Local grain anti-counterfeiting print

A printed matter and partial technology, applied in the direction of seals, stamps, instruments, etc., can solve the problems of less variety, environmental pollution, high cost, etc., and achieve the effects of easy production, lower production cost, and less impact on aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

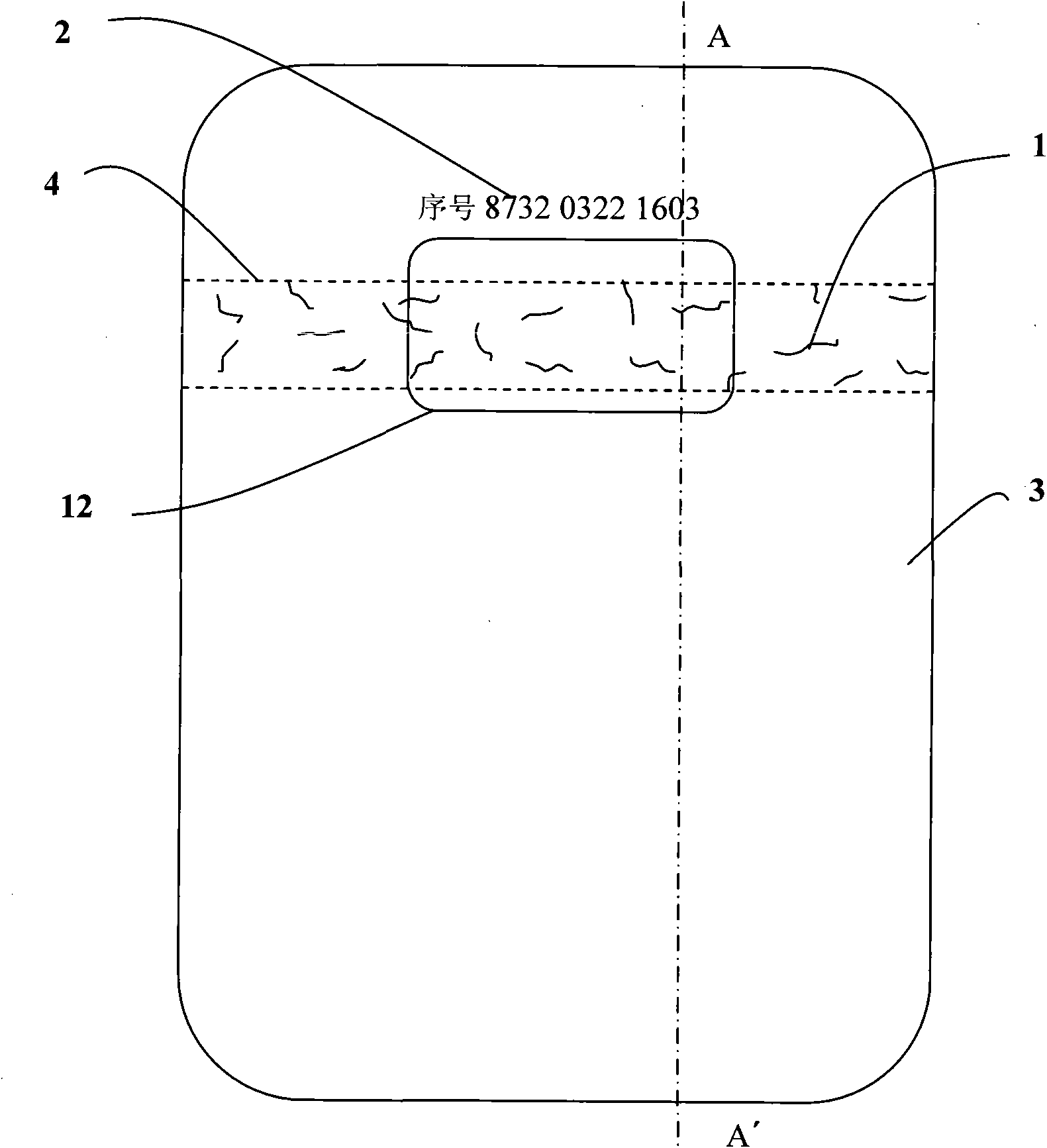

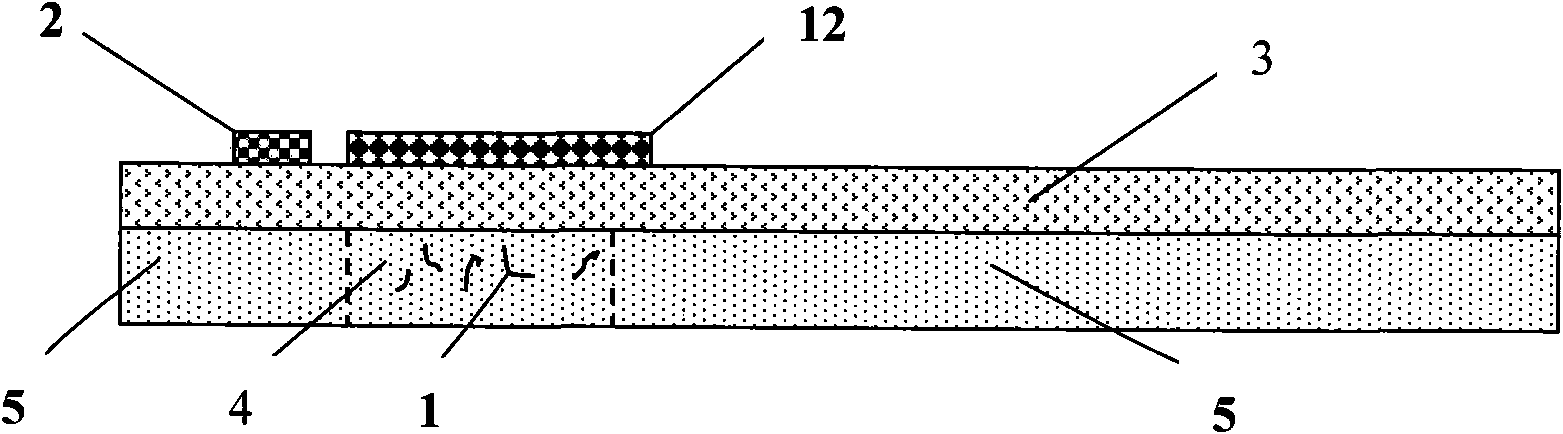

[0049] Such as figure 1 , figure 2 As shown, a 70mmx100mm partial (with fibers in the self-adhesive layer) texture anti-counterfeiting self-adhesive label, such as a bottle sticker for a certain brand of shampoo, is printed and manufactured.

[0050] The first step is to purchase a 25μm thick BOPP transparent film roll, and purchase a high-temperature red fiber (1) with a width of 0.1mm, a thickness of 22μm, and a length of 2mm per strip.

[0051] In the second step, the red fiber (1) and the hot-melt adhesive are mixed and stirred evenly at a ratio of 1:50, and then a hot-melt adhesive coater is used to coat the BOPP transparent film with a width of 10mm at intervals of 105mm. The self-adhesive tape-like fiber layer (4) containing red fiber (1), control the coating amount of fiber to maintain 2 strips / cm 2 The average density. At the same time, a fiber-free pure self-adhesive layer (5) is coated between two adjacent ribbon-shaped fiber layers (4), and then a release bottom pape...

