Method for rapidly preparing inorganic fiber-enhanced ceramic composite material

A technology of inorganic fibers and composite materials, applied in the field of inorganic non-metals, can solve problems such as poor strength of ceramic parts, and achieve the effects of good thermal stability, rapid prototyping, and high specific mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

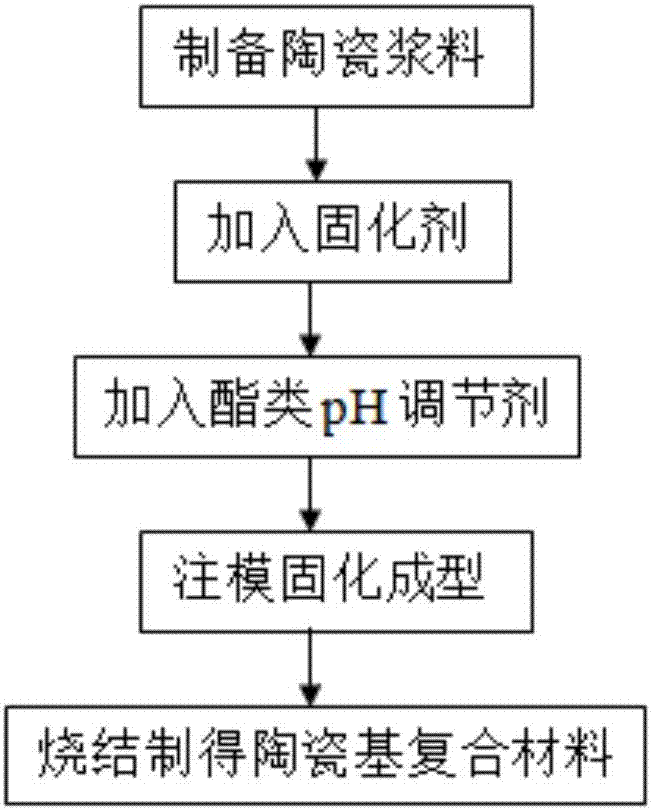

Method used

Image

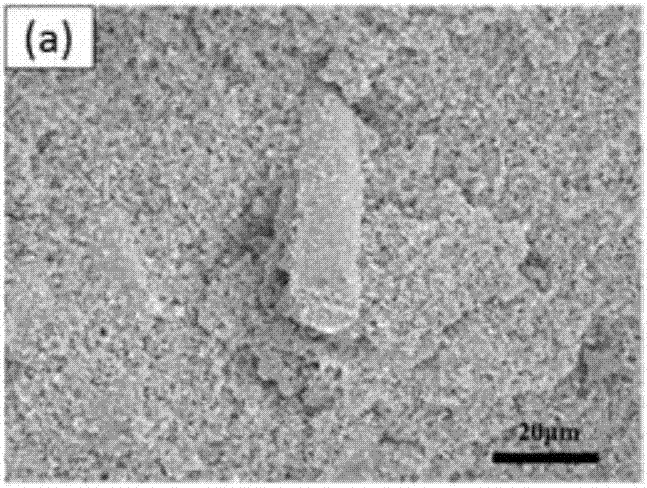

Examples

Embodiment 1

[0036] 6.25g / L calcium iodate, 1.0wt% diacetin cured 3.0wt% tetramethylammonium hydroxide dispersed 10wt% alumina fiber and 50vol% silica slurry.

[0037] 50g of silica powder, 5.0g of alumina fiber, 1.5g of tetramethylammonium hydroxide and 18.87g of deionized water were milled for 2 hours at a ball milling rate of 250r / min to prepare a particle surface with a solid phase volume fraction of 50%. Negatively charged ceramic slurry, then add 0.25g calcium iodate, mix and mill at a ball milling speed of 180r / min for 15min, then add 0.5g glycerol diacetate, stir and degas with a magnetic stirrer for 5min under vacuum conditions, Cast a non-porous silicone mold, place it at 70°C for 30 minutes and demould it, dry it at 80°C for 24 hours, then raise the temperature to 1300°C at a rate of 5°C / min and keep it warm for 2 hours, then drop it to 1300°C at a rate of 5°C / min At room temperature, the flexural strength of the obtained ceramic matrix composite is 27.6% higher than that withou...

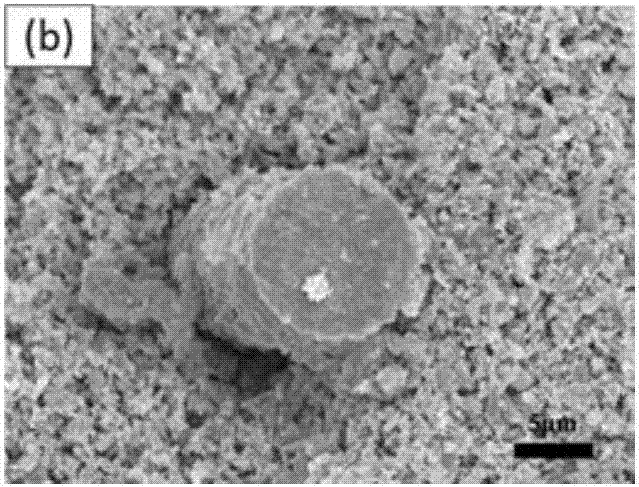

Embodiment 2

[0039] 6.0g / L nickel iodate, 0.5wt% glycerol triacetate solidified 1.5wt% ammonium polyacrylate dispersed 15wt% zirconia fiber and 55vol% alumina slurry.

[0040] Mix 50g of alumina powder, 7.5g of zirconia fiber, 0.75g of ammonium polyacrylate and 10.23g of deionized water, and ball mill for 0.5h at a ball milling rate of 400r / min to prepare a particle surface with a solid phase volume fraction of 55%. Negatively charged ceramic slurry, then add 0.12g nickel iodate, mix ball milling at a ball milling speed of 100r / min for 5min, then add 0.25g triacetin, stir and degas with a magnetic stirrer under vacuum conditions for 15min, Cast a non-porous silicone mold, place it at 35°C for 40 minutes, then demould it, dry it at 100°C for 12 hours, then heat it up to 1150°C at a rate of 3°C / min and keep it warm for 6 hours, then drop it to 1150°C at a rate of 3°C / min. At room temperature, the flexural strength of the obtained ceramic matrix composite is 28.7% higher than that without add...

Embodiment 3

[0042] 8.0g / L barium iodate, 1.5wt% ethyl acetate solidified 1.0wt% urea dispersed 35wt% carbon fiber and 50vol% silicon carbide slurry.

[0043] Mix 50g of silicon carbide powder, 17.5g of silicon carbide fiber, 0.5g of ammonium polyacrylate and 15.6g of deionized water, and ball mill for 12 hours at a ball milling rate of 200r / min to prepare a particle surface belt with a solid phase volume fraction of 50%. Negatively charged ceramic slurry, then add 0.25g barium iodate, mix ball milling at 150r / min ball milling speed for 30min, then add 0.75g ethyl acetate, stir and degas with magnetic stirrer under vacuum condition for 10min, cast without Hole silica gel mold, put it at 85°C for 10min and demould, dry at 60°C for 24h, then raise the temperature to 2200°C at a heating rate of 20°C / min and keep it for 4h (sintering under vacuum condition), and at 20°C / min When the cooling rate drops to room temperature, the flexural strength of the obtained ceramic matrix composite is 31.7% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com