Modified asphalt composition with creeping characteristic and preparation method thereof

A technology of modified asphalt and creep characteristics, which is applied to building structures, building components, building insulation materials, etc., can solve problems such as difficulty in finding the source of leakage, difficulty in repair work, water channeling, etc., to prolong service life, The effect of improving reliability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

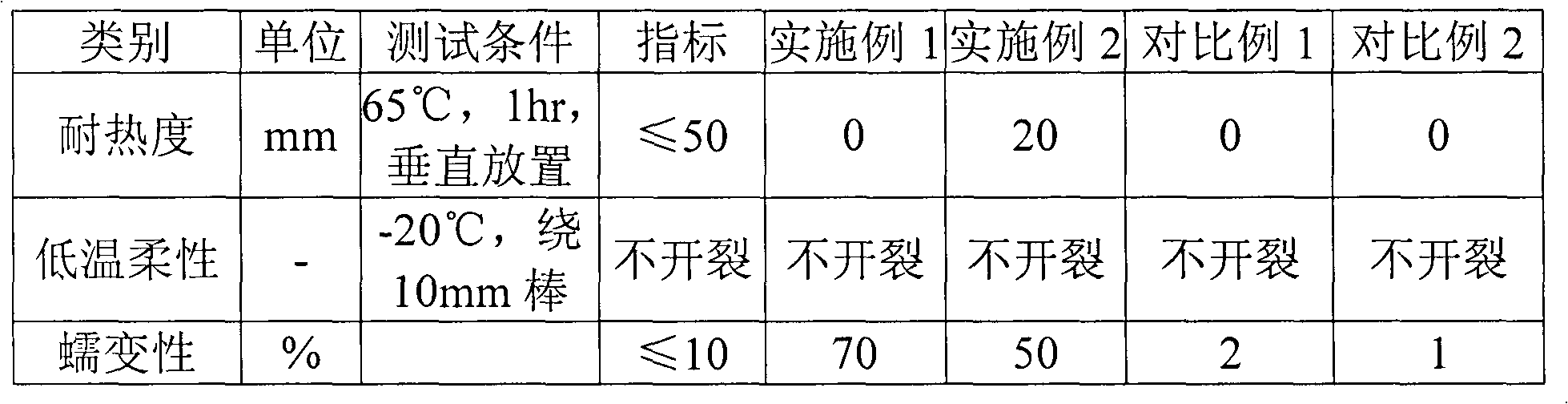

Examples

Embodiment 1

[0032] The various raw material ratios of the present embodiment are as follows:

[0033] Table 1

[0034] name

Proportion

Specification

Softener (low volatile aromatic oil)

24

Modified material (SBS)

5

Modified material (PP)

1

asphalt

25.3

Inorganic powder (stone powder)

22

120 mesh

rubber powder

10

80 mesh

Viscosity modifier (rosin resin)

4

Viscosity modifier (paraffin)

1

Viscosity modifier (terpene resin)

1

6

Peptizer (sodium pyrophosphate)

0.5

Peptizer (maleic anhydride)

0.08

[0035] Coupling agent (aluminate)

0.12

[0036] The asphalt in Table 1 is made by mixing 100# and 10# petroleum asphalt at a ratio of 5:1, and the softening point and ductility of the asphalt are adjusted.

[0037] According to the raw material pro...

