Process for preparing needle coke raw material by using coal-tar pitch and through heavy-phase circulation

A technology for coal tar pitch and needle coke raw materials, which is used in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by selective extraction, and chemically processing tar pitch/petroleum pitch/natural pitch It can solve the problems of hindering quinoline insolubles and impurities, low content of polyaromatic condensation and polycyclic aromatic components, and low yield of needle coke products, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

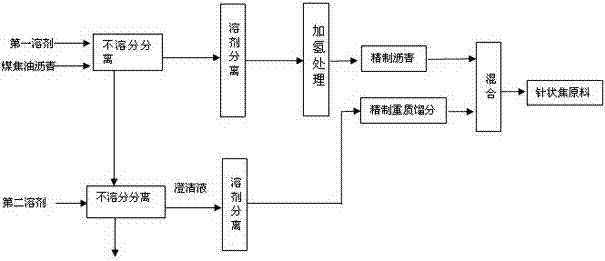

Method used

Image

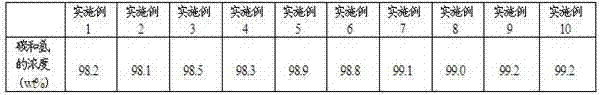

Examples

Embodiment 1

[0039] The process for preparing needle coke raw materials using coal tar pitch combined with heavy phase circulation described in this example includes:

[0040] (1) fully mixing the coal tar pitch and the first solvent, and removing the insoluble matter in the first solvent in the mixture by filtering and separating to obtain the first clear liquid;

[0041] The first solvent described in this embodiment is petroleum-based naphtha, and the mass ratio of the first solvent to the coal tar pitch is 0.1;

[0042] (2) Separating and removing the first solvent in the first clear liquid, hydrogenating the remaining components after removing the first solvent to obtain refined pitch, the temperature of the hydrogenation reaction is 410°C, and the reaction pressure is 22MPa;

[0043] (3) fully mixing the first solvent-insoluble matter obtained in step (1) with the second solvent, and removing the second solvent-insoluble matter in the mixture by filtering and separating to obta...

Embodiment 2

[0048] The process for preparing needle coke raw materials using coal tar pitch combined with heavy phase circulation described in this example includes:

[0049] (1) fully mixing the coal tar pitch and the first solvent, and removing the insoluble matter in the first solvent in the mixture by sedimentation and separation to obtain the first clear liquid;

[0050] The first solvent described in this embodiment is petroleum-based naphtha, and the mass ratio of the first solvent to the coal tar pitch is 15;

[0051] (2) Separating and removing the first solvent in the first clear liquid, hydrogenating the remaining components after removing the first solvent to obtain refined pitch, the temperature of the hydrogenation reaction is 410°C, and the reaction pressure is 22MPa;

[0052] (3) fully mixing the first solvent-insoluble matter obtained in step (1) with the second solvent, and removing the second solvent-insoluble matter in the mixture by filtering and separating to obtai...

Embodiment 3

[0057] The process for preparing needle coke raw materials using coal tar pitch combined with heavy phase circulation described in this example includes:

[0058] (1) fully mixing the coal tar pitch and the first solvent, and removing the insoluble matter in the first solvent in the mixture by sedimentation and separation to obtain the first clear liquid;

[0059] The first solvent described in this embodiment is petroleum-based naphtha, and the mass ratio of the first solvent to the coal tar pitch is 0.4;

[0060] (2) Separating and removing the first solvent in the first clear liquid, hydrogenating the remaining components after removing the first solvent to obtain refined pitch, the temperature of the hydrogenation reaction is 400°C, and the reaction pressure is 5 MPa;

[0061] (3) fully mixing the first solvent-insoluble matter obtained in step (1) with the second solvent, and removing the second solvent-insoluble matter in the mixture by filtering and separating to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com