Deep seam repairing construction method

A construction method and deep seam technology, which is applied in building maintenance, construction, building construction, etc., can solve problems such as filling and inconvenient putty, and achieve the effect of ensuring building quality and filling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

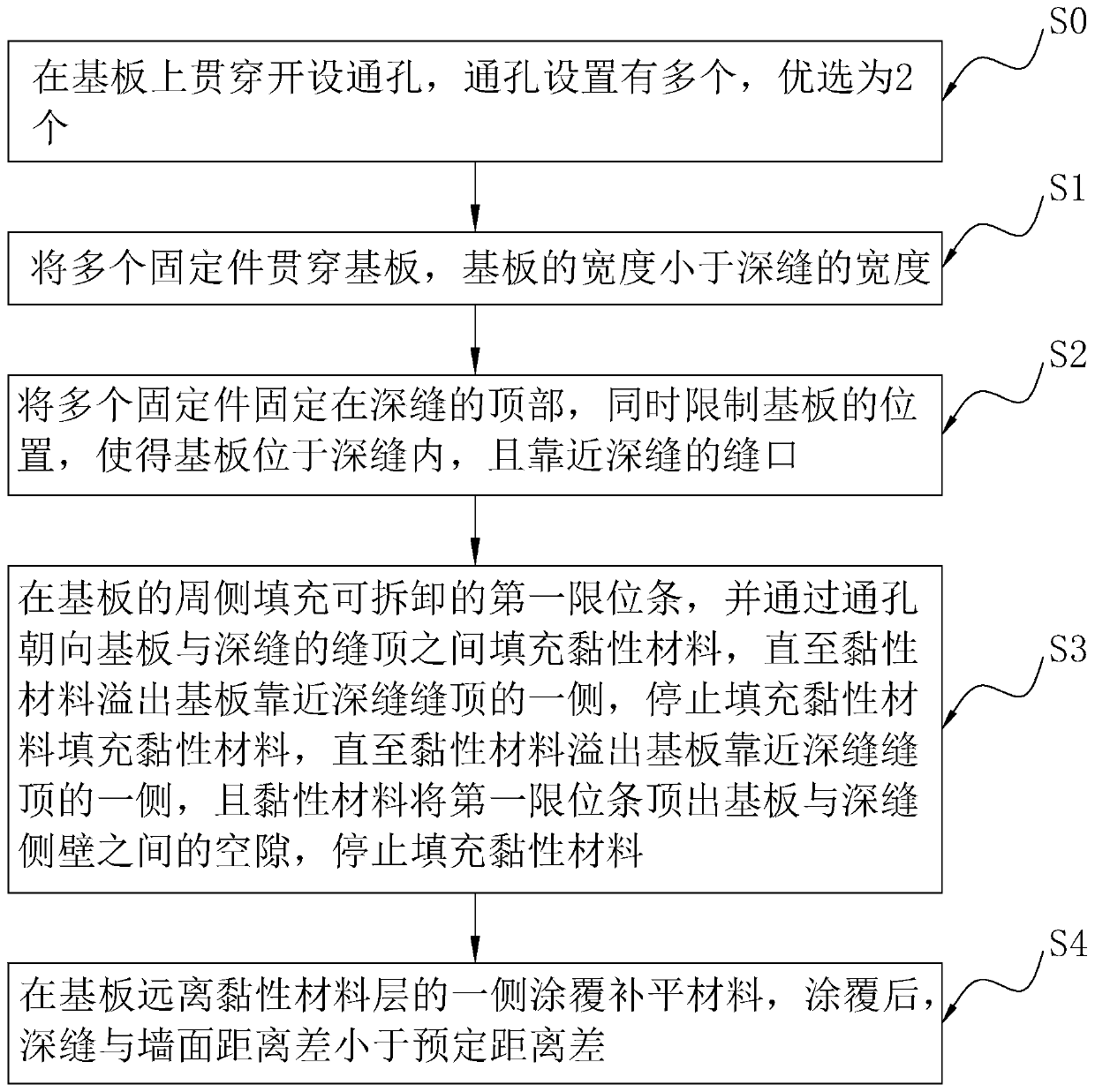

[0038] refer to figure 1 , is a kind of deep seam repair construction method disclosed by the present invention, and construction method is as follows:

[0039] S0: Through-holes are opened on the substrate. There are multiple through-holes, preferably 2. Workers can open an appropriate number of through-holes according to the length of the deep seam, so as to quickly complete the work.

[0040] S1: A plurality of fixing parts are penetrated through the substrate, and the width of the substrate is smaller than the width of the deep seam.

[0041] S2: Fix multiple fixing parts on the top of the deep slot, and restrict the position of the substrate at the same time, so that the substrate is located in the deep slot and close to the opening of the deep slot.

