Seed coating machine with filtering device

A filter device and coating machine technology, which is applied in the directions of seed coating/seed dressing, filtration, solid separation, etc., can solve the problems of wasting seed coating liquid, and achieve the goal of ensuring the coating quality and saving liquid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

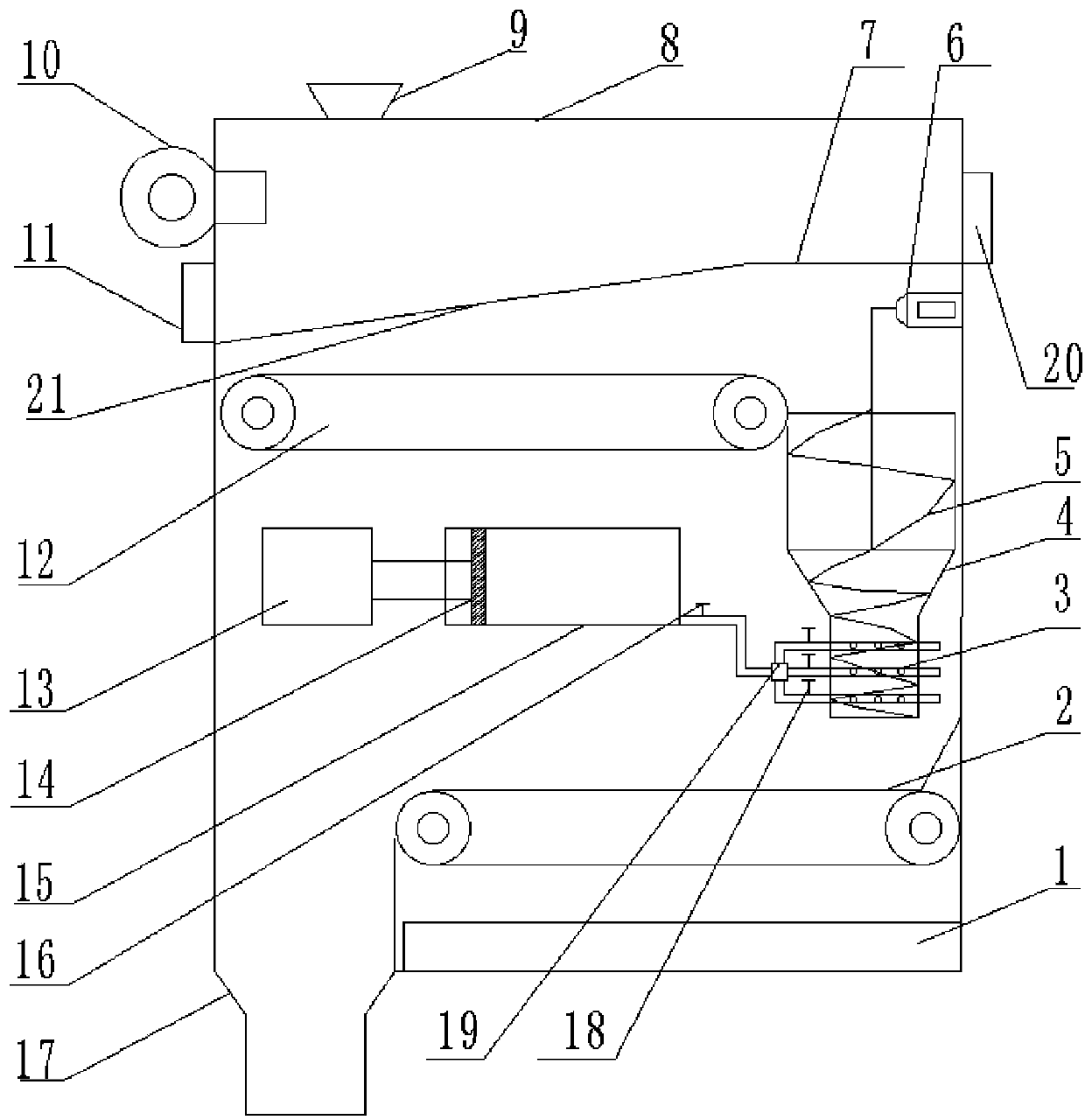

[0029] Such as figure 1 As shown, a seed coating machine with a filter device includes a casing 8, the top of the casing 8 is provided with a feed port 9, and the bottom of the casing 8 is provided with a discharge port 17, and the inside of the casing 8 is The material opening 9 below is provided with filter screen 21, is provided with blower 10 on the casing 8 sidewalls above filter screen 21, and the mouthpiece direction of described blower 10 is identical with the transmission direction of first transfer device 12, and in described filter pack 21 is provided with a first conveying device 12 below, and a mixing barrel 4 is arranged at the output end of the first conveying device 12. The inside of the stirring barrel 4 is provided with a spiral feeder 5 , and a screw feeder 5 is arranged above the stirring drum 4 to drive the spiral feeder 5 to rotate. The motor 6 is provided with a plurality of spray nozzles 3 at the bottom of the mixing barrel 4; an air storage tank 13 and...

Embodiment 2

[0031] Such as figure 1 As shown, the present embodiment is further optimized on the basis of Embodiment 1. The filter screen 21 is arranged in an inclined manner, and the end close to the blower 10 is the low end of the filter pack 21, and the high end of the filter pack 21 is 8 cm lower than the blower 10 , the high end of filter screen 21 is provided with the flat plate 7 that joins with casing 8, and described blower 10 can blow the light impurity mixed in the seed such as bean pod skin etc. on flat plate 7 to accumulate in horizontal direction than flat plate 7 , will not participate in the coating of the medicinal solution, saving the medicinal solution; the seeds can leak down along the filter screen 21 to participate in the coating; impurities larger than the particle size of the seeds, such as stones, will accumulate at the lower end of the filter screen 21 and the casing 8 Between, will not participate in the coating, saving the liquid medicine.

Embodiment 3

[0033] Such as figure 1 As shown, the present embodiment is further optimized on the basis of Embodiment 2. The filter screen 21 is arranged in an inclined manner, and the end close to the blower 10 is the low end of the filter screen 21, and the high end of the filter screen 21 is 10 cm lower than the blower 10 , the high end of filter screen 21 is provided with the flat plate 7 that joins with casing 8, and described blower 10 can blow the light impurity mixed in the seed such as bean pod skin etc. on flat plate 7 to accumulate in horizontal direction than flat plate 7 , will not participate in the coating of the medicinal solution, saving the medicinal solution; the seeds can leak down along the filter screen 21 to participate in the coating; impurities larger than the particle size of the seeds, such as stones, will accumulate at the lower end of the filter screen 21 and the casing 8 In between, it will not participate in the coating, saving the liquid medicine; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com