High-zirconium high-alkali-resistance glass fiber gridding cloth

A glass fiber, high alkali-resistant technology, used in thermal insulation, textiles, leno fabrics, etc., can solve the problems of wall cracking and falling off, hidden dangers, wall bulging, etc., to improve the safe use period of buildings and ensure building quality. , enhance the effect of boosting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

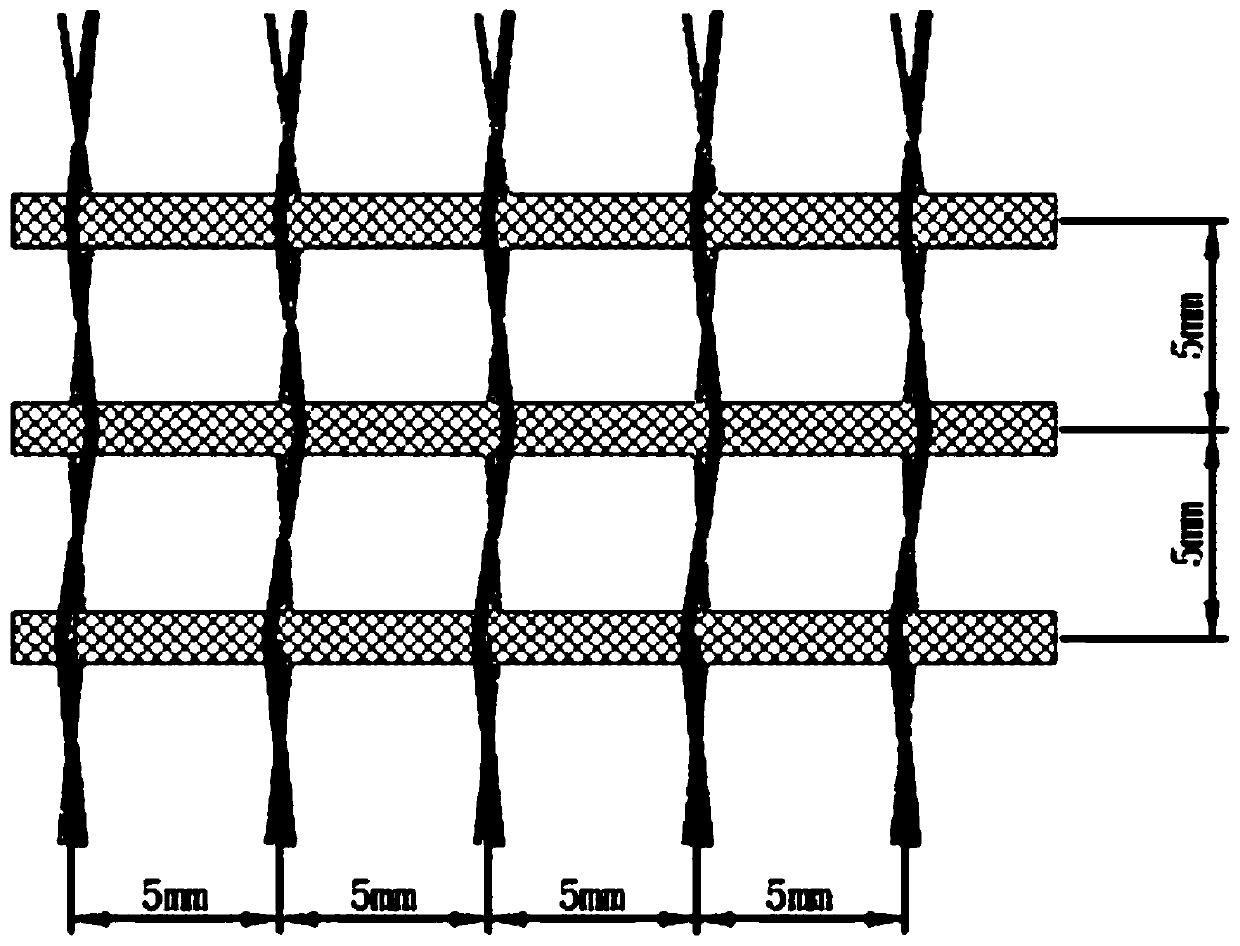

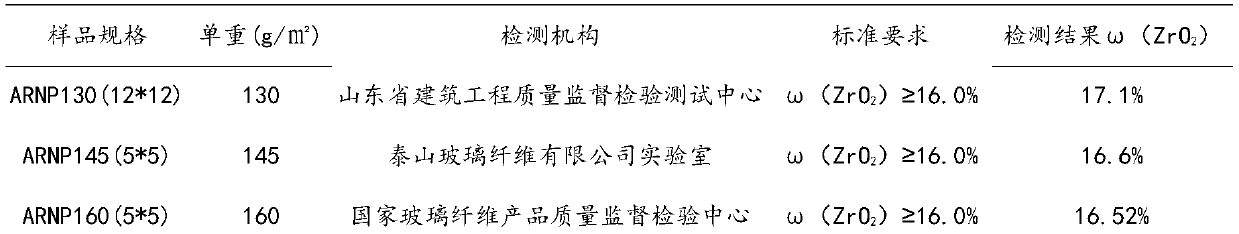

[0039] Embodiment 1 High zirconium high alkali-resistant glass fiber mesh cloth ARNP130 (12*12)

[0040] 1. Yarn formula: Warp single fiber diameter (13-14) μm, linear density (165±5) tex, each warp yarn has (400±10) single fibers, warp twist, twist (28±3) Twist / m, net weight of warp yarn package yarn package (4±0.2) kg; weft yarn is made of high zirconium and high alkali resistance glass fiber direct yarn, single fiber diameter (13-14) μm, linear density (640±50) tex, each weft yarn consists of (1600±50) single fibers;

[0041] 2. ZrO 2 (Zirconium oxide) content: (16.3-17.3)%;

[0042] 3. Product parameters: thickness: (0.55±0.05)mm; grid size: warp (12±0.5)mm, weft (12±0.5)mm; warp and weft density (8.3±0.3) root / 10cm; single weight (130± 10) grams / square meter; single weight of gray cloth (108±8) grams / square meter,

[0043] 4. Polymer coating materials account for (16-18)% of the weight of the finished product; the proportion of polymer coating materials: polyacrylates...

Embodiment 2

[0044] Example 2 High zirconium and high alkali-resistant glass fiber mesh cloth ARNP145 (5*5)

