Filling body for airtight test

An airtight test and filling body technology, which is applied in the application of light to test the fluid tightness, detect the appearance of fluid at the leakage point, and use liquid/vacuum to measure the liquid tightness, etc. It can solve the problems of poor versatility of the filling body. , to achieve the effect of improving service life, improving versatility, and ensuring pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

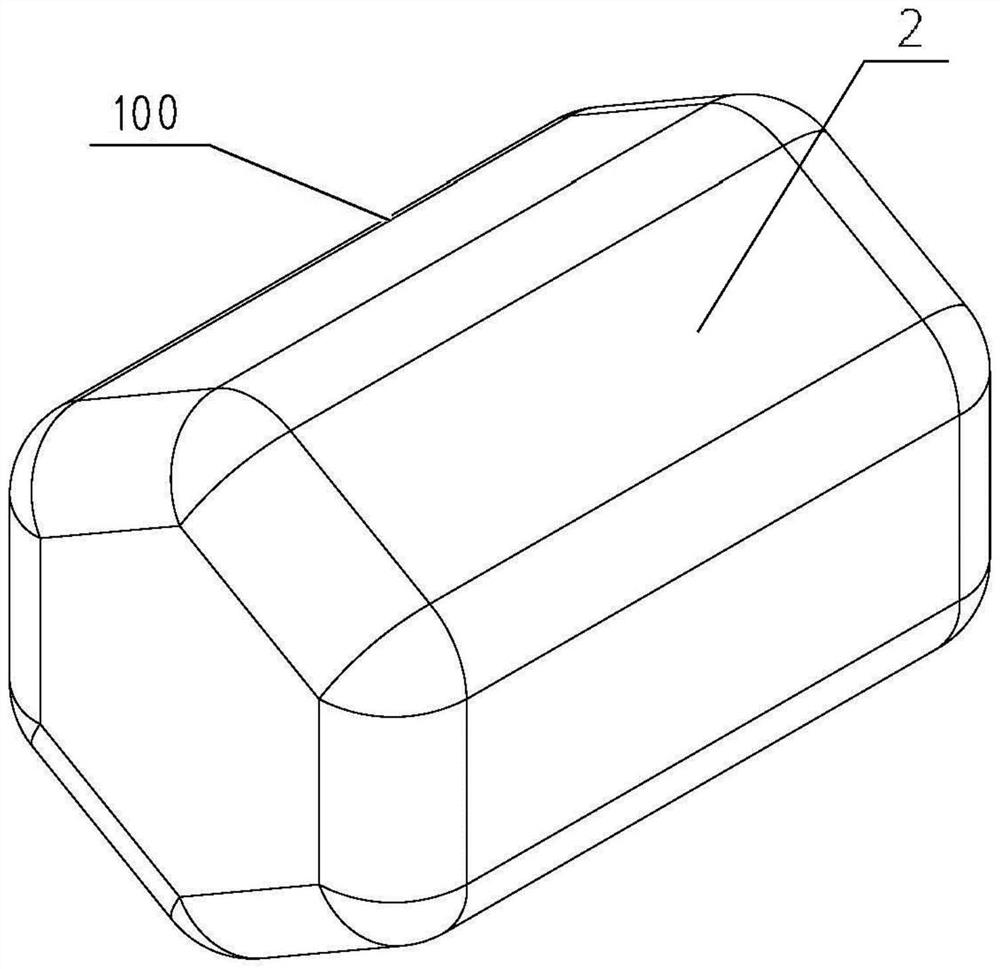

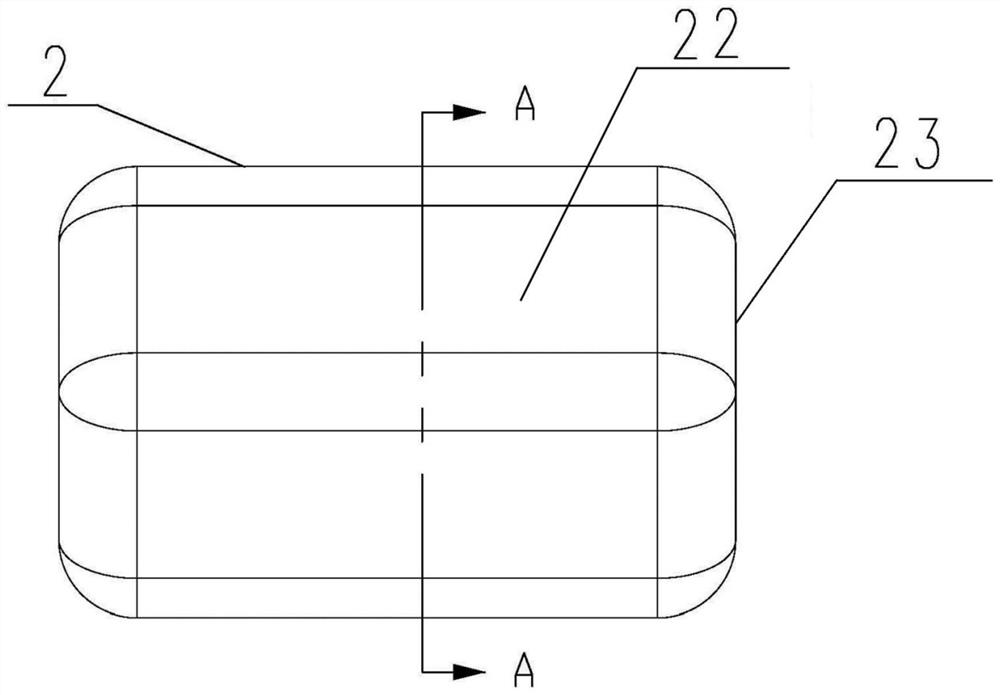

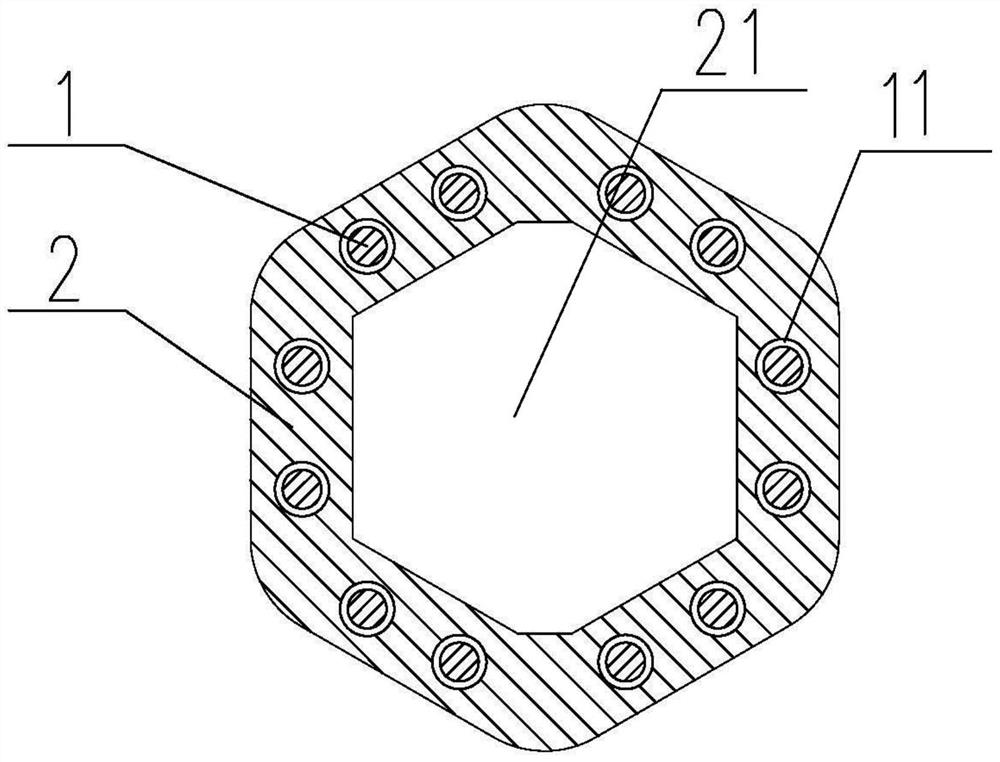

[0048] The filling body 100 used in the gas sealing test in the prior art is a large-scale tooling designed in one piece, and its shape is only suitable for testing tanks of corresponding shapes. If it is necessary to perform leak detection on other shells, it needs to be redesigned. The filling body 100 adapted to the casing, especially when the factory manufactures casings of various shapes, it is necessary to design and manufacture a large number of filling bodies 100 adapted to the corresponding casings, and the cost is relatively high. However, the filling body 100 for the airtight test provided by the present invention is designed in a separate and miniaturized form, and each filling body 100 can be magnetically attracted together. The filler of the airtight cavity 110 can fully occupy the inner space of the airtight cavity 110 , and then inject a small amount of gas into the airtight cavity 110 , which saves costs and improves the versatility of the filler 100 .

[0049...

specific Embodiment 2

