Vertical-shaft tube carbonization furnace

A carbonization furnace and shaft-type technology, which is applied in the carbonization of agricultural straw waste and waste biomass, and can solve the problems of material hanging, impreciseness, and inability to control wood vinegar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

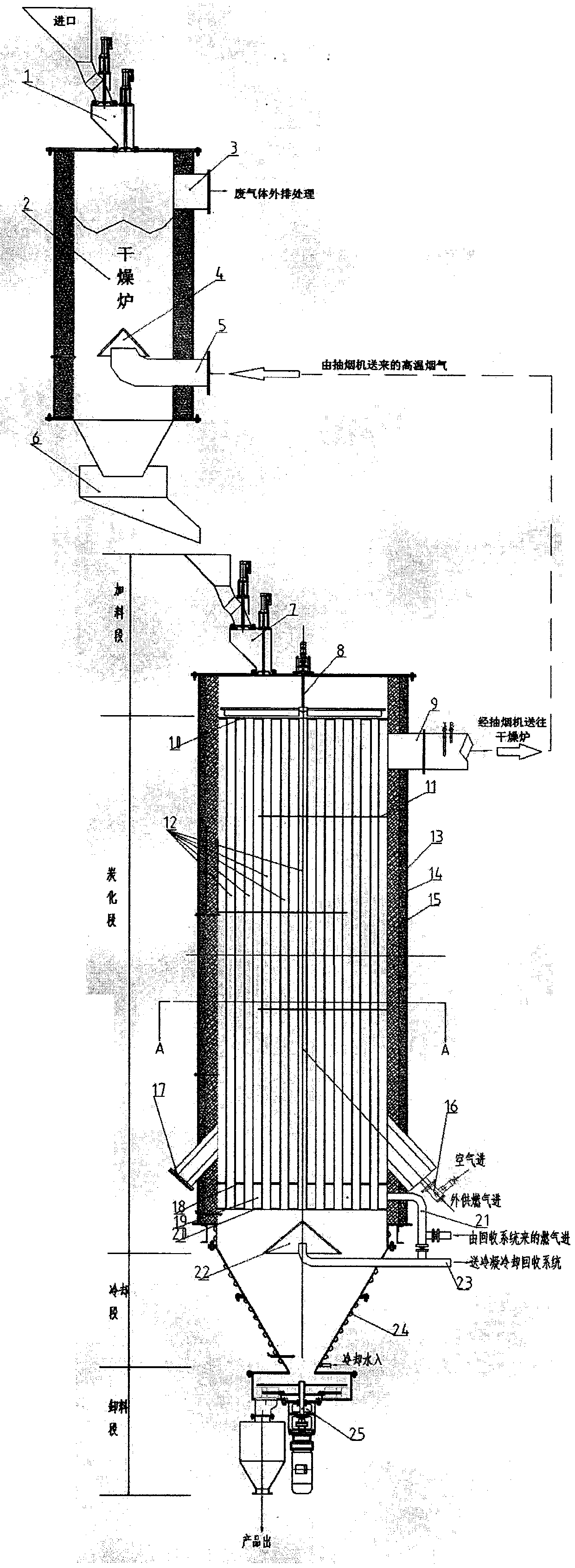

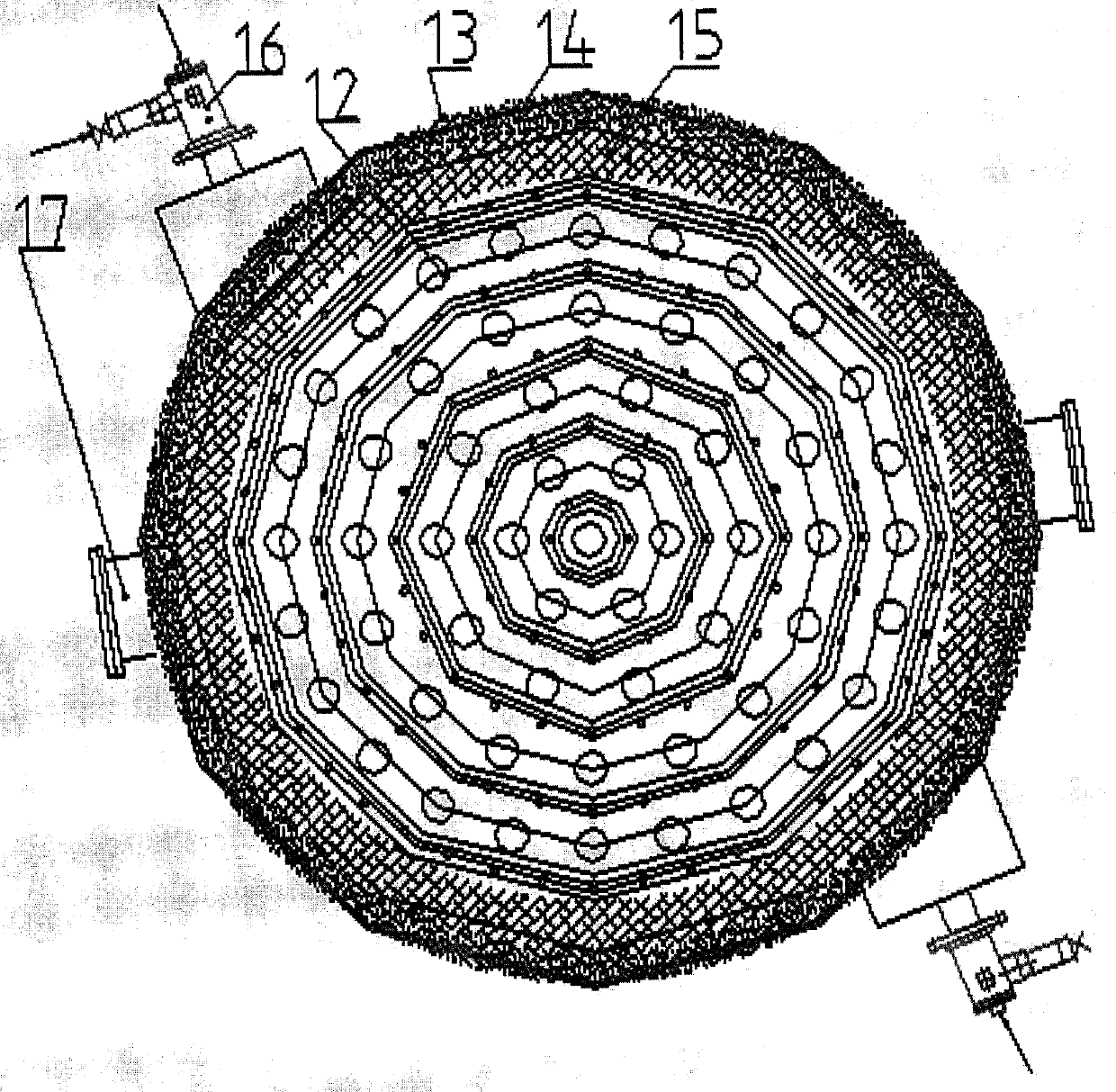

[0026] A shaft-type carbonization furnace consisting of a drying furnace and a carbonization furnace, characterized in that the drying furnace 2 is separately arranged above the side of the carbonization furnace, the top of the carbonization furnace 2 is provided with a drying furnace feeder 1, and the bottom is provided with a There is a drying furnace unloader 6, the particles with a moisture content of 12-25% are added by the drying furnace feeder 1, dried in the drying furnace 2 until the moisture content is below 2%, the drying furnace unloader 6 and the carbonization furnace are charged The machine 7 undertakes, and is continuously sent to the carbonization furnace feeder 7 with the drying furnace discharger 6, and the drying furnace feeder 1 is preferably a double material bell feeder, and the drying furnace discharger 6 is preferably a vibrating feeder. The upper side wall of the drying furnace 2 is provided with a wet flue gas outlet pipe 3 connected to its inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com