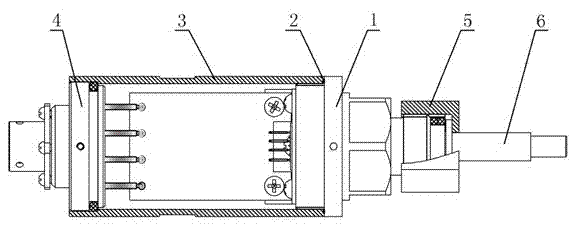

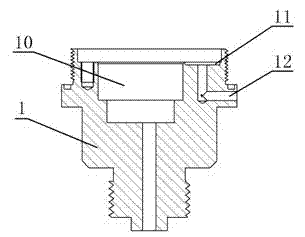

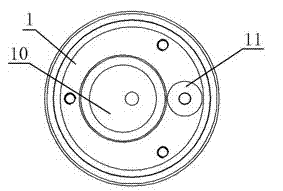

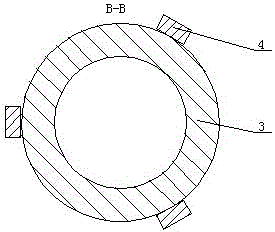

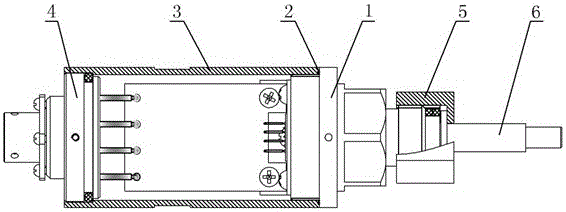

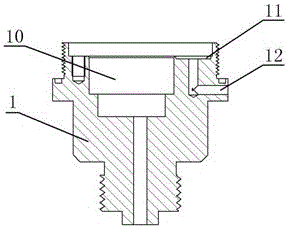

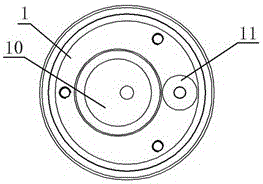

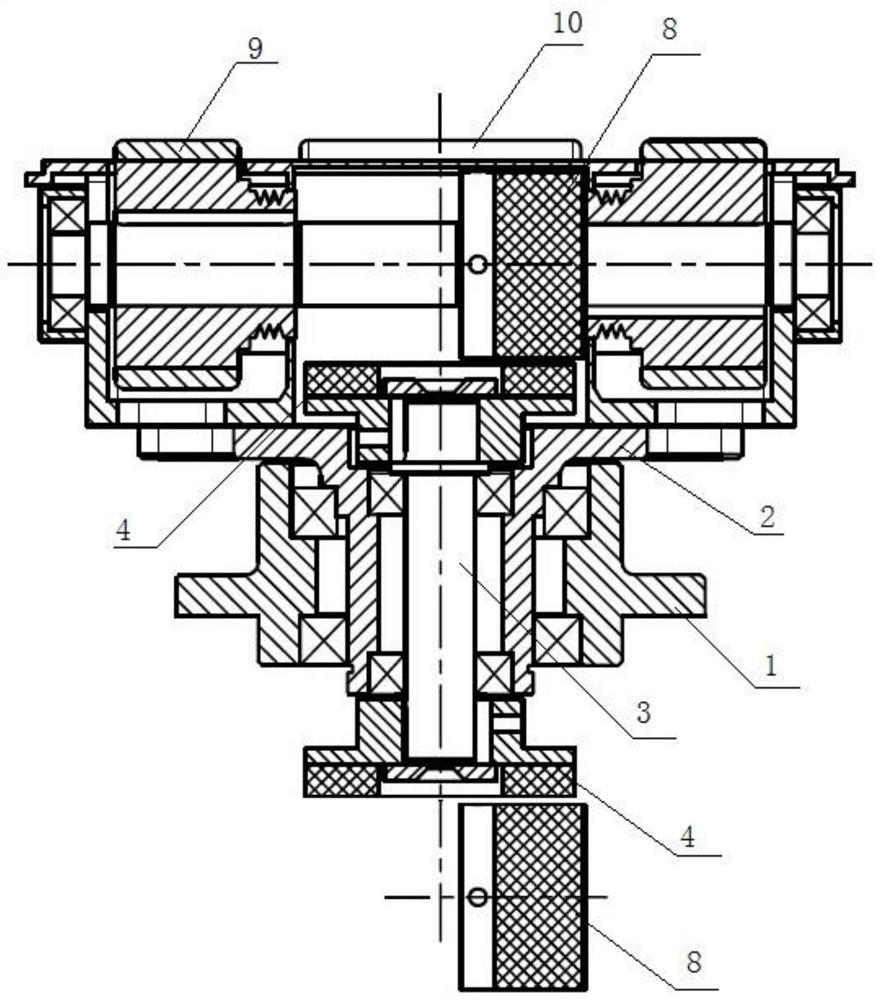

Pressure transmitter with waterproof and ventilating membrane

ActiveCN103207044AAvoid scratchesAvoid accessFluid pressure measurement by electric/magnetic elementsEngineeringMechanical engineering

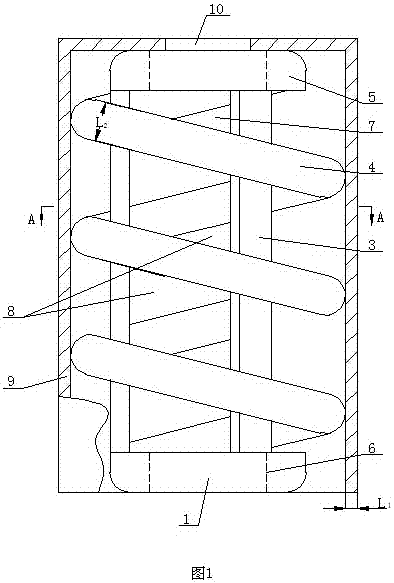

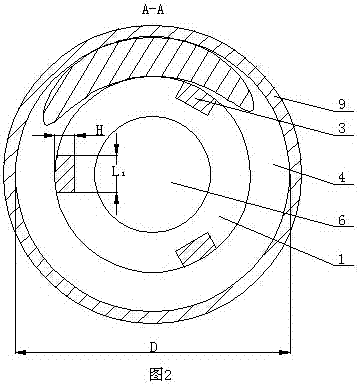

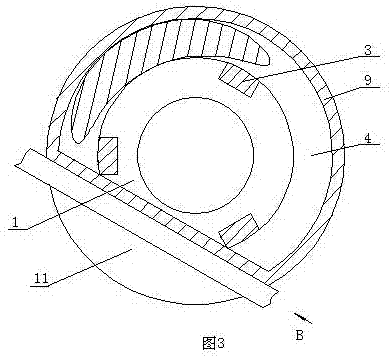

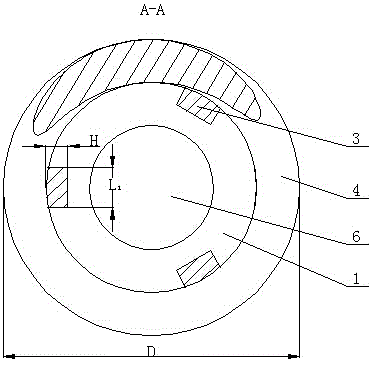

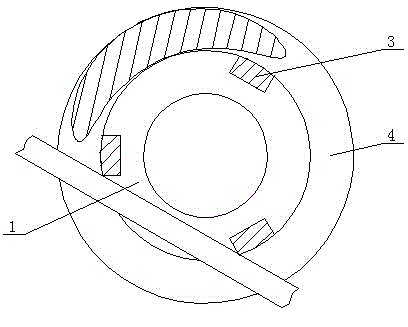

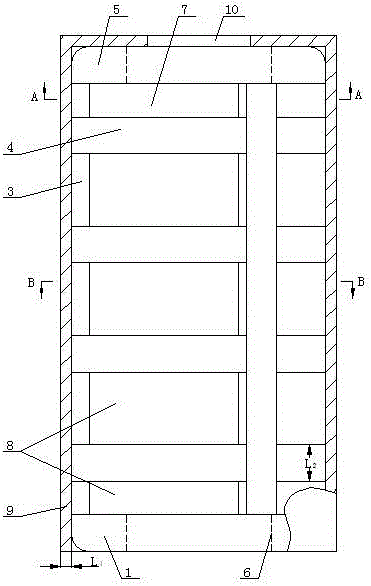

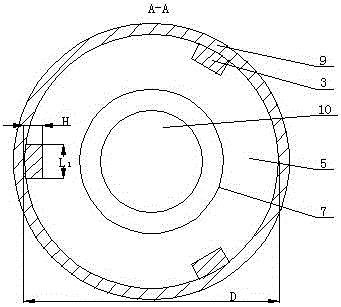

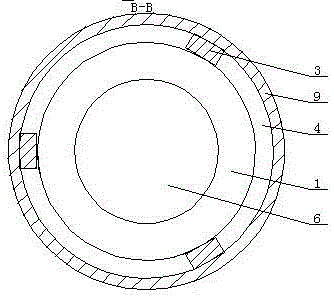

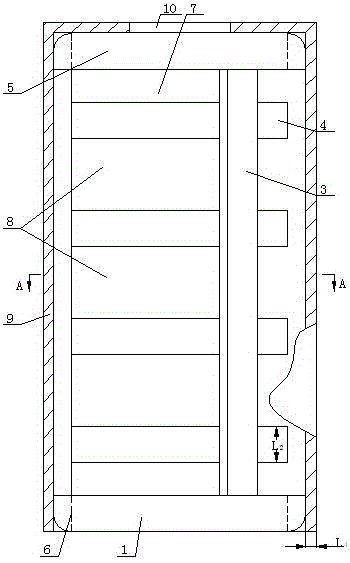

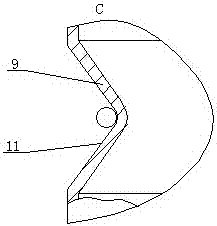

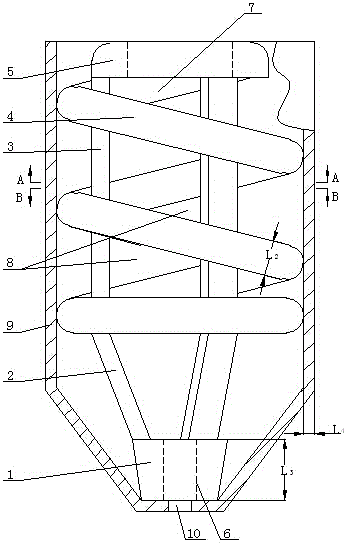

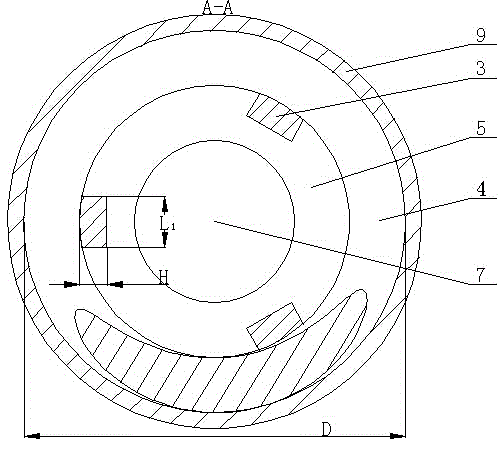

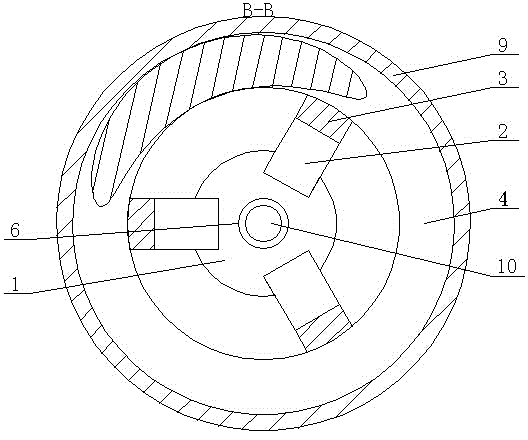

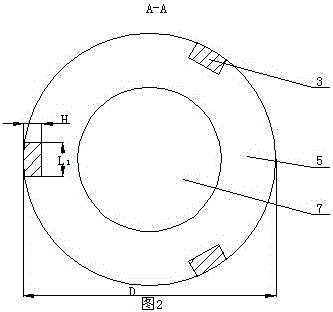

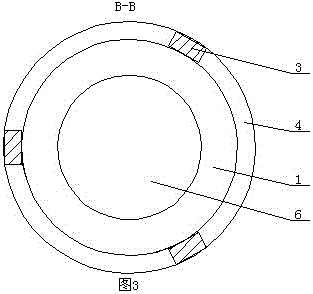

The invention discloses a pressure transmitter with a waterproof and ventilating membrane. A circuit board of the transmitter, a sensing core body and the like are arranged in a casing, the front end and the rear end of the casing are connected with a tail assembly and a head assembly, an eccentric cavity is arranged in the end face of the head assembly in the casing, a pipeline in the head assembly is communicated with the bottom of the cavity, the outer part of the head assembly is connected with an air hose connector, an L-shaped ventilating hole is arranged in the head assembly, one end of the ventilating hole is arranged on the lateral wall of the head assembly, the other end of the ventilating hole is arranged on the end face of the head assembly in the casing, a groove is arranged on the periphery of the opening of the ventilating hole, the opening is arranged at the bottom of the groove, a pressing sheet is fixed in the groove, the waterproof and ventilating membrane is fixed on a central hole portion of the pressing sheet, air inside and outside can pass through the L-shaped ventilating hole and the waterproof and ventilating membrane, and impurities of dust, water, oil and the like can be blocked.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

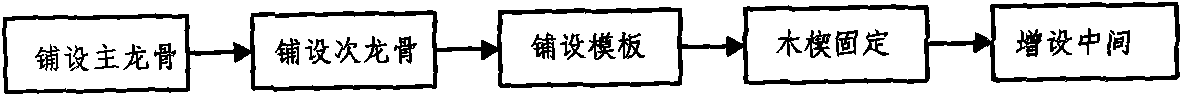

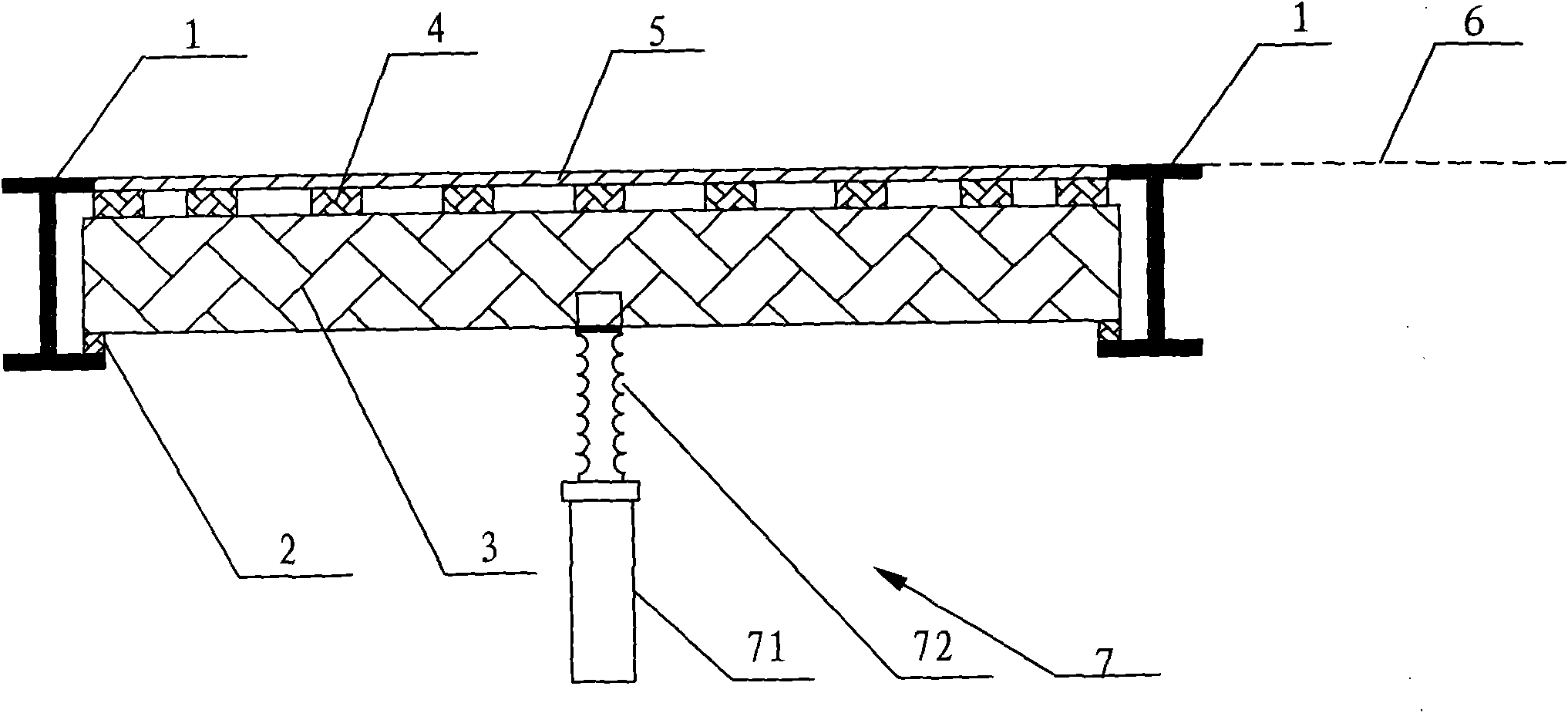

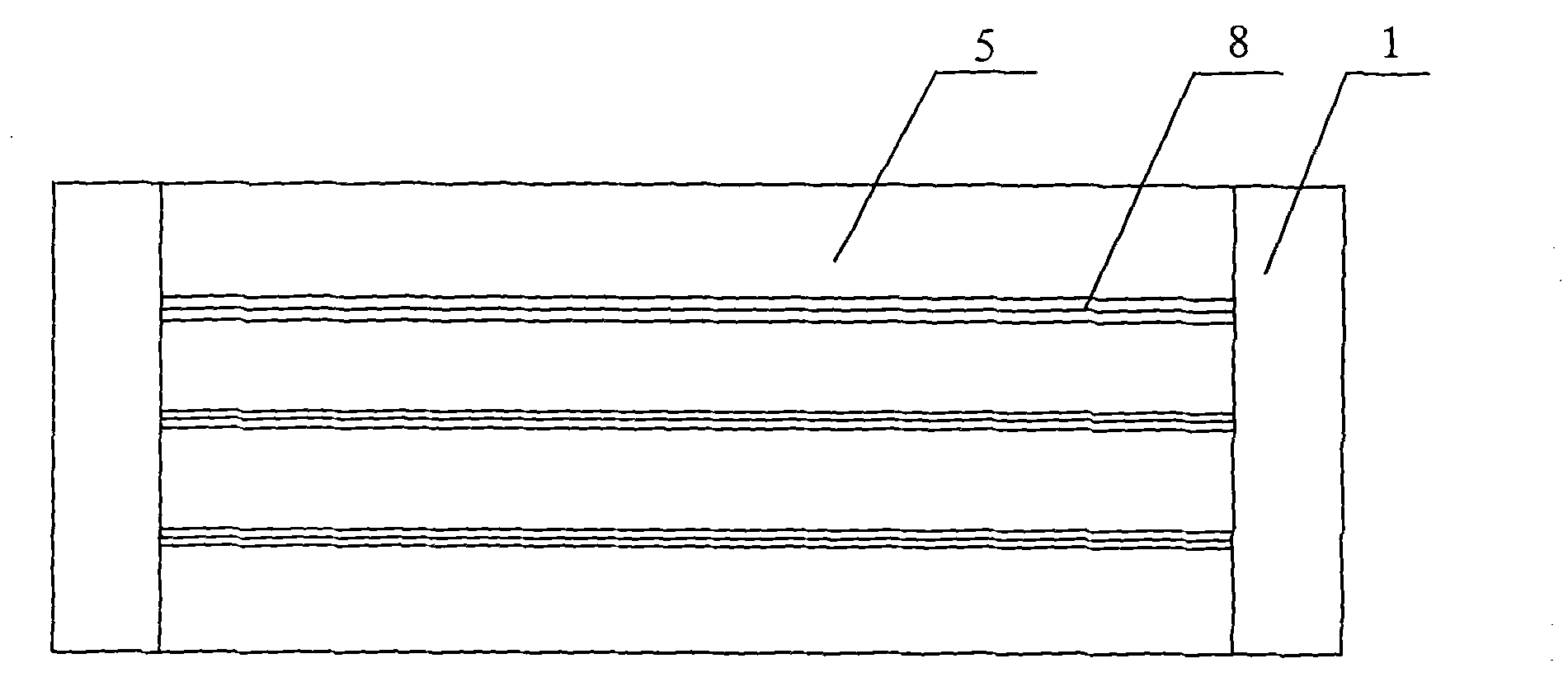

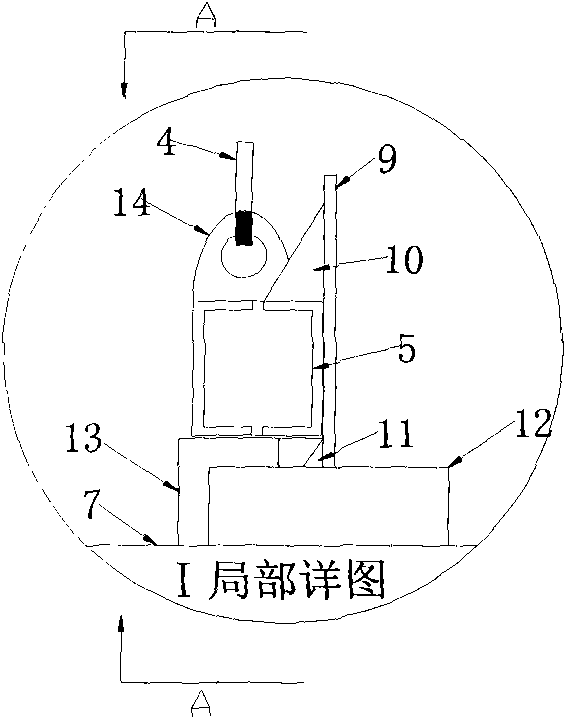

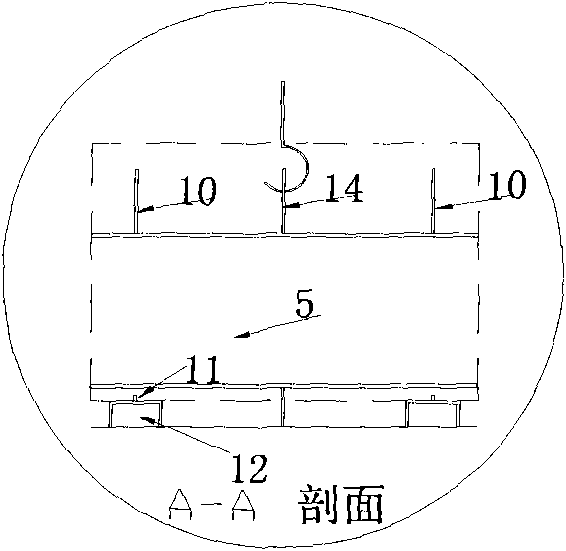

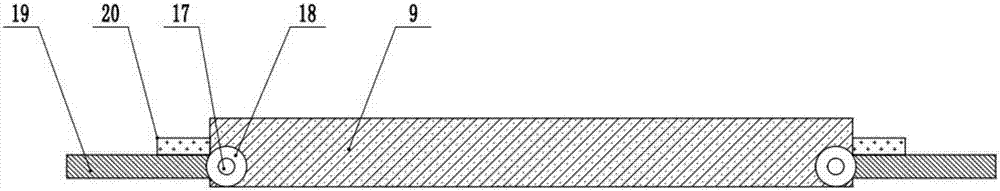

Construction method of building superstructure in high-rise steel-concrete mixed structure with few supporting formworks

