Reverse gravity filling forming method for large-size complex amorphous alloy component

An amorphous alloy and anti-gravity technology, which is applied in the field of anti-gravity filling and forming of large-scale and complex amorphous alloy components, can solve the problems of amorphous alloy pollution, difficulty in filling complete components, and failure to meet cooling rate requirements, etc., to achieve mold filling Smooth, reducing the formation of air entrainment and slag inclusion, avoiding the effect of tumbling and splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

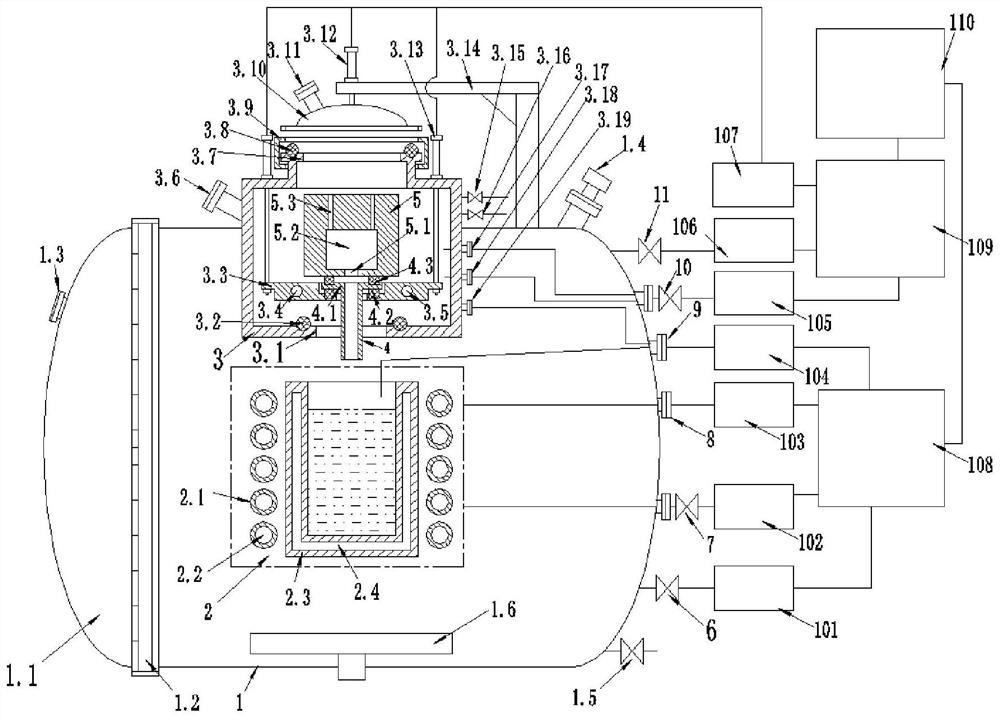

[0054] Specific implementation mode one: combine Figure 1-Figure 24 Describe this embodiment, the described method for filling and forming a large-scale complex amorphous alloy component against gravity, the method is realized according to the following structure:

[0055] It includes a smelting cabin, an induction heating system 2, an anti-gravity filling cabin 3, an anti-gravity filling riser 4, an amorphous component forming mold 5 and a computer-controlled actuator; the smelting cabin is a sealed tank, and the induction heating system 2 is set in the melting In the cabin, the reverse gravity filling cabin 3 is arranged above the induction heating system 2, and the reverse gravity filling cabin 3 is sealed and installed on the shell on the top of the smelting cabin, and the reverse gravity filling riser 4 is installed at the bottom of the reverse gravity filling cabin 3, The amorphous member forming die 5 is installed in the reverse gravity filling chamber 3 above the reve...

