Preparation method of remanufactured coating for inner wall of air cylinder sleeve

A cylinder liner and remanufacturing technology, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of material selection and processing technology without breakthrough, and achieve material cost saving, low environmental pollution, and material good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

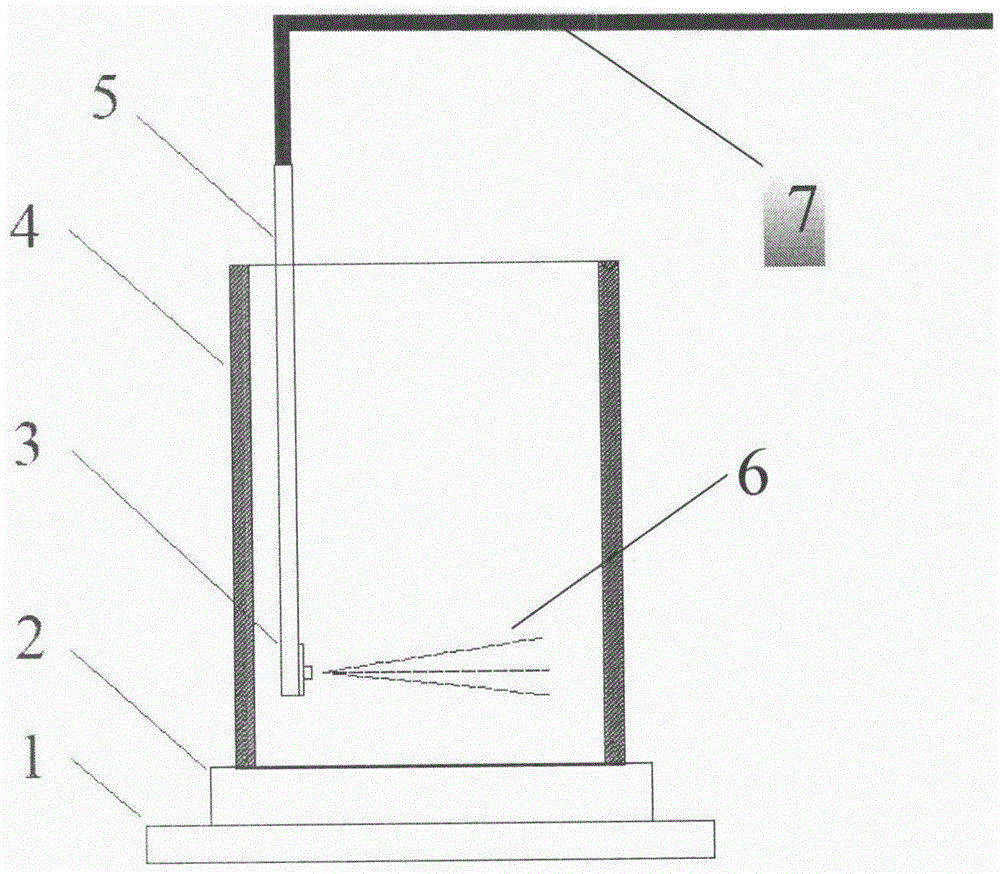

Method used

Image

Examples

Embodiment 1

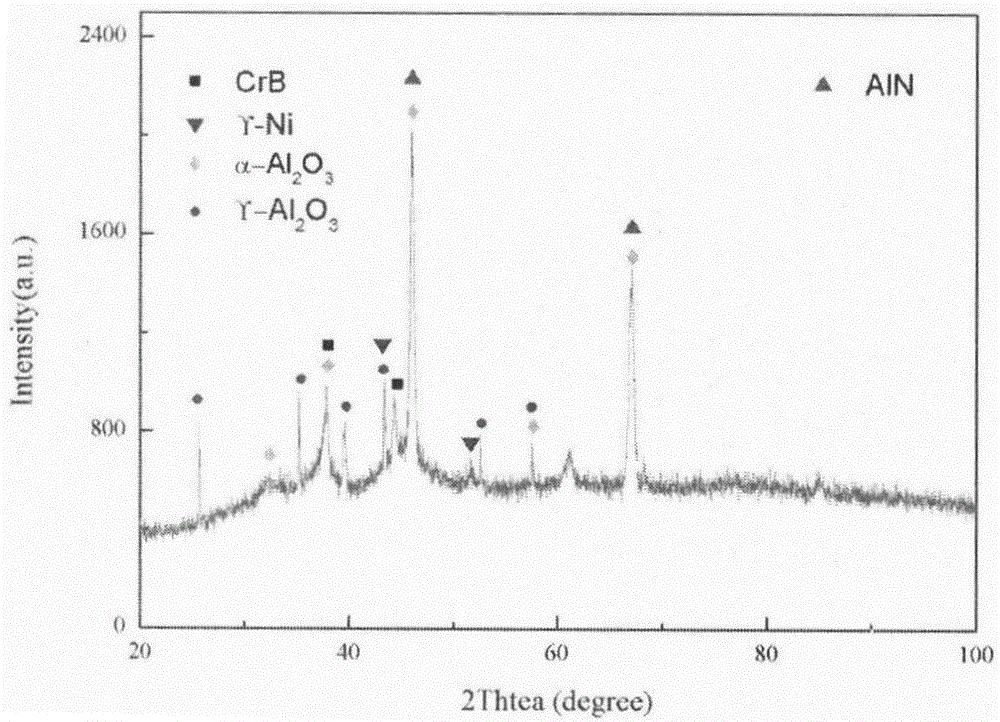

[0049] 20g of Al with a particle size of about 20μm 2 o 3 The powder is evenly mixed with 180g of NiCrBSi powder with a particle size of 40-50μm, bonded by gluing, put into the powder feeder tube 7, and the powder feeding rate is controlled at 30g / min, and sent into the plasma flame flow, and deposited on the inner wall of the cylinder liner to form For composite coating, too much or too little powder feeding will lead to unmelting or overoxidation during the powder feeding process, which will directly affect the spraying quality and coating thickness. Spraying parameters are set to H 2 The flow rate is 7L / min, the Ar flow rate is 40L / min, the current is 500A, and the voltage is 56V. In order to ensure uniform coating and controllable thickness, the moving speed of the spray gun is set at 200mm / s, moving down 3mm each time, and spraying continuously for 6 times. The phase structure was observed with an X-ray diffractometer. Such as figure 2 As shown, the coating contains...

Embodiment 2