InactiveCN102140841AReduce usageFast constructionForms/shuttering/falseworksBuilding material handlingFloor slabKeel

The invention discloses a construction method of a building superstructure in a high-rise steel-concrete mixed structure with few supporting formworks. The construction method is characterized by comprising the following steps of: lifting an H-shaped steel beam; then selecting appropriate wooden wedges according to the bottom elevation of a floor and the height of the H-shaped steel beam, and paving a key keel on the wedge; placing sub-keels on the surface of the key keel along a direction perpendicular to the key keel; paving bamboo glued plates on the sub-keels along plate joints in the arrangement direction of the sub-keels, and fixing by using the wooden wedges, wherein the elevation of the bamboo glued plates keeps consistent to the upper elevation of the H-shaped steel beam; before concrete is poured, arranging a middle supporting part by adopting a steel pipe and a screw, and measuring the elevation of the bamboo glued plates by using a gradienter in the supporting process; and after the elevation meets the requirements, arranging a middle supporting part used for reinforcing and fixing the key keel and the bamboo glued plates on the middle position of the bottom of the key keel, and then pouring the concrete. Compared with a full-scaffold formwork supporting system, the invention has the advantages of reducing the usage quantity of steel pipe scaffolds, accelerating the construction speed, reducing the consumption of revolving materials, saving the energy and meeting the requirements on the society for low-carbon economy, ensuring the construction quality of the concrete and obtaining good economic benefits and social benefits.

Owner:QINGDAO NO 1 CONSTR GRP +1

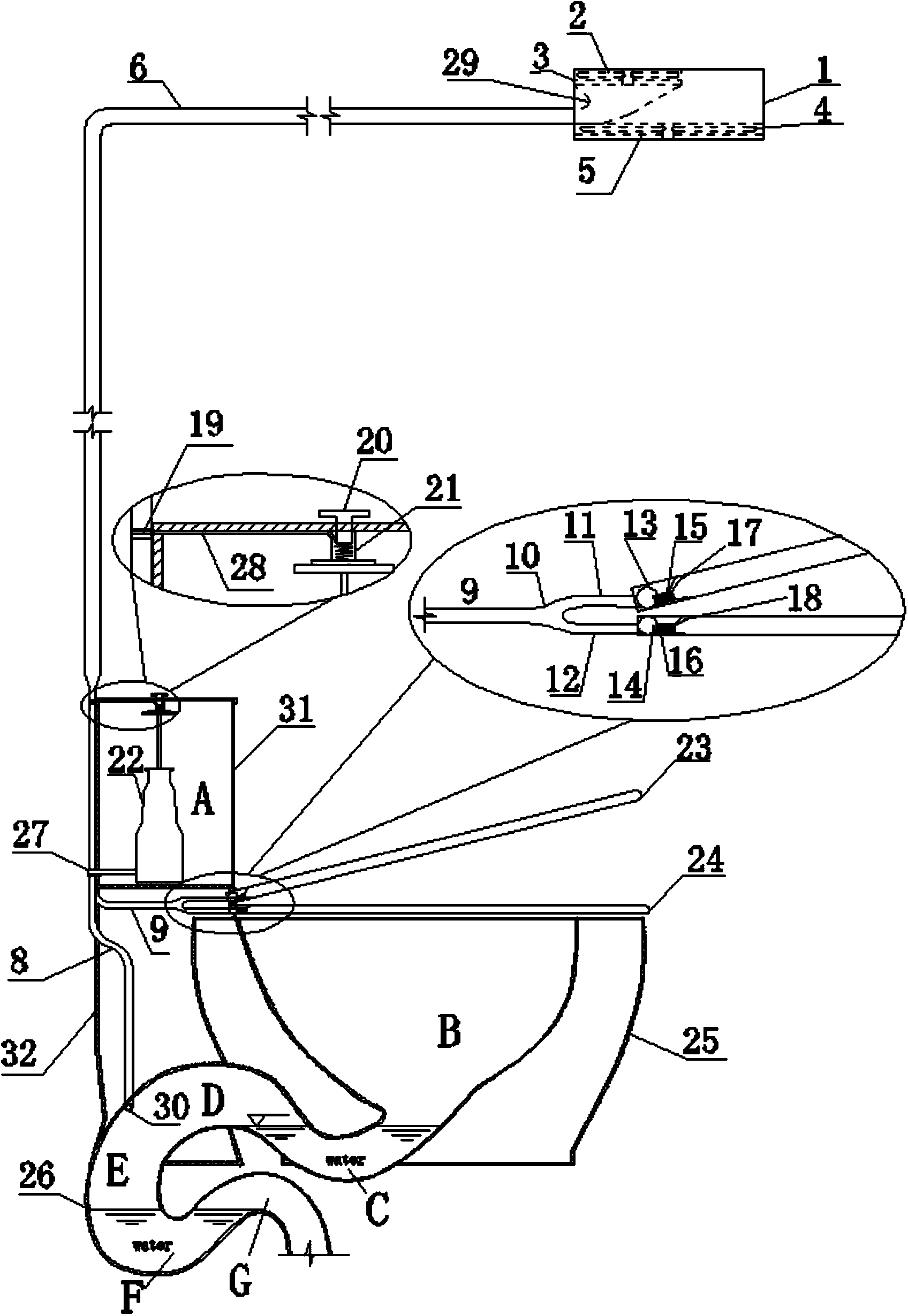

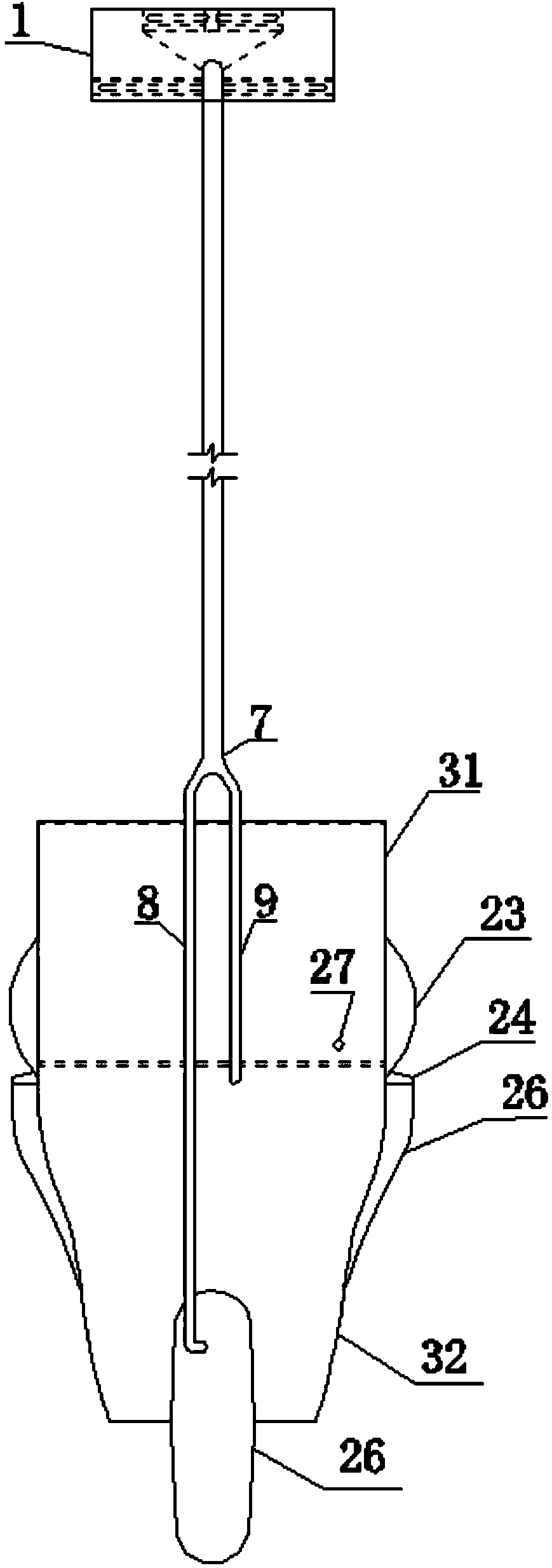

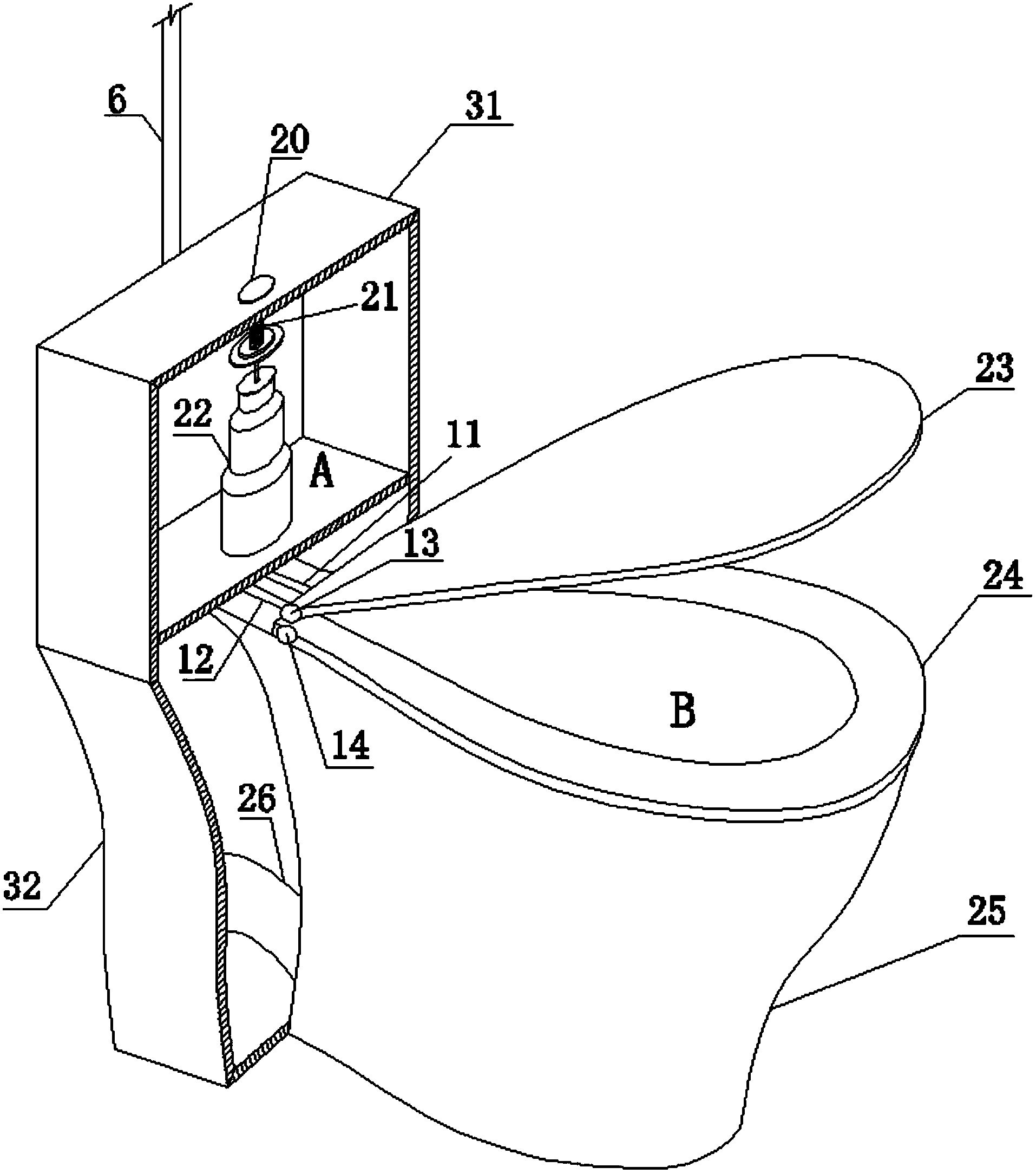

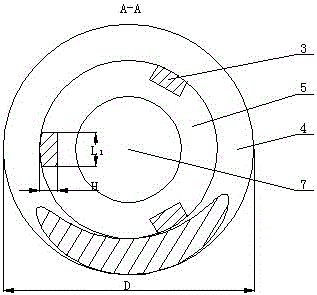

Closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing

InactiveCN103615039ADoes not increase the use of bathroom spaceAchieve exhaust and deodorizationFlushing devicesBathroom coversDaily livingVacuum assisted

The invention provides a closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing, and belongs to the technical field of daily living articles. The closestool is improved on the basis of a traditional closestool so that the disadvantages and the defects in the prior art in terms of the closestool deodorization technology and the vacuum-assisted flushing can be overcome, and a double-layer air exhaust fan serves as a power source for an air exhaust deodorization system of the whole closestool and a vacuum-assisted flushing system of the whole closestool. The air exhaust deodorization technology which saves energy and is environmentally friendly is provided for air exhaust deodorization of the closestool. Flushing is assisted by vacuum so that water resources can be saved. An existing air exhaust device in a toilet is improved and combined with the closestool to form a set of system, namely, the closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing. The air exhaust deodorization effect and the vacuum-assisted flushing effect can be achieved while no excessive devices are additionally arranged on the closestool to occupy space in the toilet. The closestool is improved so that the closestool can have the air exhaust deodorization function and the vacuum-assisted flushing function, odorous gas can not be left after people relieve the bowels due to the air exhaust deodorization function, and water resources are saved due to the vacuum-assisted flushing function.