[0058] The main difference between it and Embodiment 1 is that in Embodiment 1, the weight reducing cavity 21 is hollow. In this embodiment, when the strength of the material forming the pressure-resistant casing 2 is not high enough, such as Figure 4 As shown, the lightweight filler 3 needs to be filled in the weight-reducing cavity 21. Specifically, the lightweight filler can be ceramsite, mineral wool, asbestos, polyester foam, etc., and the lightweight filler 3 is filled with the pressure-resistant shell 2. The cavity 21 is heavy to increase the overall strength of the filling body 100 .

specific Embodiment 3

[0060] The main difference between it and the embodiment 2 is that in the embodiment 2, the light weight filler 3 is filled in the weight reduction cavity 21 to increase the strength of the filler body 100 . In this example, if Figure 5 As shown, a supporting frame 4 is provided in the weight-reducing cavity 21 of the pressure-resistant housing 2 , and the supporting frame 4 is supported and connected with the pressure-resistant housing 2 in the weight-reducing cavity 21 to increase the overall strength of the filling body 100 .

[0061] In actual implementation, the pressure-resistant shell 2 can be arranged in half. At this time, the weight-reducing cavity 21 is also set in half in the two-and-a-half pressure-resistant shell 2, and the support frame 4 is first filled into the two-and-a-half pressure-resistant shell. 2 in the weight-reducing cavity 21 of one of them, and then the two and a half pressure-resistant shells 2 are fastened and spliced together, so that the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com