Optical fiber compound phase line joint box

A technology of optical fiber composite phase line and splice box, which is applied in the coupling of optical waveguide, fiber mechanical structure, etc., and can solve the problems of further maintenance hidden dangers, hidden dangers of maintenance or repair, and optical fiber broken at the end of stainless steel pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

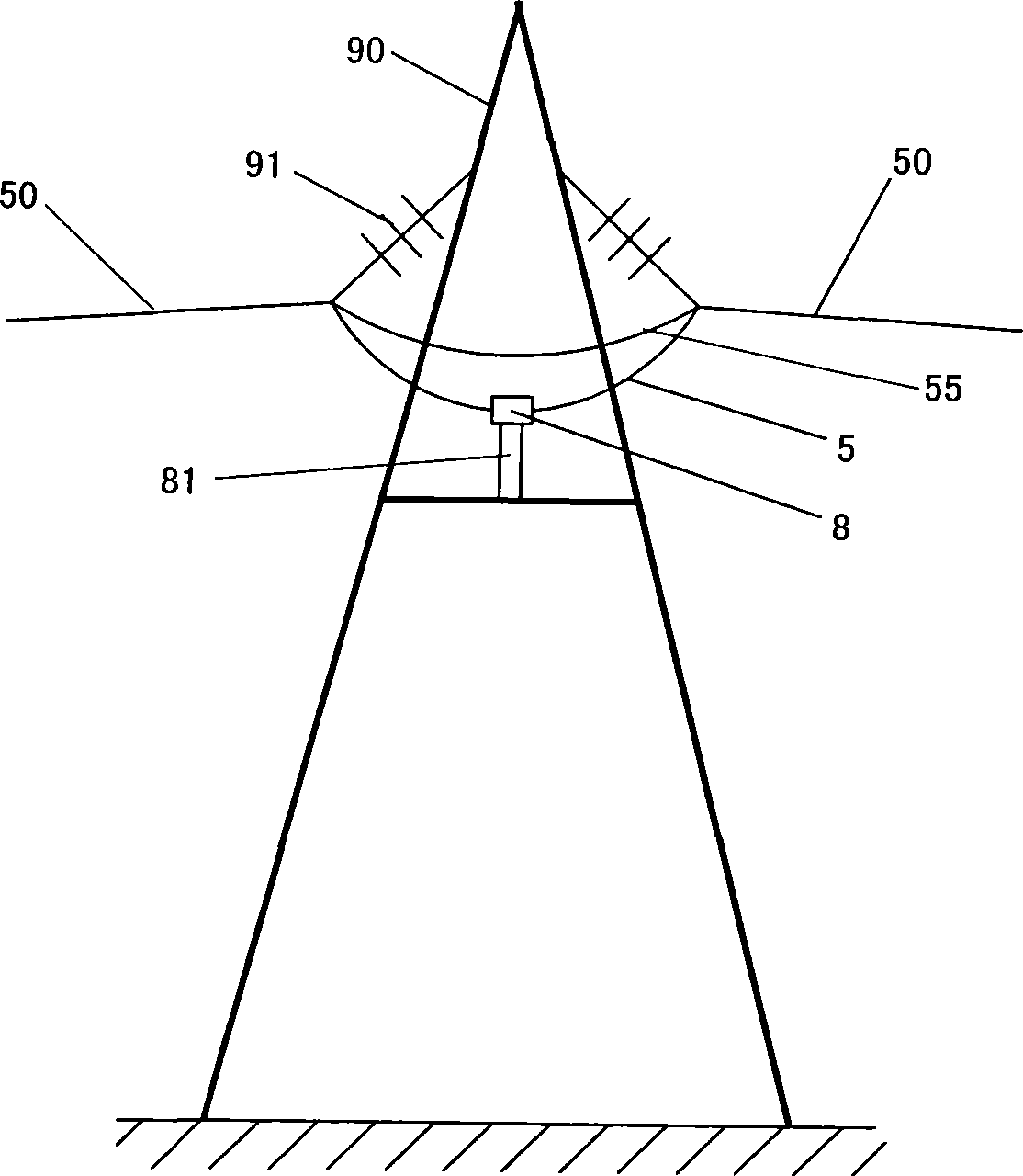

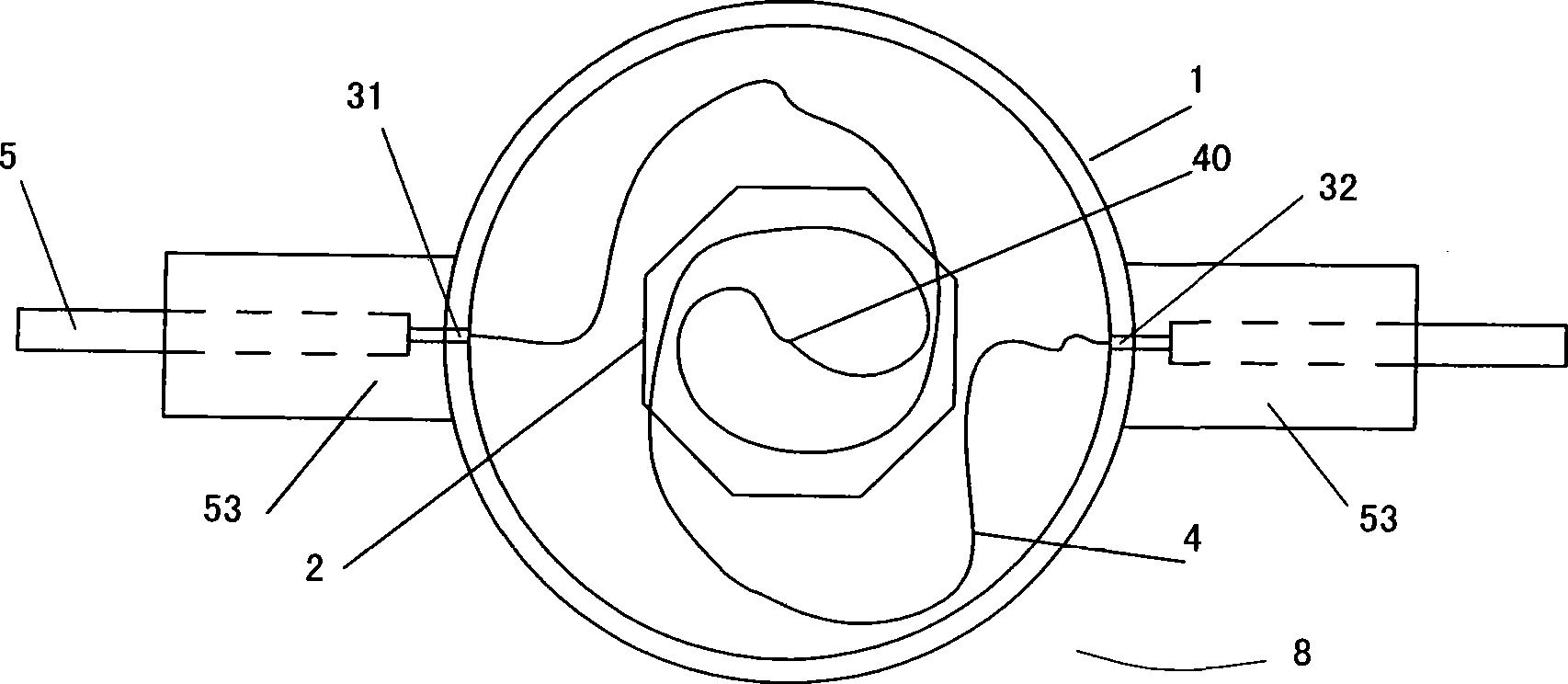

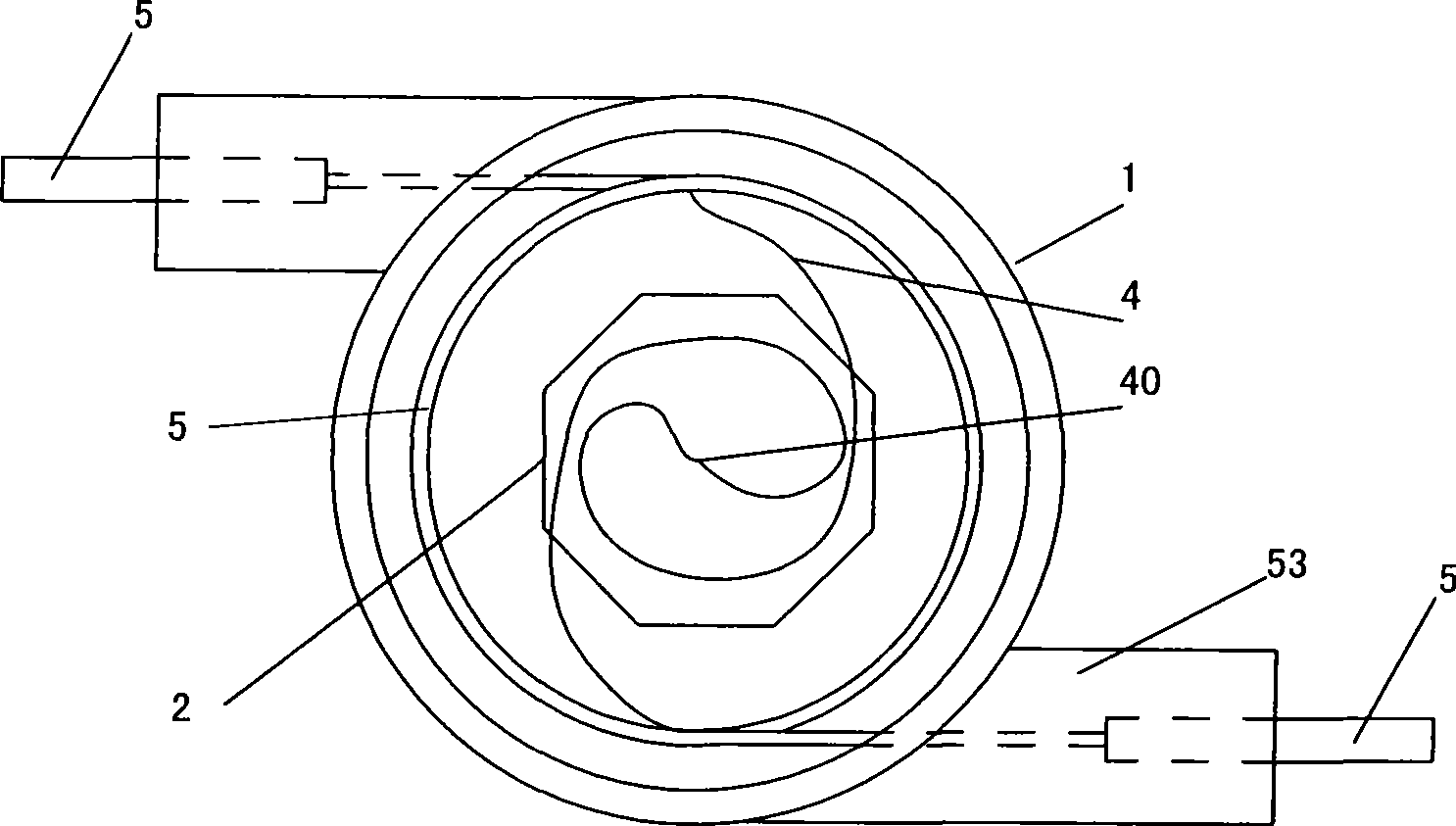

[0019] refer to image 3 , an embodiment of the optical fiber composite phase line splice box of the present invention, the splice box 8 includes a fiber tray 2 installed in the splice box box shell 1, and the box shell 1 is provided with two optical fibers for cladding The first cable inlet 31 and the second cable inlet 32 introduced by the metal pipe 5 of 4 are respectively used for the metal pipe 5 to introduce or lead out the joint box 8; the reserved optical fiber is placed in the box shell 1 and placed in the The joints 40 of the two optical fibers are fused to each other, and the first cable entry hole 31 and the second cable entry hole 32 are both arranged on the side of the box shell 1 . The metal tube 5 covering the optical fiber 4 is currently mostly made of stainless steel. Of course, as long as the tube body made of other materials can meet the use or construction requirements, it should also be considered to have the same purpose, function and effect as the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com