Owner:BEIJING UNIV OF TECH

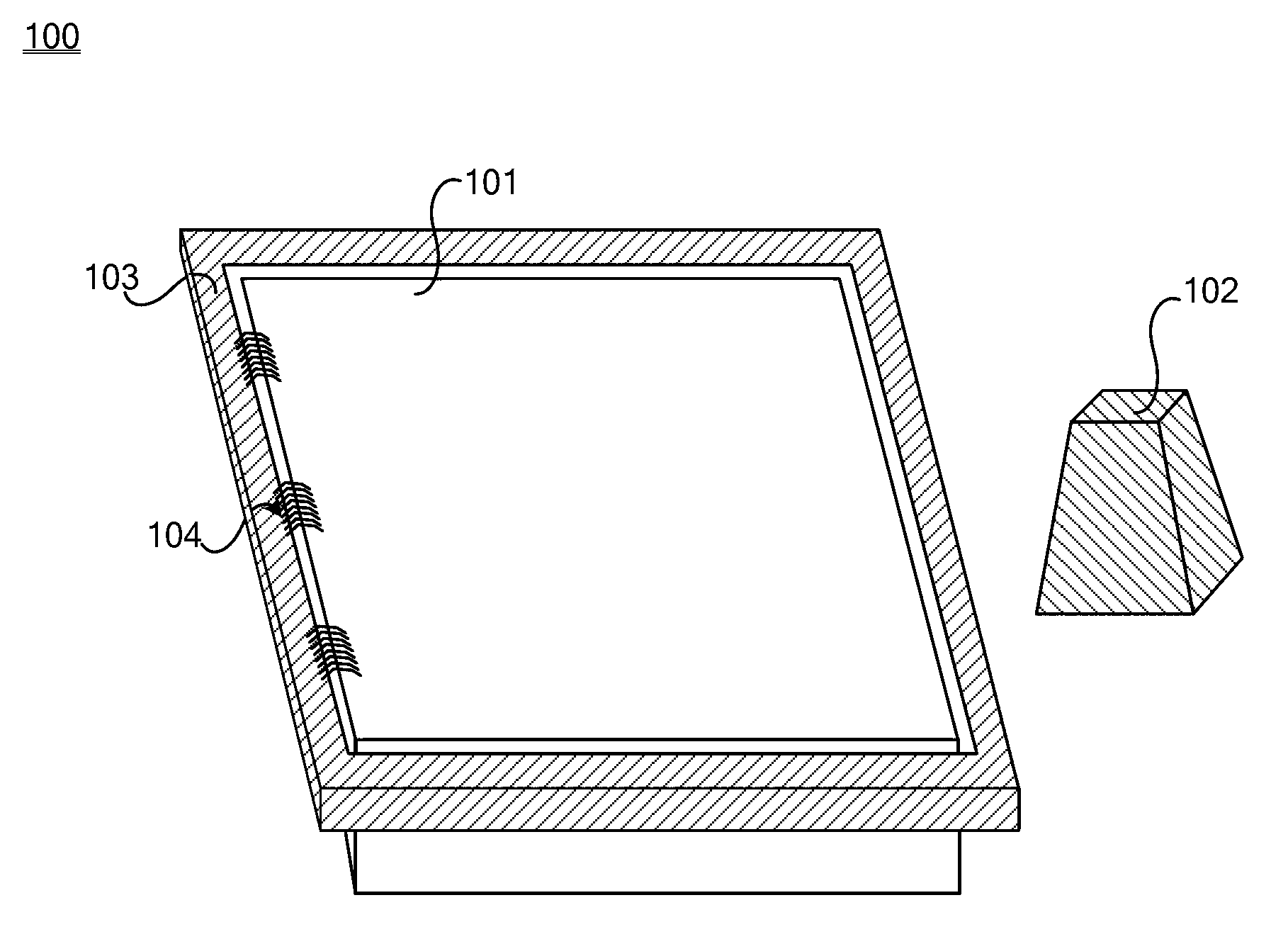

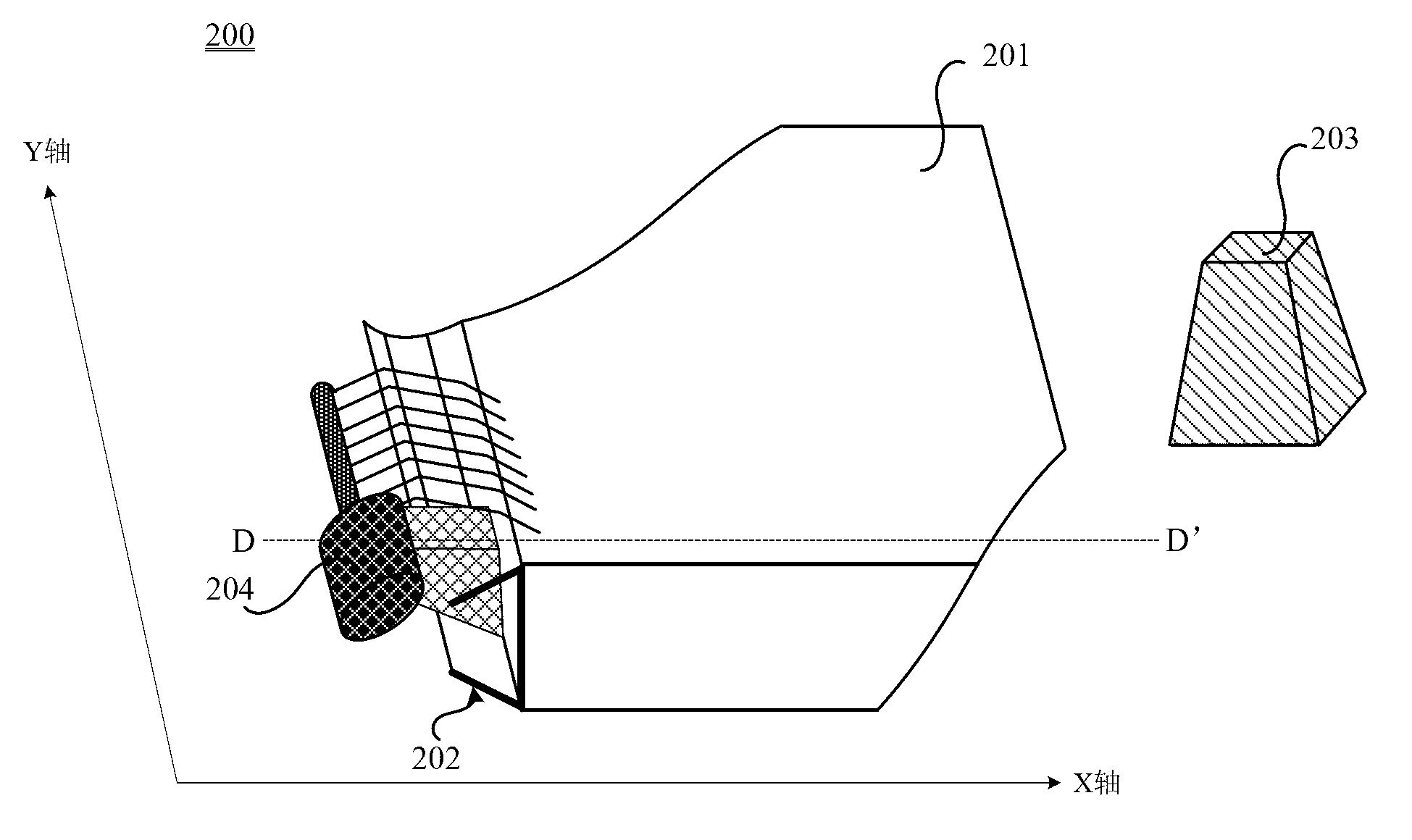

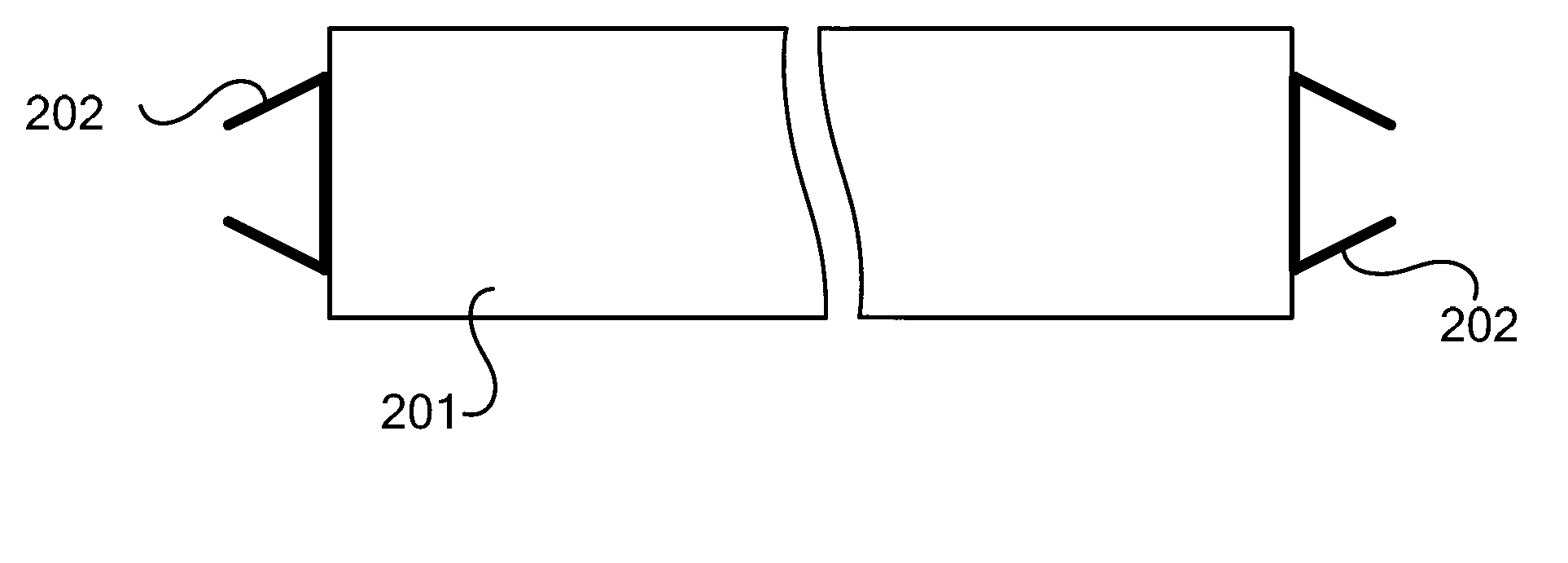

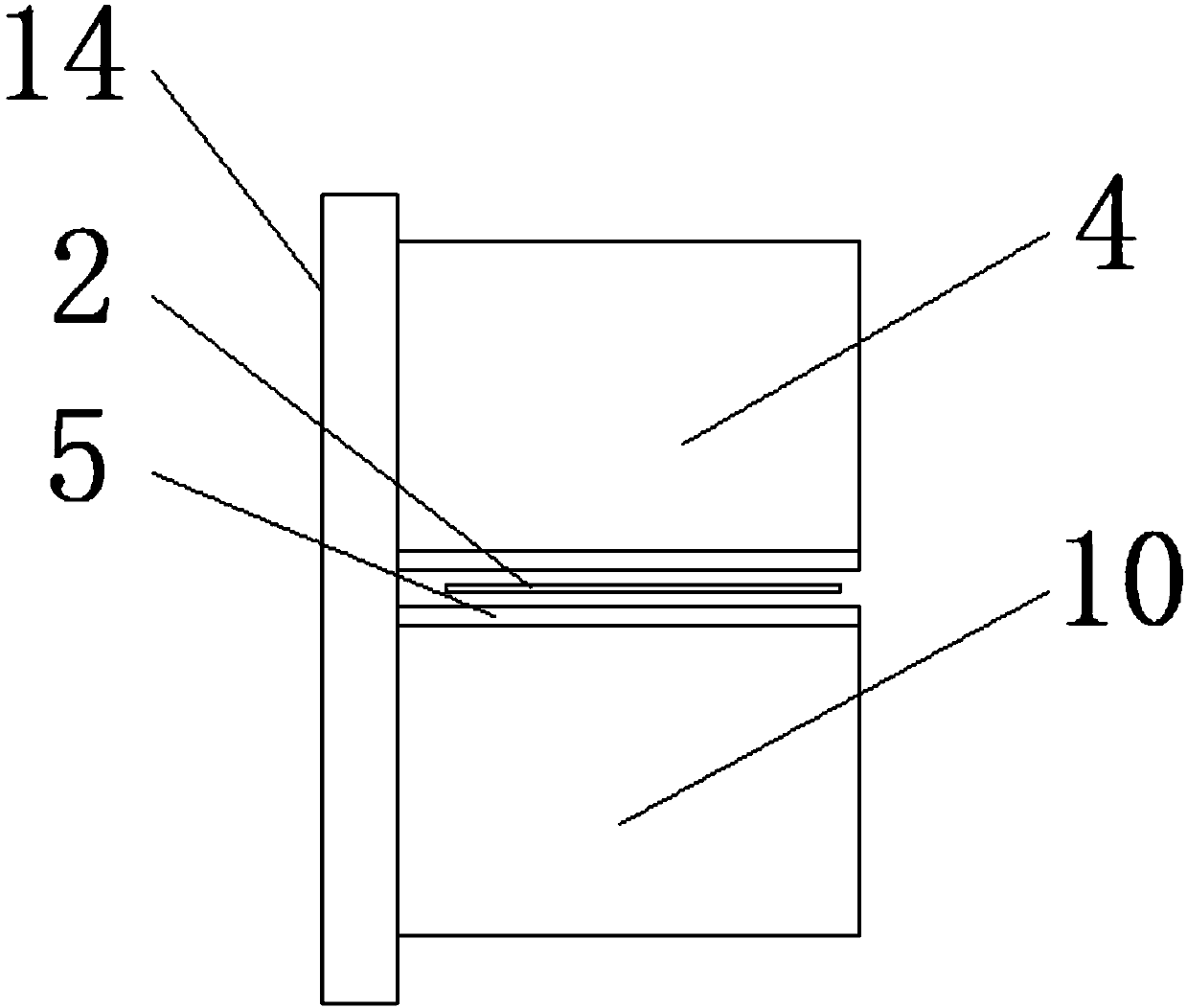

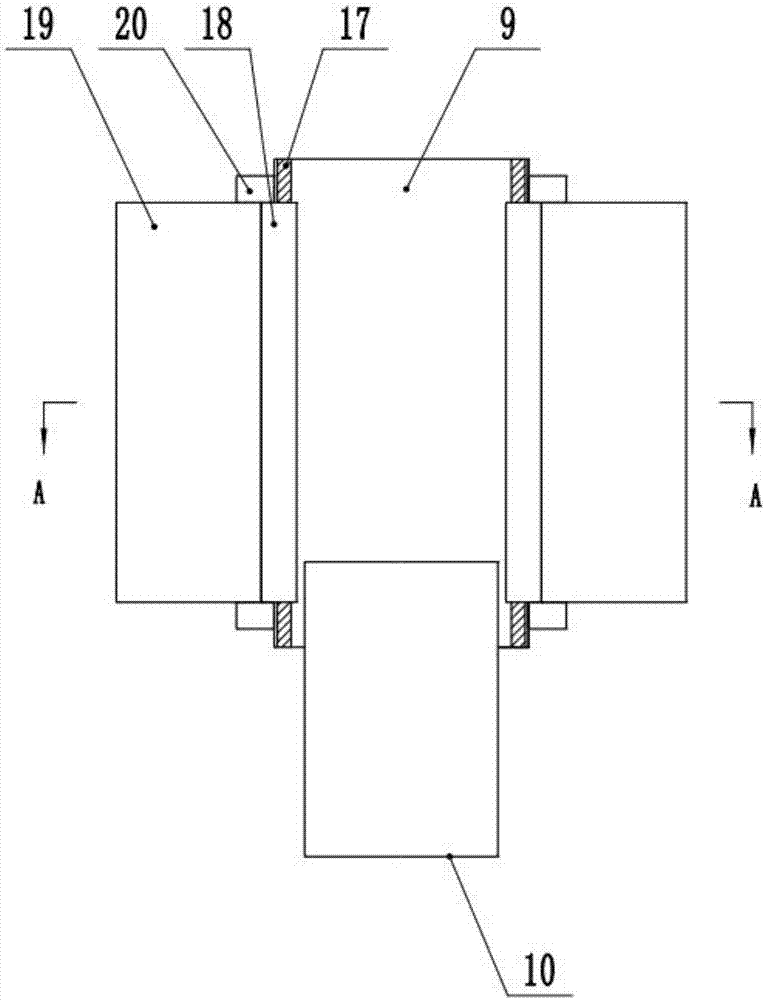

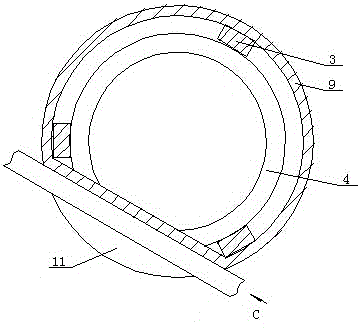

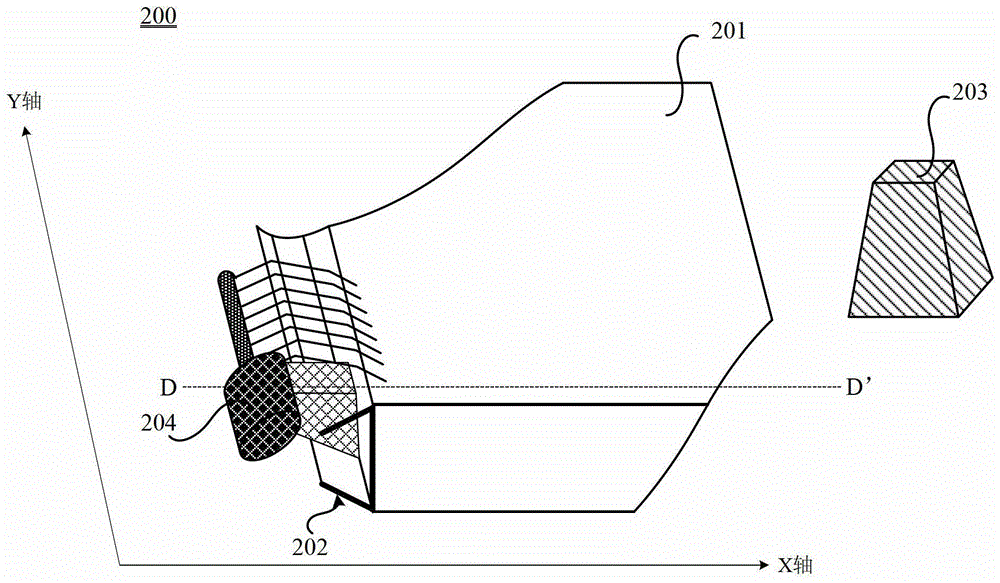

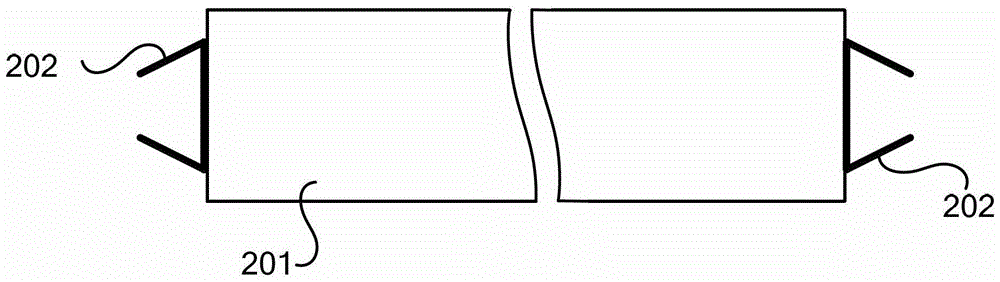

Testing device and testing method of TFT (Thin Film Transistor) base plate

ActiveCN103268027AReduce reservesAvoid possessionElectrical testingNon-linear opticsEngineeringMicroscope

The invention discloses a testing device and a testing method of a TFT (Thin Film Transistor) base plate. The testing device comprises a microscope stage, a detection unit and at least one probe unit, wherein a sliding structure is arranged on at least one side of the microscope stage; the detection unit is positioned above the microscope stage; the probe unit comprises at least one probe and a sliding component; and the probe unit slides along the sliding structure along with the sliding component. By adopting the testing device of the TFT base plate, the testing specification can be quickly changed, additionally, the reserve of a testing framework is reduced, and occupation of space and funds for reserving the testing framework is avoided.

