Testing device and testing method of TFT (Thin Film Transistor) base plate

A technology for testing devices and testing methods, which is applied to measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of frequent replacement of test frames, avoid storage space and capital occupation, prevent probe damage, and quickly change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

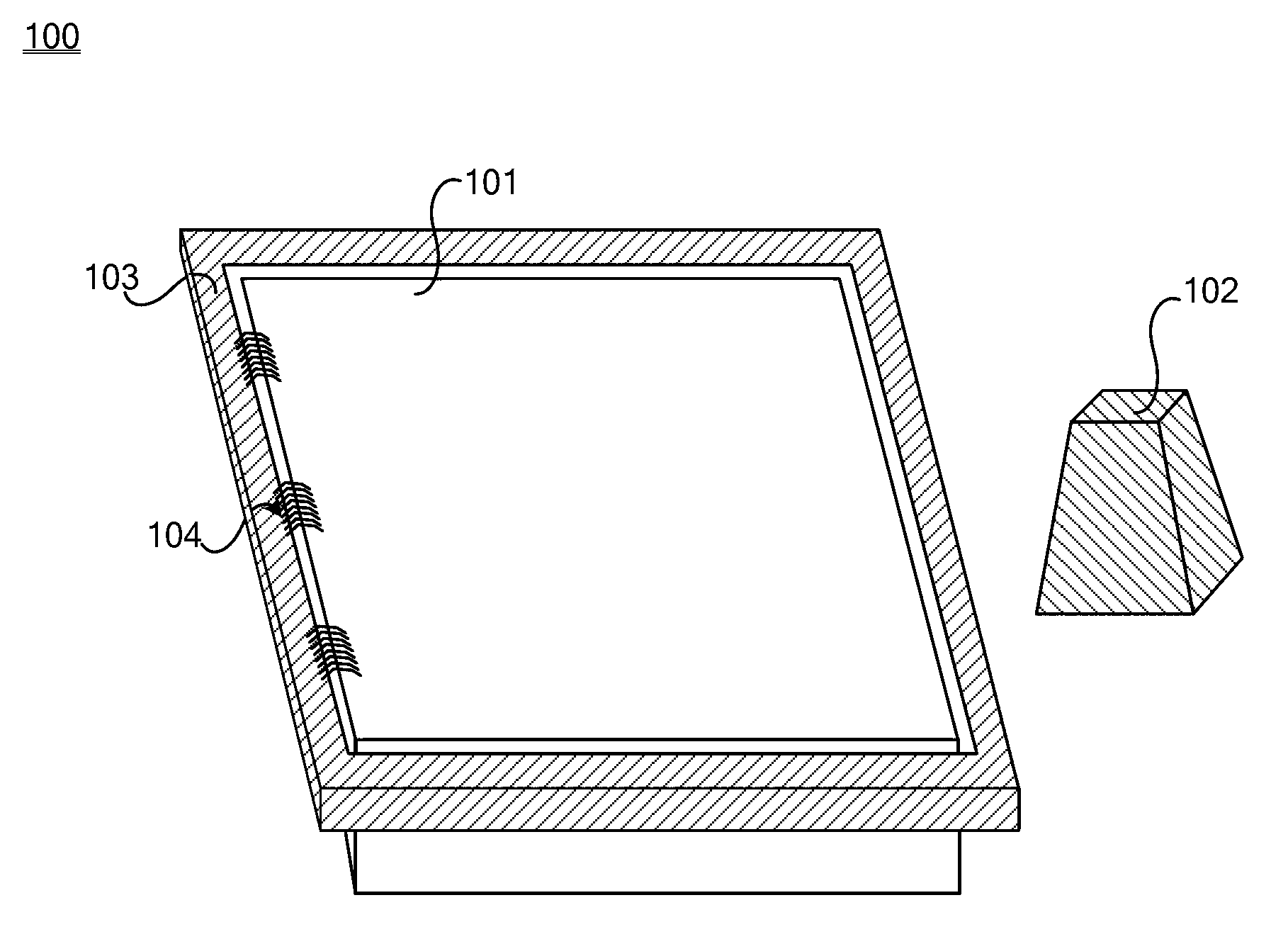