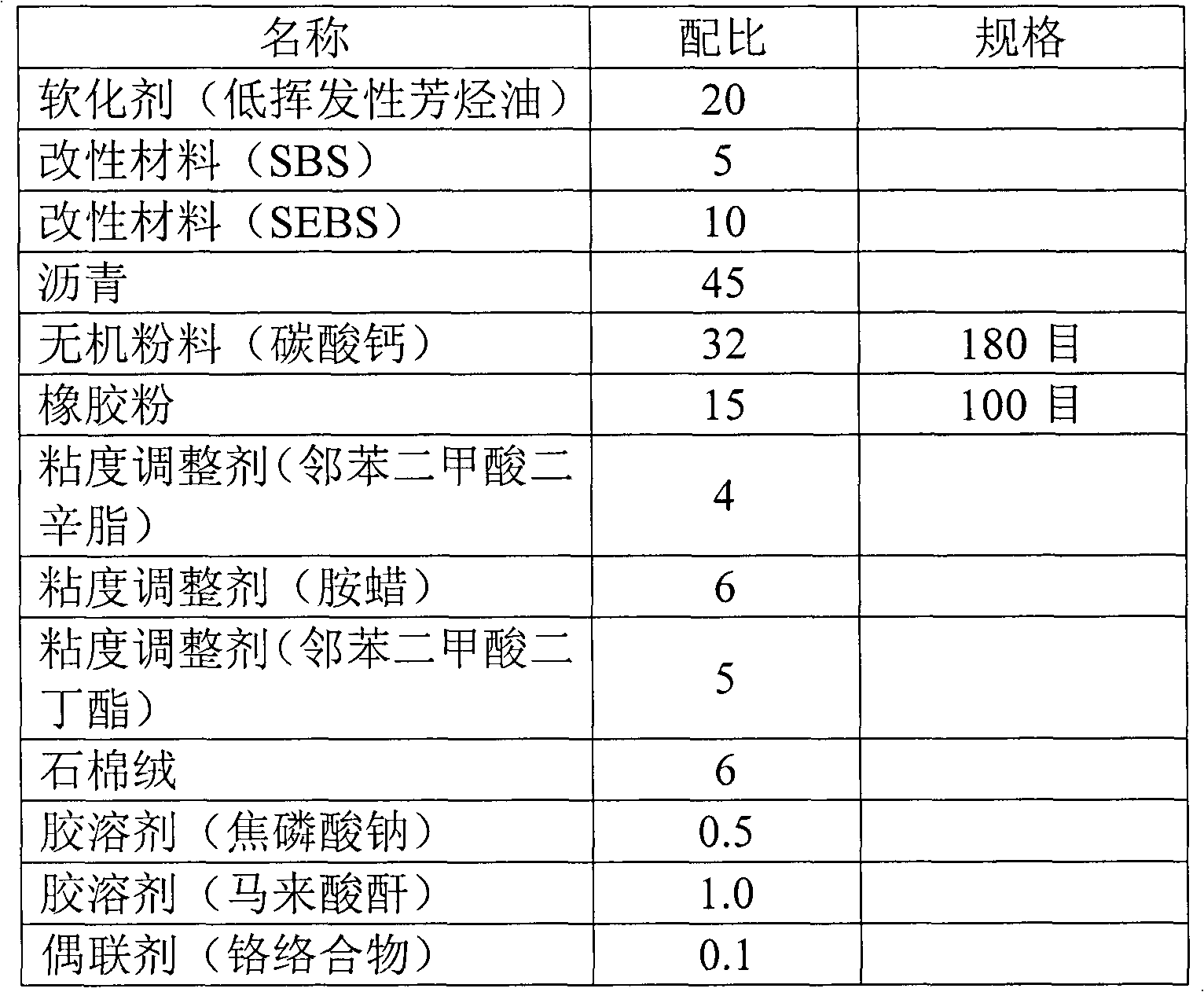

Embodiment 2

[0043] The various raw material ratios of the present embodiment are as follows:

[0044] Table 2

[0045] name

Proportion

Specification

Softener (low volatility paraffin oil)

28

Modified material (SBS)

4

asphalt

20

Inorganic powder (stone powder)

27.3

200 mesh

rubber powder

10

80 mesh

Viscosity modifier (rosin resin)

4

Viscosity modifier (paraffin)

1

Viscosity modifier (terpene resin)

1

4

Peptizer (sodium pyrophosphate)

0.5

[0046] Coupling agent (silane coupling agent)

0.2

[0047] The asphalt in Table 2 is made by mixing 100# and 10# petroleum asphalt at a ratio of 4:1, and the softening point and ductility of the asphalt are adjusted.

[0048] According to the ratio of raw materials in Table 2, the production is carried out, and the specific steps are ...