Owner:CHENGDU TIANMA MICROELECTRONICS

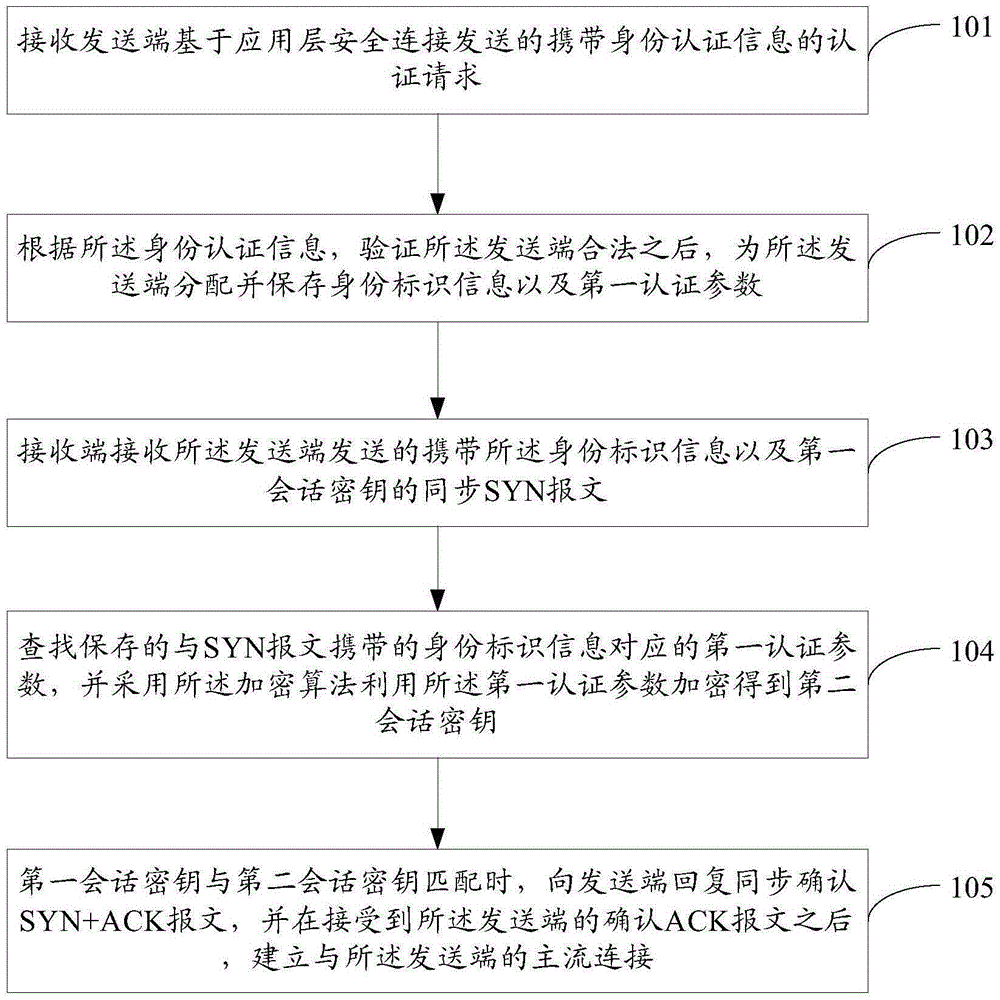

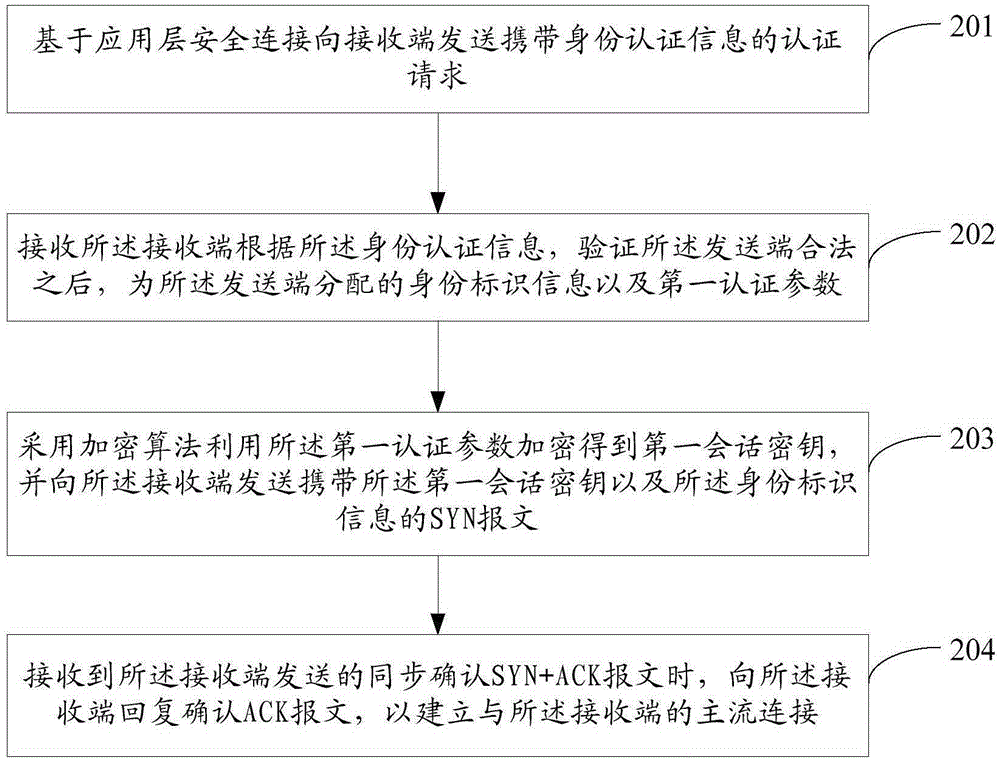

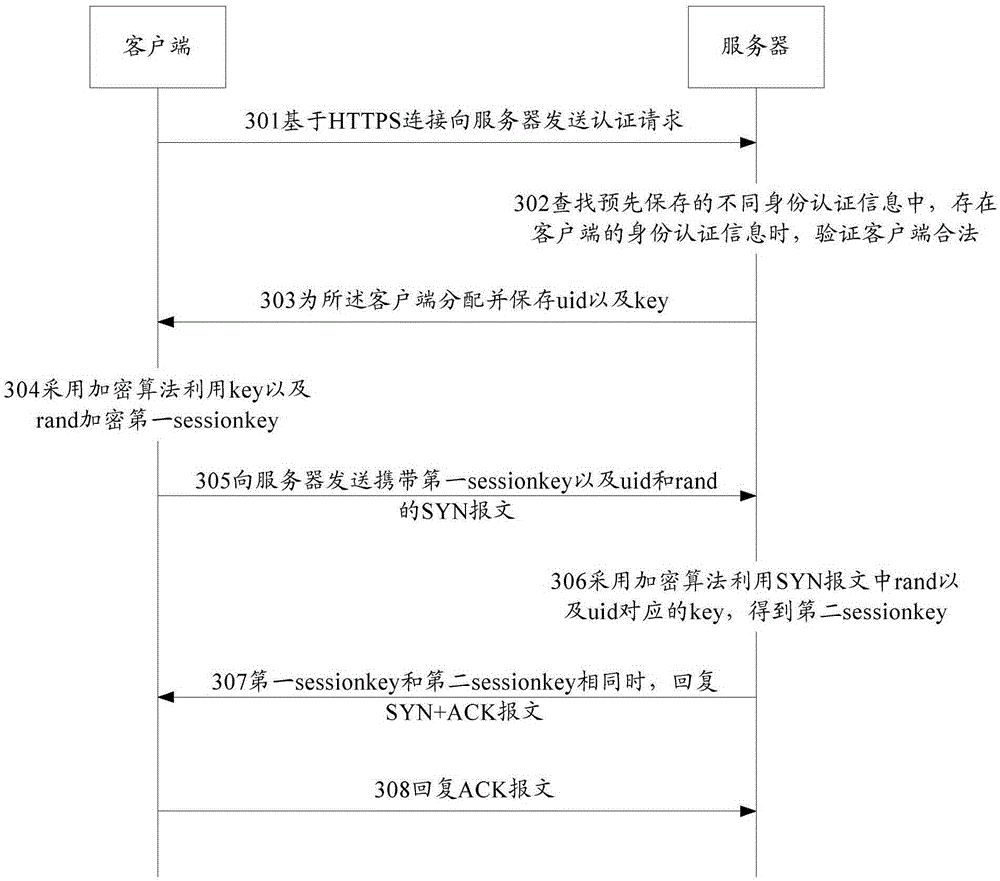

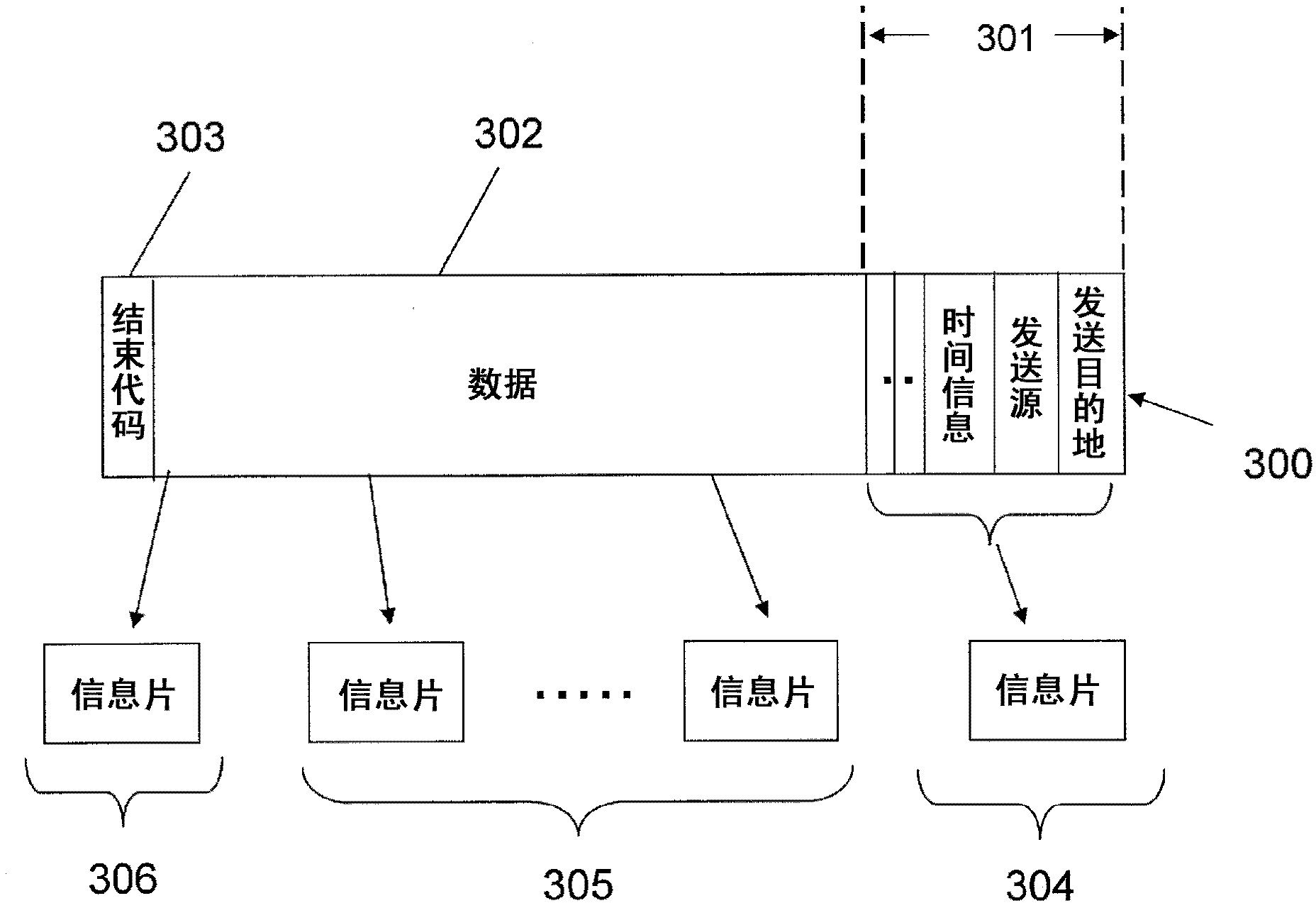

Main stream connection building method and device based on MPTCP (Multi-Path Transmission Control Protocol)

InactiveCN105656875AImprove securityImprove performanceMultiple keys/algorithms usageUser identity/authority verificationProtocol ApplicationMulti path

The embodiment of the invention provides a main stream connection building method and device based on an MPTCP. A receiving end receives an authentication request which carries identity authentication information and is sent by a sending end based on an application layer secure connection; after verifying that the sending end is legal according to the identity authentication information, allocating and storing identity identification information and a first authentication parameter for the sending end; receiving a synchronous SYN (Synchronous) message which carries the identity identification information and a first session key and is sent by the sending end; searching the first authentication parameter corresponding to the identity identification information carried in the SYN message; using the first authentication parameter to encrypt through an encryption algorithm so as to obtain a second session key; when the first session key matches with the second session key, sending a synchronous acknowledgement SYN+ACK (Synchronous + Acknowledgement) message to the sending end; and after receiving the acknowledgement ACK message of the sending end, building a main stream connection with the sending end. Through the embodiment of the invention, the problem that the receiving end is overload is avoided; and the performance of the receiving end is improved.

Owner:EVERGRANDE FF INTELLIGENT AUTOMOTIVE GUANGDONG CO LTD

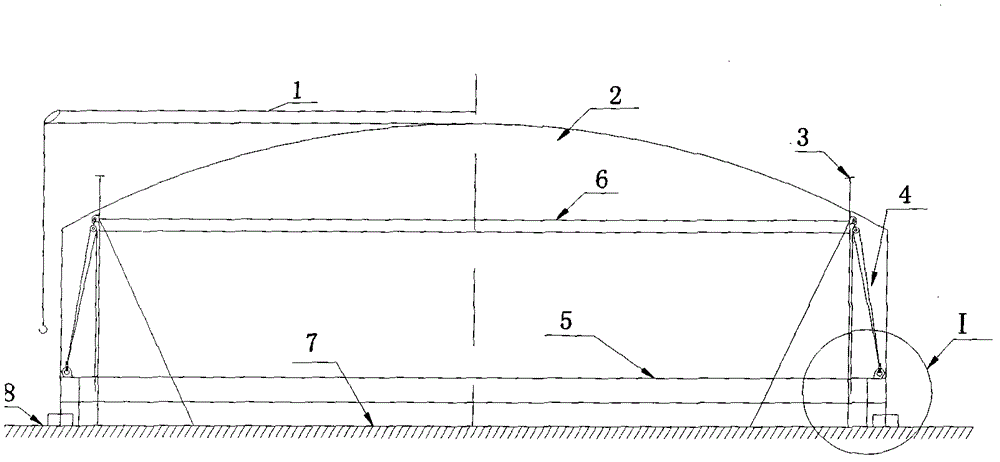

Inversing method of inner side clustering hoop of vertical storage tank

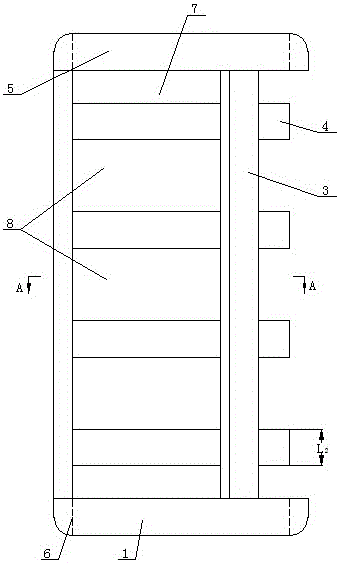

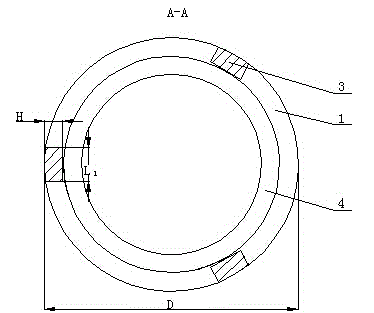

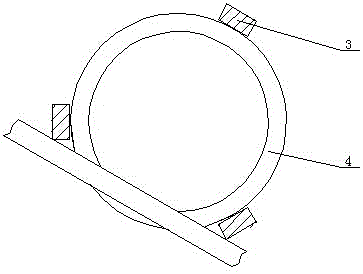

InactiveCN102720386ALow costReduce working at heightsBulk storage containerWork in processInverse method

The invention discloses an inversing method of an inner side clustering hoop of a vertical storage tank. The reversing method comprises the steps of: lifting a tensioning packing temporarily fixed at the lower part of a wall board by using holding poles with hoisting inverted chains to ensure that a precast tank top and a first ring of wall board to ascend to a preset height together with the tensioning packing, installing and welding a second ring of wall board, wherein the holding poles are uniformly arranged on the inner side of the storage tank; and then releasing the tensioning packing to descend to the lower part of the second ring of wall board for tensioning and fixing, lifting the second ring of wall board by using the hosting inverted chains on the inner-side clustering hoop until the final ring of wall board is installed and welded. All construction tools used in the invention can be repeatedly used during the construction of the storage tanks with various specifications except for the tensioning ring, semi-finished product materials are sent to the near side of an equipment foundation by needing a small crane by adopting an inner-side clustering inversing method, residual works are completed by using a crane jib on the top of the storage tank, the holding poles and the inverted chains. Compared with the prior art, the inversing method has the advantages of saving a large quantity of automobile machine teams, and greatly reducing cot; and meanwhile, the more the quantity of the storage tanks is, the larger the saved cost is.

Owner:QINGDAO INSTALLATION & CONSTR +1

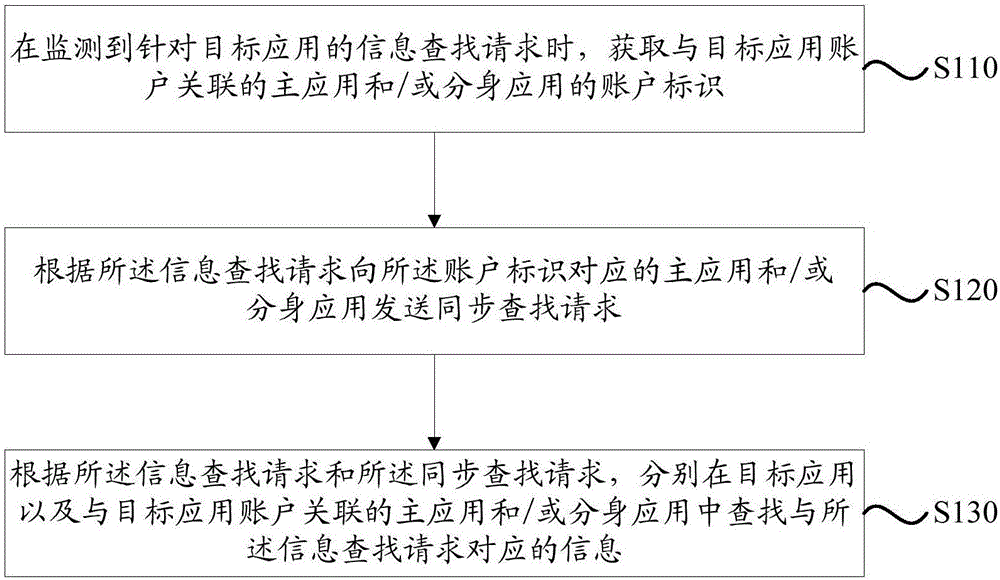

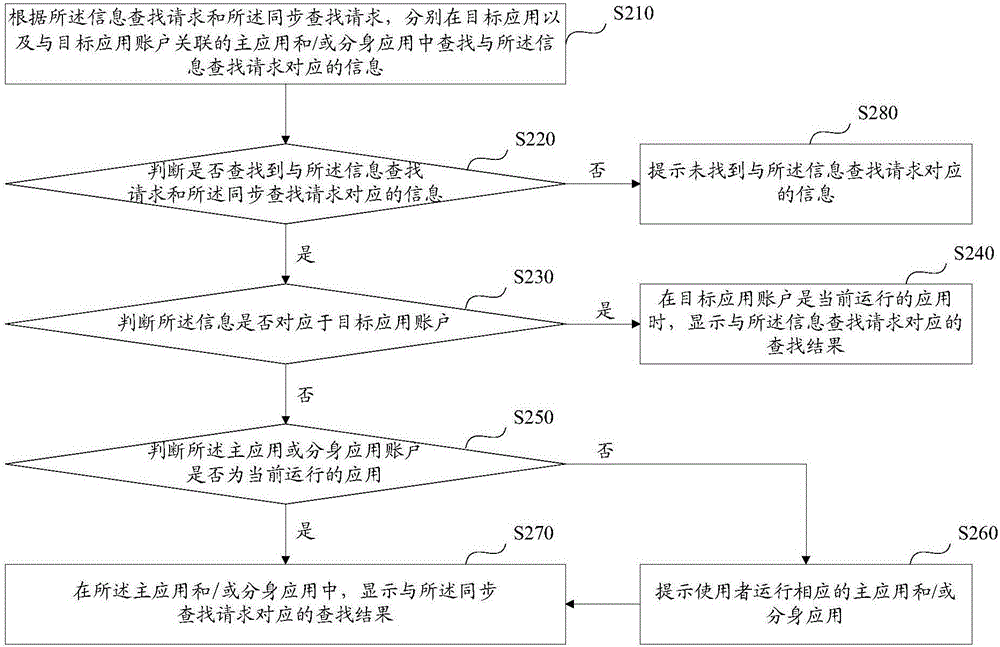

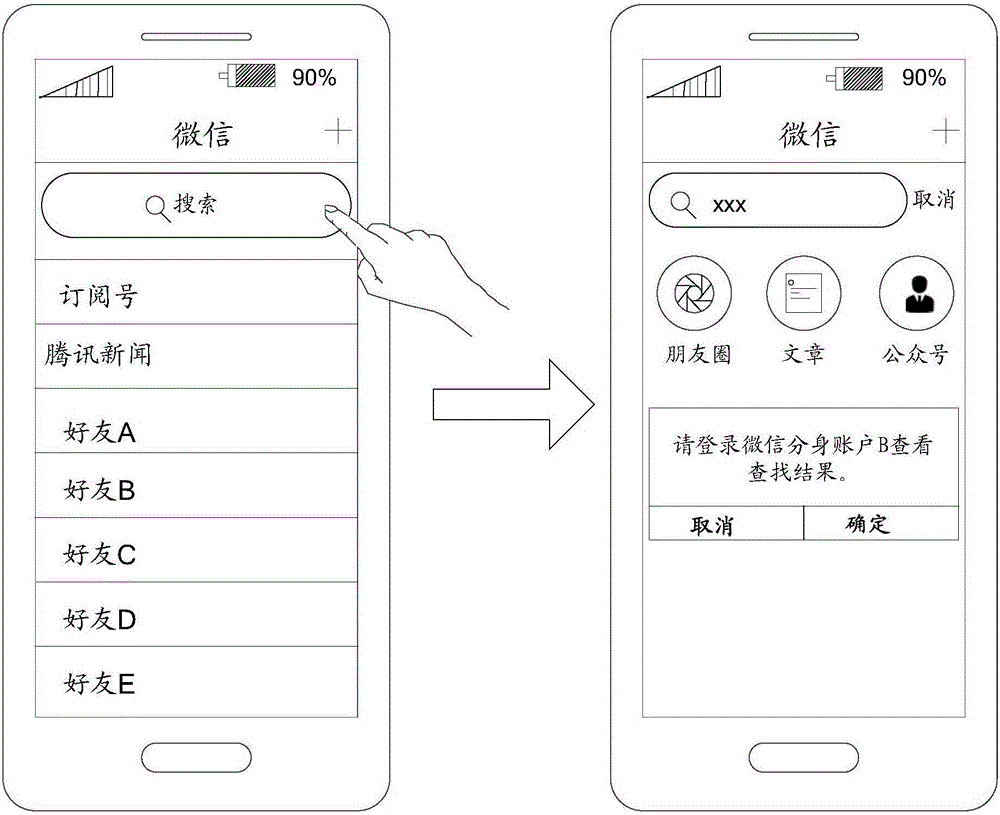

Information searching method and device in applications, and mobile terminal

InactiveCN106484419AAvoid possessionImprove search efficiencyWeb data indexingDigital data authenticationComputer terminalInformation searching

The embodiment of the invention discloses an information searching method and device in applications, and a mobile terminal and relates to a technology of the mobile terminal. The method comprises the steps of when an information searing request for a target application is monitored, obtaining account identification of a master application and / or a branch application associated with a target application account; sending a synchronous searching request to the master application and / or the branch application corresponding to the account identification according to the information searing request; and searching information corresponding to the information searing request in the target application and the master application and / or the branch application associated with the target application account according to the information searing request and the synchronous searching request. According to the technical scheme of the embodiment of the method, the device and the terminal, the problem that the searching efficiency is low due to the fact that at present, the information only can be searched in the currently operated target application of a current user is solved. The user is avoided from troublesome operations of manually switching a plurality of accounts and inputting the information searching request into each account, the searching efficiency is improved, and system resources are saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