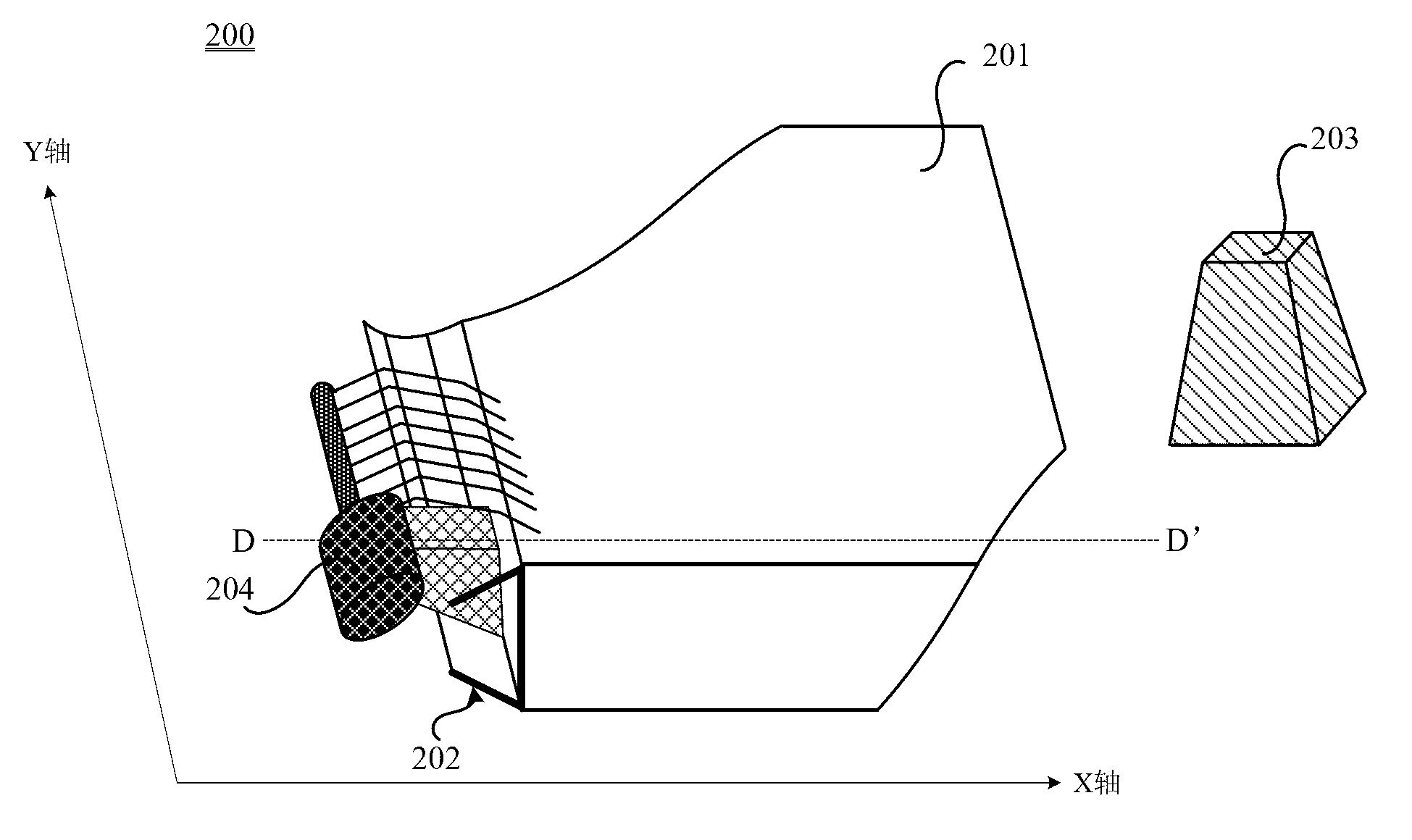

[0073] Such as figure 2 As shown, the TFT substrate testing device 200 of this embodiment includes: a stage 201, a sliding structure 202 arranged on at least one side of the stage 201, a detection unit 203 above the stage 201, and at least one probe. needle unit 204 .

[0074] The sliding structure, the probe unit and the detection unit will be described in detail below in sequence.

