Tubular spiral space lattice structure steel bar connector and construction method of tubular spiral space lattice structure steel bar connector

A technology of steel bar connectors and spatial grids, applied in structural elements, building components, manufacturing tools, etc., can solve problems such as reduced strength, reduced connection strength, and increased construction difficulty, and achieves improved bending resistance and reduced weight. , the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

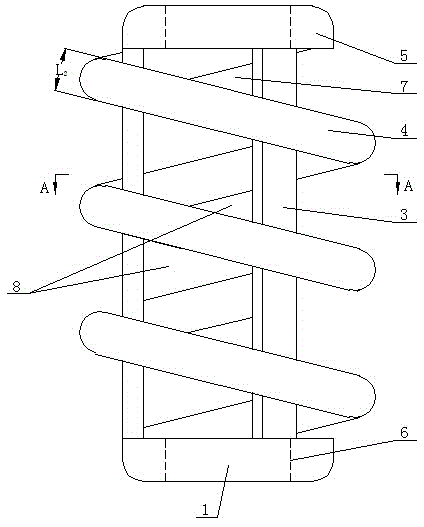

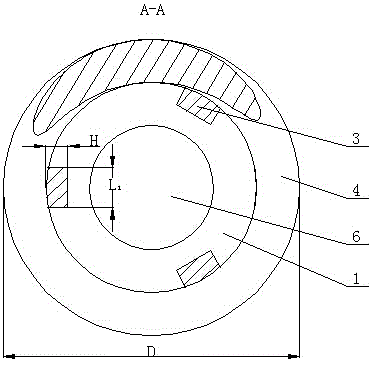

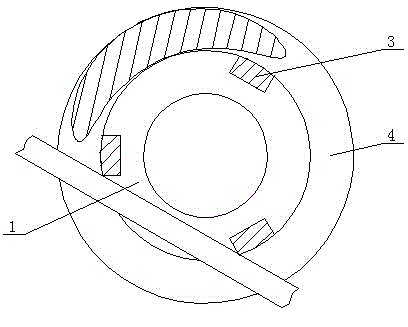

[0013] A cylindrical spiral space grid structure steel bar connector according to the present invention comprises a first support ring 1 and a second support ring 5, at least two longitudinal bars are connected between the first support ring 1 and the second support ring 5 Support ribs 3, a plurality of longitudinal support ribs 3 at 360 0 Evenly distributed, the outer walls of a plurality of longitudinal support ribs 3 are connected to the spiral support ribs 4, the spiral support ribs 4 are evenly distributed on the height of the longitudinal support ribs 3, the outer diameters of the first support ring 1 and the second support ring 5 are equal, The spiral support ribs 4 are connected with the longitudinal support ribs 3 to form several spatial grids 8, the first support ring 1, the second support ring 5, the longitudinal support ribs 3 and the spiral support ribs 4 are connected to form a grid-like cylinder, A cylinder chamber 7 with equal upper and lower diameters is arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com