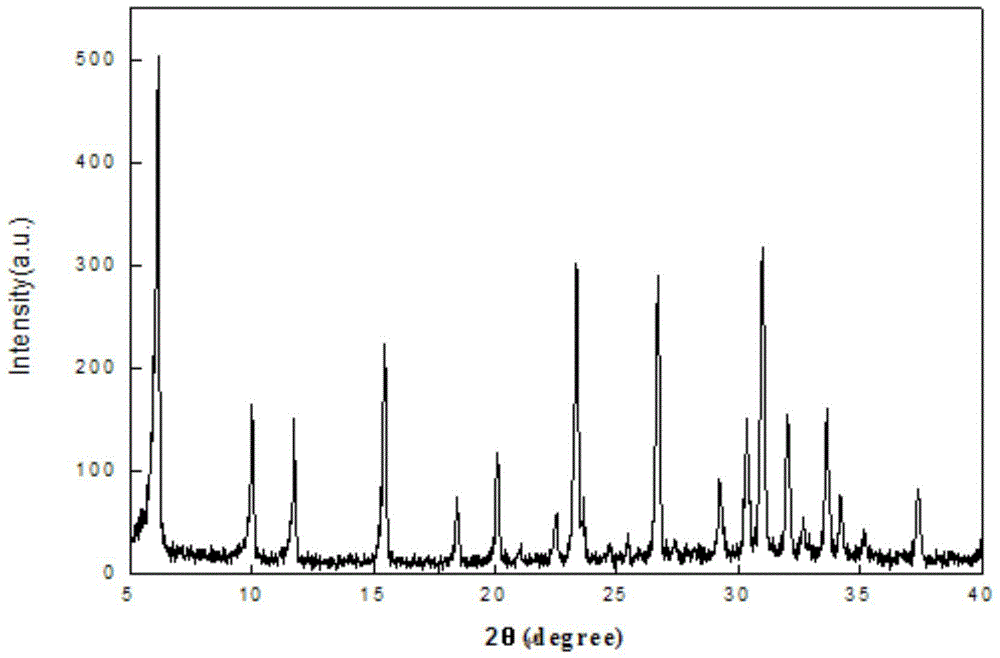

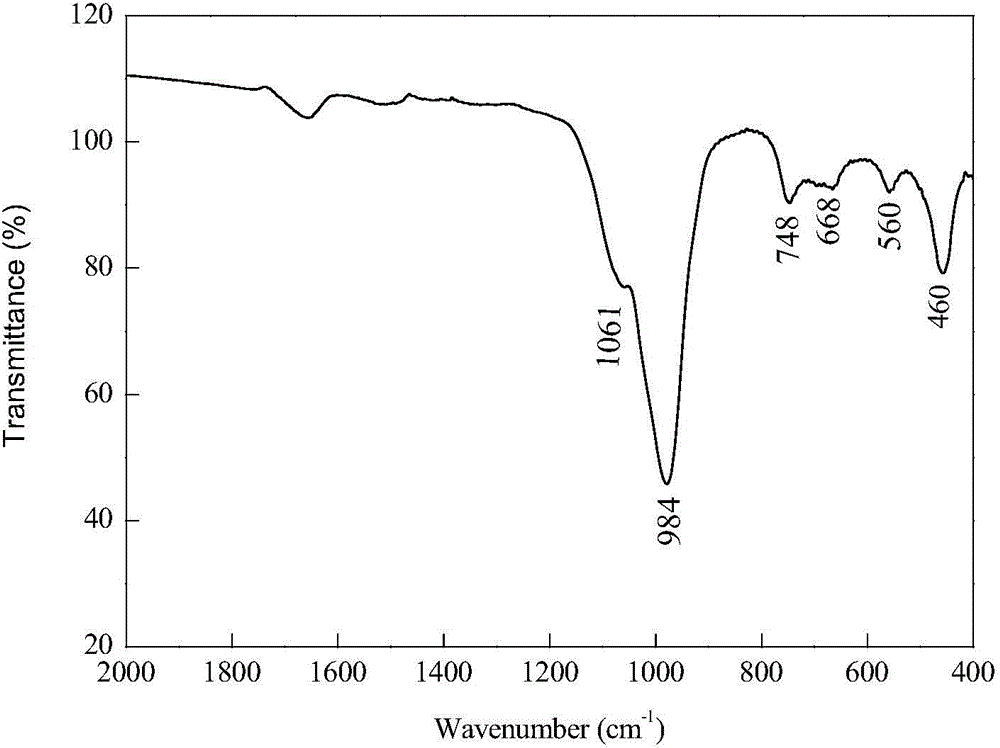

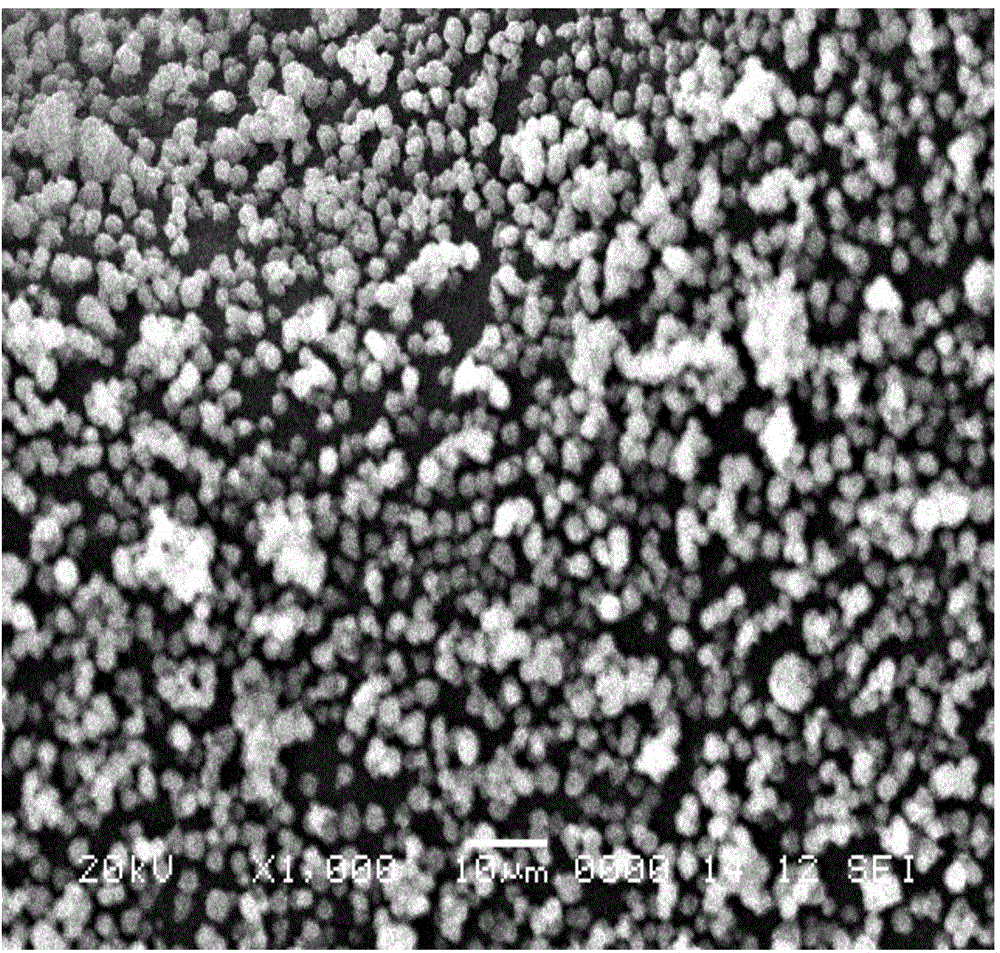

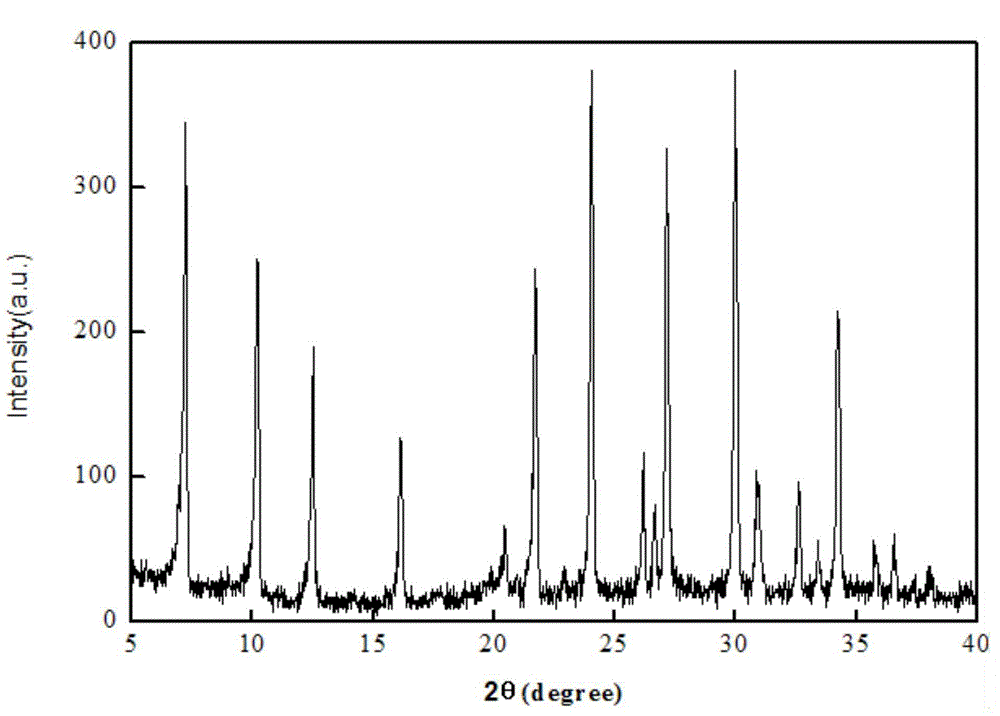

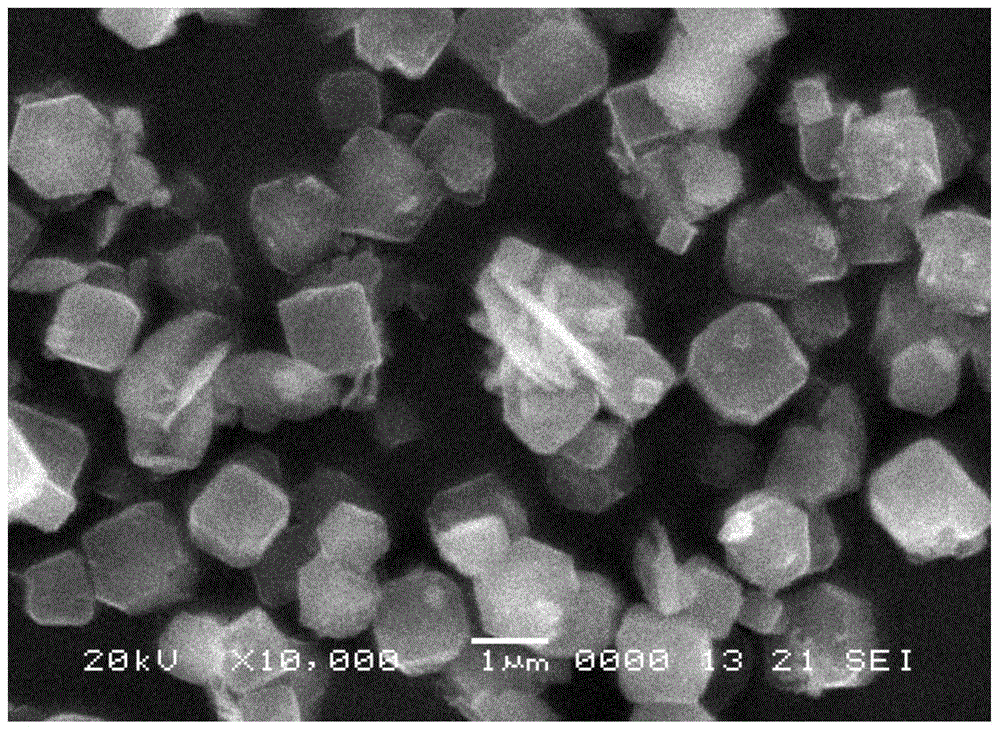

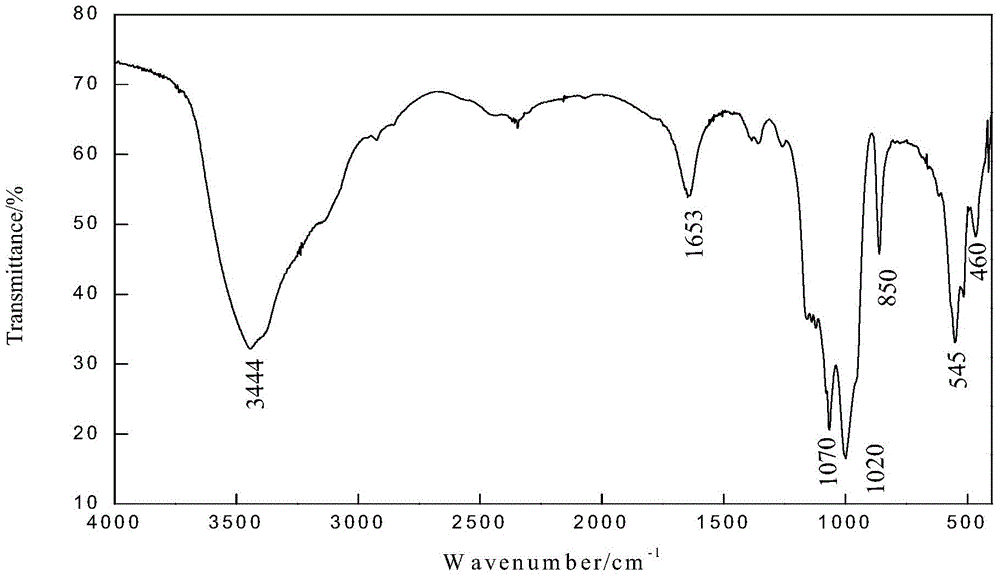

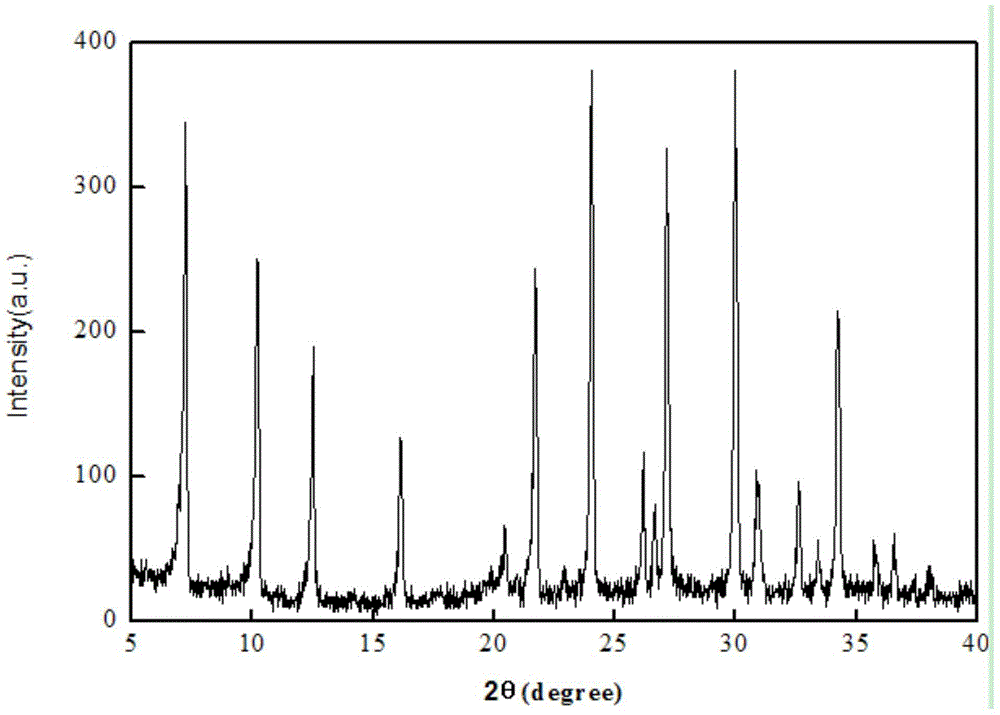

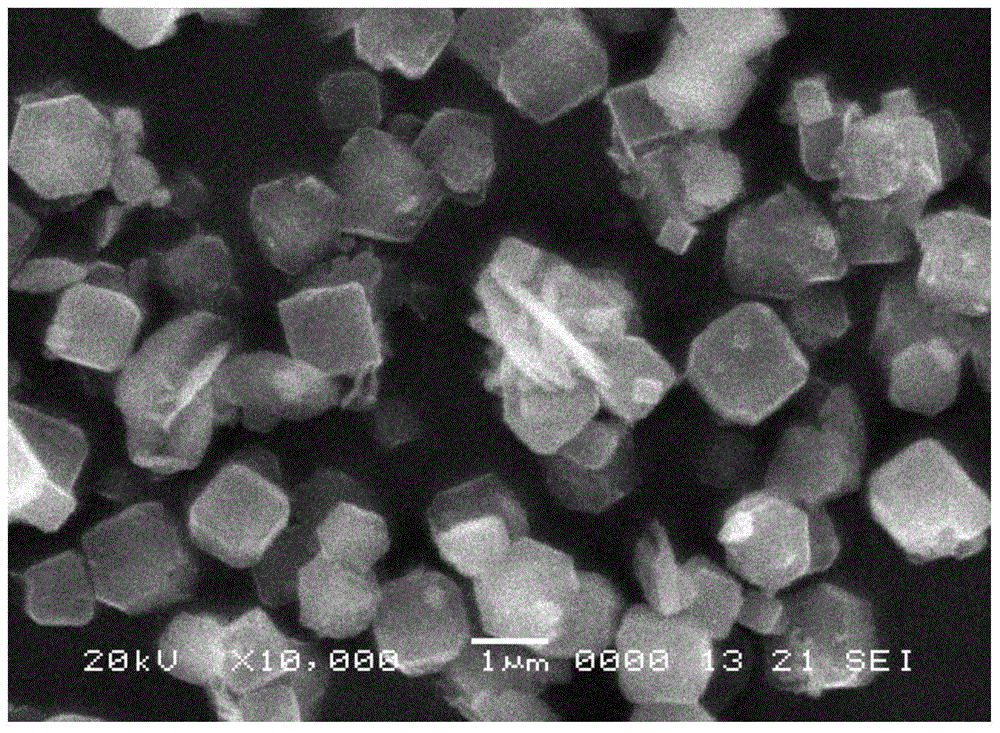

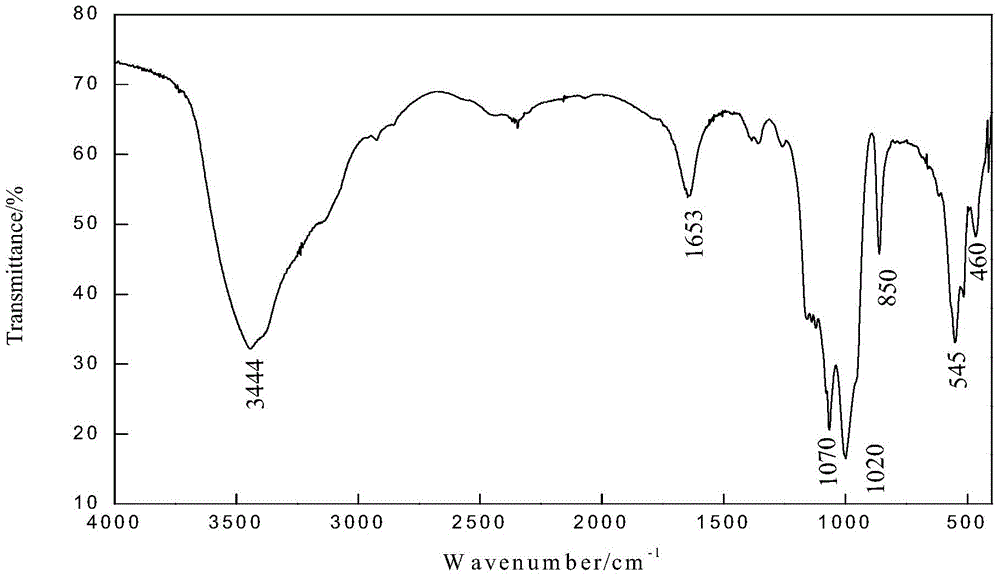

Method for preparing 13X molecular sieve by adopting coal slime

The invention discloses a method for preparing a 13X molecular sieve by adopting coal slime. The method comprises the steps of 1, grinding and sieving the coal slime, and calcining the sieved matter to obtain coal slime ash; 2, mixing a hydrochloric acid solution with the coal slime ash, reacting while stirring, filtering to obtain filter residue, and drying the filter residue for later use; 3, mixing NaOH with the dried filter residue, and performing alkali fusion to obtain slag; 4, adding sodium metaaluminate and water into the slag, and stirring uniformly to obtain a mixture; 5, ageing the mixture and then crystallizing to obtain a solid-liquid mixture; and 6, filtering the solid-liquid mixture in vacuum to obtain a filter cake, washing the filter cake with deionized water, and drying to obtain the 13X molecular sieve. By adopting the method, the coal slime can be sufficiently utilized, the utilization rate and the additional value of the coal slime are greatly improved, the preparation cost of the 13X molecular sieve is reduced, land occupation and environmental pollution caused by accumulating massive 13X molecular sieve are avoided, and the prepared 13X molecular sieve product has uniform granularity distribution and stable quality.