[0042] S3: Fill the detachable first limit strip on the peripheral side of the substrate, and fill the viscous material between the substrate and the top of the deep slot through the through hole until the viscous material...

Embodiment 2

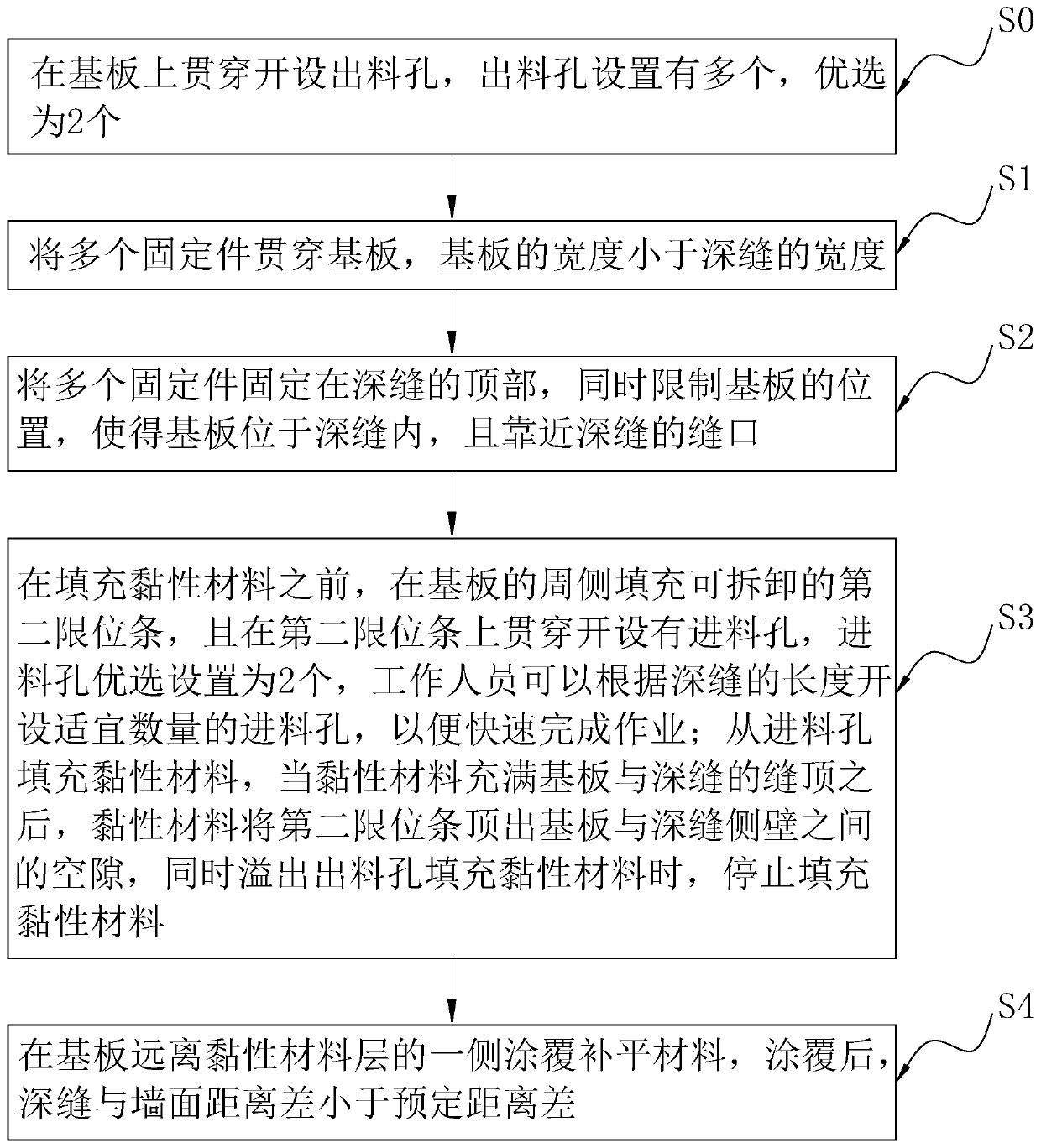

[0047] refer to figure 2 , is a kind of deep seam repair construction method disclosed by the present invention, and the difference with embodiment one is:

[0048] In S0, a discharge hole is opened through the substrate, and there are multiple discharge holes, preferably 2 discharge holes.

[0049] In S3, before filling the viscous material, a detachable second limiting strip is filled on the peripheral side of the substrate, and a feeding hole is opened through the second limiting strip, preferably two feeding holes are set, The staff can open an appropriate number of feed holes according to the length of the deep seam, so as to complete the work quickly; fill the viscous material from the feed hole, and when the viscous material fills the top of the substrate and the deep seam, the viscous material will be released for the second time. Stop filling the viscous material when the limit bar pushes out the gap between the substrate and the side wall of the deep slot, and over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com