[0075] sliding structure

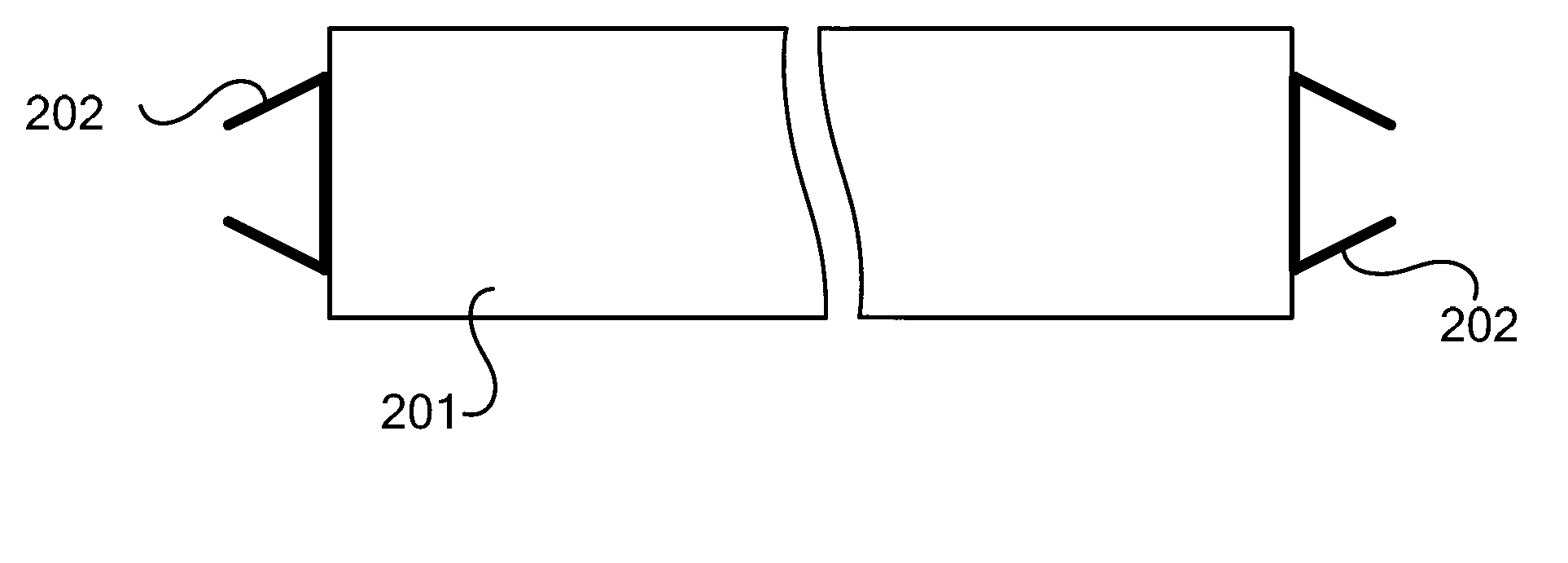

[0076] Such as image 3 As shown, the sliding structure 202 is a sliding guide rail disposed on the side of the platform 201 and parallel to the side. In this embodiment, the sliding structures 202 are respectively arranged on two sides of the platform 201 . It can be understood that, in order to adapt to TFT substrates of more specifications, sliding structures 202 may also be provided on more than two sides or all sides of the carrier 201 . Of course, as long as the test of the TFT substrate to be tested can be completed, the sliding structure 202 can also be pr...

Embodiment 2

[0098] The difference between this embodiment and the first embodiment lies in that the sliding structure 202 is a sliding groove provided on the side of the carrier 201 and parallel to the side. Such as Figure 9 As shown, the sliding structure 202 is respectively arranged on two sides of the carrier 201 . It can be understood that, in order to adapt to TFT substrates of more specifications, sliding structures 202 may also be provided on all sides of the carrier 201 . Of course, as long as the test of the TFT substrate to be tested is completed, the sliding structure 202 can also be provided only on one side of the stage 201 .

Embodiment 3

[0100] Such as figure 2 As shown, in the first embodiment through the sliding structure 202, the probe 205 can be along the length direction of the sliding structure 202 ( figure 2 in the Y-axis direction) freely slides, but cannot slide along the width direction of the sliding structure 202 ( figure 2 If the signal access point of the TFT substrate changes in the width direction of the sliding structure 202, the test device for the TFT substrate mentioned above cannot be used for testing. For this reason, in this embodiment, the section of the sliding member 206 is designed as a rectangle to ensure that the probe 205 can also have a certain range of movement along the width direction of the sliding structure 202 (direction perpendicular to the length direction).

[0101] Such as Figure 10 As shown, by controlling the embedding length of the sliding component 206 in the sliding structure 202 , the sliding component 206 can move in a small range along the width direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com