specific Embodiment approach 2

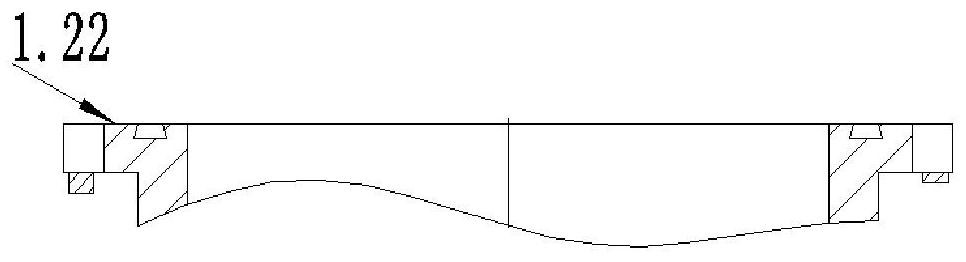

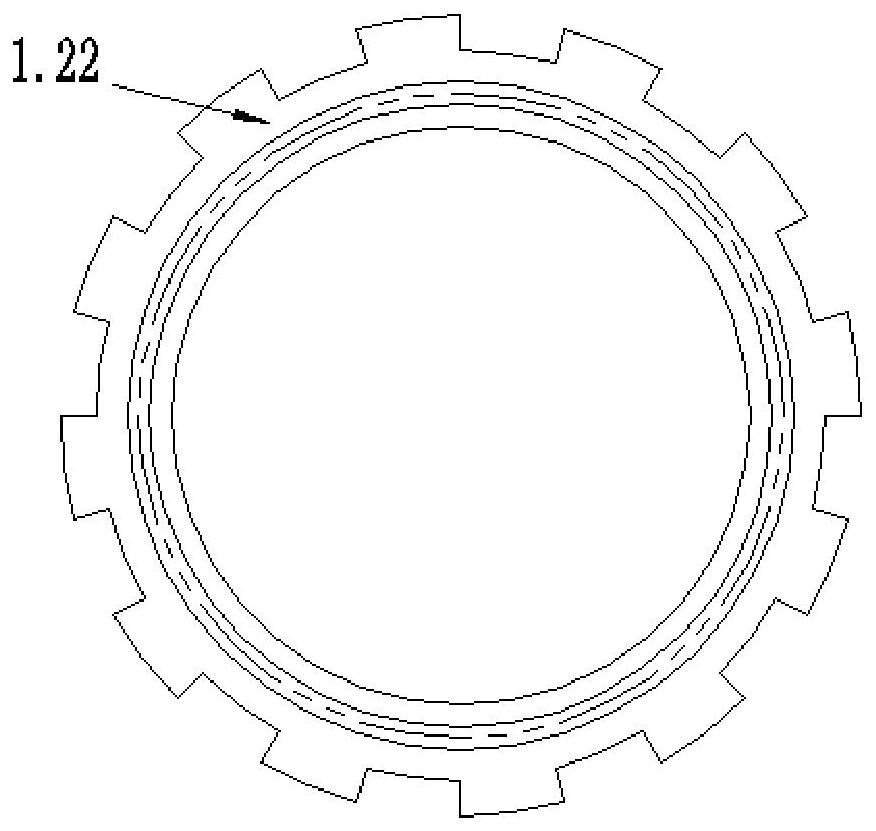

[0093] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, a method for filling and forming large-scale complex amorphous alloy components against gravity in this embodiment, in step 1, the piston rod of the locking oil cylinder 1.23 drives the locking ring 1.21 of the smelting chamber on the two locking flanges 1.22, and the wedge-shaped iron block on the locking flange 1.22 and the wedge-shaped iron block of the smelting cabin locking ring 1.21 are squeezed when the smelting cabin locking ring 1.21 rotates, and then the two locking flanges 1.22 are squeezed Press to seal. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0094] Specific implementation mode three: combination Figure 1-Figure 6 Describe this embodiment, a method for reverse gravity filling and forming of large-scale complex amorphous alloy components described in this embodiment, in step 2, the door drive cylinder 3.12 on the filling chamber opens the filling chamber top cover 3.10 in the pouring chamber, and is supported by the top cover of the filling chamber The arm 3.14 lifts the top cover 3.10 of the filling chamber and rotates it to a position deviated from the top opening of the cabin body 3.1, so as to facilitate loading and unloading of filling parts in the reverse gravity filling chamber 3. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com