Frame seal glue coating device and method

A coating device and coating method technology, which is applied to the surface coating liquid device, coating, optics, etc., can solve the problems of affecting the coating quality, sealing frame glue hanging, glue breaking, etc., to improve the product quality Yield rate, guaranteed coating quality, and the effect of avoiding glue hanging or broken glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

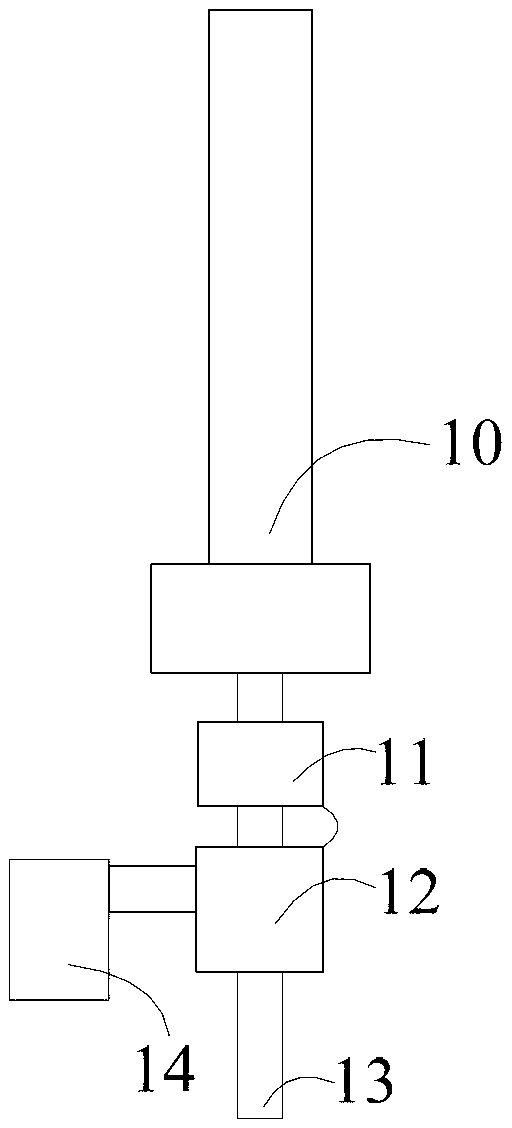

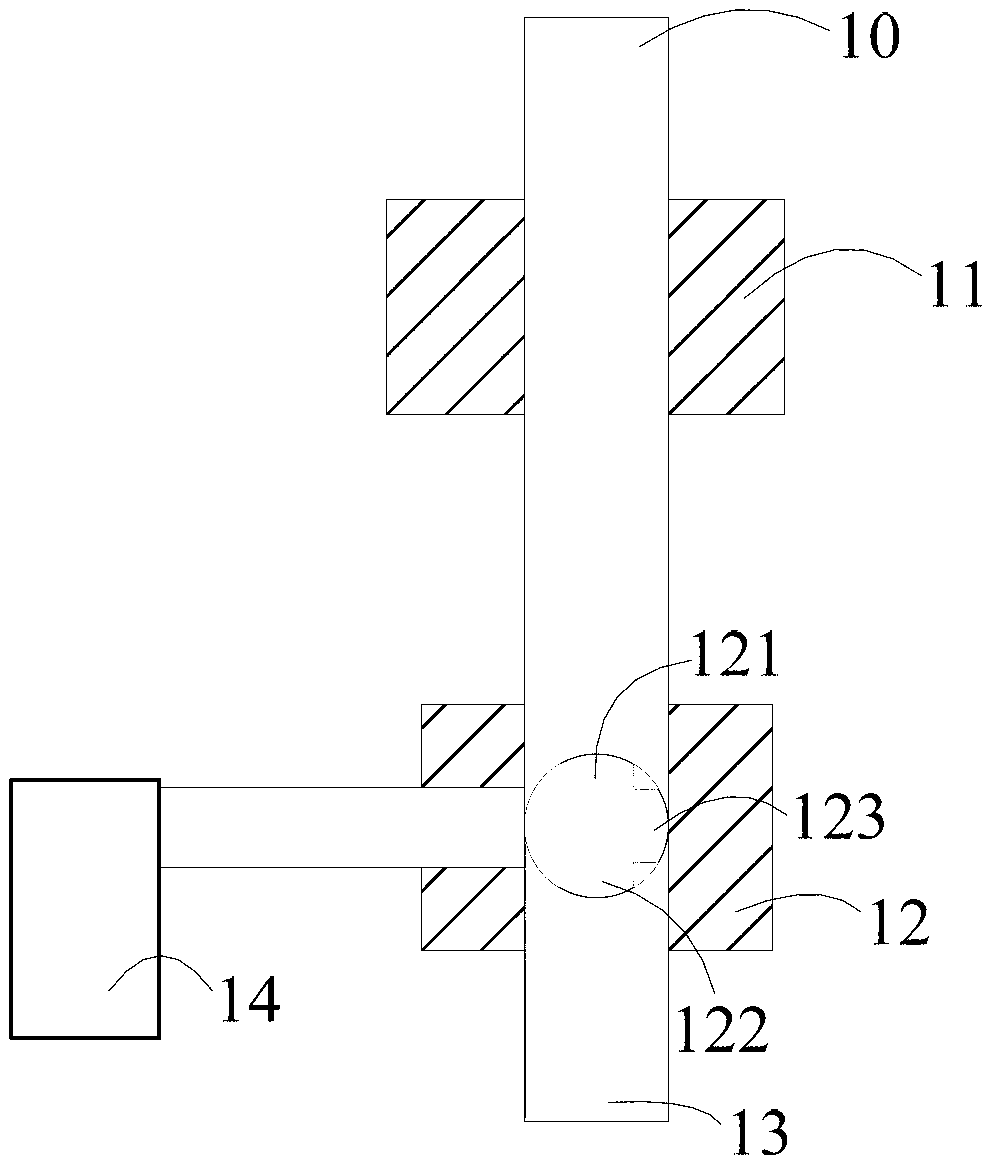

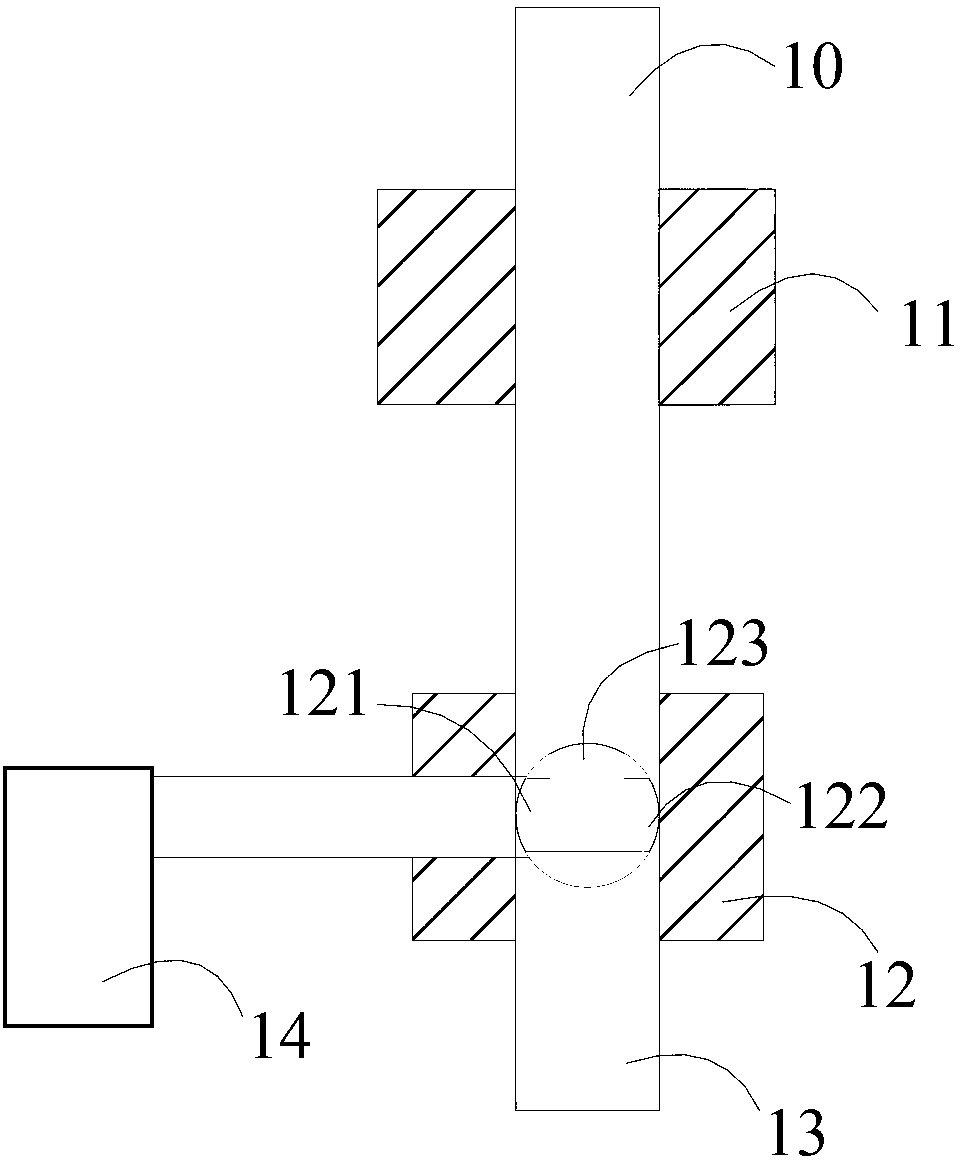

[0020] refer to Figure 1 to Figure 3 , The frame sealing glue application device 100 of the present invention includes a glue storage unit 10 , a bubble detection unit 11 , a flow direction control unit 12 , a nozzle 13 and a temporary storage unit 14 .

[0021] In this embodiment, the glue storage unit 10 is a cylindrical, tubular or box-shaped object connected to the flow direction control unit 12 , and includes a bottom cover 101 disposed at an end away from the flow direction control unit 12 . The glue storage unit 10 stores the frame sealing glue (not shown) used in the frame sealing process. Frame sealants include glue, fibers and / or gold balls.

[0022] The bubble detection unit 11 is sleeved on the end of the glue storage unit 10 close to the flow direction control unit 12 . The air bubble detection unit 11 is used to detect whether there are air bubbles in the sealant flowing from the glue storage unit 10 to the nozzle 13 . For example, the air bubble detection un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com