Owner:XIAN UNIV OF SCI & TECH

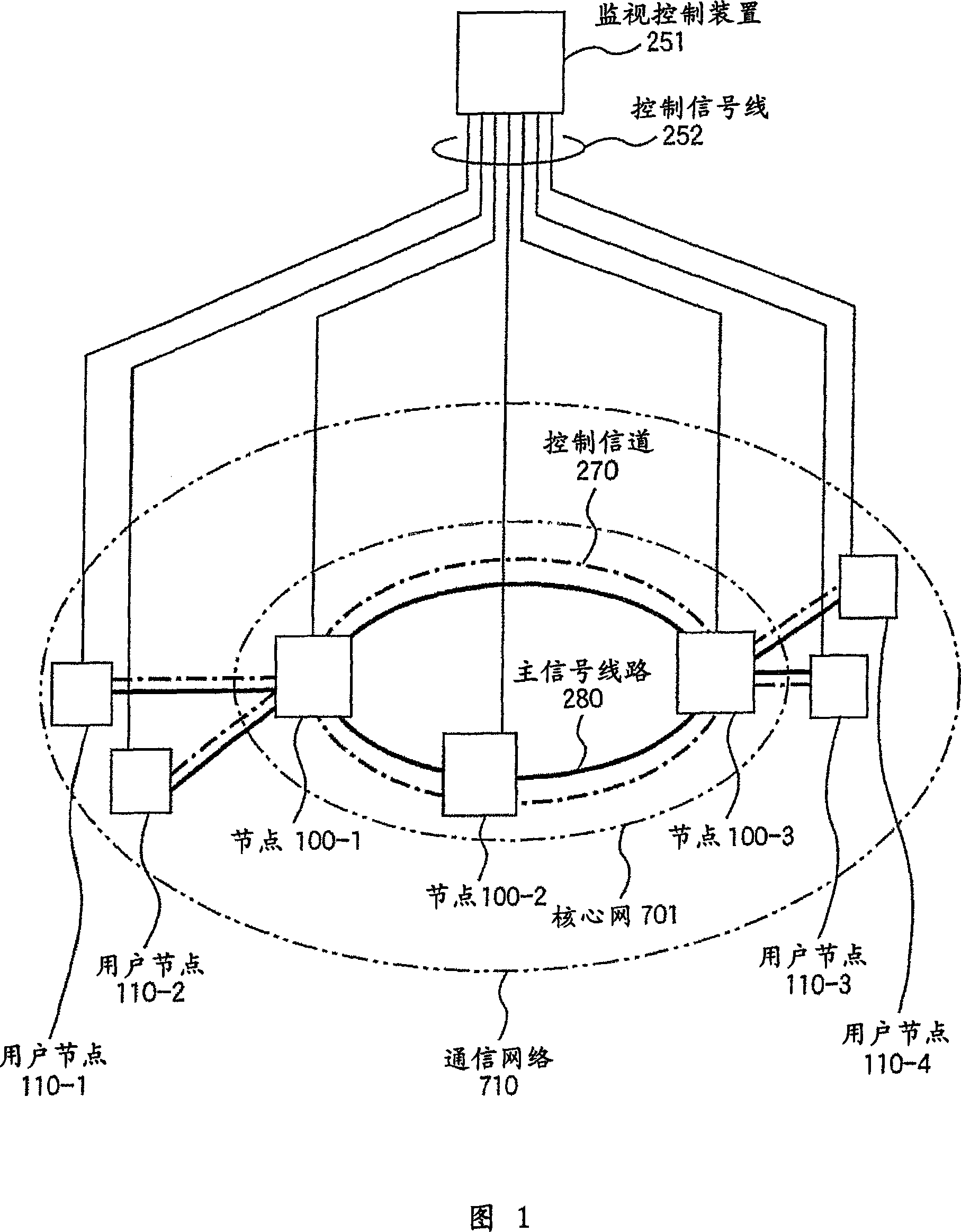

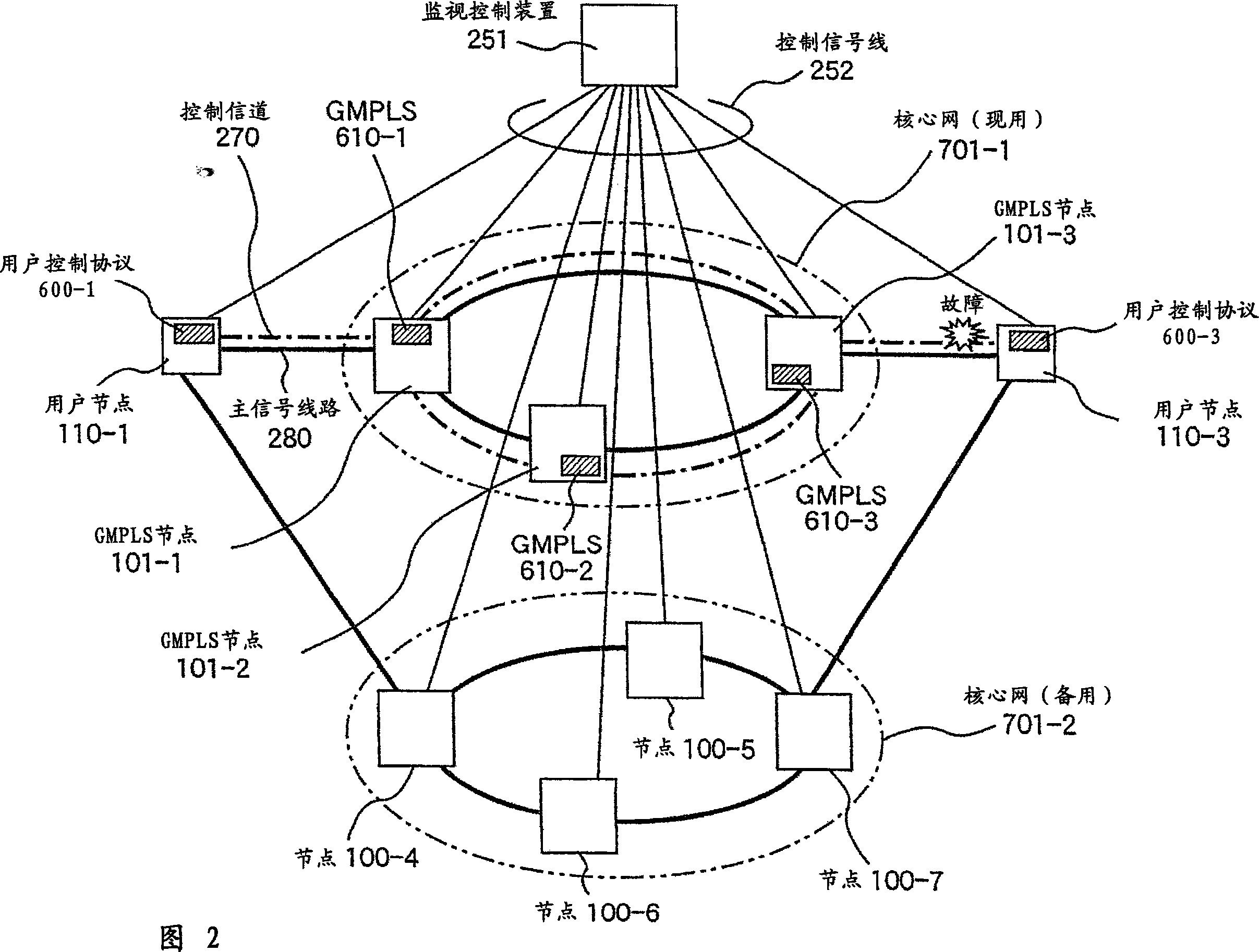

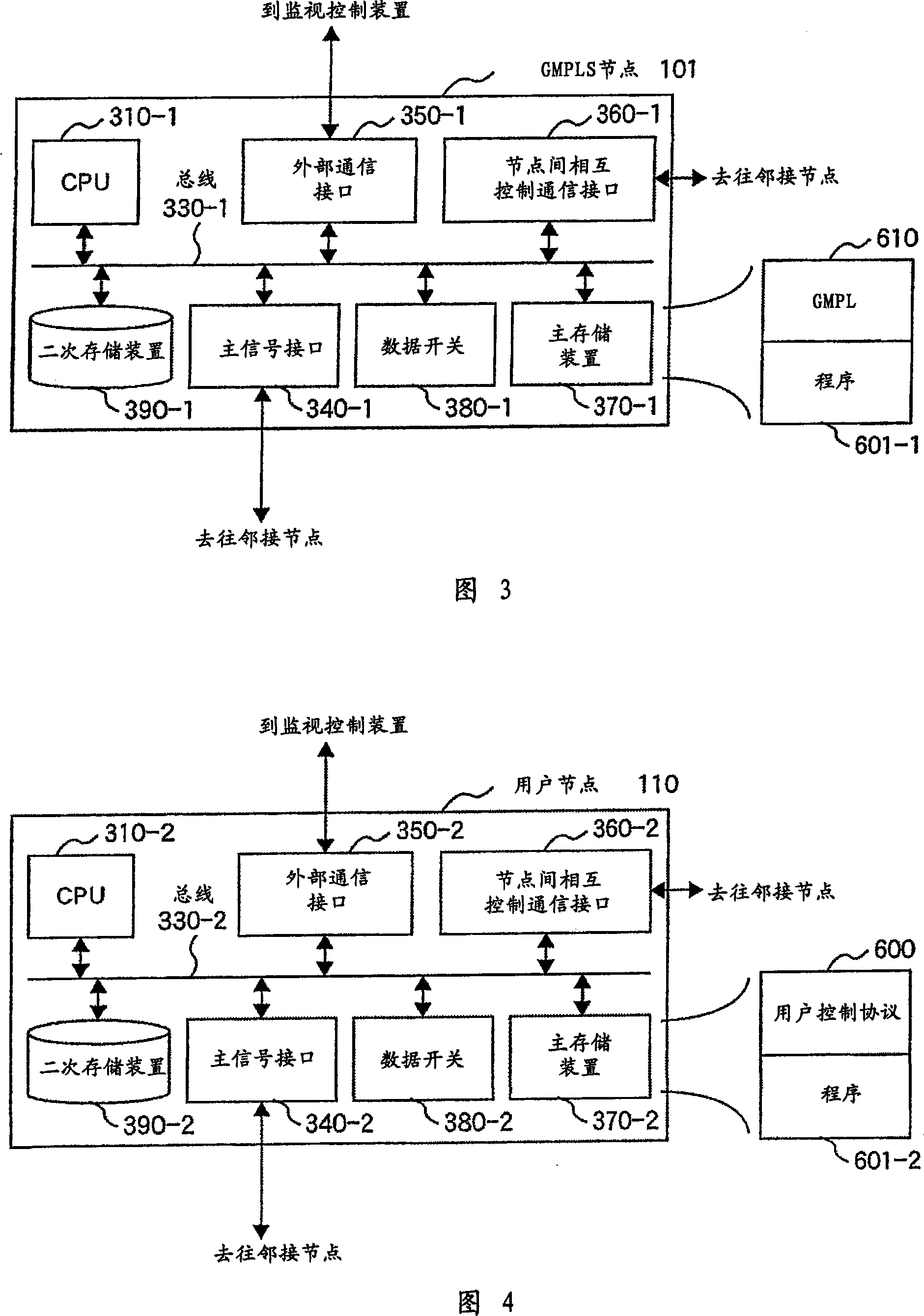

Method for setting path and node apparatus

InactiveCN101136858AOpen automaticallyGuaranteed resourcesData switching networksDistributed computing

In a GMPLS node provided with inter-node control protocols including GMPLS, when an adjacent node is in a failure state, path establishment is automatically accomplished by providing a temporary reply to a path establishment request source node in response to a path establishment request, securing a source of an intermediate route, repeatedly transmitting a path establishment request to the adjacent node in the failure state according to specified conditions after completion of temporary path establishment, performing a path establishment process for the remaining section when the adjacent node recovers from the failure, and then transmitting a path establishment completion notification message to the request source node.

Owner:HITACHI COMM TECH

Method for preparing 4A molecular sieve by adopting coal slime

The invention discloses a method for preparing a 4A molecular sieve by adopting coal slime. The method comprises the steps: 1, grinding and sieving the coal slime, and calcining the sieved matter to obtain coal slime ash; 2, mixing a hydrochloric acid solution with the coal slime ash, reacting while stirring, filtering to obtain filter residue, and drying the filter residue for later use; 3, mixing NaOH with the dried filter residue, and performing alkali fusion to obtain slag; 4, adding sodium metaaluminate and water into the slag, and stirring uniformly to obtain a mixture; 5, ageing the mixture and crystallizing to obtain a solid-liquid mixture; and 6, filtering the solid-liquid mixture to obtain a filter cake, washing the filter cake with deionized water, and drying to obtain the 4A molecular sieve. By adopting the method, the coal slime can be sufficiently utilized, the utilization rate and the additional value of the coal slime are greatly improved, the preparation cost of the 4A molecular sieve is reduced, land occupation and environmental pollution caused by accumulating massive 4A molecular sieve are avoided, and the prepared 4A molecular sieve product has uniform granularity distribution and stable quality.

Owner:XIAN UNIV OF SCI & TECH

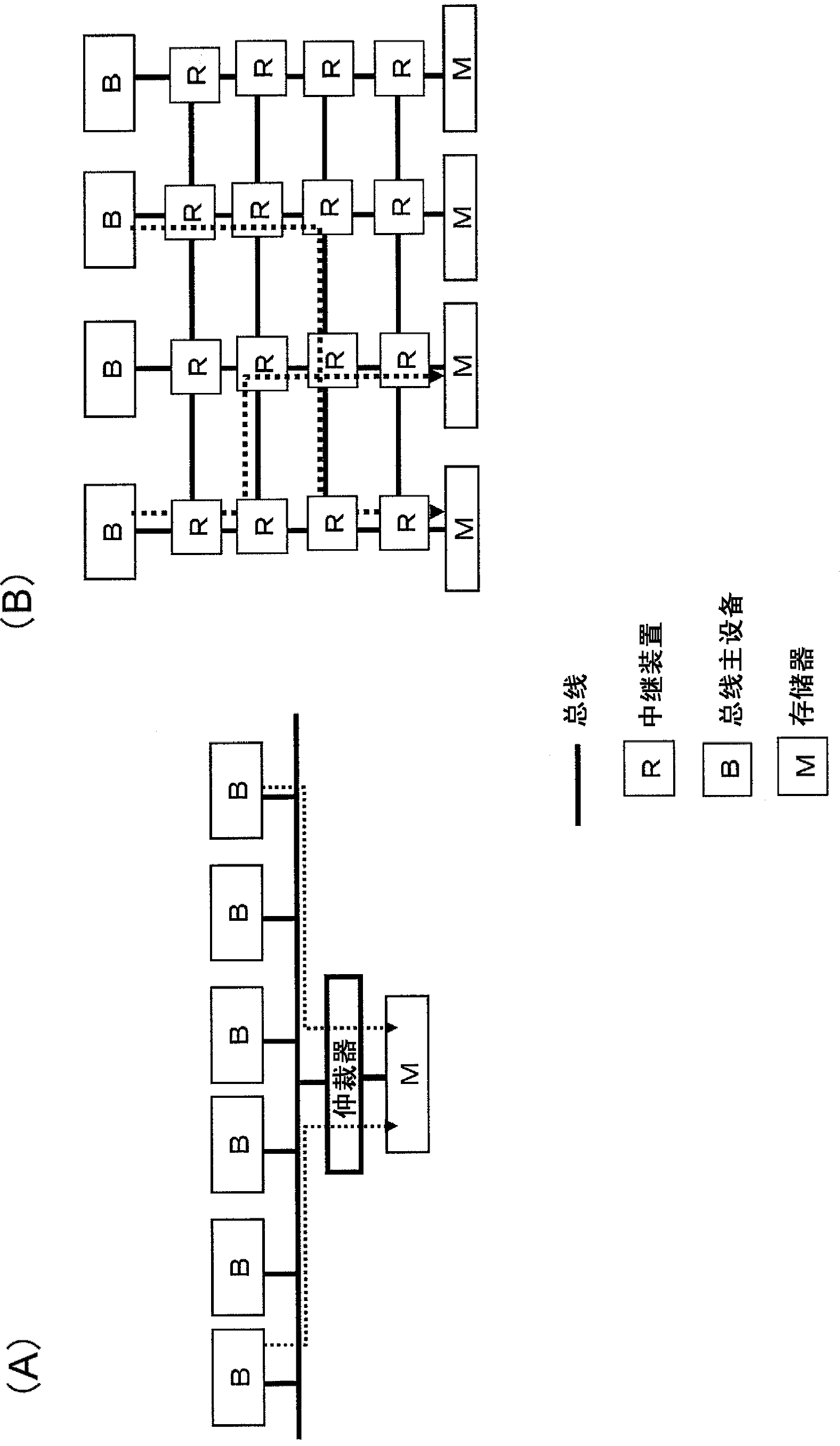

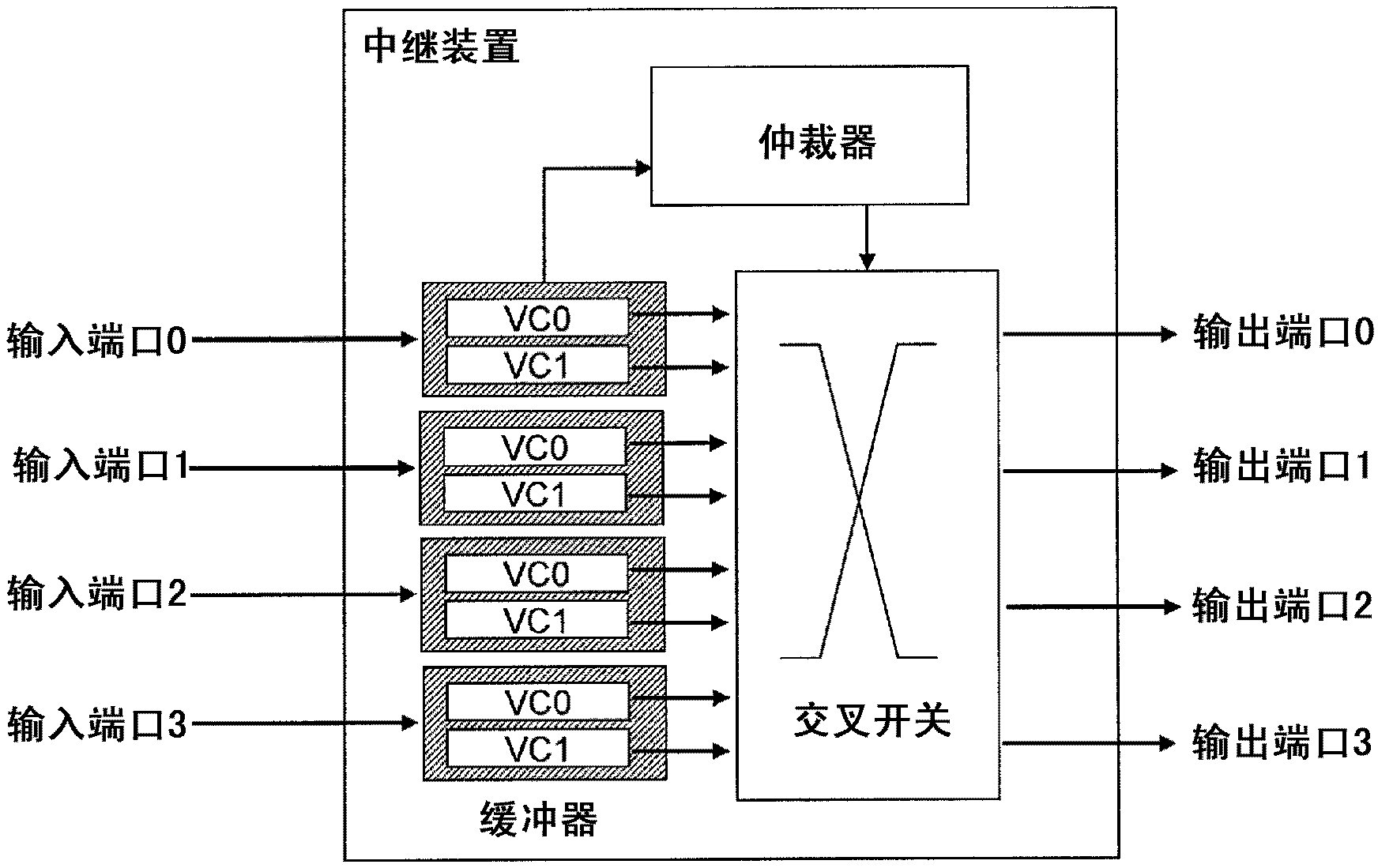

Relay device

ActiveCN103348640AAvoid possessionHigh throughput lowData switching networksThroughputIntegrated circuit

The router is used to relay a packet to be transmitted from one node to another in an integrated circuit that has distributed buses according to a packet exchange method. The router includes: a plurality of buffers, each of which configured to store packets with information indicating their transmission node; a classifying section configured to classify the buffers that store the packets into a number of groups according to the transmission nodes of the packets; a selecting section configured to select at least one of the buffers of each group; and an output port configured to sequentially output the packets that are stored in the selected buffer.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

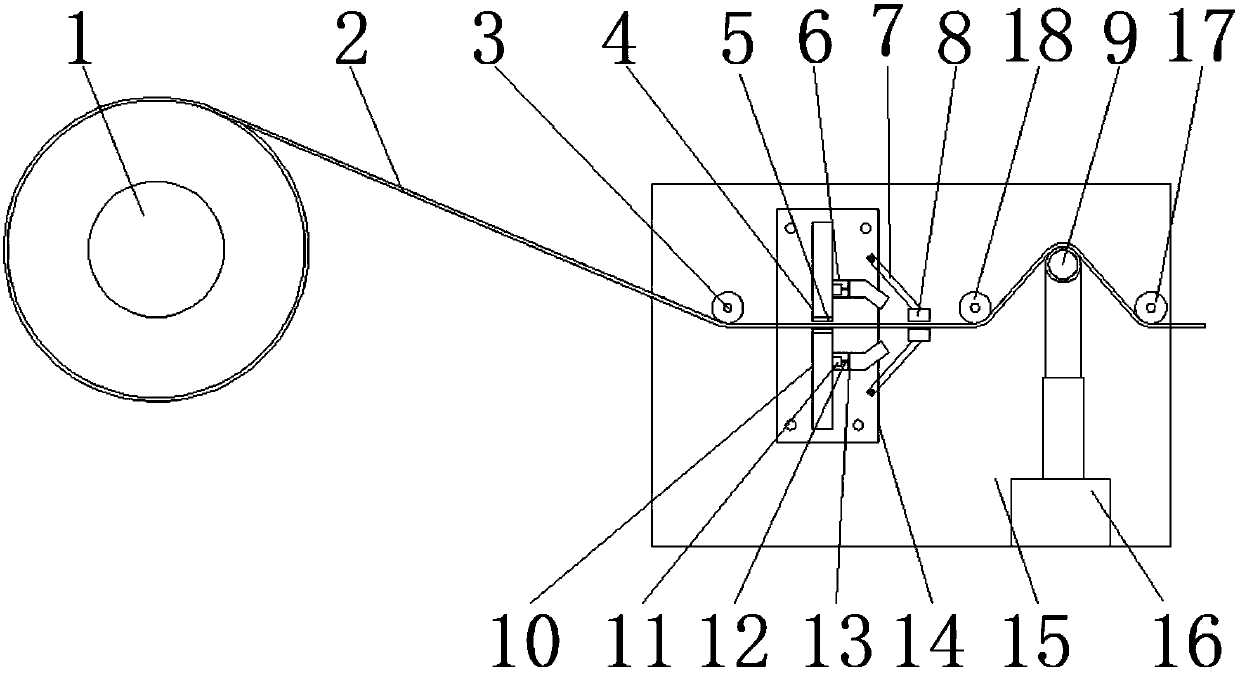

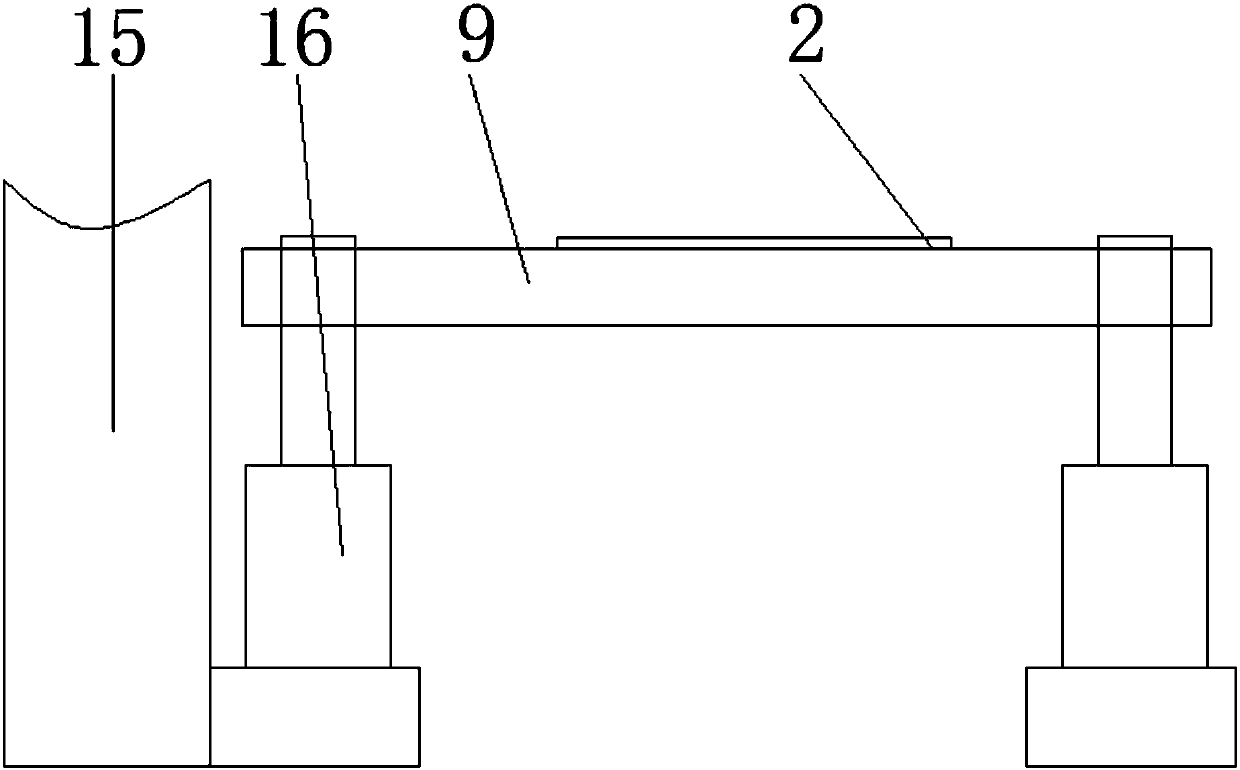

Cleaning and tension complement device for coiling aluminum foils

The invention discloses a device for cleaning and tension compensation for aluminum foil coiling, which comprises a reel and a fixing frame arranged on one side of the reel, the surface of the fixing frame is connected with a fixing plate through bolts, and the middle part of the surface of the fixing plate is welded There are a first fixed block and a second fixed block, the bottom of the first fixed block and the top of the second fixed block are adhesively connected with a dust cloth, and one side of the first fixed block and one side of the second fixed block are welded with A blowing pipe, the inside of the blowing pipe is welded with a motor, the output end of the motor is provided with an output shaft, the end of the output shaft is sleeved with fan blades, one side of the fixing plate is connected with a connecting rod through bolts, and the connecting rod The end is welded with a pressure block, the surface of the fixed frame is rotatably connected with the first guide shaft, the third guide shaft and the fourth axis, the surface of the fixed frame is welded with an electric push rod, and the end of the electric push rod is rotatably connected with the second Two guide shafts, aluminum foil is wound on the surface of the reel. The present invention is worth popularizing and using.