[0045] 1. Yarn formula: Warp single fiber diameter (13-14) μm, linear density (165±5) tex, each warp yarn has (400±10) single fibers, warp twist, twist (28±3) Twist / m, net weight of warp yarn package yarn package (4±0.2)kg; weft yarn is made of high zirconium and high alkali-resistant glass fiber direct yarn, single fiber diameter (13-14) μm, linear density (320±18) tex, each weft yarn consists of (800±20) single fibers;

[0046] 2. ZrO 2 (Zirconium oxide) content: (16.3-17.3)%;

[0047] 3. Product parameters: thickness: (0.48±0.05)mm; grid size: warp (5±0.4)mm, weft (5±0.4)mm; warp and weft density (20±1.6) pieces / 10cm; single weight (145± 11) grams / square meter; single weight of gray cloth (127±10) grams / square meter,

[0048] 4. Polymer coating materials account for (10-14)% of the weight of the finished product; the proportion of polymer coating materials: polyacrylates: (6...

Embodiment 3

[0049] Embodiment 3 High zirconium and high alkali resistance glass fiber mesh cloth ARNP160 (5*5)

[0050] 1. Yarn formula: Warp single fiber diameter (13-14) μm, linear density (165±5) tex, each warp yarn has (400±10) single fibers, warp twist, twist (28±3) Twist / m, net weight of warp yarn package yarn package (4±0.2)kg; weft yarn is made of high zirconium and high alkali resistance glass fiber direct yarn, single fiber diameter (13-14)μm, linear density (350±20) tex, each weft yarn consists of (800±20) single fibers;

[0051] 2. ZrO 2 (Zirconium oxide) content: (16.3-17.3)%;

[0052] 3. Product parameters: thickness: (0.5±0.05)mm; grid size: warp (5±0.4)mm, weft (5±0.4)mm; warp and weft density (20±1.6) pieces / 10cm; single weight (160± 12) grams / square meter; single weight of gray cloth (139±10) grams / square meter,

[0053] 4. Polymer coating materials account for (10-14)% of the weight of the finished product; the proportion of polymer coating materials: polyacrylates:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com