[0051] 40g of Al with a particle size of about 20μm 2 o 3 The powder is evenly mixed with 160g of NiCrBSi powder with a particle size of 40-50μm, due to Al 2 o 3 The density is smaller than alloy powders such as NiCrBSi, Al 2 o 3 The mass ratio is controlled at 10%-30% to prevent the self-fluxing property of the obtained coating from being poor due to excessive content, which reduces the quality of the coating. After bonding by adhesive method, it is sent to the spraying device, and the powder feeding amount is controlled to be 35g / min. Into the plasma flame flow, deposited on the inner wall of the cylinder liner to form a composite coating. h 2 The flow rate is 5L / min, the Ar flow rate is 40L / min, the current is 500A, and the voltage is 56V. The moving speed of the spray gun is 200mm / s, moving down 3mm each time, due to the large amount of powder feeding, the number of spraying is appropriately reduced to control the thickness of the obtained coating, and the spraying i...

Embodiment 3

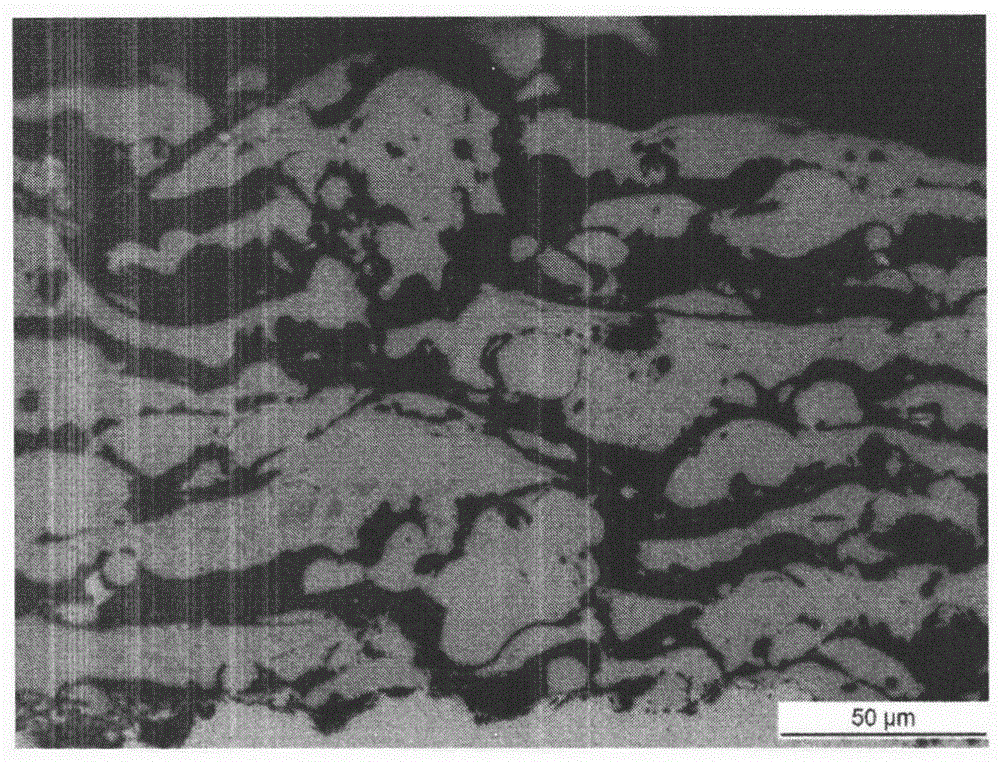

[0053] Compared with NiCrBSi, FeCrBSi has lower cost and is more suitable for industrial mass production. Combining FeCrBSi with Al 2 o 3 Mix uniformly with a mass ratio of 8:2, and send it into the flame flow of a flame spray gun after being glued, and deposit on the substrate to form a metal-ceramic composite coating. The gas used in the spray gun is oxygen and acetylene, and its combustion temperature can reach 3000 ° C, which fully meets the requirements of FeCrBSi and Al 2 o 3 The melting temperature of the material, the moving speed of the spray gun is 150mm / s, each time moving down 2mm, continuous spraying 15 times. The cross-sectional morphology was observed with a Veka microscope, such as Figure 4 As shown, the thickness of the coating is about 150 μm, the dispersion is uniform, the bonding of the layer and the base is good, and it meets the high-strength wear resistance test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com