A seed coating machine provided with a dust collector

A technology of dust removal device and coating machine, which is applied in the directions of seed coating/seed dressing, cleaning method using gas flow, solid separation, etc., which can solve the problems of wasting seed coating liquid, etc., to ensure the coating quality, Save liquid medicine and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

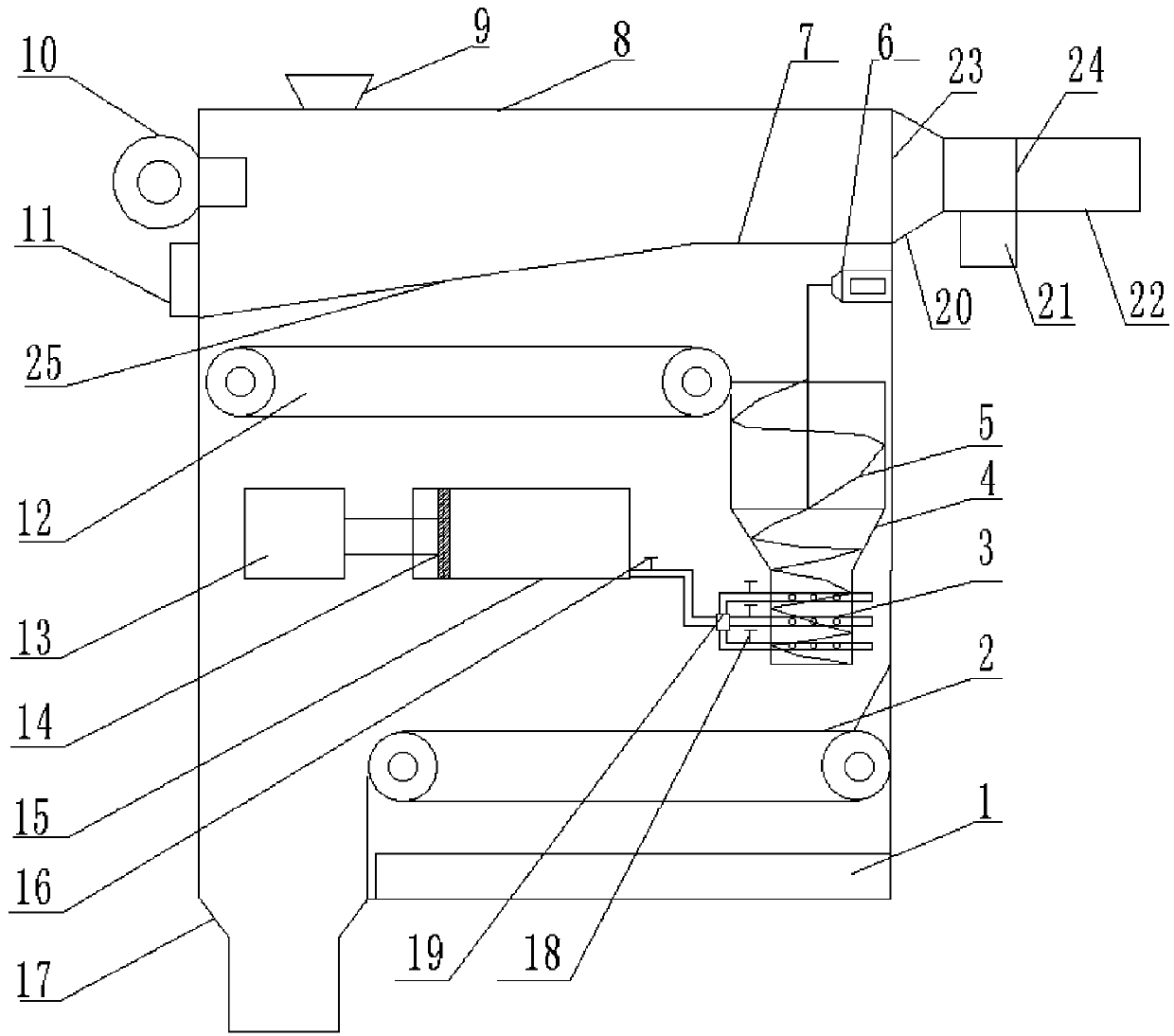

[0029] Such as figure 1 As shown, a seed coating machine with a dedusting device includes a casing 8, the top of the casing 8 is provided with a feed port 9, and the bottom of the casing 8 is provided with a discharge port 17, and the casing 8 is provided with an inner feed port 9. The first filter screen 25 is provided below the feed port 9, and the blower 10 is provided on the side wall of the casing 8 above the first filter screen 25. The first filter screen 25 is inclined, and the end near the blower 10 is the first The low end of a filter screen 25, the high end of the first filter screen 25 is 8cm lower than the blower 10, and the high end of the first filter screen 25 is provided with a flat plate 7 joining with the casing 8, and the mouthpiece direction of the blower 10 is in line with the first The transmission direction of conveying device 12 is identical, and described air blower 10 can blow the light impurity mixed in the seed such as bean pod skin etc. on flat pla...

Embodiment 2

[0035] Such as figure 1 As shown, the present embodiment is further optimized on the basis of Embodiment 1. A seed coating machine with a dust removal device includes a casing 8, the top of the casing 8 is provided with a feed port 9, and the bottom of the casing 8 is Be provided with discharge port 17, described casing 8 is provided with first filter screen 25 below feed port 9, is provided with blower 10 on casing 8 sidewalls above first filter screen 25, and described first filter screen Net 25 is inclined type setting, and one end near hair dryer 10 is the low end of first filter net 25, and the high end of first filter net 25 is 10cm lower than blower 10, and the high end of first filter net 25 is provided with casing 8 to join. flat plate 7, the mouthpiece direction of the blower 10 is the same as the transmission direction of the first transfer device 12, and the blower 10 can blow light impurities such as bean pod skins mixed in the seeds to Accumulation on the flat p...

Embodiment 3

[0041] Such as figure 1 As shown, the present embodiment is further optimized on the basis of Embodiment 2. A seed coating machine with a dust removal device includes a casing 8, the top of the casing 8 is provided with a feed port 9, and the bottom of the casing 8 is Be provided with discharge port 17, described casing 8 is provided with first filter screen 25 below feed port 9, is provided with blower 10 on casing 8 sidewalls above first filter screen 25, and described first filter screen Net 25 is inclined type setting, and one end near hair dryer 10 is the low end of first filter net 25, and the high end of first filter net 25 is 9cm lower than blower 10, and the high end of first filter net 25 is provided with casing 8 to join. flat plate 7, the mouthpiece direction of the blower 10 is the same as the transmission direction of the first transfer device 12, and the blower 10 can blow the light impurities mixed in the seeds such as pod skin etc. Accumulation on the flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com