Combined inserting protective sleeve of waste heat boiler

A technology for waste heat boilers and protective sleeves, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as high repair costs, leakage of heat exchange tubes, powdering of tube sheet metal surfaces, etc., and achieve simple structure , good sealing, reduce the effect of abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

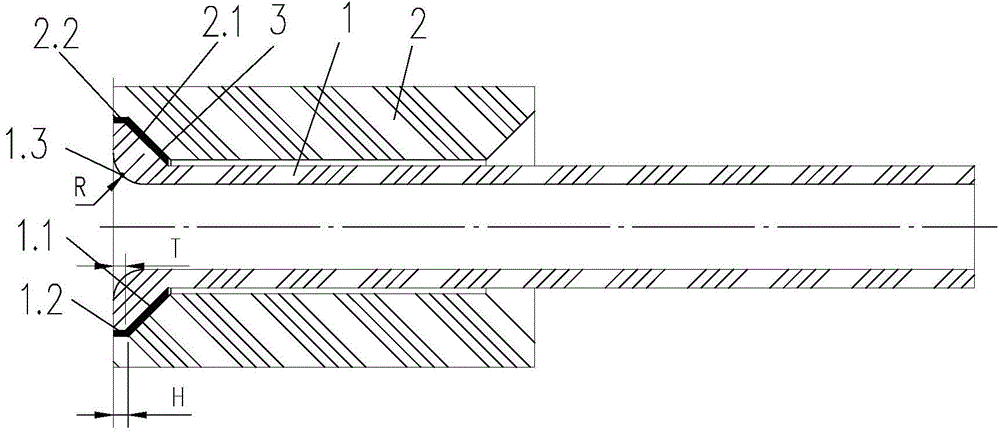

[0016] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0017] refer to figure 1 , an inner protective tube 1 is set inside the outer protective tube 2, the outer tube wall at the inlet end of the inner protective tube 1 has a conical surface 1.1, and the inner tube wall at the inlet end of the outer protective tube 2 also has a conical surface 2.1, two conical surfaces 1.1, 2.1 Direct fit, wherein, the rear section of the conical surface 1.1 of the inner protection tube 1 is provided with a step 1.2, and the height T of the step 1.2 is 1.5-4mm; the rear section of the conical surface 2.1 of the outer protection tube 2 is also provided with There is a step 2.2, the height H of the step 2.2 of the outer protective tube 2 is greater than the height T of the step 1.2 of the inner protective tube 1 by 0-0.5 mm, and the two steps 1.2 and 2.2 are also matched correspondingly. Cement layer 3 is filled in the gap formed between the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com