Flexible marching type continuous conveying system

A conveying system, a step-by-step technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, as high as more than 300,000 to 400,000 yuan, and cannot achieve high cleanliness. The effect of large area and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described by examples below, and it should be noted that the examples listed should not be construed as limiting the invention.

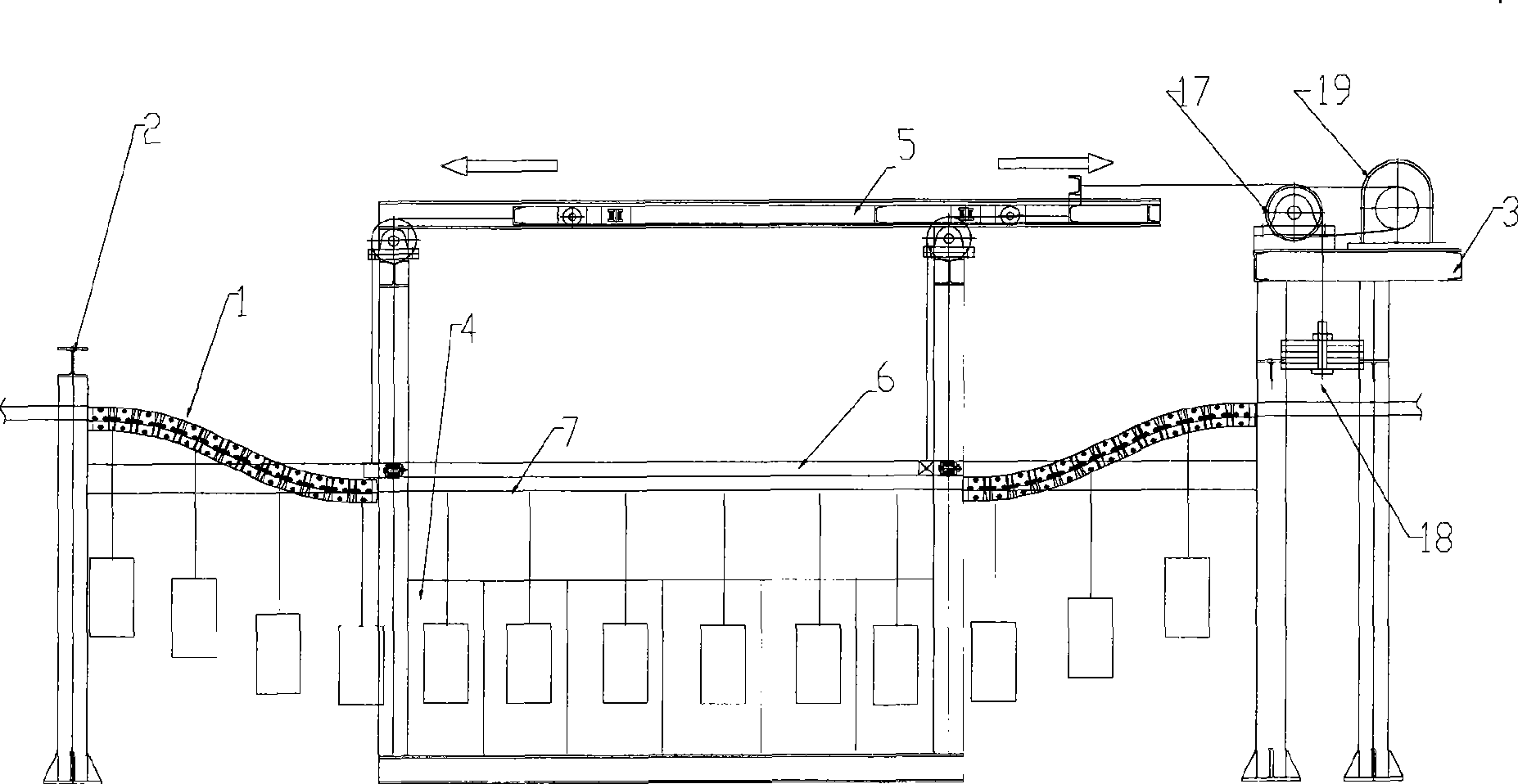

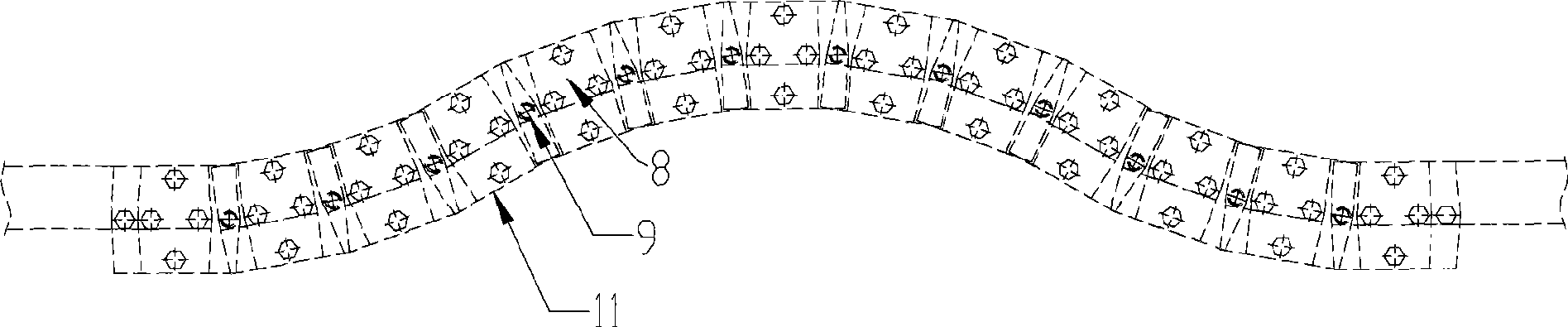

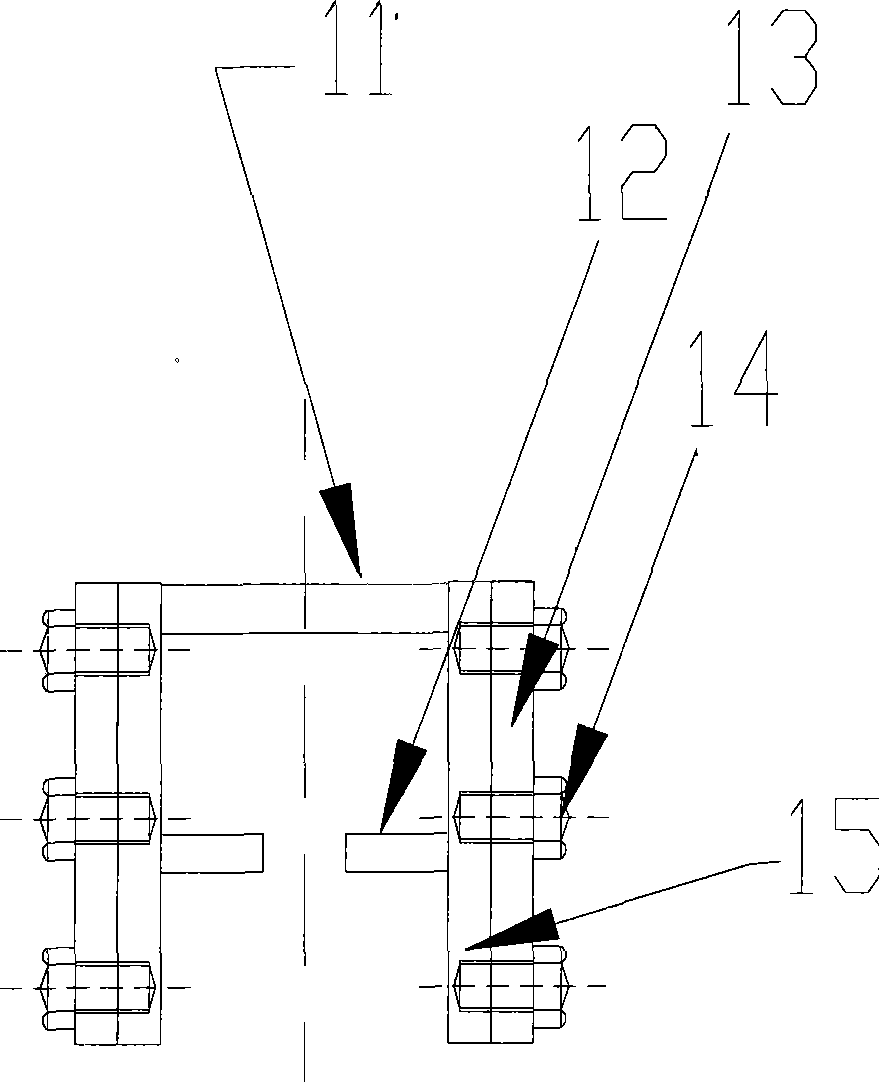

[0026] Such as figure 1 As shown, the flexible step-by-step continuous conveying system of the embodiment of the present invention is composed of a front fixed support frame 2, a rear fixed support frame 3, an up and down lifting tackle 6, a flexible chain rail 1, a chain rail track 7, and a handling slot 4; standard The track 7 is fixed below the lifting tackle 6 up and down, and the flexible chain track 1 is positioned at the two ends of the standard track 7 . Up and down lifting tackle 6 is connected with horizontal translation tackle 5. The two ends of processing the dress tank body 4 frames are provided with front fixed support frame 2 and rear fixed support frame 3, and flexible chain rail 1 passes through the front fixed support frame 2 and handles the upper and lower lift tackles installed on the overall fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com