A cage-type steel bar connector with a cone and its construction method

A technology of steel bar connector and construction method, which is applied in the processing of building materials, structural elements, building components, etc., can solve the problems of reduced strength, reduced connection strength, increased construction difficulty, etc., and achieves improved bending resistance and self-weight. The effect of reducing and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

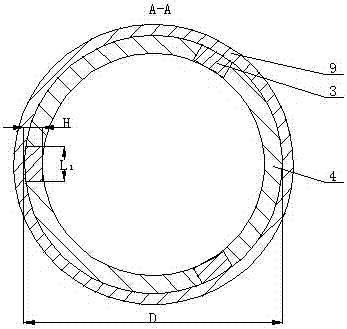

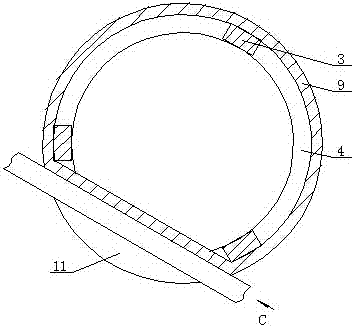

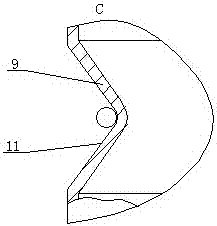

[0015] A cage-type steel bar connector with a cone according to the present invention includes a cone 1, a through hole 6 is opened on the cone 1, and threads are arranged on the hole wall of the through hole 6, and the large diameter end of the cone 1 is connected to the circumference of the cone. One end of at least two oblique support ribs 2 is connected, and the other end of each oblique support rib 2 is respectively connected with one end of a respective longitudinal support rib 3, and a plurality of longitudinal support ribs 3 are connected at 360 0 Evenly distributed within the range, the diameter of the outer wall of the plurality of longitudinal support ribs 3 is the same as the outer diameter of the large diameter end of the cone 1, the other end of each longitudinal support rib 3 is connected to the support ring 5, the cone 1, the oblique support rib 2 1. The support ring 5 is connected with a plurality of longitudinal support ribs 3 to form a cylindrical frame, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com