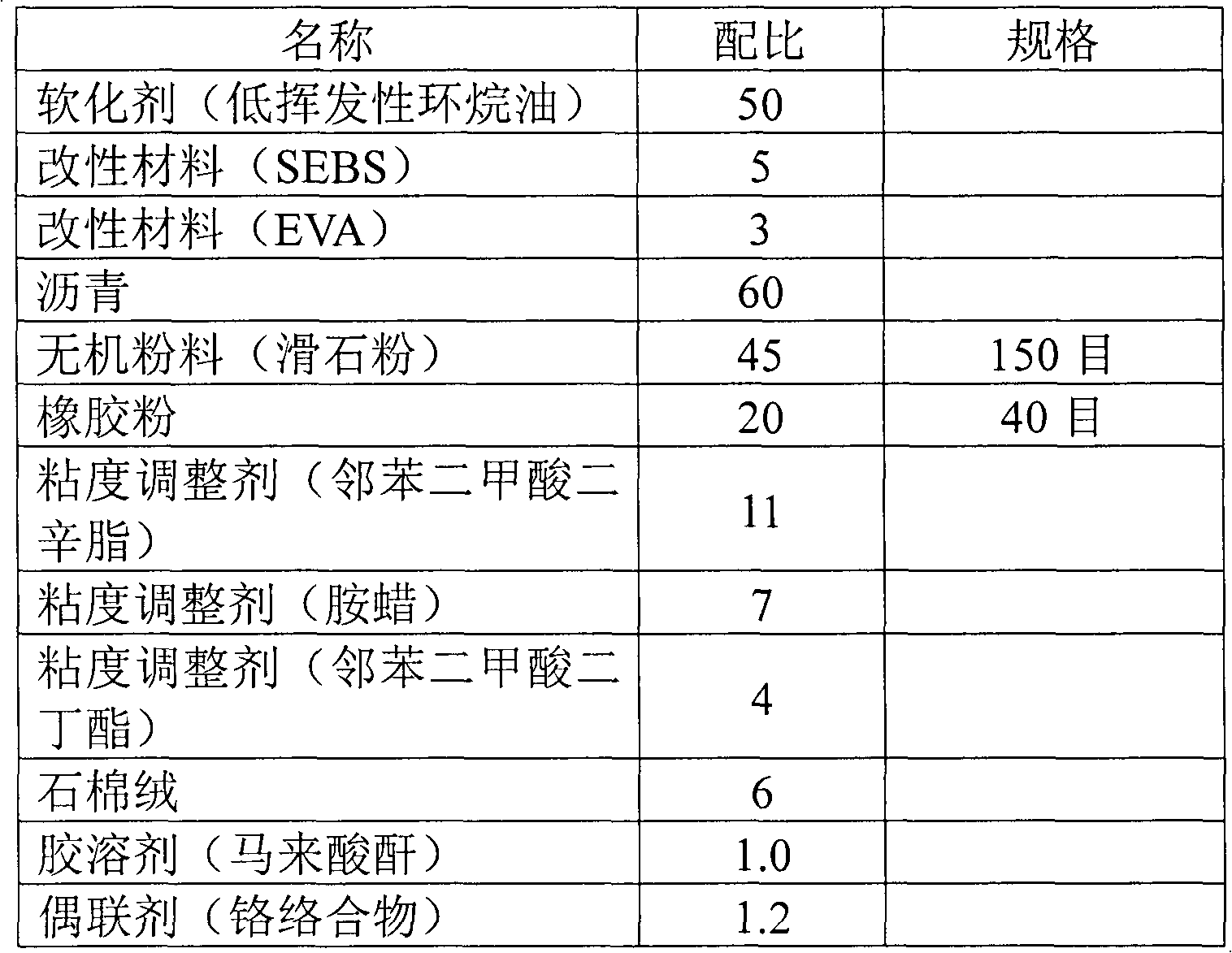

Embodiment 3

[0059] The various raw material ratios of the present embodiment are as follows:

[0060] Table 6

[0061] name

Proportion

Specification

[0062] Softener (low volatility naphthenic oil)

15

Modified material (SEBS)

12

asphalt

40

Inorganic powder (talc powder)

40

230 mesh

rubber powder

30

50 mesh

Viscosity modifier (microcrystalline wax)

2

Viscosity modifier (polyethylene wax)

1

Viscosity modifier (polypropylene wax)

1

6

Peptizer (sodium pyrophosphate)

0.2

Peptizer (maleic anhydride)

0.1

Coupling agent (chromium complex)

0.8

[0063] The asphalt in Table 6 is made by mixing 100# and 10# petroleum asphalt at a ratio of 4.2:1, and the softening point and ductility of the asphalt are adjusted.

[0064] According to the ratio of raw materials in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com