Owner:JIANGSU FUWEI ENERGY CO LTD

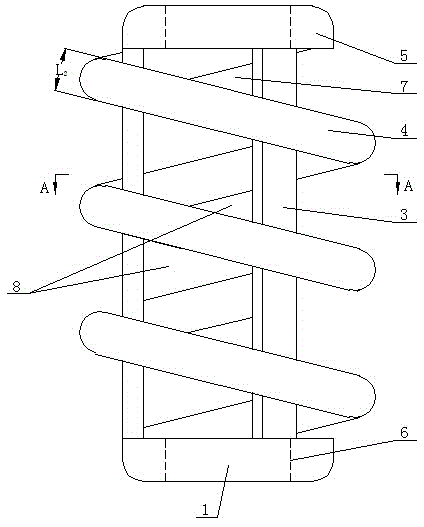

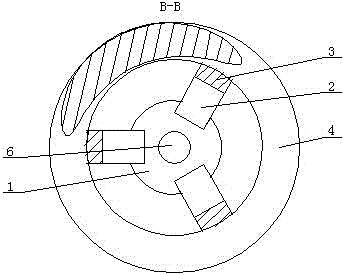

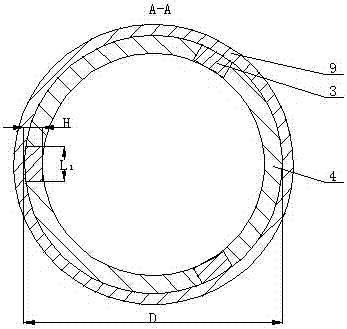

A cylindrical spiral structure steel bar connector and its construction method

The invention provides a cylindrical spiral structure steel bar connector and its construction method, comprising a first support ring and a second support ring, at least two longitudinal support ribs are connected between the first support ring and the second support ring, and more The longitudinal support ribs are evenly distributed at 3600, the outer walls of the plurality of longitudinal support ribs are connected to the spiral support ribs, the spiral support ribs are evenly distributed on the height of the longitudinal support ribs, the outer diameters of the first support ring and the second support ring are equal, The spiral support ribs are connected with the longitudinal support ribs to form several space grids. A metal sleeve is installed outside the space grid-shaped cylinder. The shape of the metal sleeve is a cylinder. One end of the metal sleeve is open and the other end is provided with a through hole. The preparation method is as follows: taking a columnar mold and placing it in the cylinder cavity, pouring concrete on the outer periphery of the columnar mold, taking out the columnar mold, pouring concrete into the connecting hole, and then the construction is completed. The invention completely changes the structure of the steel bar connector in the prior art, so as to solve the deficiencies in the prior art.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

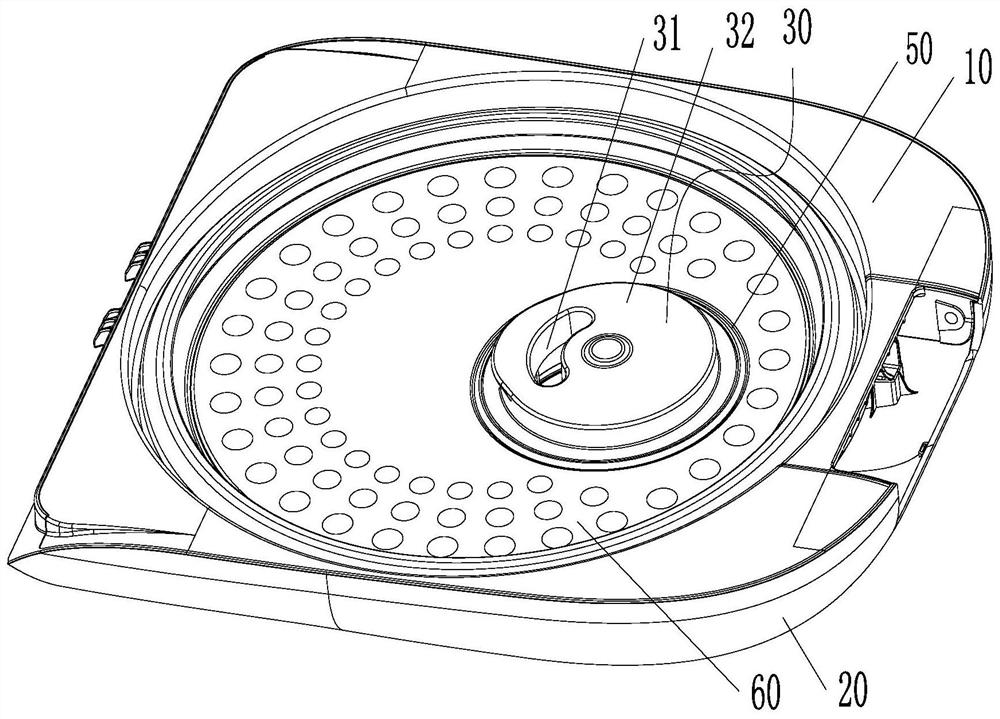

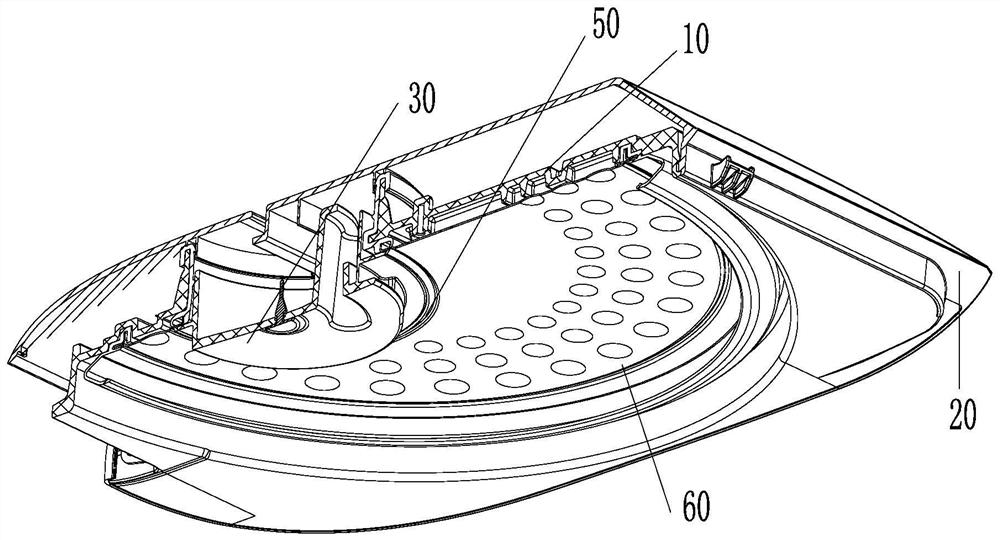

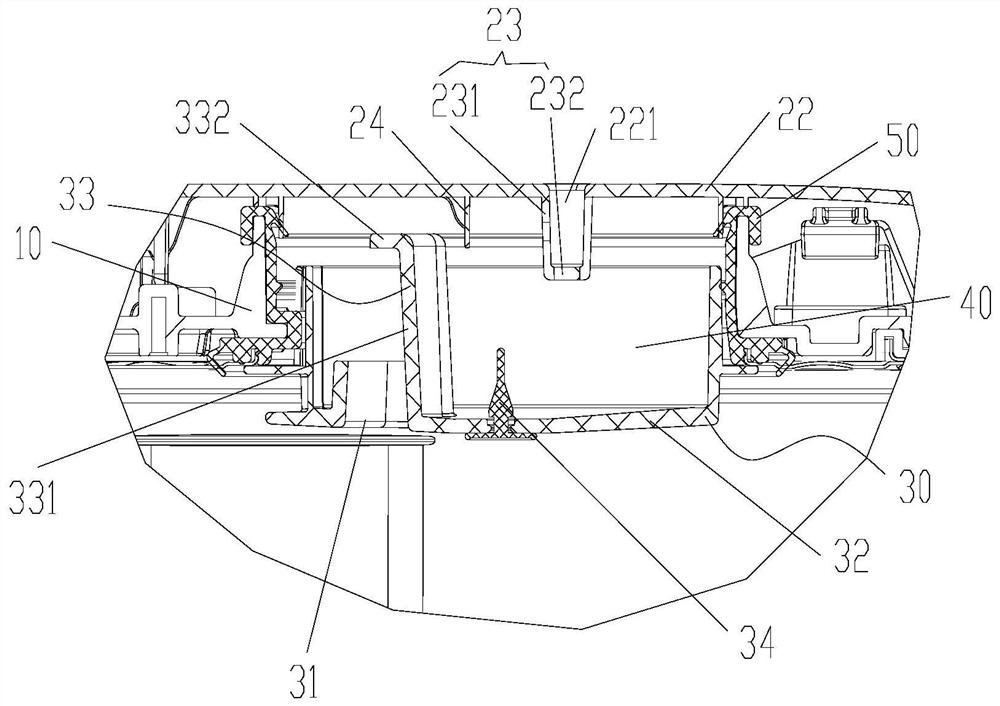

Cooker cover assembly and electric cooker with same

ActiveCN112315329ASolve the technical problem of poor cleaning effectAvoid possessionCooking-vessel lids/coversCooking vessel constructionsStructural engineeringCooker

The invention provides a cooker cover assembly and an electric cooker with the same, wherein the cooker cover assembly comprises an inner cover, a surface cover and a valve cover; the inner cover is provided with a mounting hole; the surface cover is arranged on the outer side of the inner cover, the surface cover comprises a cover body and a mounting cover, the mounting cover is connected with the cover body, the mounting cover is mounted at one end of the mounting hole, and an air outlet is formed in the mounting cover; the valve cover is detachably mounted at the other end of the mounting hole, so that a valve cavity is defined by the valve cover, the mounting cover and the mounting hole; an air inlet is formed in the valve cover, so that air flowing in from the air inlet passes throughthe valve cavity and then is exhausted from the air outlet. By means of the technical scheme, the technical problem that in the prior art, the cleaning effect on a steam valve is poor can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Spatial grid structure steel bar connector with cone and construction method thereof

The invention provides a steel bar connector with an inner ring cylindrical space latticed structure and a construction method of the steel bar connector. The steel bar connector comprises first supporting rings and second supporting rings, wherein at least two longitudinal supporting ribs are connected between the first supporting rings and the second supporting rings; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity; pouring concrete at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

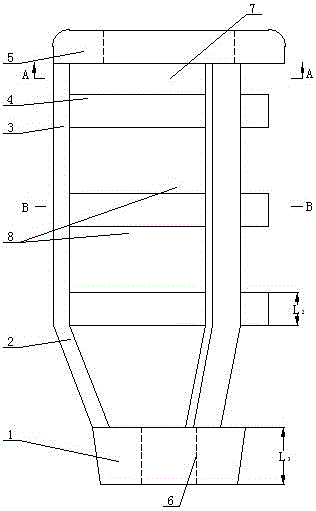

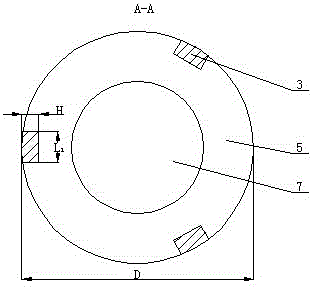

Pressure Transmitter with Waterproof Vent

ActiveCN103207044BAvoid scratchesAvoid accessFluid pressure measurement by electric/magnetic elementsMechanical engineeringTransmitter

The invention discloses a pressure transmitter with a waterproof and ventilating membrane. A circuit board of the transmitter, a sensing core body and the like are arranged in a casing, the front end and the rear end of the casing are connected with a tail assembly and a head assembly, an eccentric cavity is arranged in the end face of the head assembly in the casing, a pipeline in the head assembly is communicated with the bottom of the cavity, the outer part of the head assembly is connected with an air hose connector, an L-shaped ventilating hole is arranged in the head assembly, one end of the ventilating hole is arranged on the lateral wall of the head assembly, the other end of the ventilating hole is arranged on the end face of the head assembly in the casing, a groove is arranged on the periphery of the opening of the ventilating hole, the opening is arranged at the bottom of the groove, a pressing sheet is fixed in the groove, the waterproof and ventilating membrane is fixed on a central hole portion of the pressing sheet, air inside and outside can pass through the L-shaped ventilating hole and the waterproof and ventilating membrane, and impurities of dust, water, oil and the like can be blocked.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

A kind of method adopting coal slime to prepare 4a type molecular sieve

The invention discloses a method for preparing a 4A molecular sieve by adopting coal slime. The method comprises the steps: 1, grinding and sieving the coal slime, and calcining the sieved matter to obtain coal slime ash; 2, mixing a hydrochloric acid solution with the coal slime ash, reacting while stirring, filtering to obtain filter residue, and drying the filter residue for later use; 3, mixing NaOH with the dried filter residue, and performing alkali fusion to obtain slag; 4, adding sodium metaaluminate and water into the slag, and stirring uniformly to obtain a mixture; 5, ageing the mixture and crystallizing to obtain a solid-liquid mixture; and 6, filtering the solid-liquid mixture to obtain a filter cake, washing the filter cake with deionized water, and drying to obtain the 4A molecular sieve. By adopting the method, the coal slime can be sufficiently utilized, the utilization rate and the additional value of the coal slime are greatly improved, the preparation cost of the 4A molecular sieve is reduced, land occupation and environmental pollution caused by accumulating massive 4A molecular sieve are avoided, and the prepared 4A molecular sieve product has uniform granularity distribution and stable quality.

Owner:XIAN UNIV OF SCI & TECH

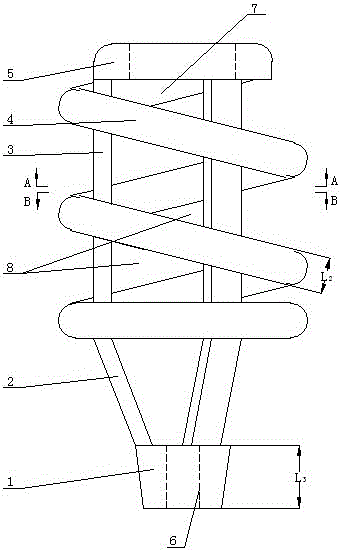

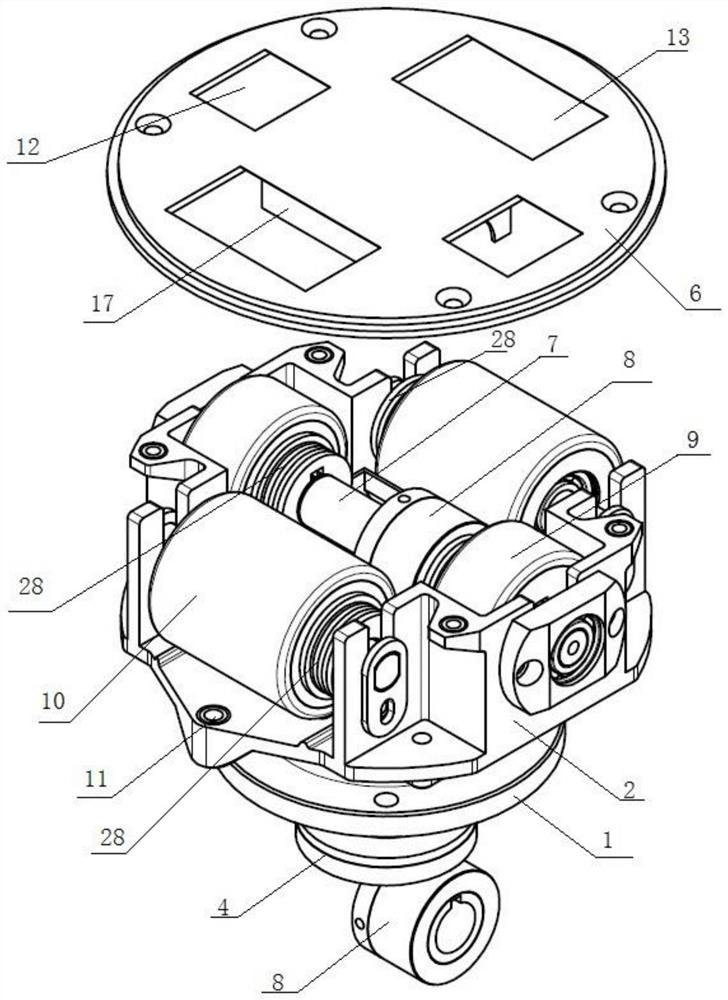

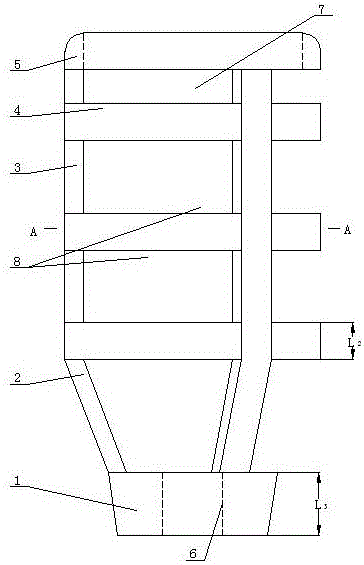

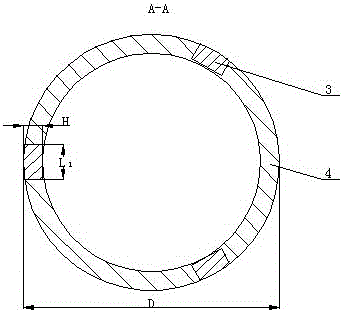

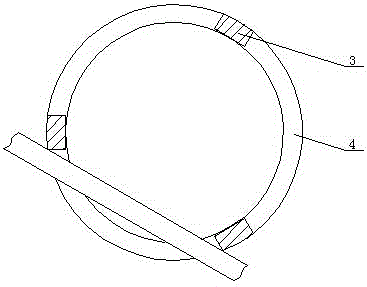

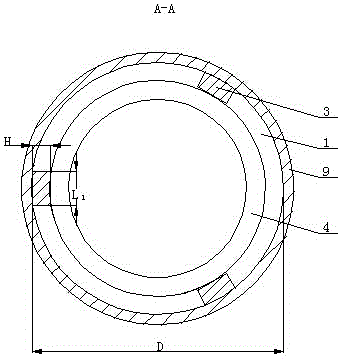

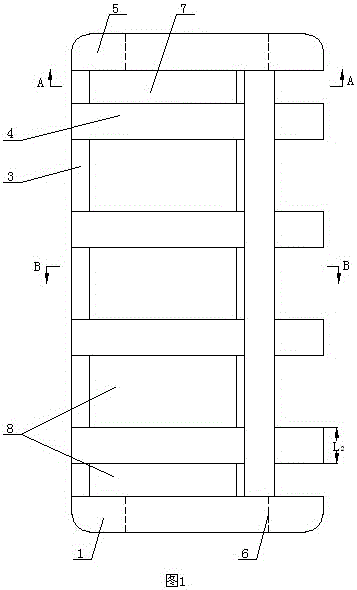

Tubular spiral space lattice structure steel bar connector and construction method of tubular spiral space lattice structure steel bar connector

