Single sheet type sheet metal roll coating mechanism

A metal sheet, single-sheet technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem that the surface quality of the coating can only be coated on one side, the roller coating of the single plate is not synchronized, and the supporting point of the thin plate Short distance and other problems can achieve the effect of reducing sticking phenomenon, stable coating quality and reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

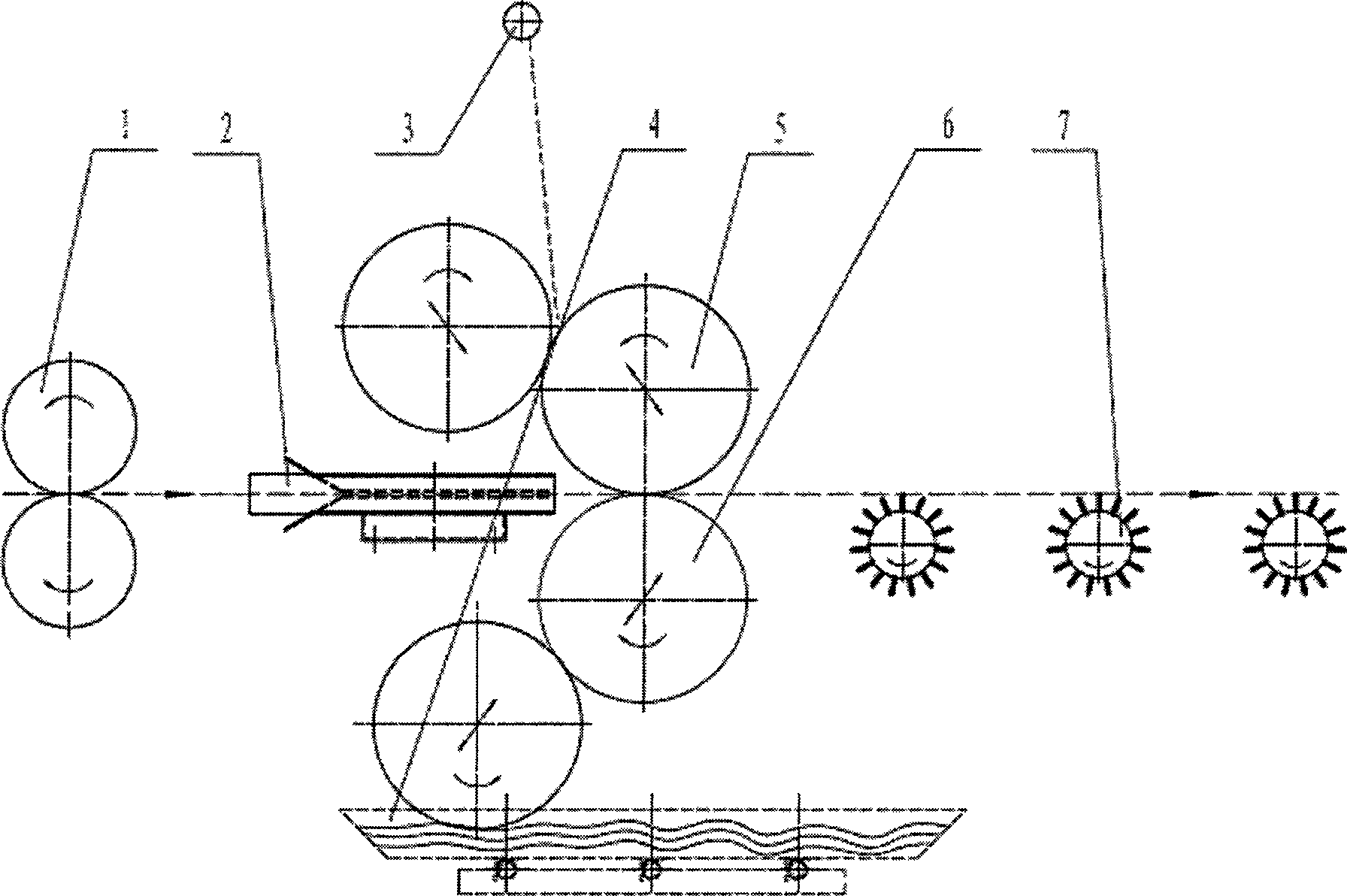

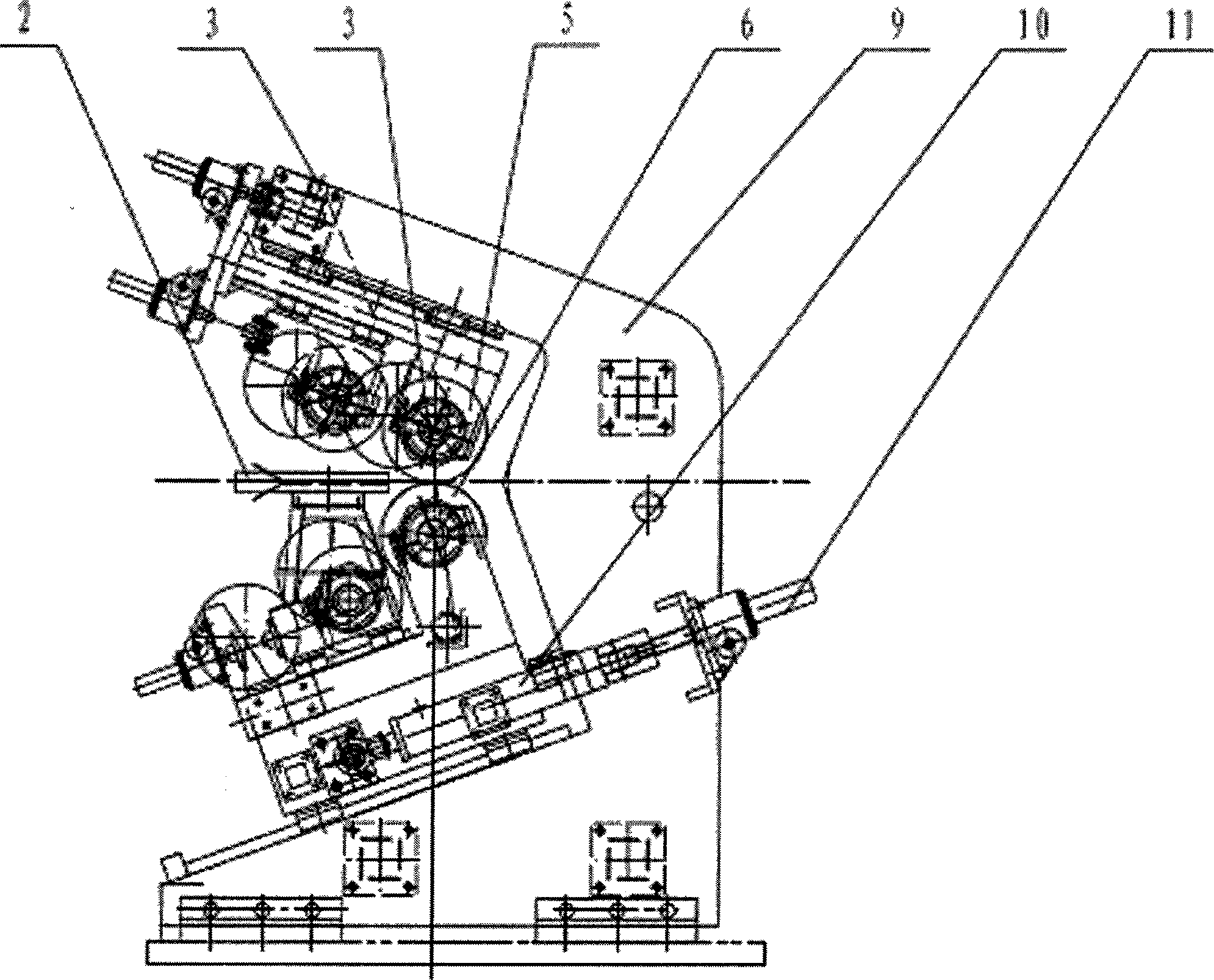

[0017] In embodiment 1: in appending figure 1 Among them, including the electrical control system, the equipment is composed of a pair of pinch rollers 1, a material guide part 2, a veneer roller coater, and a pin-wheel conveyor 7. The electrical part controls the pinch roller 1 to operate synchronously with the veneer roller coater and the pin wheel conveyor 7, which is conducive to the stable quality of the steel plate coating, and effectively controls the thickness and quality of the coating according to the coating thickness. The front end of the material guide part is made into a bell-mouth structure, and the bottom part can be a non-powered roller. The raw steel plate can pass through the material guide part directly, or the contact with the formed roller is rolling friction. In this way, the material guide part roller and the steel plate The friction force is small, and the required energy consumption is less. The pin wheel type conveying 7 is composed of a pin type rol...

