Construction method of building superstructure in high-rise steel-concrete mixed structure with few supporting formworks

A technology of mixed structure and construction method, applied in the direction of formwork/formwork/work frame, building, building structure, etc., can solve the problems of simultaneous construction of multiple layers, occupation of turnover materials, high construction cost, etc., to reduce turnover materials The use, increase the construction progress, the effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

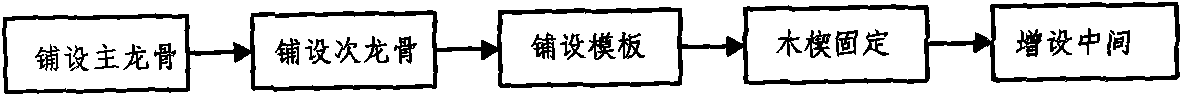

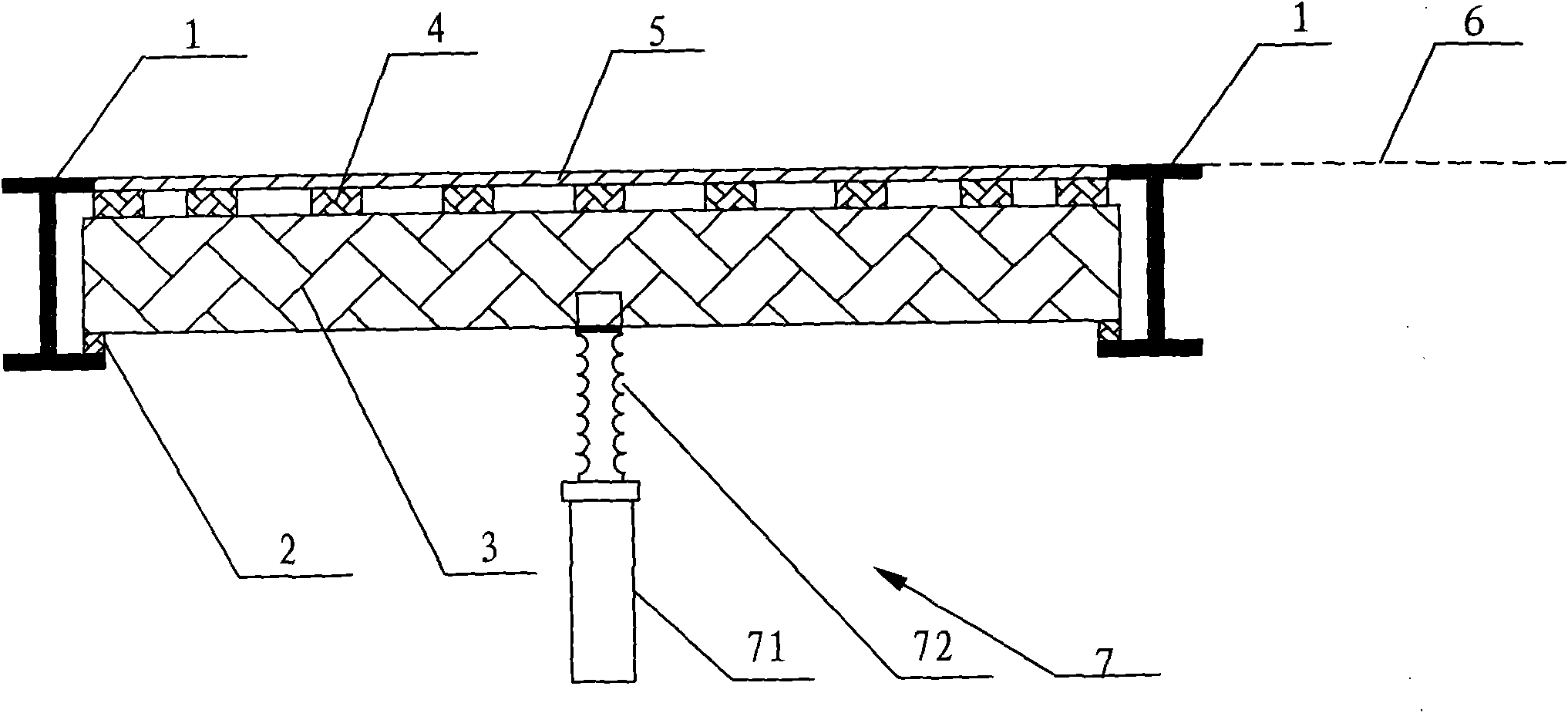

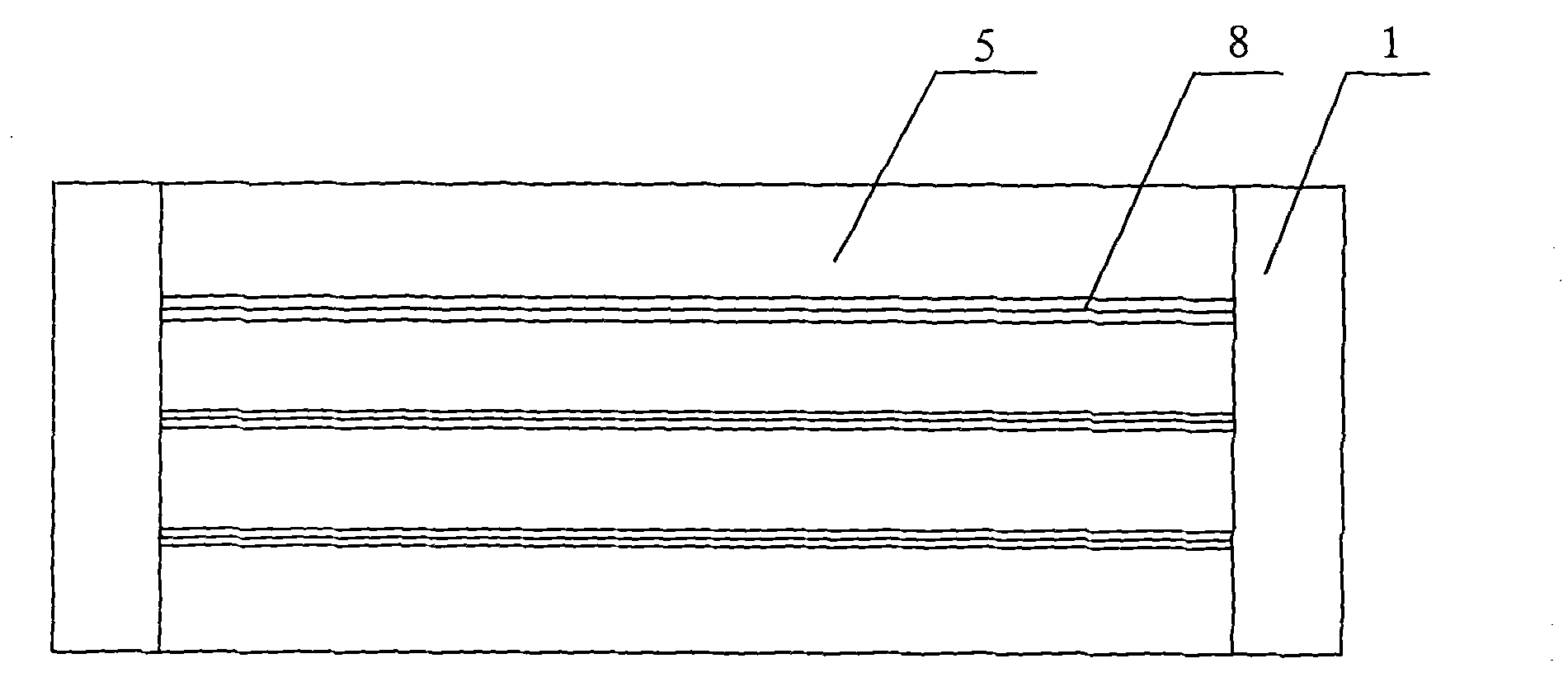

[0022] like figure 1 , 2 As shown, a construction method of less-supported formwork for the floor of a high-rise steel-concrete hybrid structure includes laying the main keel, laying the secondary keel, laying the formwork, fixing with wooden wedges, and finally adding the middle, etc. The specific operation steps are: hoisting H-shaped steel Beam 1, and then select the appropriate wooden wedge 2 according to the height of the bottom of the floor and the height of the H-shaped steel beam 1. For the higher H-shaped steel beam 1, the wooden square can be placed on the lower flange, and then the wooden wedge 2 is used for leveling. The main keel 3 is laid on the wooden wedge 2. The material of the main keel 3 can be wooden material or H-shaped steel beam 1. The main keel 3 adopts the specification of 100×150mm, and is directly supported on the H-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com