Continuous winding magnetic control sputtering vacuum coating device

A magnetron sputtering and vacuum coating technology, applied in the field of special production equipment and continuous coating equipment, can solve very effective technical solutions, problems such as not being obtained, and achieve the effect of increasing adaptability and preventing gas channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

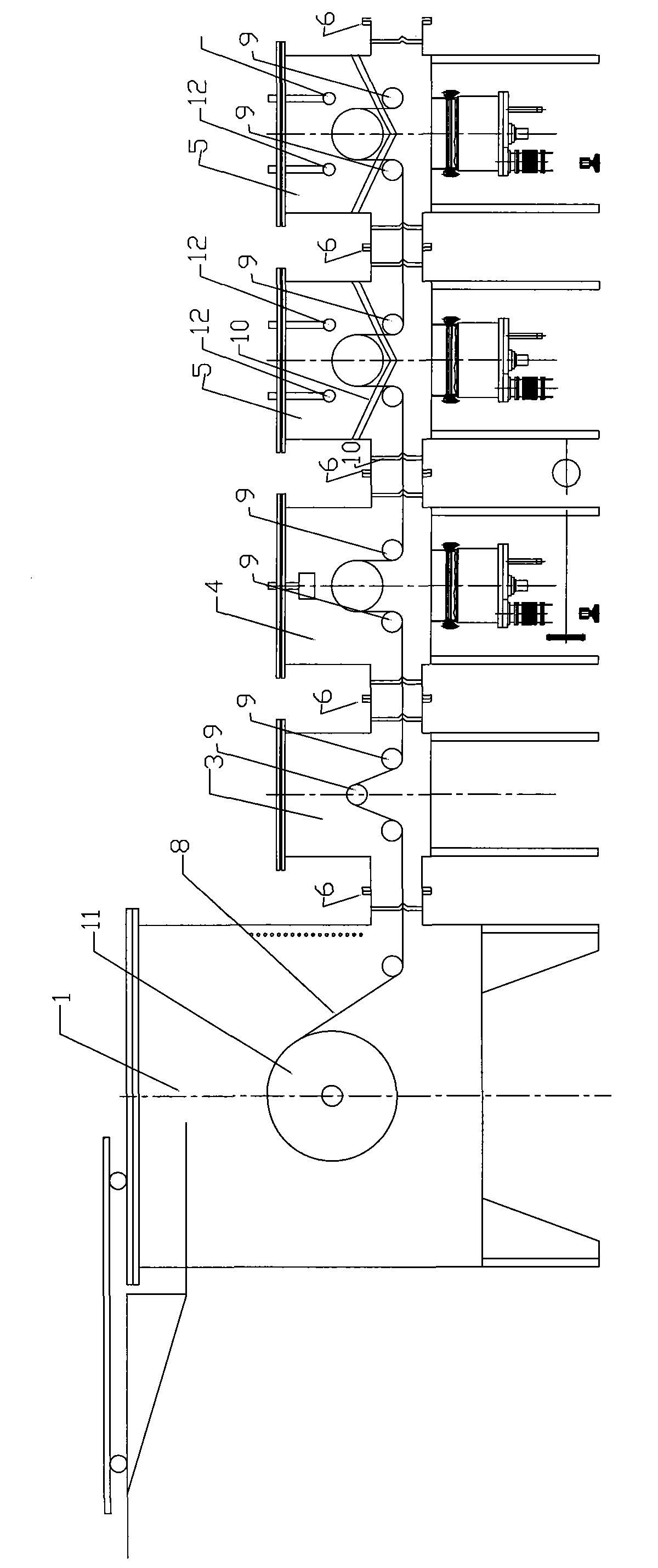

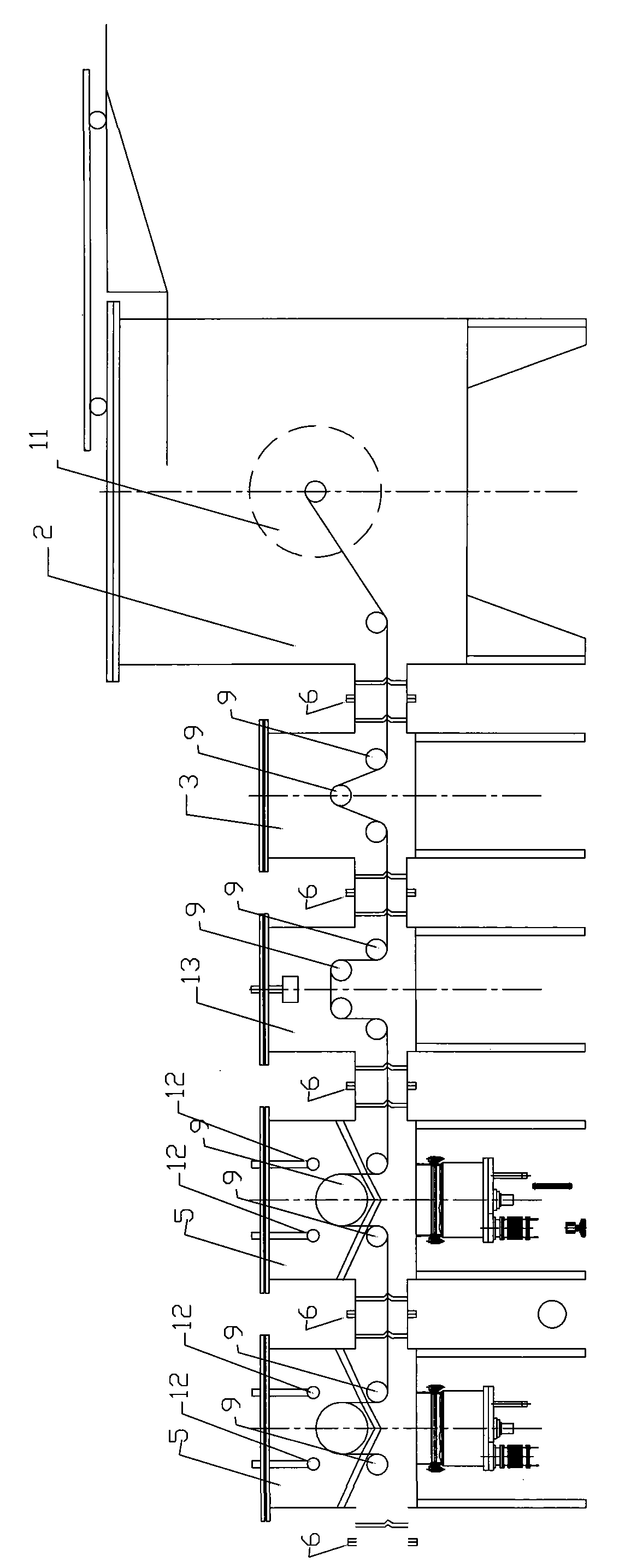

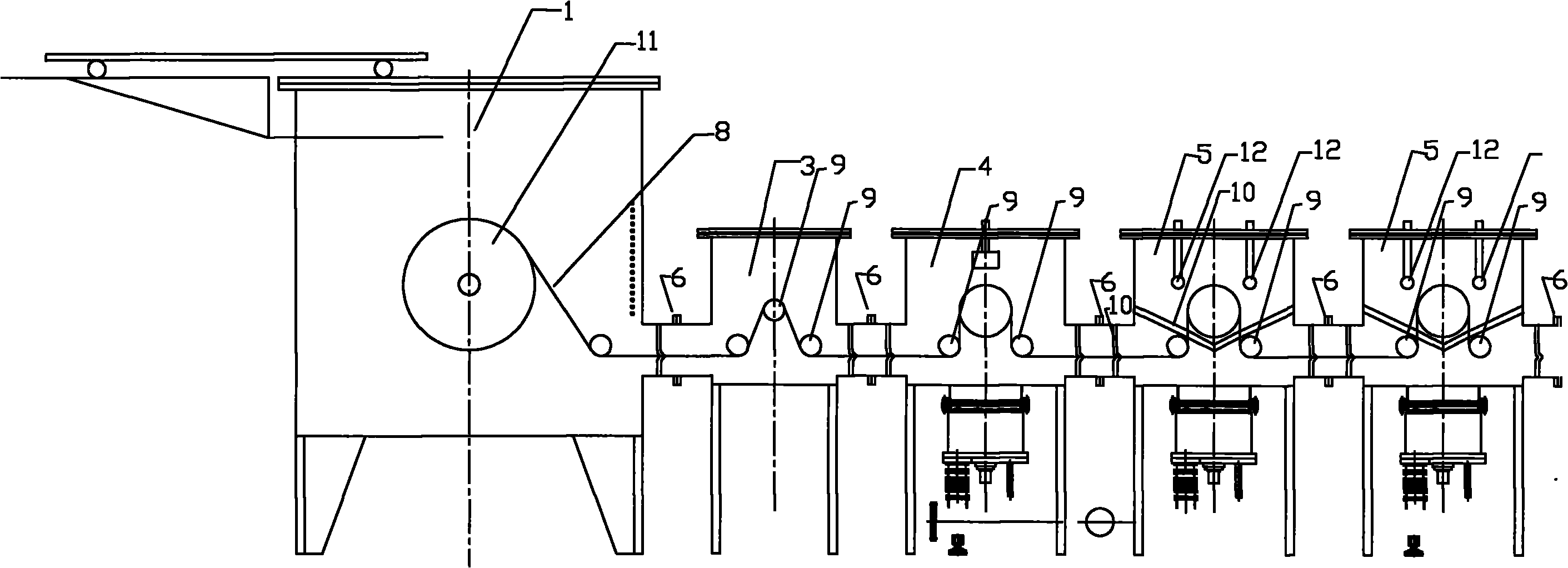

[0016] Next step the present invention is further described in conjunction with accompanying drawing:

[0017] The present invention is a special equipment for the selective absorption coating plated on the surface of the heat collecting plate used in the plate solar heat collector. The main advantage of the equipment is a continuous winding magnetron sputtering vacuum coating device. Long-term continuous coating work for large coiled strips can greatly improve the production efficiency of the coating, reduce production costs and improve the quality of the coating. As shown in Figure 1, the production line consists of an unwinding chamber 1, a winding chamber 2, a tension control chamber 3, a pretreatment chamber 4, and a process chamber 5. The unwinding chamber 1 and the winding chamber 2 are respectively located at the beginning and end of the equipment. , the main function is to place and collect metal strips, the commonly used strips are copper strips or aluminum strips wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com