Embodiment 2

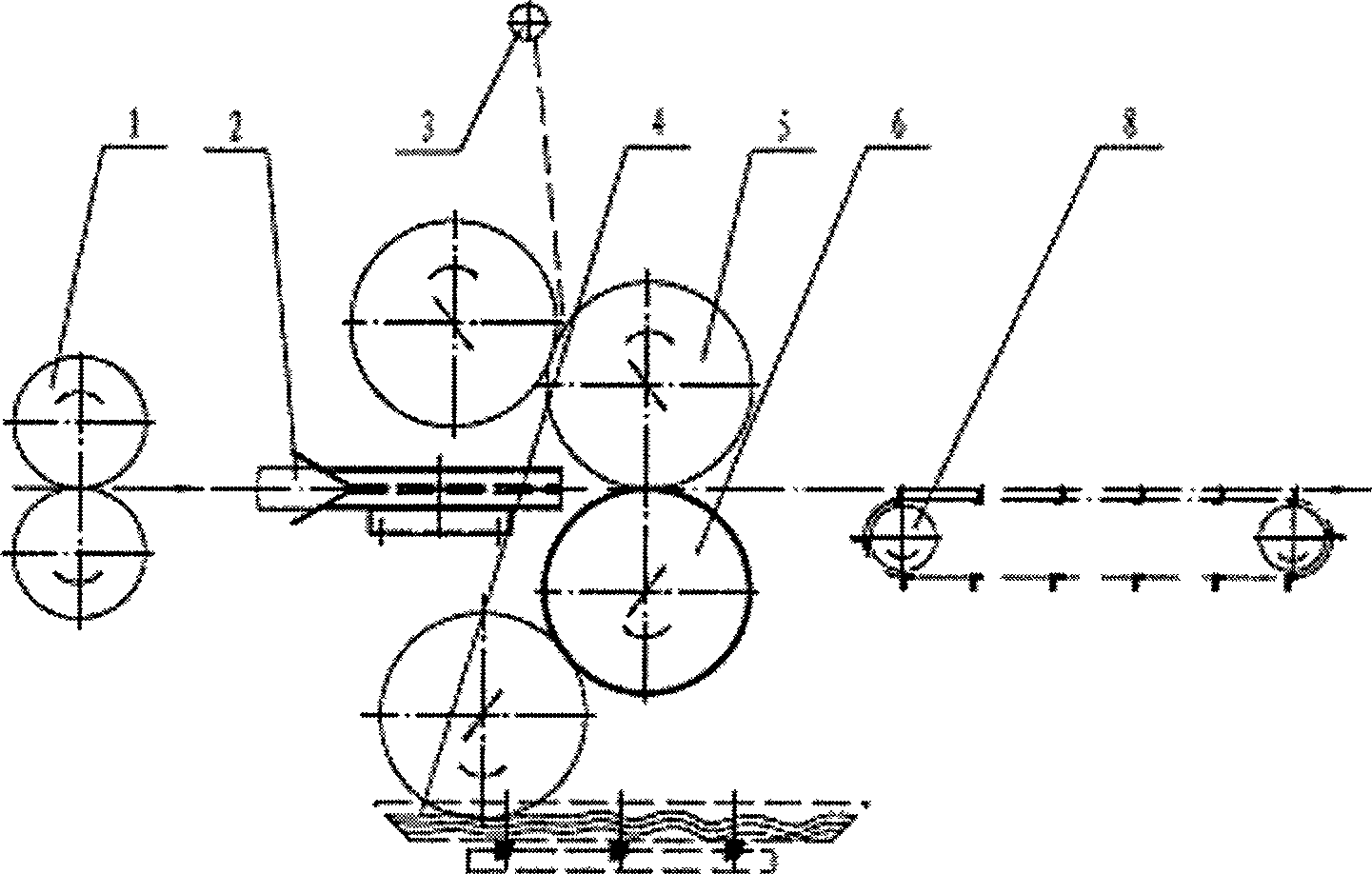

[0019] In embodiment 2: in the attached figure 2 Among them, including the electrical control system, the equipment is composed of a pair of pinch rollers 1, a material guide part 2, a veneer roller coater, and a chain conveyor 8. The electrical part controls the pinch roller 1 to operate synchronously with the veneer roller coater and the pin wheel chain conveyor 8, which is conducive to the stable quality of the steel plate coating, and effectively controls the thickness and quality of the coating according to the coating thickness. The front end of the material guide part is made into a bell-mouth structure, and the bottom part can be a non-powered roller. The raw steel plate can pass through the material guide part directly, or the contact with the formed roller is rolling friction. In this way, the material guide part roller and the steel plate Less friction and less energy required. The chain conveyor 8 is composed of a sprocket pair, and multiple rows of chains are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com