Embodiment 2

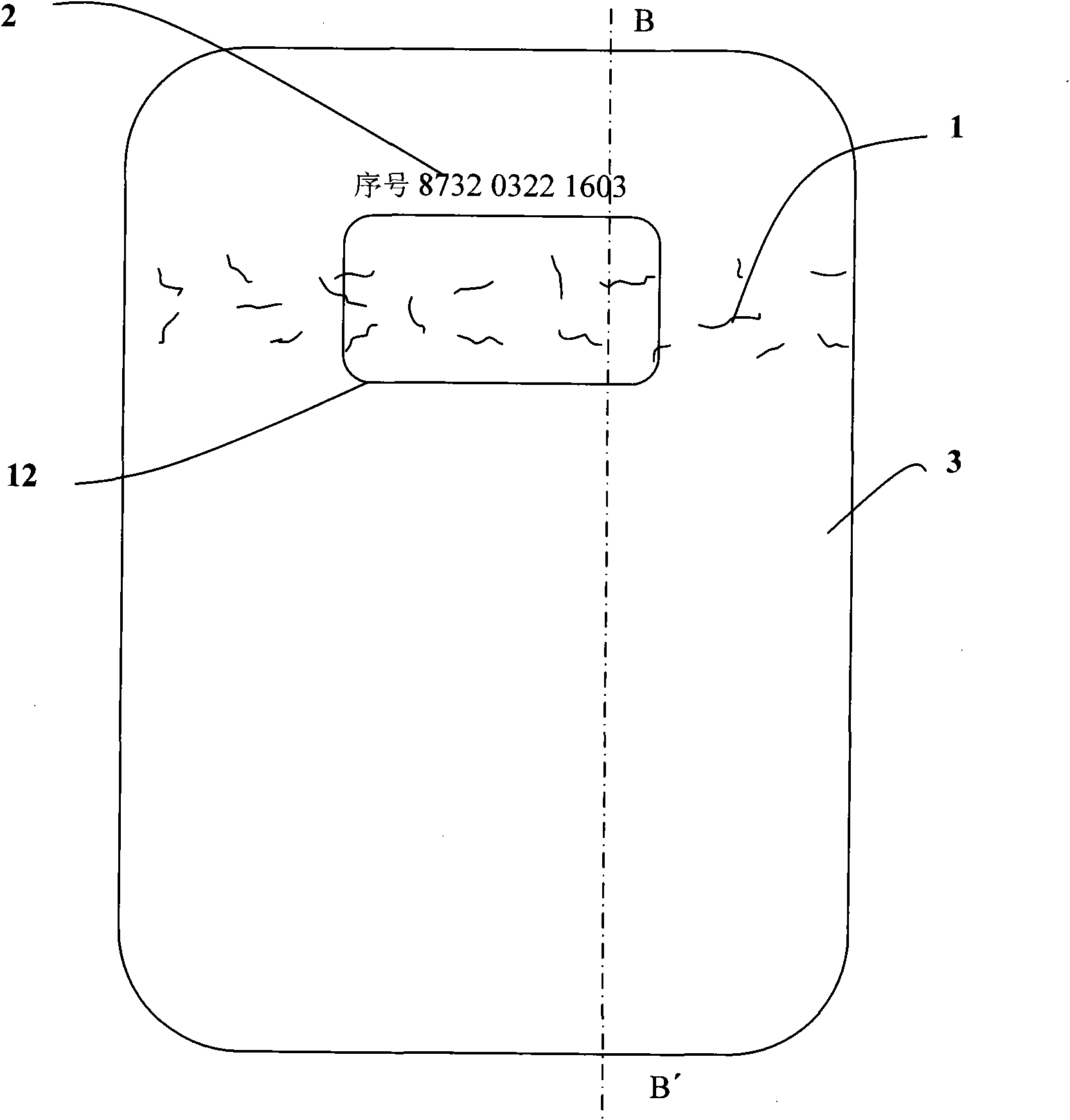

[0059] Such as image 3 , Figure 4 As shown, a 70mmx100mm partial (fiber on the self-adhesive surface) texture anti-counterfeiting self-adhesive label is printed and manufactured, such as a bottle sticker for a certain brand of shampoo.

[0060] The first step is to purchase a 25μm thick BOPP transparent self-adhesive printing roll material, and purchase a gold fiber (1) with a wire diameter of 0.1mm for use.

[0061] In the second step, use a self-adhesive separating and laminating machine to peel the release paper, and then on the self-adhesive layer (5) of the BOPP transparent self-adhesive film, throw a row of ribbon-like golden fiber layers with a width of about 5mm at intervals of 105mm , Control the amount of golden fiber throwing well to keep it at 3 strips / cm 2 The average density.

[0062] The third step is to use a self-adhesive separating and laminating machine to press the peeled release paper and BOPP transparent self-adhesive film.

[0063] The fourth step is to us...

Embodiment 3

[0069] Such as Figure 5 , Figure 6 As shown, a 70mmx100mm partial (with fibers in the paper strip) texture anti-counterfeiting self-adhesive label is printed and manufactured.

[0070] The first step is to purchase a 25μm-thick BOPP transparent self-adhesive printing roll material, and purchase a translucent texture anti-counterfeiting paper with fibers (1) inside, the fiber length is preferably 3mm / strand, and the fiber diameter is the best 0.1mm, the fiber color is preferably black, and the fiber density is preferably 3 strips / cm 2 , The thickness of the paper is preferably 40g / cm 2 .

[0071] In the second step, according to the line spacing of 12mm, print a line with the identification number (2) and other structural texture anti-counterfeiting identifier information on the textured anti-counterfeiting paper, scan and collect it, and record the random distribution of black fibers (1) Features, with the identification number (2) as the file name, the electronic photos of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com