Additive for improving cement performance and preparation method

An additive and efficiency technology, which is applied in the field of additives and preparations for improving cement performance, can solve problems such as poor effect, lower production costs, and inability to effectively improve cement performance, so as to reduce energy consumption, improve reinforcement effect, reduce particle mutual aggregation and Effect of Adhesion Phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

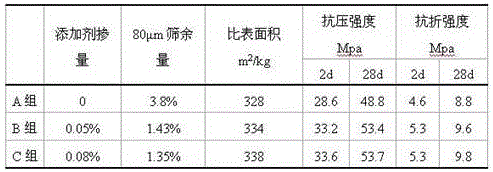

Examples

Embodiment 1

[0023] Example 1 The additive for improving cement performance is mainly prepared from the following raw materials (5 kg per part): 4 parts of sodium ethylenediamine tetramethylene phosphonate, 2 parts of molasses, 2 parts of sodium thiosulfate, and 1 part of sodium hexametaphosphate 1 part, 1 part of sodium aminotrimethylene phosphonate, 0.5 part of diisopropylethanolamine, 0.2 part of triisopropanolamine, 1 part of waste engine oil, 0.1 part of dipropylene glycol, 0.2 part of glycerin, 0.5 part of urea, calcium lignosulfonate 0.1 part, 0.3 part of borax, 0.4 part of dioctyl phthalate, 0.1 part of dibutyl phthalate, 0.2 part of zinc stearate, 0.2 part of surfactant Tween-800. The preparation method of the above-mentioned additive for improving cement performance is:

[0024] (1) Take molasses (can be purchased from Jinan Changyingda Chemical Co., Ltd.) and heat it to a boil over low heat, stir for 15 minutes, take it out, add water that is 1 times the mass of molasses to dilu...

Embodiment 2

[0028] Example 2 The additive for improving cement performance is mainly prepared from the following raw materials (5 kg each): 6 parts of sodium ethylenediamine tetramethylene phosphonate, 5 parts of molasses, 4 parts of sodium thiosulfate, and 3 parts of sodium hexametaphosphate 2 parts, 2 parts of sodium aminotrimethylene phosphonate, 1.5 parts of diisopropylethanolamine, 0.8 part of triisopropanolamine, 2 parts of waste engine oil, 0.4 part of dipropylene glycol, 0.6 part of glycerin, 1.0 part of urea, calcium lignosulfonate 0.4 parts, 0.6 parts of borax, 0.8 parts of dioctyl phthalate, 0.3 parts of dibutyl phthalate, 0.4 parts of zinc stearate, and 0.4 parts of surfactant Tween-800. The preparation method of the above-mentioned additive for improving cement performance is:

[0029] (1) Take molasses (can be purchased from Jinan Changyingda Chemical Co., Ltd.) and heat to boil on low heat, stir for 25 minutes, take it out, add water 3 times the mass of molasses to dilute, ...

Embodiment 3

[0033] Embodiment 3 The additive for improving cement performance is mainly prepared from the following raw materials (5kg per part): 4.5 parts of sodium ethylenediamine tetramethylene phosphonate, 3 parts of molasses, 2.5 parts of sodium thiosulfate, and 2.5 parts of sodium hexametaphosphate 1.2 parts of sodium aminotrimethylene phosphonate, 0.8 parts of diisopropylethanolamine, 0.4 parts of triisopropanolamine, 1.2 parts of waste engine oil, 0.2 parts of dipropylene glycol, 0.3 parts of glycerin, 0.6 parts of urea, calcium lignosulfonate 0.2 parts, 0.4 parts of borax, 0.5 parts of dioctyl phthalate, 0.0.15 parts of dibutyl phthalate, 0.25 parts of zinc stearate, and 0.25 parts of surfactant Tween-800. The preparation method of the above-mentioned additive for improving cement performance is:

[0034] (1) Take molasses (can be purchased from Jinan Changyingda Chemical Co., Ltd.) and heat it to a boil over low heat, stir for 18 minutes, take it out, add water 1.5 times the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com