ActiveCN104963457AGuaranteed building qualityEliminate construction hazardsCeramic shaping apparatusBuilding reinforcementsRebarMesh grid

The invention provides a tubular spiral space lattice structure steel bar connector and a construction method of the tubular spiral space lattice structure steel bar connector. The tubular spiral space lattice structure steel bar connector comprises a first support ring and a second support ring, wherein at least two longitudinal support ribs are connected between the support rings; a plurality of longitudinal support ribs are uniformly distributed in 360 degrees; the outer walls of the plurality of longitudinal support ribs are connected with spiral support ribs; the spiral support ribs are uniformly distributed in the height of the longitudinal support bars; the outer diameters of the support rings are identical; the spiral support ribs and the longitudinal support ribs form a plurality of space lattices after being connected; the support rings, the longitudinal support ribs and the spiral support ribs are connected to form a lattice-shaped tube body; a tube cavity with the same diameters at the upper part and the lower part is arranged in the lattice-shaped tube body. A preparing method comprises the following steps of taking a cylindrical mold, and putting the mold into a tube cavity; casting concrete on the periphery of the cylindrical mold; taking out the cylindrical mold; completing the construction after the concrete casting into a connecting hole. The tubular spiral space lattice structure steel bar connector and the construction method of the tubular spiral space lattice structure steel bar connector have the advantages that the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A grid structure steel bar connector and its construction method

ActiveCN104963465BEven by forceReduce weightBuilding reinforcementsBuilding material handlingGrid connectionRebar

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A spiral space grid steel bar connector with a cone and its construction method

The invention provides a steel bar connector with an inner ring cylindrical space latticed structure and a construction method of the steel bar connector. The steel bar connector comprises first supporting rings and second supporting rings, wherein at least two longitudinal supporting ribs are connected between the first supporting rings and the second supporting rings; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity; pouring concrete at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Steel bar connector with inner ring cylindrical space latticed structure and construction method of steel bar connector

ActiveCN104963464AEven by forceReduce your weightBuilding reinforcementsBuilding material handlingRebarMesh grid

The invention provides a steel bar connector with an inner ring cylindrical space latticed structure and a construction method of the steel bar connector. The steel bar connector comprises first supporting rings and second supporting rings, wherein at least two longitudinal supporting ribs are connected between the first supporting rings and the second supporting rings; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity; pouring concrete at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

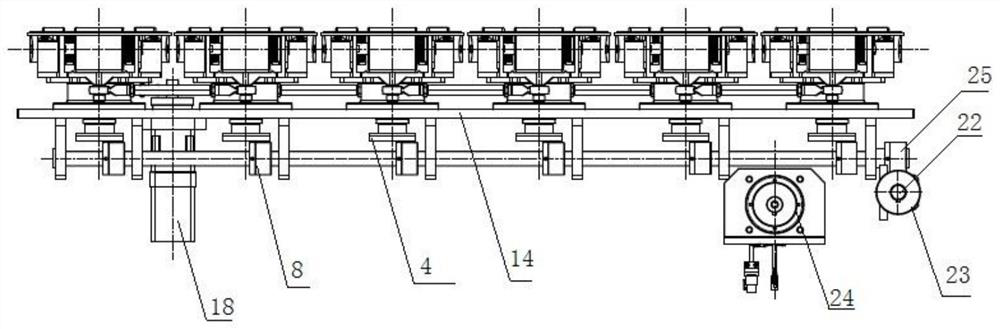

High-speed mute shunting device

PendingCN112141597AGuaranteed to be normalPrevent malfunctionConveyorsControl devices for conveyorsShunt DeviceMagnetic tension force

The invention relates to a high-speed mute shunting device. A second driving unit and a plurality of shunting modules are mounted on a main body bracket, a second transmission rod is horizontally arranged on one side of the shunting modules arranged side by side, a plurality of driving magnetic rings corresponding to the shunting modules are arranged on the second transmission rod, and a transmission wheel is arranged at one end of the second transmission rod; the second driving unit is in transmission connection with the transmission wheel; the driving magnetic rings magnetically drive the shunting modules at the corresponding positions to operate; and a driving roller is also arranged on the main body bracket. According to the high-speed mute shunting device, a plurality of shunting machine modules are driven to operate by one second driving unit through magnetic force at the same time, the second driving unit drives the second transmission rod, the second transmission rod drives thedriving magnetic rings to drive magnetic rings on first transmission rods to rotate through magnetic force, transmission shafts are driven to rotate through magnetic force of the magnetic rings on the first transmission rods, and the transmission shafts and driving units are driven by magnetic force. Through multi-layer magnetic force, the friction loss is reduced, the service life of the equipment is prolonged, and the stable operation of the equipment is ensured.

Owner:SHANGHAI BOWOO AUTOMATION SYST +1

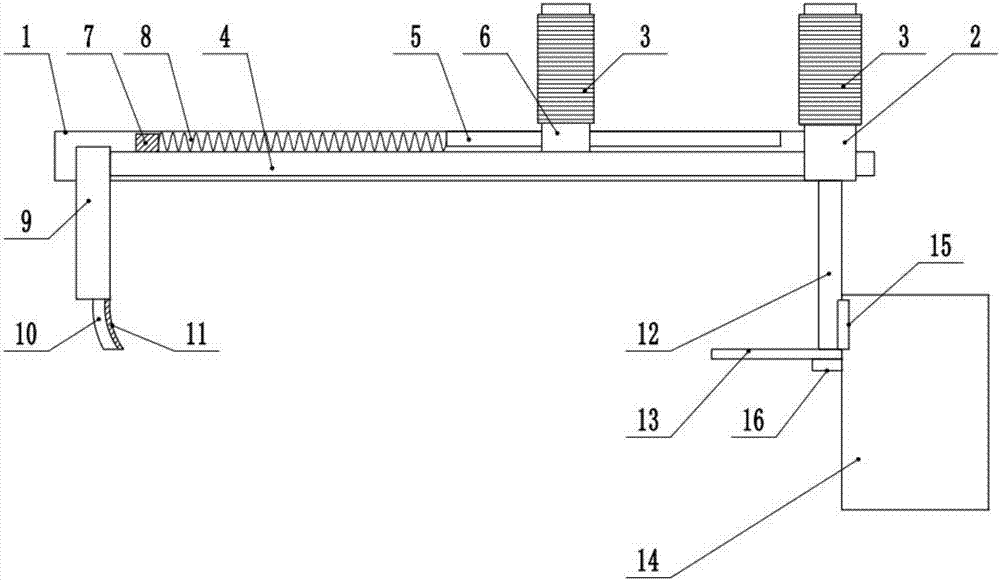

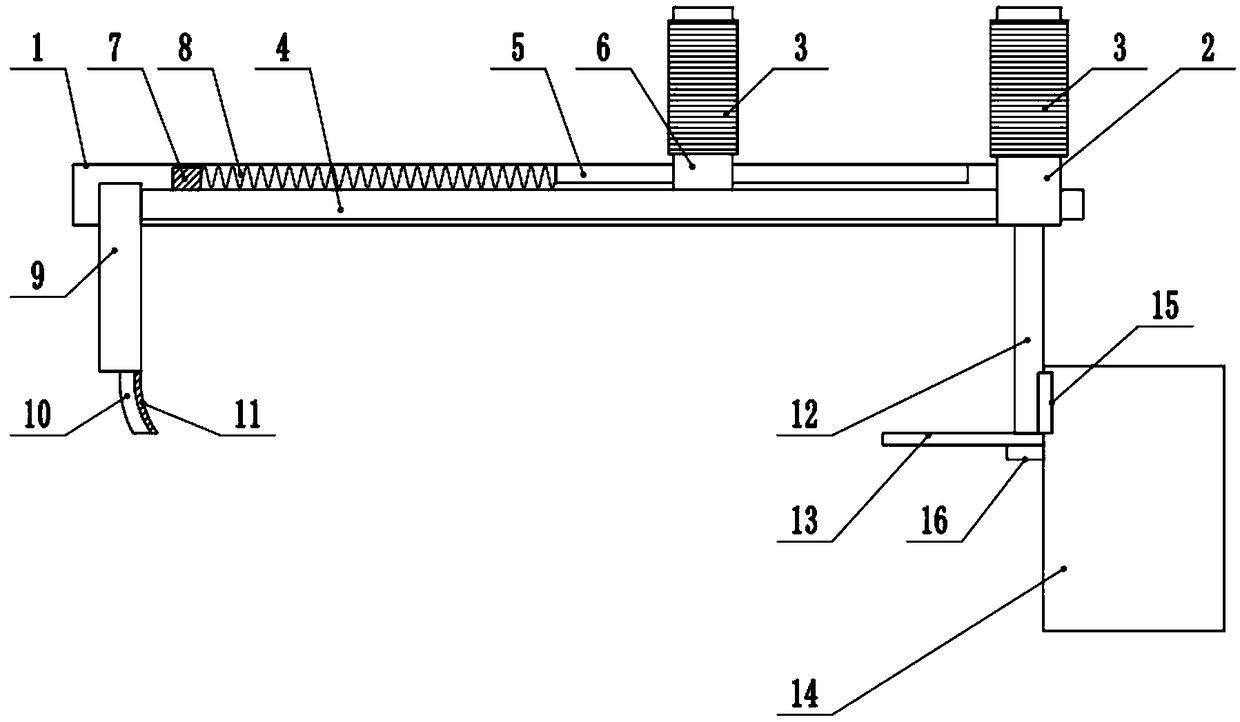

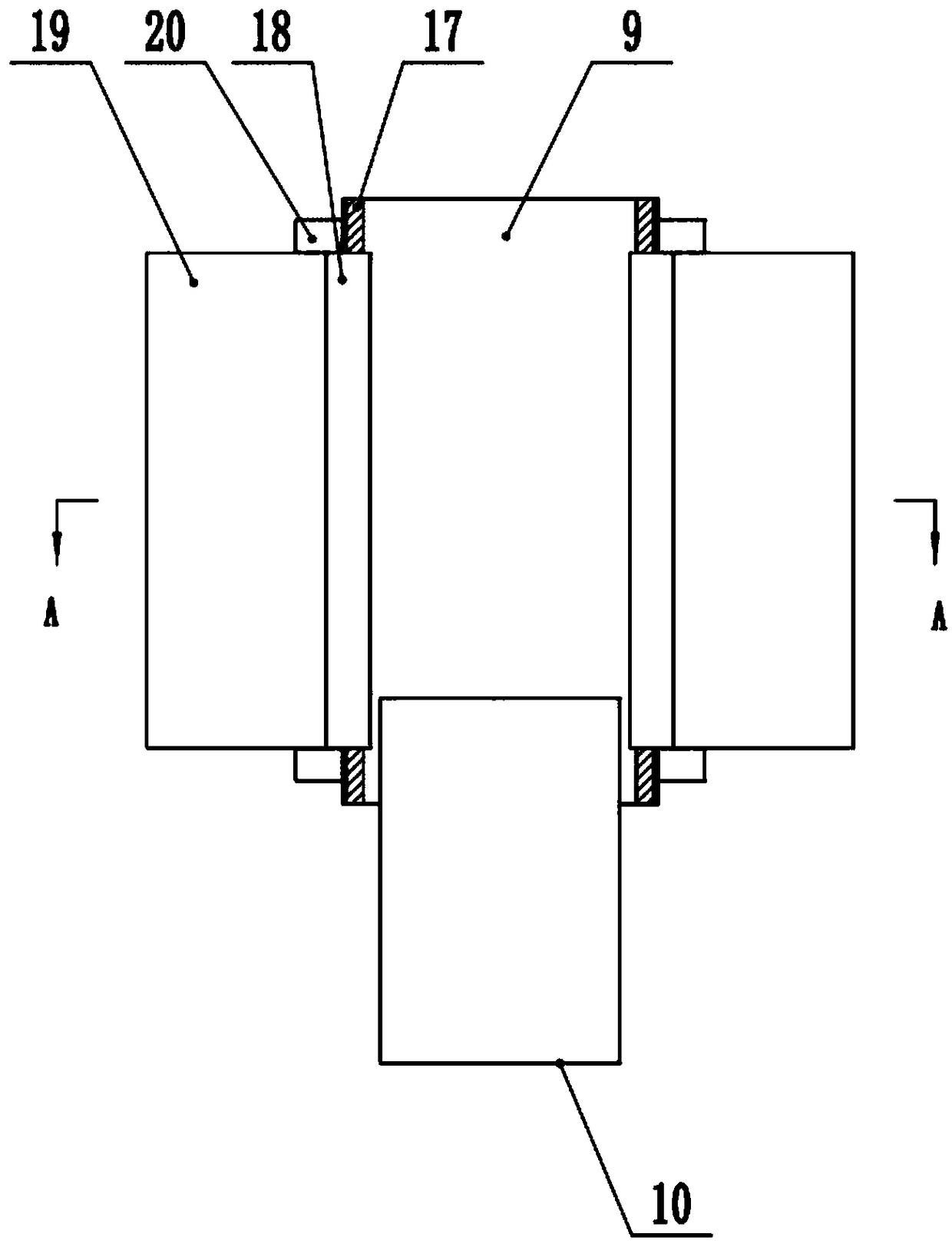

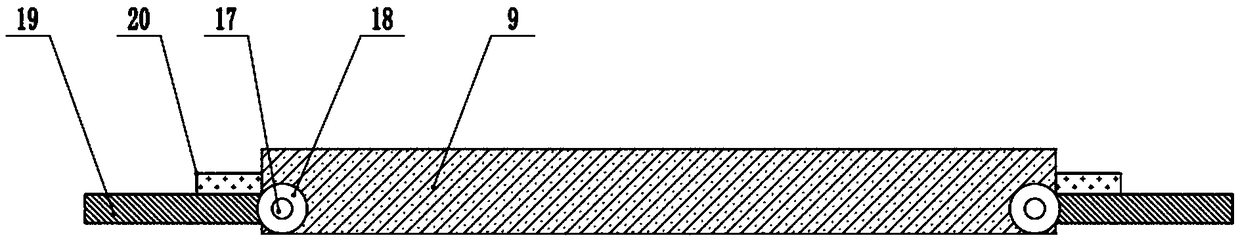

Environmentally friendly copper thread cleaning device for motor winding cutting

ActiveCN107070118AEfficient removalAvoid possessionManufacturing dynamo-electric machinesCoils manufactureArchitectural engineeringCopper

The invention discloses an environmentally friendly copper thread cleaning device for motor winding cutting. The environmentally friendly copper thread cleaning device comprises a device body; the device body is provided with a main support; the tail of the main support is provided with a handle A; the upper end of the main support is provided with a slot; the inside of the main support is provided with a slide bar; the slide bar is provided with a handle B; the left end of the slide bar is provided with a fixing block; the inside of the main support is provided with a reset spring; the left end of the main support is provided with a baffle; the bottom of the baffle is provided with a shaving tooth; the bottom of the right end of the main support is provided with a connecting rod; the bottom of the connecting rod is provided with a locating plate; and the right side of the connecting rod is provided with a storage box. The environmentally friendly copper thread cleaning device for the motor winding cutting provided by the invention is simple in structure and convenient in use, capable of effectively removing winding copper threads inside winding cutting equipment, so as to avoid the existence of a large number of threads inside a groove of the cutting equipment; besides, the threads are avoided flying around through the function of the device body; and in addition, the cleaning method is simple and feasible, and is very environmentally friendly, the cleaning effect is good and the practicability is strong.

Owner:浙江菱德电梯部件有限公司

A kind of construction method of cage type space grid structure steel bar connector with cone

ActiveCN104963456BEven by forceReduce your weightCeramic shaping apparatusBuilding reinforcementsEngineeringRebar

The invention provides a steel bar connector with an inner ring cylindrical space latticed structure and a construction method of the steel bar connector. The steel bar connector comprises first supporting rings and second supporting rings, wherein at least two longitudinal supporting ribs are connected between the first supporting rings and the second supporting rings; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity; pouring concrete at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A steel bar connector with inner ring cylindrical structure and its construction method

ActiveCN104963458BEven by forceLight weightBuilding reinforcementsBuilding material handlingRebarMesh grid

The invention provides a steel bar connector with an inner ring cylindrical structure and a construction method of the steel bar connector. The steel bar connector comprises supporting rings, wherein at least two longitudinal supporting ribs are connected between the supporting ring; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices; a metallic sheath is arranged outside the space latticed cylinder body. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity, and pouring at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A kind of testing device and testing method of TFT substrate

ActiveCN103268027BReduce reservesAvoid possessionElectrical testingNon-linear opticsThermodynamicsMicroscope

The invention discloses a testing device and a testing method of a TFT (Thin Film Transistor) base plate. The testing device comprises a microscope stage, a detection unit and at least one probe unit, wherein a sliding structure is arranged on at least one side of the microscope stage; the detection unit is positioned above the microscope stage; the probe unit comprises at least one probe and a sliding component; and the probe unit slides along the sliding structure along with the sliding component. By adopting the testing device of the TFT base plate, the testing specification can be quickly changed, additionally, the reserve of a testing framework is reduced, and occupation of space and funds for reserving the testing framework is avoided.

Owner:CHENGDU TIANMA MICROELECTRONICS

A cage-type steel bar connector with a cone and its construction method

ActiveCN104963454BEven by forceReduce your weightBuilding reinforcementsBuilding material handlingRebarSpatial distribution

The invention provides a cage-type steel bar connector with a cone and a construction method thereof. Longitudinal support ribs at 360 0 Evenly distributed within the range, the diameter of the outer wall of the multiple longitudinal support ribs is the same as the outer diameter of the large diameter end of the cone, the other end of each longitudinal support rib is connected to the support ring, and the circular support rib is connected to the cylindrical frame , the cone tube, oblique support ribs, longitudinal support ribs, circular support ribs and support rings are connected to form a grid-shaped cylinder, and several spatial grids are distributed on the circumference of the network-shaped cylinder. set. The preparation method is as follows: taking a columnar mold and placing it in the cylinder cavity, pouring concrete on the outer periphery of the columnar mold, taking out the columnar mold, pouring concrete into the connecting hole, and then the construction is completed. The invention completely changes the structure of the steel bar connector in the prior art, so as to solve the deficiencies in the prior art.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A copper wire end cleaning device for motor winding cutting

ActiveCN107070118BEfficient removalAvoid possessionManufacturing dynamo-electric machinesCoils manufactureCopper wireArchitectural engineering

Owner:浙江菱德电梯部件有限公司

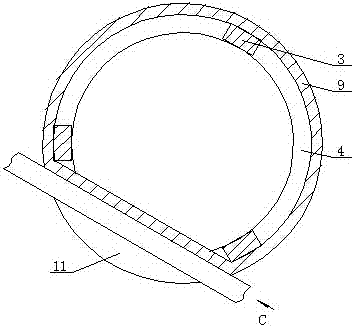

Spiral steel bar connector with cone-shaped barrel and construction method for spiral steel bar connector

ActiveCN104963462AEven by forceReduce your weightBuilding reinforcementsBuilding material handlingRebarOgive

The invention provides a spiral steel bar connector with a cone-shaped barrel and a construction method for the spiral steel bar connector. The spiral steel bar connector comprises the cone-shaped barrel, wherein a through hole is formed in the cone-shaped barrel; the circumference of the large-diameter end of the cone-shaped barrel is connected with one end of each of inclined supporting ribs; the other end of each inclined supporting rib is connected with one end of a corresponding longitudinal supporting rib respectively; the longitudinal supporting ribs are uniformly distributed within a range of 360 degrees; the diameters of the outer walls of the longitudinal supporting ribs are the same as the outer diameter of the large-diameter end of the cone-shaped barrel; the cone-shaped barrel, the inclined supporting ribs, the longitudinal supporting ribs, spiral supporting ribs and supporting rings are connected to form a latticed barrel body; a barrel cavity is formed in the latticed barrel body; a plurality of space lattices are distributed on the circumference of the latticed barrel body; a metal sleeve is arranged outside the space latticed barrel body. The preparation method for the spiral steel bar connector comprises the following steps of putting a columnar die into the barrel cavity, pouring concrete to the periphery of the columnar die, taking out the die, and pouring concrete into a connection hole to complete construction. According to the spiral steel bar connector, the structure of a steel bar connector in the prior art is completely changed, so that the shortcomings in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

A space grid structure steel bar connector and its construction method

The invention provides a steel bar connector with an inner ring cylindrical space latticed structure and a construction method of the steel bar connector. The steel bar connector comprises first supporting rings and second supporting rings, wherein at least two longitudinal supporting ribs are connected between the first supporting rings and the second supporting rings; three or more than three inner ring supporting ribs are connected onto the inner walls of the longitudinal supporting ribs; the outer diameters of the first supporting rings are identical to those of the second supporting rings; the first supporting rings, the second supporting rings, the longitudinal supporting ribs and the inner ring supporting ribs are connected to form a latticed cylinder body; a cylindrical cavity of which the diameter of the upper part is identical to that of the lower part is formed in the latticed cylinder body; the first supporting rings, the second supporting rings, the inner ring supporting ribs and the longitudinal supporting ribs are connected to form a plurality of space lattices. A preparation method of the steel bar connector comprises the following steps of taking a columnar die and placing the columnar die into the cylindrical cavity; pouring concrete at the periphery of the columnar die; taking out the columnar die; pouring the concrete into connecting holes and finishing the construction. According to the steel bar connector and the construction method disclosed by the invention, the structure of the steel bar connector in the prior art is thoroughly changed, so that the defects existing in the prior art are overcome.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com